Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - OLIN Corp | form8kubsslidepres022513.htm |

| EX-99.2 - PRESS RELEASE DATED FEBRUARY 8, 2013 - OLIN Corp | anaylstconfexhibit992.htm |

1 UBS SMID Cap One-on-One Symposium February 26, 2013 Exhibit 99.1

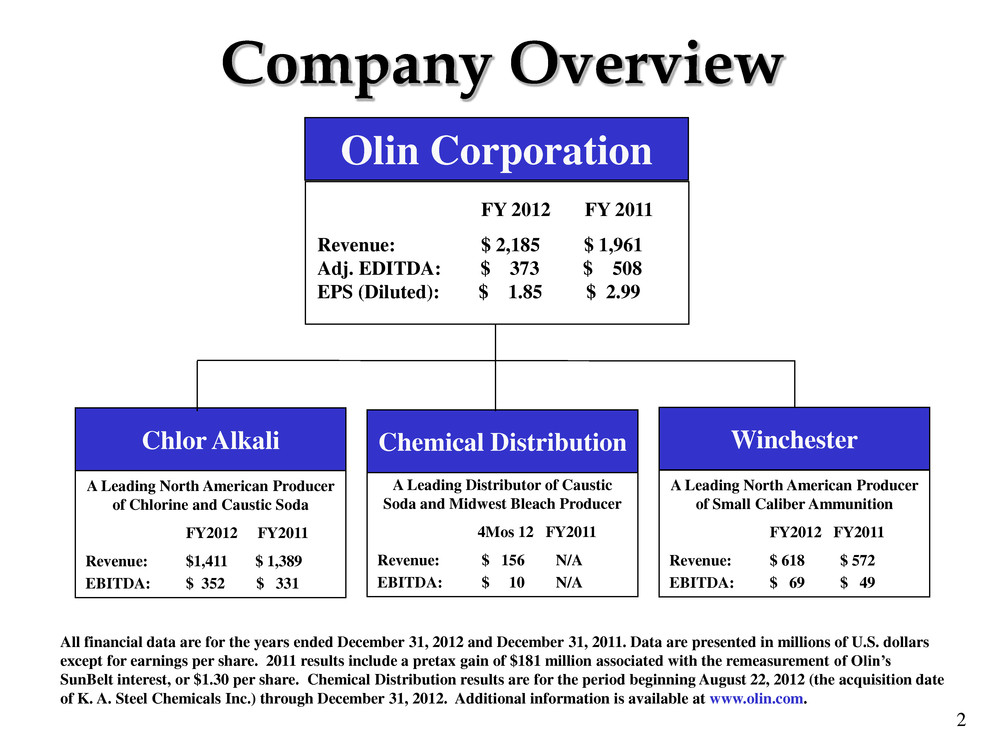

2 Company Overview All financial data are for the years ended December 31, 2012 and December 31, 2011. Data are presented in millions of U.S. dollars except for earnings per share. 2011 results include a pretax gain of $181 million associated with the remeasurement of Olin’s SunBelt interest, or $1.30 per share. Chemical Distribution results are for the period beginning August 22, 2012 (the acquisition date of K. A. Steel Chemicals Inc.) through December 31, 2012. Additional information is available at www.olin.com. Winchester Chlor Alkali A Leading North American Producer of Chlorine and Caustic Soda FY2012 FY2011 Revenue: $1,411 $ 1,389 EBITDA: $ 352 $ 331 A Leading North American Producer of Small Caliber Ammunition FY2012 FY2011 Revenue: $ 618 $ 572 EBITDA: $ 69 $ 49 Revenue: $ 2,185 $ 1,961 Adj. EDITDA: $ 373 $ 508 EPS (Diluted): $ 1.85 $ 2.99 Olin FY 2012 FY 2011 Olin Corporation A Leading Distributor of Caustic Soda and Midwest Bleach Producer 4Mos 12 FY2011 Revenue: $ 156 N/A EBITDA: $ 10 N/A Chemical Distribution

3 Investment Rationale • Leading Positions In: North American Chlor-Alkali Products Industrial Bleach Burner Grade Hydrochloric Acid Small Caliber Ammunition • History of Successful Acquisitions and Delivering Synergies: Pioneer Companies – August 31, 2007 SunBelt – February 28, 2011 K. A. Steel Chemicals Inc. – August 22, 2012 • Compelling Financials: Strong Balance Sheet Fully Funded Pension Plan 345th Consecutive Quarterly Common Dividend Declared Growing EBITDA ($410 to $440 million expected in 2013)

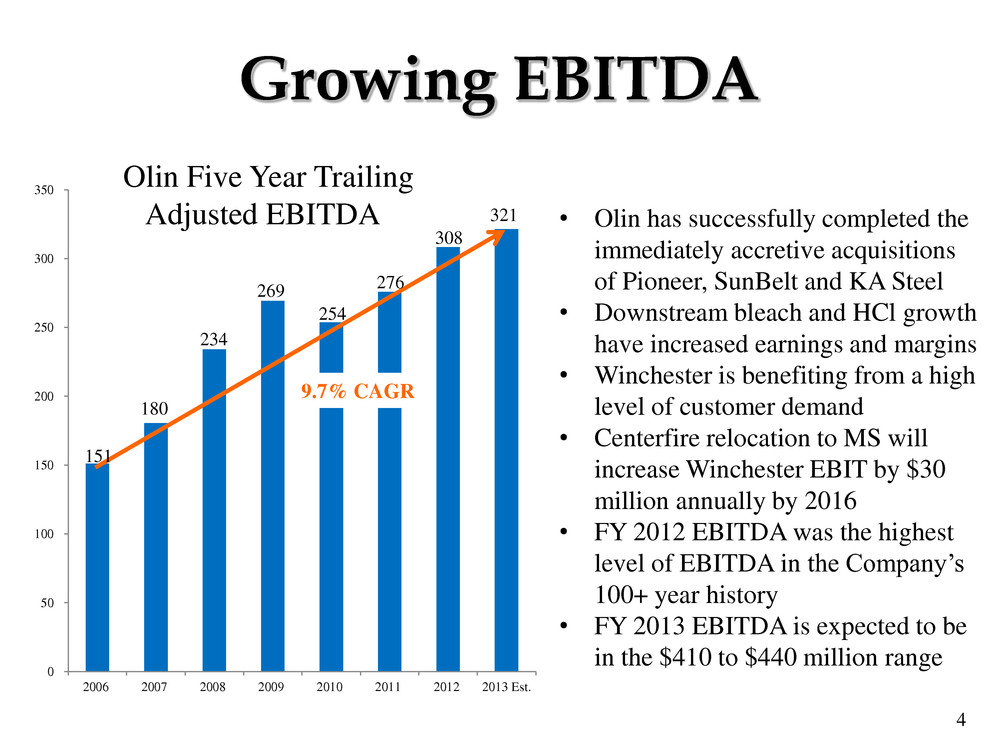

4 0 50 100 150 200 250 300 350 2006 2007 2008 2009 2010 2011 2012 2013 Est. Growing EBITDA • Olin has successfully completed the immediately accretive acquisitions of Pioneer, SunBelt and KA Steel • Downstream bleach and HCl growth have increased earnings and margins • Winchester is benefiting from a high level of customer demand • Centerfire relocation to MS will increase Winchester EBIT by $30 million annually by 2016 • FY 2012 EBITDA was the highest level of EBITDA in the Company’s 100+ year history • FY 2013 EBITDA is expected to be in the $410 to $440 million range Olin Five Year Trailing Adjusted EBITDA 151 180 269 234 254 276 308 321 9.7% CAGR

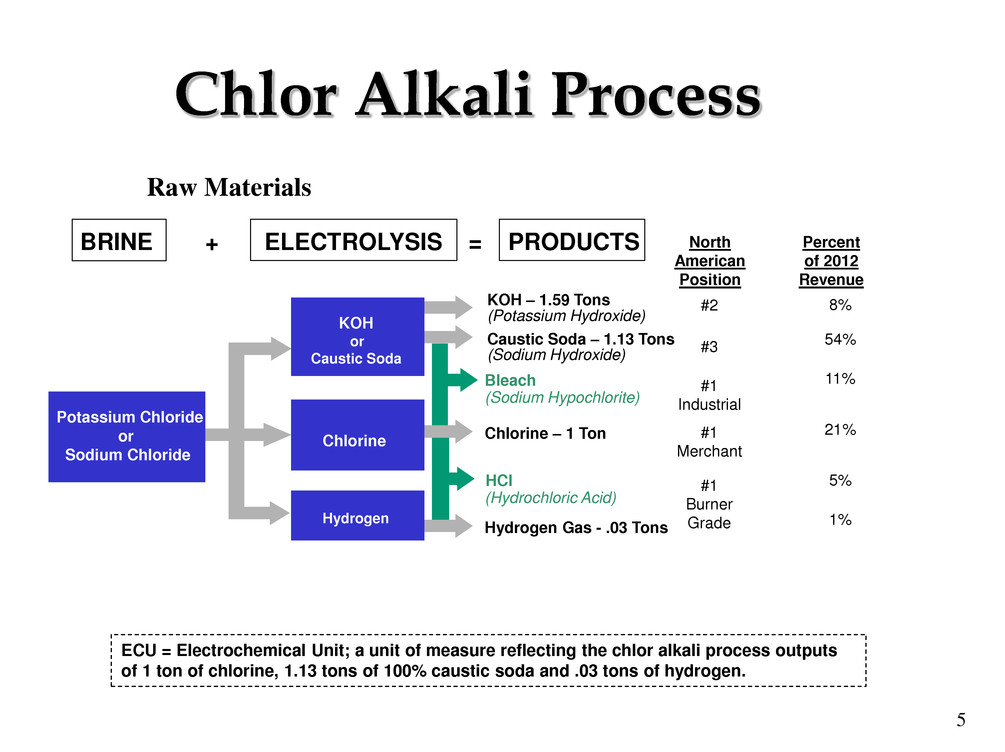

5 Chlor Alkali Process ECU = Electrochemical Unit; a unit of measure reflecting the chlor alkali process outputs of 1 ton of chlorine, 1.13 tons of 100% caustic soda and .03 tons of hydrogen. North American Position Percent of 2012 Revenue #2 #3 #1 Industrial #1 Merchant #1 Burner Grade 54% 11% 5% 8% 21% 1% Raw Materials BRINE + ELECTROLYSIS = PRODUCTS Caustic Soda – 1.13 Tons (Sodium Hydroxide) (Potassium Hydroxide) Bleach (Sodium Hypochlorite) Chlorine – 1 Ton Potassium Chloride or Sodium Chloride KOH – 1.59 Tons HCl (Hydrochloric Acid) Hydrogen Gas - .03 Tons KOH or Caustic Soda Chlorine Hydrogen

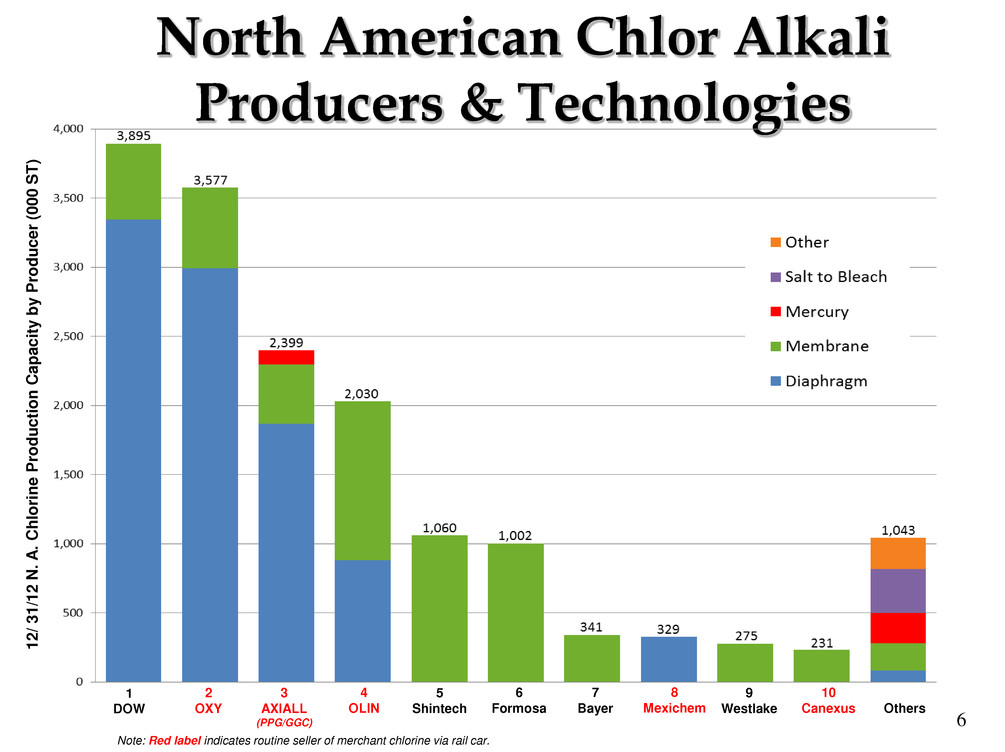

6 North American Chlor Alkali Producers & Technologies Note: Red label indicates routine seller of merchant chlorine via rail car. 1 2 / 3 1 /1 2 N. A . Chlor ine P roduction C a pa c it y b y P roduc e r (0 0 0 S T ) 1 DOW 2 OXY 3 AXIALL (PPG/GGC) 4 OLIN 5 Shintech 6 Formosa 7 Bayer 8 Mexichem 9 Westlake 10 Canexus Others

7 • Mercury Free Chlor-alkali Products – Augusta, GA facility discontinued production September 2012 – Charleston, TN caustic cell room converted to membrane technology September 2012 and is operating at design rate – Charleston, TN potassium hydroxide cell room converted to membrane technology October 2012 and is operating at design rate • Bleach Initiative – HyPure® plants in McIntosh, AL and Niagara Falls, NY completed in 2012 and producing product to specifications – Henderson, NV HyPure® plant to be completed during Q2 2013 – Including KA Steel capabilities, we will be able to convert more than 17% of our chlor-alkali capacity into higher margin bleach • Hydrochloric Acid – During the first half of 2013, we will expand our HCl capabilities at our Henderson, NV facility increasing our capacity by approximately 10% – When completed we could convert 13% of our chlorine capacity into HCl Capital Projects Driving EBITDA Growth

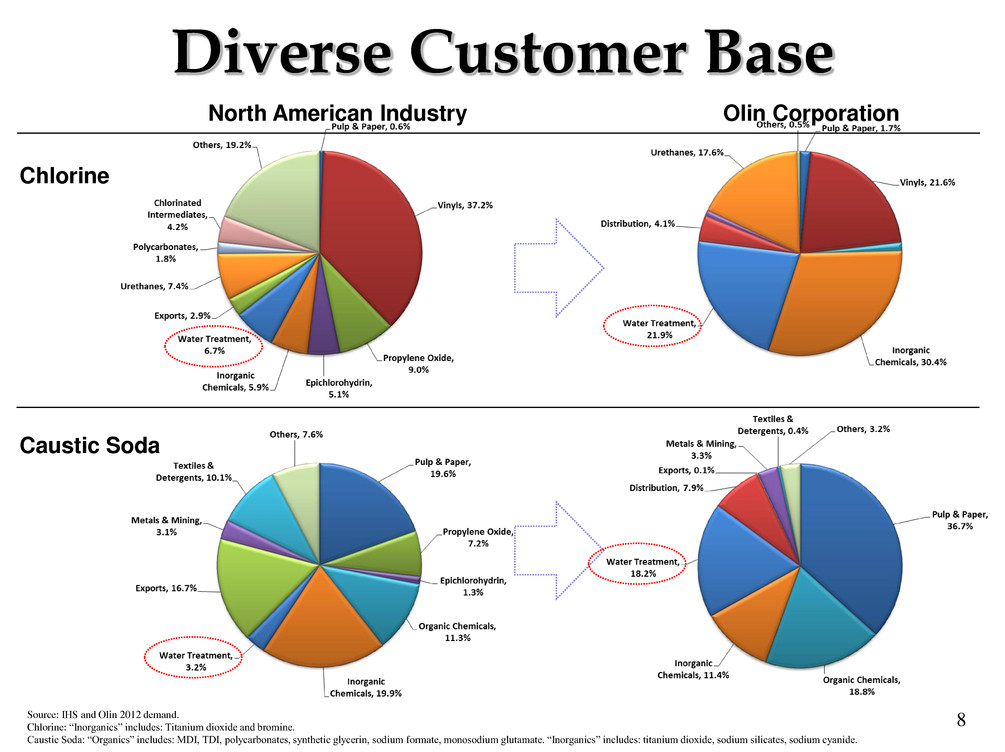

8 Diverse Customer Base Chlorine Caustic Soda North American Industry Olin Corporation Source: IHS and Olin 2012 demand. Chlorine: “Inorganics” includes: Titanium dioxide and bromine. Caustic Soda: “Organics” includes: MDI, TDI, polycarbonates, synthetic glycerin, sodium formate, monosodium glutamate. “Inorganics” includes: titanium dioxide, sodium silicates, sodium cyanide.

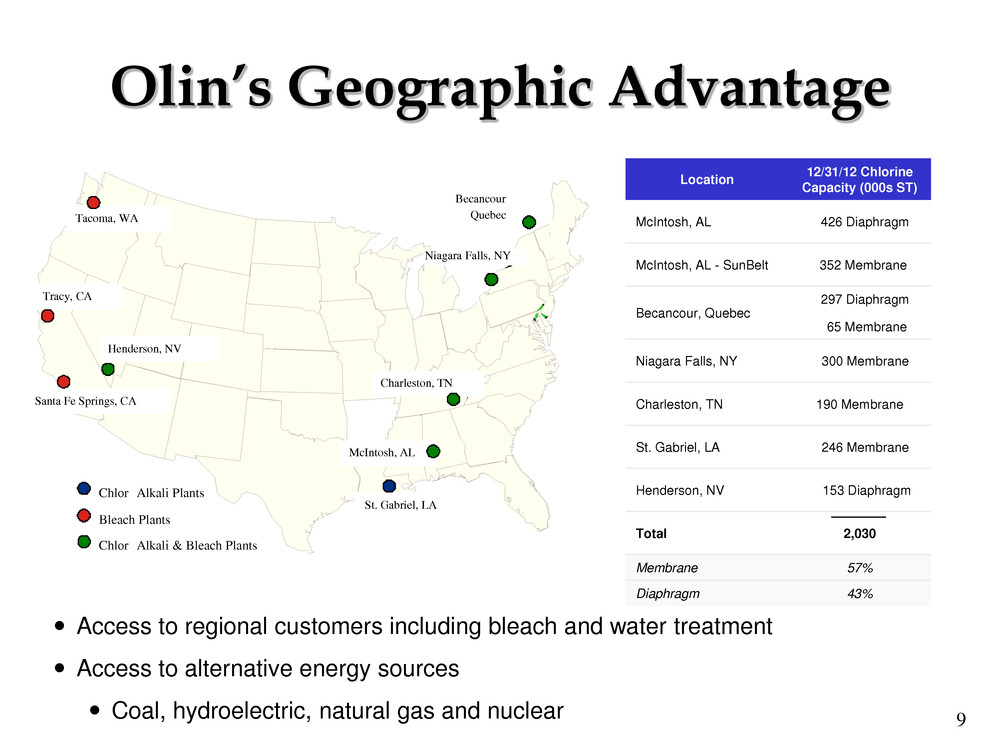

9 Olin’s Geographic Advantage Location 12/31/12 Chlorine Capacity (000s ST) McIntosh, AL 426 Diaphragm McIntosh, AL - SunBelt 352 Membrane Becancour, Quebec 297 Diaphragm 65 Membrane Niagara Falls, NY 300 Membrane Charleston, TN 190 Membrane St. Gabriel, LA 246 Membrane Henderson, NV 153 Diaphragm Total 2,030 Membrane 57% Diaphragm 43% Access to regional customers including bleach and water treatment Access to alternative energy sources Coal, hydroelectric, natural gas and nuclear 32 49 55 25 57 18 60 8 29 2 53 30 35 43 39 44 54 41 17 Chlor Alkali Plants Bleach Plants Chlor Alkali & Bleach Plants Tacoma, WA Tracy, CA Santa Fe Springs, CA Henderson, NV St. Gabriel, LA McIntosh, AL Charleston, TN Niagara Falls, NY Becancour Quebec

10 Industrial Bleach Initiative • Why Industrial Bleach? – Bleach utilizes both chlorine and caustic soda in an ECU ratio – Demand is seasonal, but not cyclical – Bleach commands a premium price over an ECU • Why Olin? – Regional nature of the bleach business benefits Olin’s geographic profile – Olin’s proprietary railcar technology extends geographic reach – KA Steel’s Midwest bleach manufacturing & distribution completes coverage • Olin Actions – The leading North American bleach producer – 3 new HyPure® Bleach investments add 50% more bleach capacity to the Olin system, extend product shelf life and lower freight costs – Q4 2012 bleach shipments were 20% higher than Q4 2011 marking the 20th consecutive quarter of year-over-year increases in bleach shipments

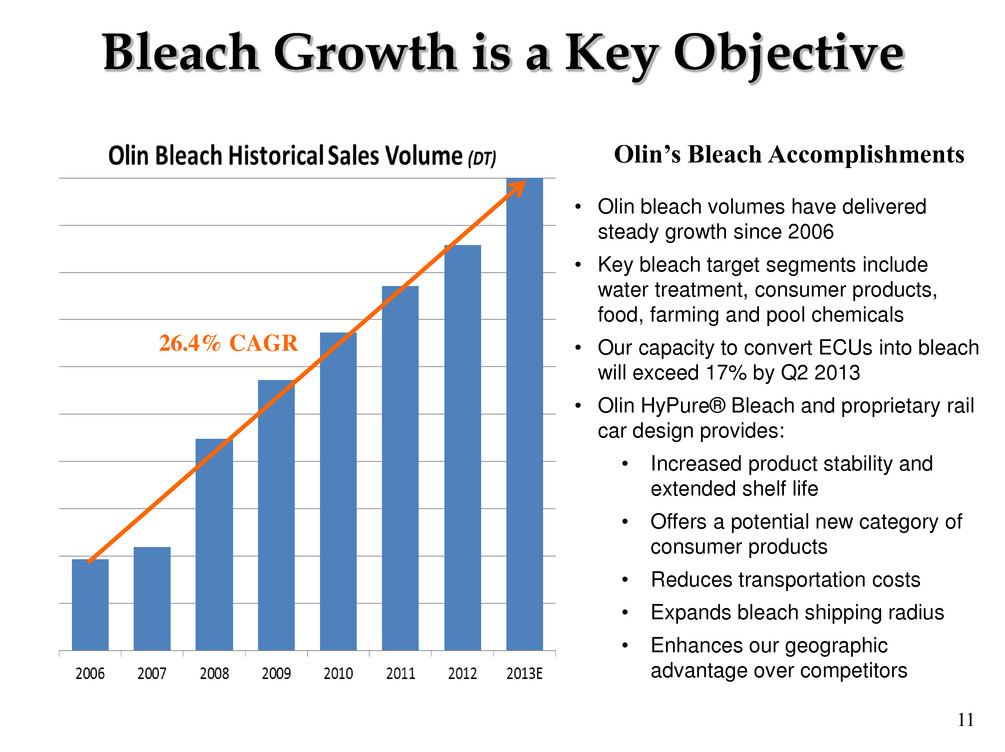

11 26.4% CAGR Bleach Growth is a Key Objective • Olin bleach volumes have delivered steady growth since 2006 • Key bleach target segments include water treatment, consumer products, food, farming and pool chemicals • Our capacity to convert ECUs into bleach will exceed 17% by Q2 2013 • Olin HyPure® Bleach and proprietary rail car design provides: • Increased product stability and extended shelf life • Offers a potential new category of consumer products • Reduces transportation costs • Expands bleach shipping radius • Enhances our geographic advantage over competitors Olin’s Bleach Accomplishments

12 Hydrochloric Acid • HCl demand has strengthened, primarily due to its use as a lead chemical in oil and gas exploration • During 2012, demand for HCl exceeded supply leading to improved pricing as compared to 2011 • By-product HCl accounts for 75% of the market supply, but availability is subject to urethane and fluorocarbon demand • Currently 25% of HCl supply is “Burner-grade” or “on-purpose” HCl • Burner grade HCl is a reliable source, and while a small cost component in oil and gas exploration, is critical to the process • Olin has the ability to convert 10% of its chlorine capacity into higher margin HCl sales and will increase that capability to 13% following the completion of the Henderson, NV expansion project in 1H 2013

13 Growing HCl Demand North American HCl Supply • Burner acid is the only growing HCl supply source • 75% of HCl is supplied by Gulf by-product producers • By-product HCl availability is less reliable than burner • Olin is ideally positioned to serve the West & North through expanded distribution capabilities North American HCl Demand • Demand for oil and gas exploration has increased • U.S. steel industry demand has been recovering • Diverse demand segments follow GDP growth 15.7% CAGR

14 Key Chlor-Alkali Factors • ECU netback improved $20 to $580 in Q4 2012 from Q3 2012 levels and we expect to realize additional caustic pricing in Q2 2013 from the November 2012 caustic price announcement • Q4 EBITDA improved 8% year-over-year with upside in 2013 • Increased higher-margin bleach sales are expected to continue their 5 year growth trend through 2013 • Higher margin HCl sales are contributing to EBITDA growth, and we are adding capacity to meet higher HCl demand in the West • A full year of KA Steel ownership and realization of synergies will benefit the sales of our Chlor Alkali products • Our investments in membrane cell technology have lowered operating costs and positioned us as the largest producer of premium priced membrane caustic soda in North America

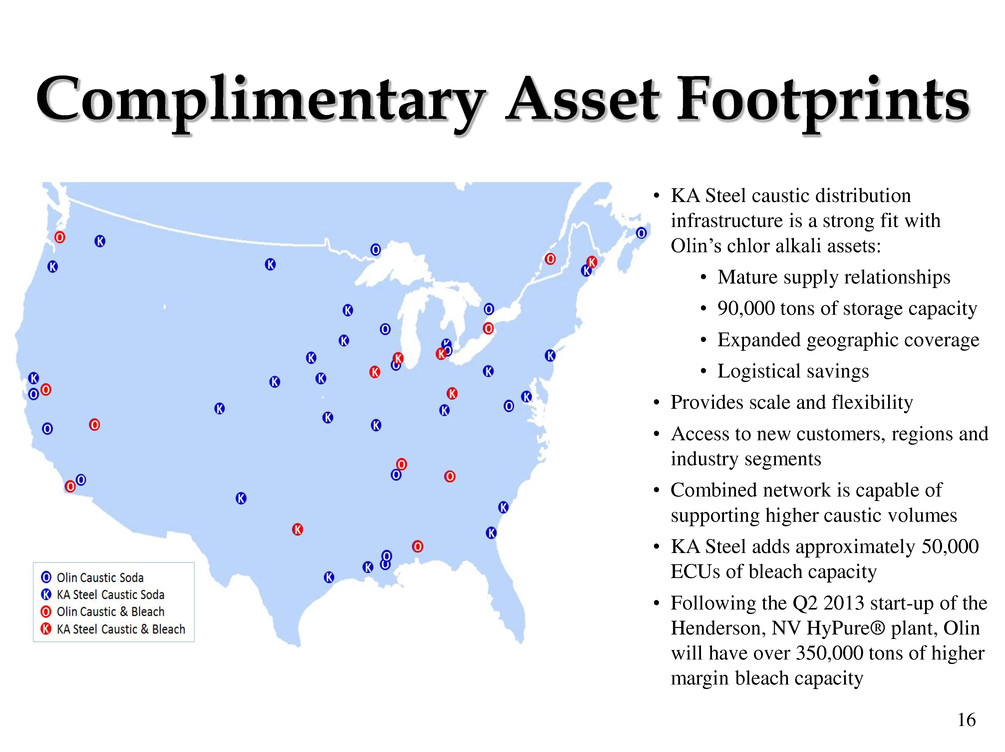

15 • KA Steel is one of the largest distributors of caustic soda in North America and manufactures and sells bleach in the Midwest • On August 22, 2012, we acquired privately held KA Steel for $312 million in cash, subject to certain post-closing adjustments • 2011 KA Steel sales were $435 million and Adjusted EBITDA was $31 million, during Q4 2012 sales were $109 million and EBITDA was $6 million • The combination of Olin and KA Steel is expected to generate $7 to $10 million of annual synergies in first 12 months of ownership, growing to approximately $35 million annually by the end of year 3 • The Section 338(h)(10) tax election provides a $60 million NPV tax benefit to Olin; when considering this and the expected synergies, results in an EBITDA multiple of approximately 4 times • The transaction was financed through the sale of $200 million of 5.5%, 10- year notes and cash on hand KA Steel Acquisition

16 Complimentary Asset Footprints • KA Steel caustic distribution infrastructure is a strong fit with Olin’s chlor alkali assets: • Mature supply relationships • 90,000 tons of storage capacity • Expanded geographic coverage • Logistical savings • Provides scale and flexibility • Access to new customers, regions and industry segments • Combined network is capable of supporting higher caustic volumes • KA Steel adds approximately 50,000 ECUs of bleach capacity • Following the Q2 2013 start-up of the Henderson, NV HyPure® plant, Olin will have over 350,000 tons of higher margin bleach capacity

17 KA Steel Synergies Update • Platform to expand Olin sales of industrial bleach, HCl and KOH • Optimizes use of KA Steel’s existing freight and logistics network to reduce Olin’s shipping expense • Provides platform to reduce freight and logistics costs • Expands presence in core caustic soda business with a combined capacity to ship 3 million tons of caustic soda • Increases stability of core Chlor-Alkali business • Significant synergy potential of $7 to $15 million in first full year of ownership and $35 million annually after the third year of ownership • Expected to be immediately accretive to both earnings and cash flow, excluding one-time transaction costs

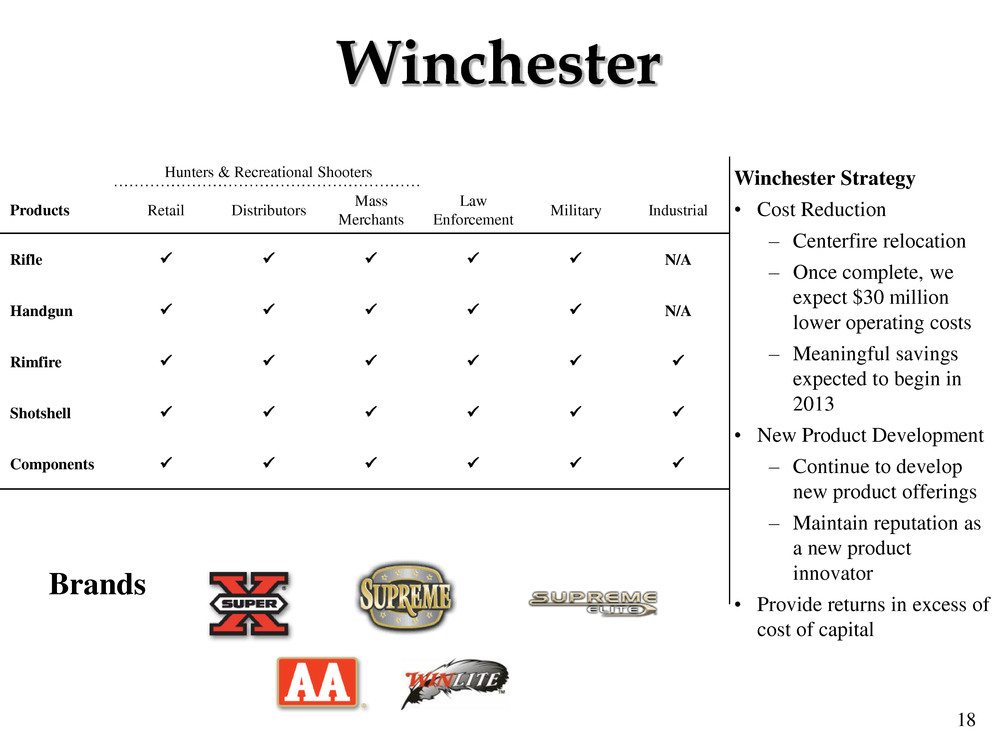

18 Winchester Winchester Strategy • Cost Reduction – Centerfire relocation – Once complete, we expect $30 million lower operating costs – Meaningful savings expected to begin in 2013 • New Product Development – Continue to develop new product offerings – Maintain reputation as a new product innovator • Provide returns in excess of cost of capital Hunters & Recreational Shooters Products Retail Distributors Mass Merchants Law Enforcement Military Industrial Rifle N/A Handgun N/A Rimfire Shotshell Components Brands

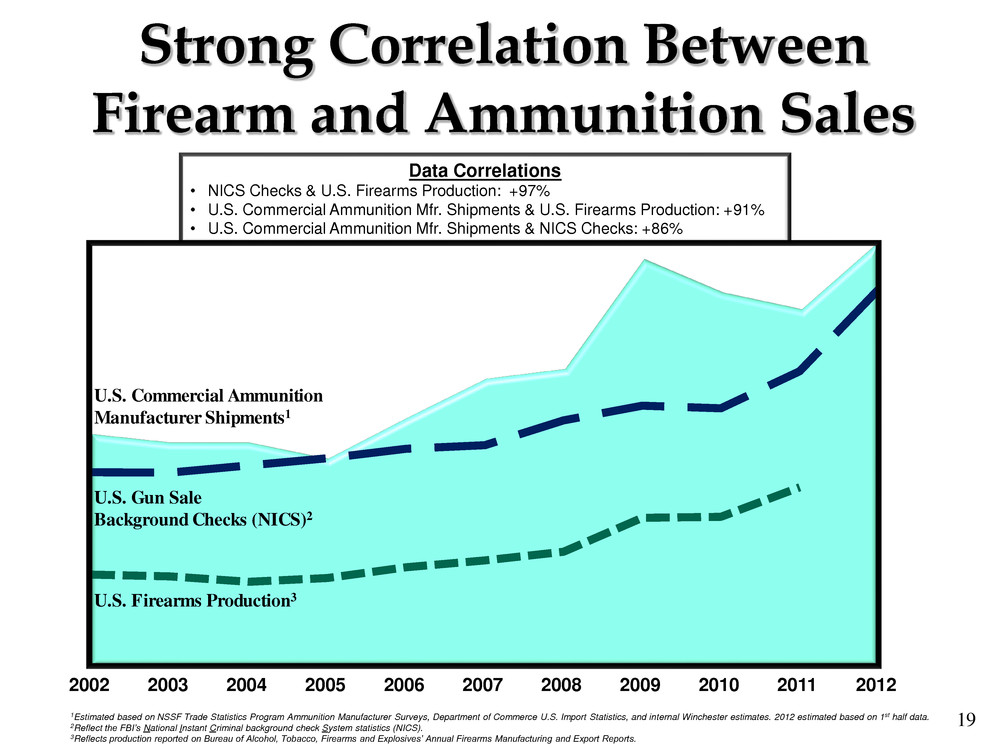

19 Strong Correlation Between Firearm and Ammunition Sales Data Correlations • NICS Checks & U.S. Firearms Production: +97% • U.S. Commercial Ammunition Mfr. Shipments & U.S. Firearms Production: +91% • U.S. Commercial Ammunition Mfr. Shipments & NICS Checks: +86% 1Estimated based on NSSF Trade Statistics Program Ammunition Manufacturer Surveys, Department of Commerce U.S. Import Statistics, and internal Winchester estimates. 2012 estimated based on 1st half data. 2Reflect the FBI’s National Instant Criminal background check System statistics (NICS). 3Reflects production reported on Bureau of Alcohol, Tobacco, Firearms and Explosives’ Annual Firearms Manufacturing and Export Reports. 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 U.S. Gun Sale Background Checks (NICS)2 U.S. Firearms Production3 U.S. Commercial Ammunition Manufacturer Shipments1

20 Winchester Is Growing • Surge beginning prior to the 2012 election drove Q4 record earnings • Currently, sales are only limited by product availability • Commercial backlog now exceeds $250 million • Centerfire relocation to MS will increase Winchester EBIT by $10 to $15 million in 2013 vs. a $5 million net expense in 2012 • Once completed in 2016, annual savings are expected to be $30 million • In 2016, we expect Winchester to be able to generate annual EBITDA of $85 to $100 million 0 10 20 30 40 50 60 70 80 90 2006 2007 2008 2009 2010 2011 2012 18.4% CAGR Annual EBITDA

21 Centerfire Relocation • The decision to relocate Winchester’s centerfire operations, including 1,000 jobs, was made on November 3, 2010 • The net project cost is estimated to be $80 million, of which approximately $50 million is related to capital expenditures • The project is on schedule and on budget to be completed in 2016 • The new 500,000 square foot facility was opened in October 2011 and equipment relocation began in Q3 2011 • By the end of 2012, the vast majority of all pistol ammunition was being manufactured in Oxford, MS • Cost savings are expected to be $10 to $15 million in 2013, against net incremental cost of $5 million in 2012, and total $30 million in lower costs by 2016 • In addition to $31 million of grants from MS, $42 million of low- cost MS tax-exempt debt was made available to Olin

22 Strong Balance Sheet • The 12/31/12 cash balance of $177 million reflects: • $312 million for the acquisition of KA Steel; • $256 million of capital spending in 2012 associated with the exiting of mercury technology projects, construction of 3 HyPure® Bleach plants and the centerfire relocation to Oxford, MS; • The repayment of $20.0 million of long-term debt; and • Includes proceeds from issuance of $200 million debt in Q3 2012 • No material debt maturities until 2016 and no debt towers in excess of $200 million, which is not due until 2022 • The Olin pension plans remain fully funded with no contributions expected for several years • 2013 CAPEX forecast to be in $100 to $130 million range

23 • 2012 EBITDA of $373 million is the highest level of EBITDA in the Company’s 100+ year history • Further EBITDA growth of $410 to $440 million in 2013 is driven by the successful completion of several strategic initiatives in 2012 and the on-going bleach and HCl growth initiatives, KA Steel synergies and centerfire relocation to Oxford, MS • Continued growth in bleach sales driven by the 3 new HyPure® Bleach plants will provide Olin the ability to convert over 17% of our ECUs into higher margin bleach • HCl pricing and volumes remain strong as oil and gas exploration drives demand; Olin capacity expansion coming on stream in 1H 2013 will allow Olin to convert 13% of chlorine into higher margin HCl • 2013 will include a full year of KA Steel earnings and the realization of increased synergy contributions • Winchester is experiencing another surge period coupled with significant cost savings from the centerfire relocation Profit Outlook

24 Forward-Looking Statements This presentation contains estimates of future performance, which are forward-looking statements and actual results could differ materially from those anticipated in the forward-looking statements. Some of the factors that could cause actual results to differ are described in the business and outlook sections of Olin’s Form 10-K for the year ended December 31, 2012. These reports are filed with the U.S. Securities and Exchange Commission.