Attached files

Changing the way you succeed.

Owen Kratz, Helix ESG Chairman and CEO

Well Intervention

Overview

Overview

1

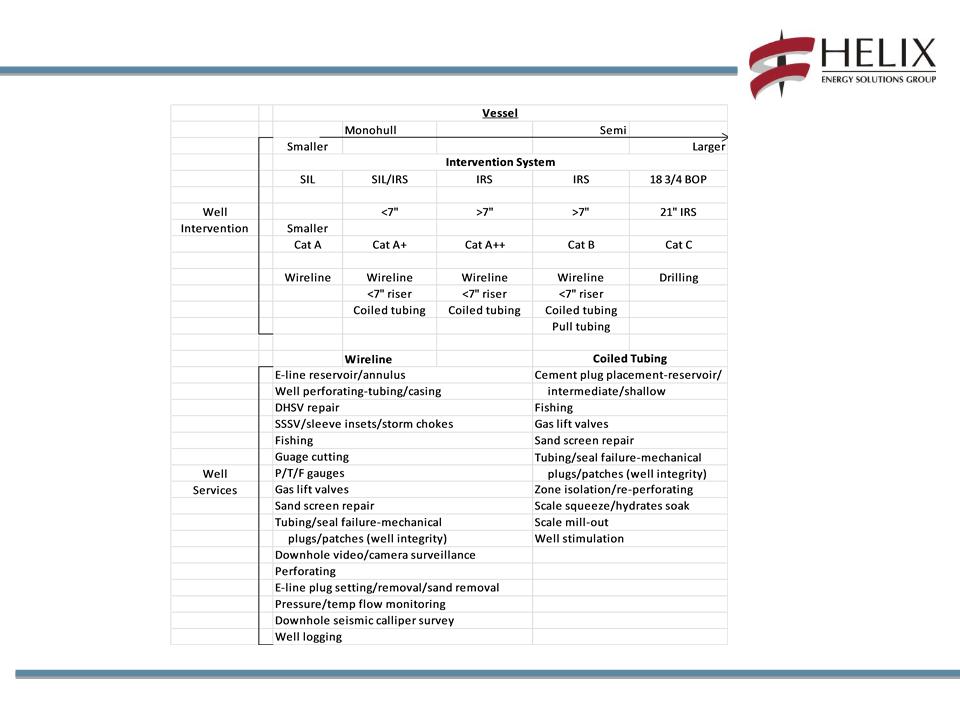

What is well intervention?

2

• Well intervention is the ability to safely enter a well with well control for the

purpose of doing a number of tasks other than drilling.

purpose of doing a number of tasks other than drilling.

• Well intervention historically was done with drill rigs, with an 18-3/4” BOP and

21” marine riser as the only means of well access with well control.

21” marine riser as the only means of well access with well control.

• In the 80’s, technology was developed that afforded for re-entry into wells with

alternatives to the drilling well control systems and rigs for delivery of non-

drilling services.

alternatives to the drilling well control systems and rigs for delivery of non-

drilling services.

• As technology is developed, water depth increases, well head design evolves

and well construction changes, intervention also evolves and demand grows.

and well construction changes, intervention also evolves and demand grows.

Intervention Today

3

• Xmas tree recovery/installation

• Xmas tree/wellhead maintenance

• Choke change-out

• Light construction

• Saturation diving (inspection, repair & maintenance)

• ROV support services

Future Applications of Some Intervention Assets:

• Through tubing well intervention

• Top hole drilling

• Extended top hole drilling

• Riserless Mud Return

• Subsea Rotary Controlled Device

• Well flowback and Well testing

• Subsea Construction

4

Related Operations with Intervention Assets

Downhole Well Intervention Solutions

ü First Subsea Intervention Lubricator

operations in the North Sea

operations in the North Sea

ü First build and launch of dedicated

intervention vessel - Seawell

intervention vessel - Seawell

ü First coil tubing deployed on a

subsea well from a rig alternative

monohull

subsea well from a rig alternative

monohull

ü Build and operation of prototype

vessel Q4000

vessel Q4000

ü First rig alternative

decommissioning of offshore

production facility with multiple

subsea wells

decommissioning of offshore

production facility with multiple

subsea wells

ü First application of Huisman

multipurpose tower

multipurpose tower

Helix Intervention Industry Firsts

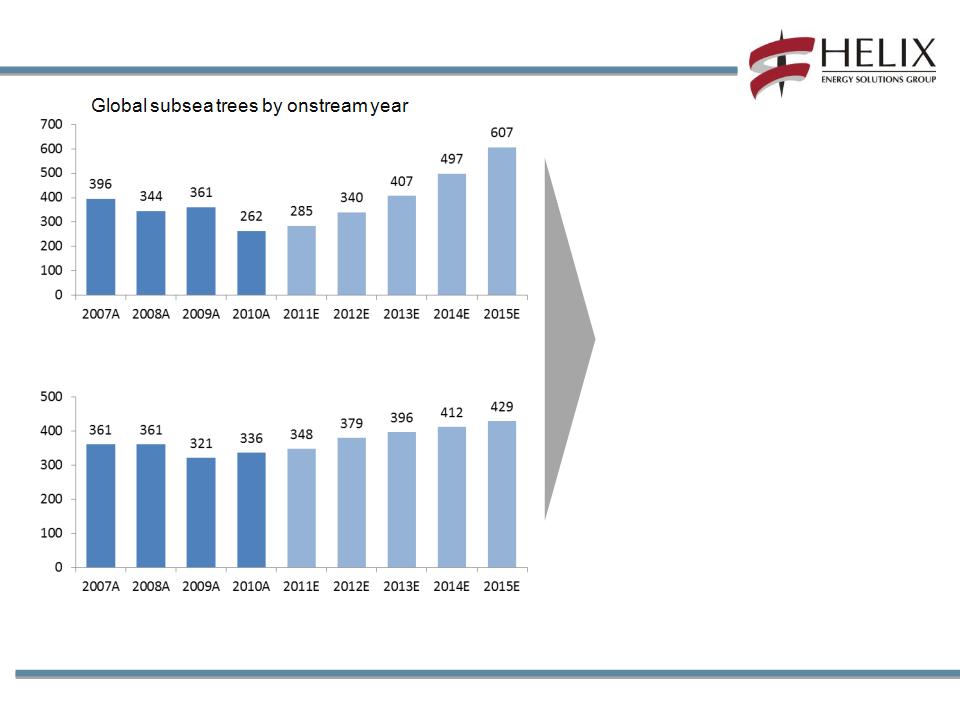

• As production goes to deeper water, subsea wells market grows.

• As the number of subsea wells increase and they age, the demand and

frequency of required servicing through intervention grows.

frequency of required servicing through intervention grows.

• The market is in its infancy with huge growth potential.

7

Growing Market

Well Intervention Demand Drivers

8

Global offshore rig count

• Declining shallow water

resources have spurred

technical advances that allow

offshore exploration and

production in deeper, harsher

environments

resources have spurred

technical advances that allow

offshore exploration and

production in deeper, harsher

environments

• New discoveries and

pressure to improve recovery

rates from developed fields

increase demand for subsea

intervention

pressure to improve recovery

rates from developed fields

increase demand for subsea

intervention

• Subsea trees are expected to

increase at an 18.3% CAGR

and global offshore rig count

is expected to increase at a

5% CAGR from 2010 to 2015

increase at an 18.3% CAGR

and global offshore rig count

is expected to increase at a

5% CAGR from 2010 to 2015

The global subsea intervention market is expected to expand as the focus of offshore drilling

shifts to more challenging environments

shifts to more challenging environments

Source: Spears & Associates, Quest Offshore Resources

Intervention Needs Rises with Subsea Well Count

Source: Quest Offshore Resources

Subsea wells installed base (2002 - 2012)

Installed subsea completion base over 5 yrs

old

old

Installed subsea completion base 5 yrs

or younger

or younger

Note: Total installed base includes all subsea well completions from 1990, not adjusted for wells decommissioned 2007-2012

■ Need for intervention typically

occurs after 5 years of

production, due to:

occurs after 5 years of

production, due to:

– Reduced pressure in wells

– Increased water or sand

production

production

– Scaling in wells

– Other factors

■ Oil wells generally have a

greater need for intervention

than gas and injection wells

greater need for intervention

than gas and injection wells

+200

%

%

+94%

Market Outlook for Well Intervention

10

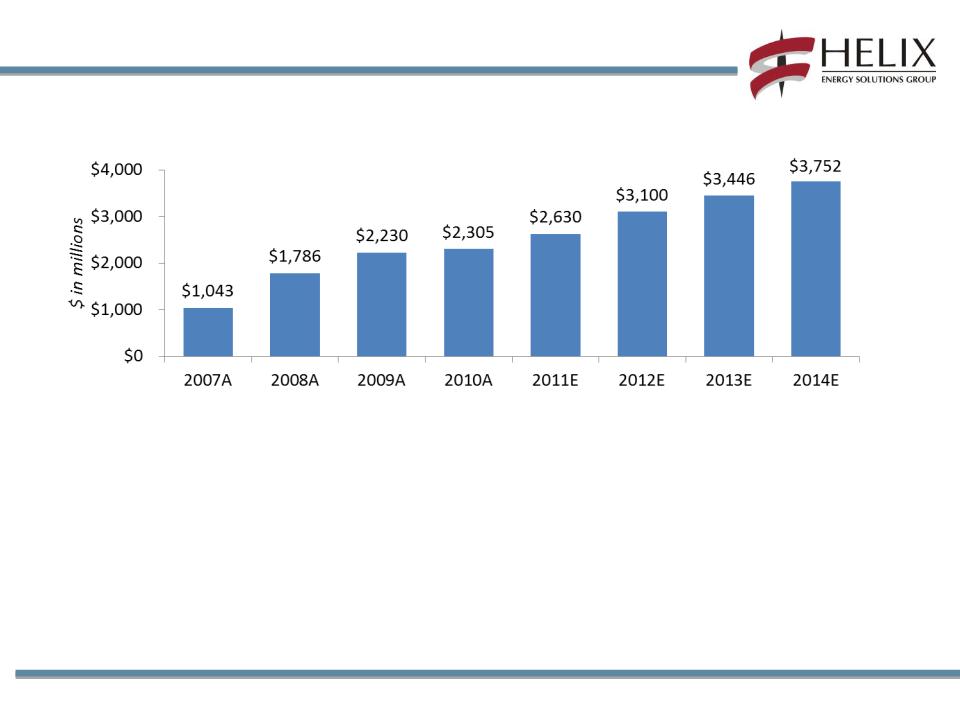

• Subsea intervention demand driven by increasing activity and rising

subsea well counts

subsea well counts

• Maintenance intensity expected to rise as greater share of production

moves into deepwater fields and as operators face increasing oil

recovery needs from maturing fields

moves into deepwater fields and as operators face increasing oil

recovery needs from maturing fields

• Global expenditures on intervention are expected to grow 11%

annually from 2009 to 2014, reaching nearly $3.8 billion

annually from 2009 to 2014, reaching nearly $3.8 billion

Subsea well intervention expenditures

Source: Douglas-Westwood

2011 Market for Well Intervention Services

11

North America

SS Intervention spend: $470mm

Offshore rigs: 31

Offshore wells drilled: 260

Latin America

SS Intervention spend: $427mm

Offshore rigs: 88

Offshore wells drilled: 572

United Kingdom

SS Intervention spend: $272mm

Offshore rigs: 16

Offshore wells drilled: 157

Norway

SS Intervention spend: $303mm

Offshore rigs: 19

Offshore wells drilled: 188

Africa

SS Intervention spend: $746mm

Offshore rigs: 37

Offshore wells drilled: 531

Asia Pacific

SS Intervention spend: $375mm

Offshore rigs: 80

Offshore wells drilled: 1,072

Source: Douglas-Westwood, Spears & Associates

Regulatory Limitations

Vessel Class - Many independent classing societies

• Most Prominent - DNV (Det Norske Veritas),

ABS (American Bureau of Shipping)

ABS (American Bureau of Shipping)

• MODU Notation - Specific requirements for a vessel used in intervention

including zoning for handling hydrocarbons.

including zoning for handling hydrocarbons.

• Government - No international standard. All strictly enforced by each country.

• Prescription vs. Safety Case

Client - Every client and sometimes every engineer has a different set of

compliance standards. Now driven by SEMS.

compliance standards. Now driven by SEMS.

Industry - Many depositories of guidance principles.

• Voluntary Compliance

• Generally accepted by Industry but different clients will look at different

sets of guidance.

sets of guidance.

• APL - Most generally accepted.

12

13

Wireline Deployment via SIL

• 7-3/8” bore, 10ksi WP - single trip

• 600 m water depth rated

• Various wireline & coiled tubing modes

with sub-modes (long and short tools,

etc.)

with sub-modes (long and short tools,

etc.)

• Live well decommissioning & stimulation

modes

modes

• Balanced stabs with valves

• Modular design

• LRA / URA - VXT, HXT & CT riser

• URA only - VXT wireline

• Dual BOP position

• 18.5 m or 22 m toolstrings

• Norwegian compliant

• Except DNV-E-101 re: QOD

• Minor lessons learned in next version

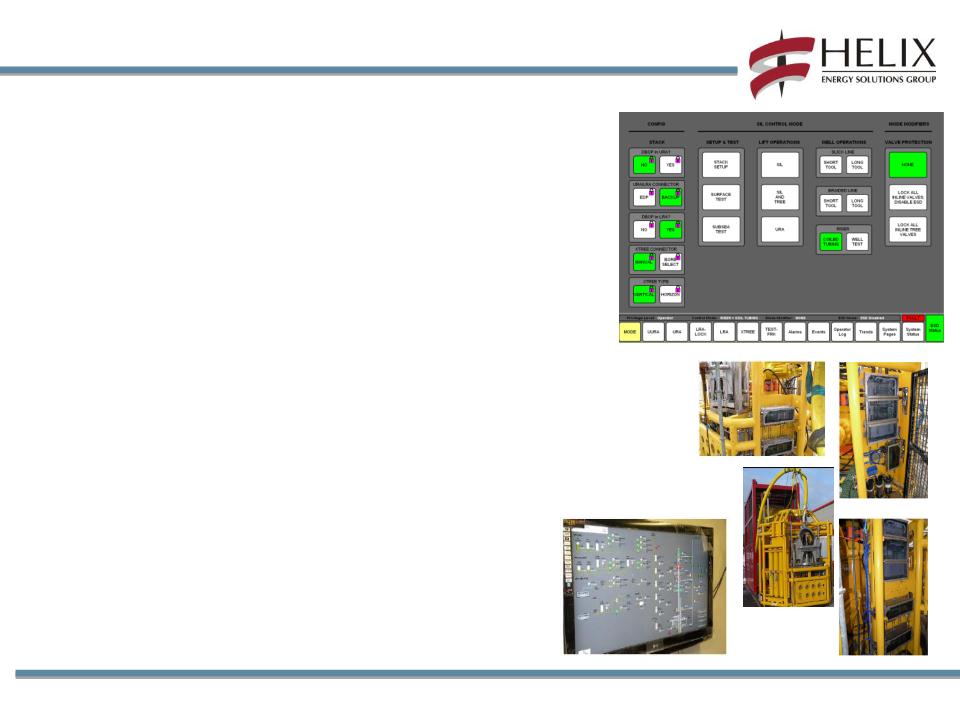

SIL Overview - MUX Controls

MUX EH control system

• Mode Screens

• Auto Set Interlocks

• Configuration, Set Up & Test, Lifting Ops

• Slickline, Braided Line & Riser

• ROV electronics technology

• Grease system same as Seawell & Enhancer

• Not electric pump - seawater powered from surface

• No wireline shear upon subsea comms failure

• 6hrs POOH - batteries & surface grease pump

• Auxiliary umbilical option to LRA / URA & extend

• ROV controls

• Full LRA WCE

• Primary URA safety functions

• Client Mimic Screen

14

Intervention Riser System for CT Deployment

• As water depth increases, the cost of intervention increases. If a problem

is encountered, wireline alone is limited in being an effective

remediation tool.

is encountered, wireline alone is limited in being an effective

remediation tool.

• To run coiled tubing into a well requires either an absurdly complicated

well head mounted system or requires a riser back to the surface. This

creates an extremely complicated interface occurring between the

stationing riser and a tugging mooring vessel. These relative motions and

the fact that the interface between the well’s high pressured hydrocarbons

and the low ambient pressures on the vessel creates technical

challenges.

well head mounted system or requires a riser back to the surface. This

creates an extremely complicated interface occurring between the

stationing riser and a tugging mooring vessel. These relative motions and

the fact that the interface between the well’s high pressured hydrocarbons

and the low ambient pressures on the vessel creates technical

challenges.

15

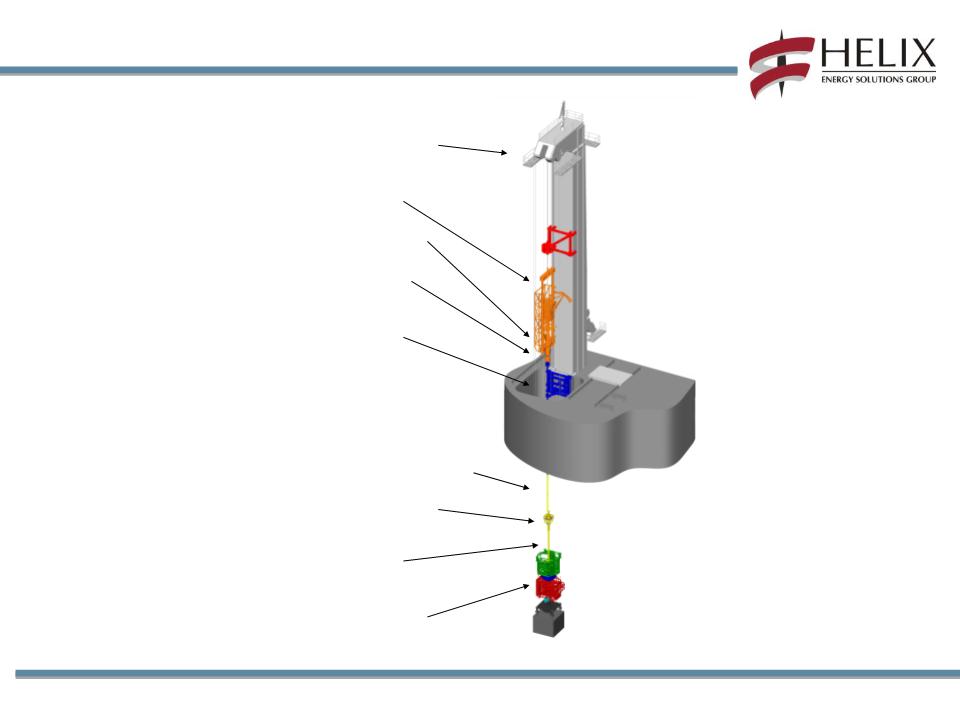

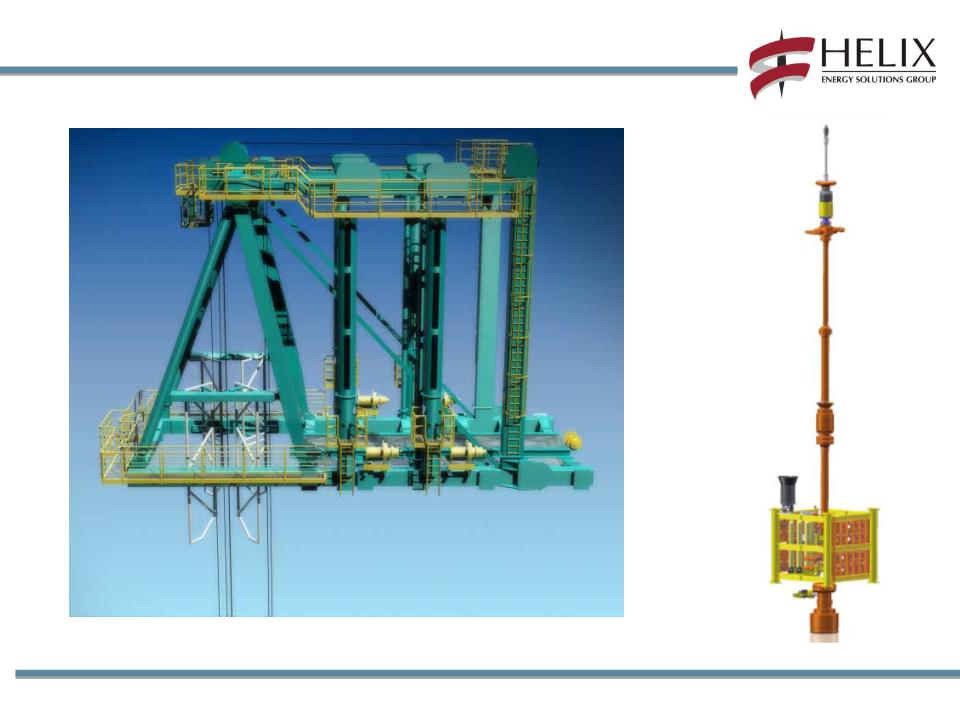

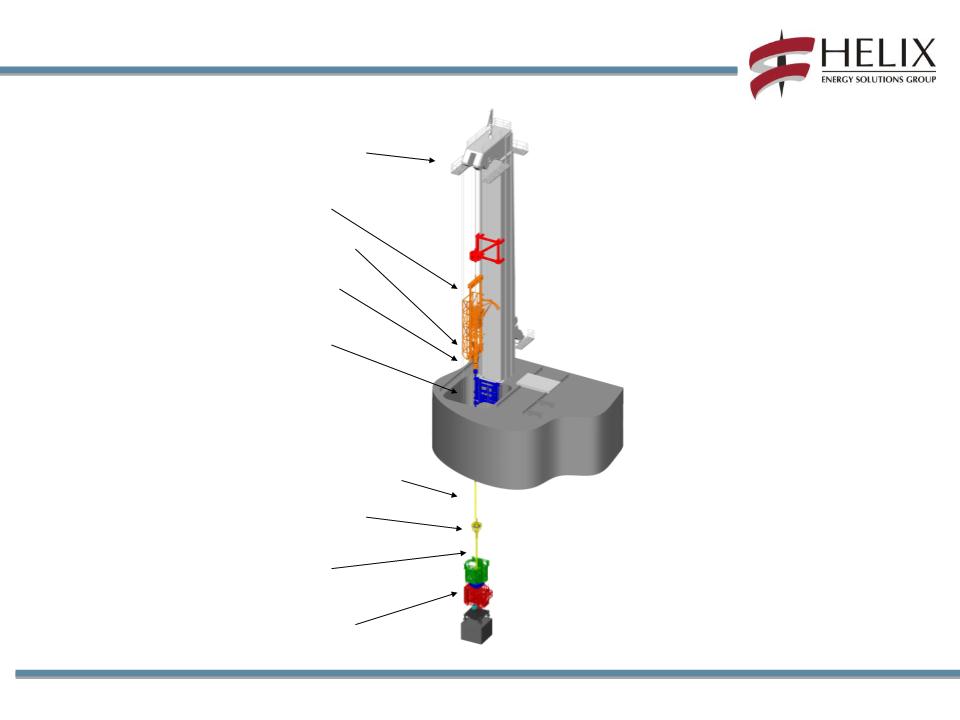

Compensation

Frame CCTLF

Frame CCTLF

Flow Tee and Swivel

Riser Centraliser

Moonpool Joint

Fatigue Enhanced Riser

Mid Joint Connector

Stress Joint

SIL including EDP

Assembly

Assembly

Multi Purpose Tower

MPT

MPT

Helix Coiled Tubing Setup

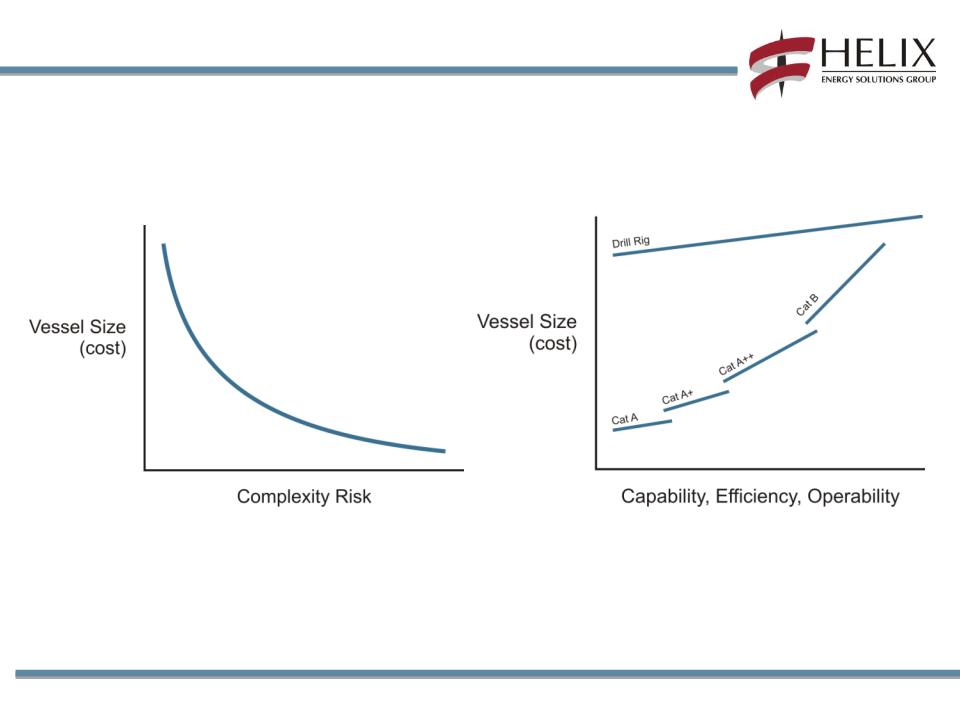

Vessels - Category A Intervention

Category A - Wireline only deployed via a SIL. Typically a monohull due to

build cost and spend of transit.

build cost and spend of transit.

• Smaller the better to keep costs down commensurate with limited

capability.

capability.

• Limited deck area required for necessary equipment. $110 million and

larger typically.

larger typically.

• Operability limited if size is so small that motions become too great for

safe operating. Has even greater effect in harsh environments

safe operating. Has even greater effect in harsh environments

• Water depth limited by seal technology and cost associated with

complexity of system required to accommodate depth.

complexity of system required to accommodate depth.

17

Vessels - Category A+ Wireline

18

Category A + - wireline and coiled tubing deployed via SIL and sub 7” riser,

i.e. drill pipe. Also typically a monohull.

i.e. drill pipe. Also typically a monohull.

• Greater capability with CT but unable to work full bore 7” which restricts

what can be done.

what can be done.

• Advantage of being smaller and lower cost.

• Motions are high thus complexity is difficult.

• High motions result in narrow operating envelope resulting in more down

time and higher risk if emergency disconnect is required. Smaller vessel

makes it difficult to be able to operate on station in high seas.

time and higher risk if emergency disconnect is required. Smaller vessel

makes it difficult to be able to operate on station in high seas.

• High motions adds to safety risk, i.e. man riding.

Vessels - Category A++ Intervention

Category A ++ - Wireline and CT deployed via a 7” riser.

• Has full bore capability with coiled tubing through full 7” bore of the

well.

well.

• May have limited capability of pulling tubing.

• Size of the vessel increases deck space required for equipment and

riser handling.

riser handling.

• Larger size vessels handle sea motion better.

• System required to compensate for motions is still relatively complex.

• Overall cost is now getting high.

19

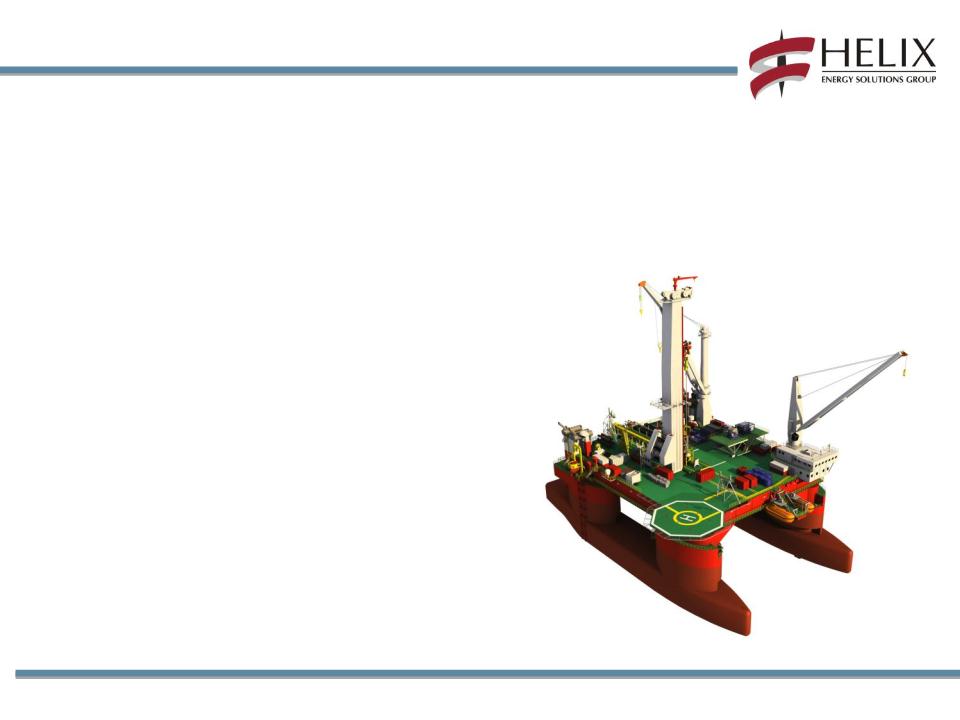

Vessels - Category B Intervention

Category B - Semi Submersible

• Ample deck area

• Motions are the best and allows for less complexity and risk in systems

design.

design.

• Greatest number of applications possible.

20

Industry Considerations

21

Determining which solution makes sense is a balance between

small, low cost vessel with a complex high risk system. (Technology

is not fully developed)

small, low cost vessel with a complex high risk system. (Technology

is not fully developed)

Or

Larger, high cost vessel with simpler low risk system.

Primary Focus: Semi Platform Deploying IRS

22

Conclusion

Colin Johnston, Helix Well Ops Senior Engineer

Well Intervention

Fleet Overview

Fleet Overview

1

2

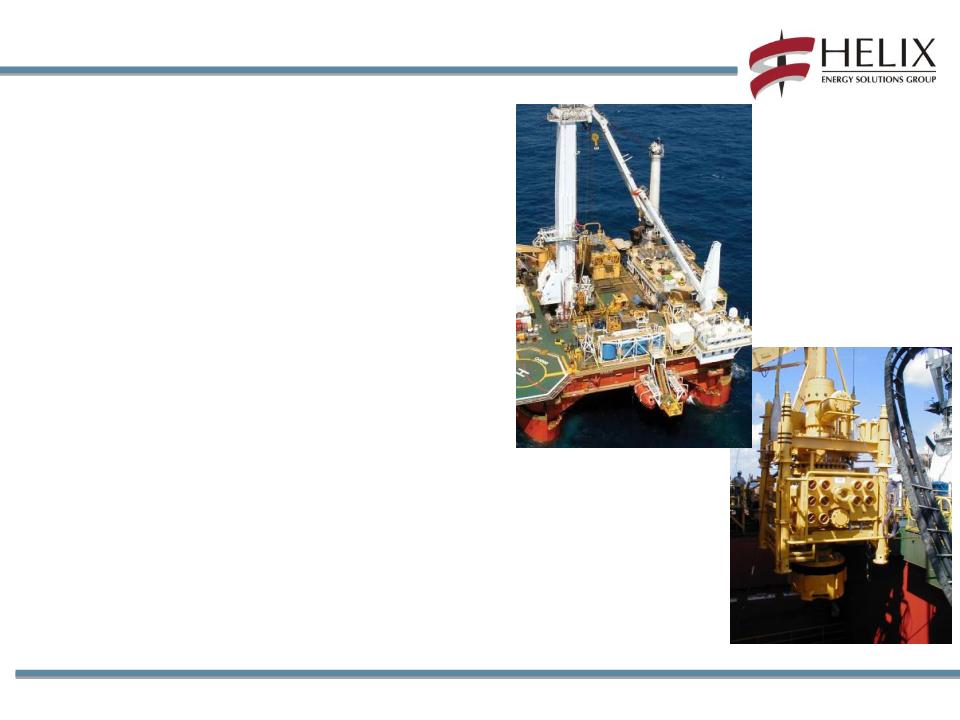

MODU DP3 Q4000

MSV DP3 Well Enhancer

Vessel of opportunity

MSV DP2 Seawell

Well Intervention Assets

Helix is the leader in subsea through-tubing

intervention

intervention

•Global Reach

• 24 years experience in the North Sea on more

than 600 wells

than 600 wells

• 14 years experience in the Gulf of Mexico on

more than 100 wells

more than 100 wells

• 5 years experience in Australia & Sea East Asia

on more than 20 wells

on more than 20 wells

•Successful application of prototype equipment

• Q4000 - IRS, HFRS, MPT, VDS

• Well Enhancer

•Track record of cooperative contracting and

scheduling

scheduling

• Gulf of Mexico

• North Sea Collaboration - Multi client

• Helix Well Containment Group

•Proven capability to manage:

• Marine vessels,

• Crewing

• Subsea systems

•Subsea controls, downhole services, diving,

construction, and WROV operations

construction, and WROV operations

• Well Enhancer CT system

• WOUS IRS MUX upgrade

3

Providing World Class Intervention Services

History and Evolution - Seawell

4

5

History and Evolution - Well Enhancer

6

History and Evolution - Vessels of Opportunity

7

History and Evolution - Q4000

Where the value is found

• Efficiency - Main Driver

• Time efficient

• Cost efficient

• Campaign Based

• Shared across BU, Assets,

Operators

Operators

• Broad Functionality

• Minimal Built-ins

• Variable deck lay out

• Construction Support

• Construction and well intervention

capability

capability

• Seabed access and recovery

• Emergency Response

• Knowledgeable, integrated crews

• Integrated Onshore Management

• Assessment and investment in new

technology

technology

• Integration of Technology

8

9

Accommodation (122)

& project offices

18 man saturation

1 x WROV

1 x Obs ROV

Active heave-comp Derrick

Twin Crane & Well

Services spread:

Services spread:

Slickline

E-line

Pumping

Well test

• Main deck

• (Client supplied)

• Below deck

• 2 x drill water tanks 258m3

• 4 x bulk fluid tanks 240 m3 (1509 bbl)

114m

• Derrick Lifting Capacity 80Te

• Crane 130Te (twin lift)

• 2 x 15k psi OPI triplex pumps

Seawell Light Well Intervention Vessel

10

• Main deck

• 1 x bulk fluid tank 150m3 (943bbls)

• Below deck

• 2 x drill water tanks 90m3 each

• 1 x bulk fluid tank 190m3

• Tower Lifting Capacity 100Te

• Crane 150Te

• 2 x 10k psi SPM600 pumps

Well Services

spread:

spread:

Slickline

E-line

Pumping

Well test

Coiled Tubing

Active heave-comp Tower, Crane, Riser Handling & Skidding system

18 man saturation

1 x WROV

1 x Obs ROV

Accommodation (120)

& project offices

132m

Well Enhancer Light Well Intervention Vessel

11

7 3/8” SIL in the Well Enhancer Tower

5 1/8” SIL in the Seawell Derrick

7 1/16” SIL in the Seawell Derrick

Subsea Intervention Lubricators (SILs)

Well Enhancer - Overview

Tower, Riser Handling

& Skidding systems

Crane & Well Services

•Slickline

•E-line

•Pumping

•Well test

•Coiled Tubing

• Tower Lifting Capacity = 150Te

• Tower Active Heave Comp = 130Te

• Crane = 100Te

• Guide Line Tensioner = 4 off (10te)

• Active Pod Line Tensioner = 2 off (15te)

• 2 x SPM600 673kw 10k pumps

• 1 x s/steel frac tanks = 200 m3 (1260 bbl)

• 2 x drill water tanks = 190m3

• Deck tanks = >266m3

Compensation

Frame CCTLF

Frame CCTLF

Flow Tee and Swivel

Riser Centraliser

Moonpool Joint

Fatigue Enhanced Riser

Mid Joint Connector

Stress Joint

SIL including EDP

Assembly

Assembly

Multi Purpose Tower

MPT

MPT

Well Enhancer Coiled Tubing Setup

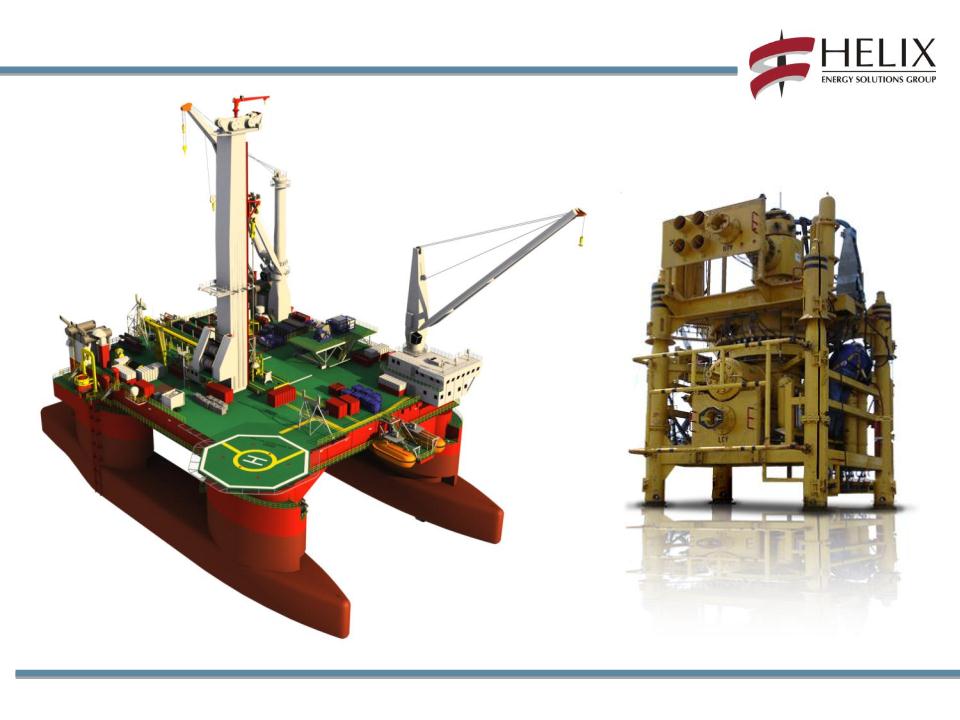

Q4000 DP3 MODU Semi-submersible

14

4,000 mT variable main deck load

• MPT Tower Lifting

Capacity 600 mT

Capacity 600 mT

• Active and Passive Heave

Comp

Comp

• 360 mT Huisman crane

with

10,000 ft capacity traction

winch

with

10,000 ft capacity traction

winch

Well Services spread:

Slickline

E-line

Pumping

Well test

Coiled Tubing

Active heave-comp Tower, Crane,

Riser Handling & Skidding system

Riser Handling & Skidding system

Accommodation (133)

& project offices

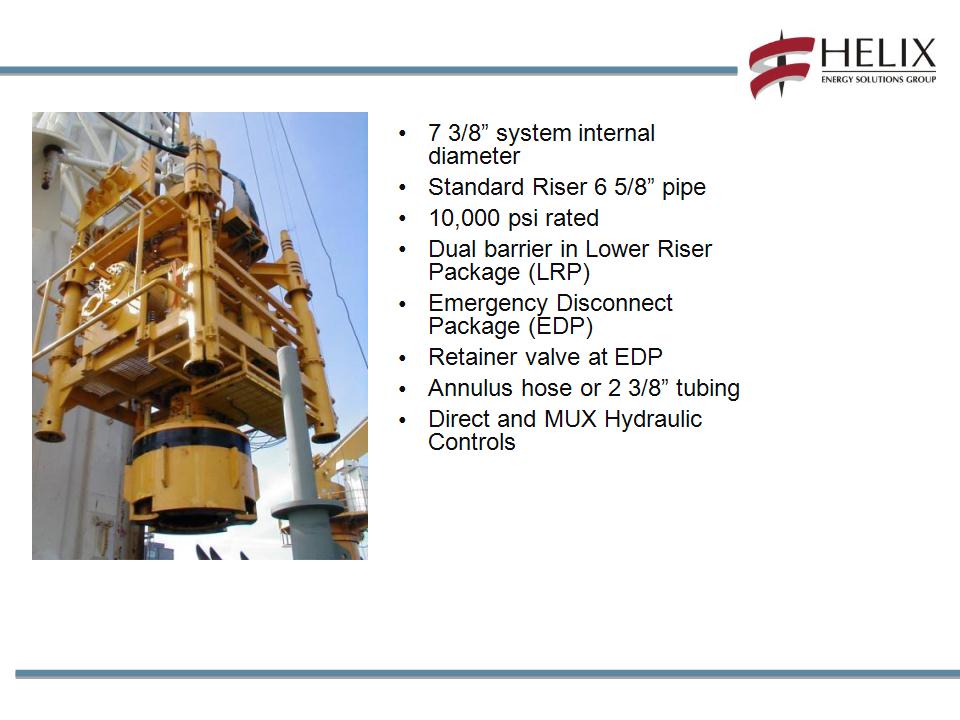

Well Ops 7-3/8” Intervention Riser System

Future Vessels

• Through tubing well intervention

• Top hole drilling

• Extended top hole drilling

• Riserless Mud Return

• Subsea Rotary Controlled Device

• Well flow back, well testing

• Subsea construction

• Subsea processing support

• Open Water Completions

Kurt Hurzeler, Helix Well Ops Commercial Manager

Well Intervention

Methodologies

Methodologies

1

Critical Skill Sets

• Specialized vessels and vessel

management

management

• Down hole & Service Options

expertise

expertise

• ROV expertise

• In-house Subsea expertise

• Construction expertise

• Saturation Diving expertise

• Multi Functional Crew Management

Vessel Functions

•Adequate usable Deck space

•Adequate Accommodation

•Certified and classed for

hydrocarbons on deck

hydrocarbons on deck

•Lifting Capacity and Stability

•Heavy weather dynamic positioning

•Fluid storage and handling

•IRS tubular handling and tensioning

Consistent Success Requires…

Facilitate Wellbore Access

• Flexibility of system to interface with all subsea well types with minimal

modification.

modification.

• Provide systems on a day rate basis to reduce end user’s cost

• Minimize complication, deployment and testing time

• Reduce rig requirements and costs

Reduce Decommissioning Liability

• Lower cost well abandonment

• Reliable and successful completion

Improve Intervention Response

• Provide a rig alternative with 4 season capability.

• Minimize mobilization, demobilization and transit time

• Pre-engineer capability to allow rapid response for clients needs

• Stay in the field

Provide Surveillance & Flow Assurance

• Reduce access costs for subsea production evaluation

• Reduce Inspection, Repair & Maintenance (IRM) Costs

Where the Value is Found

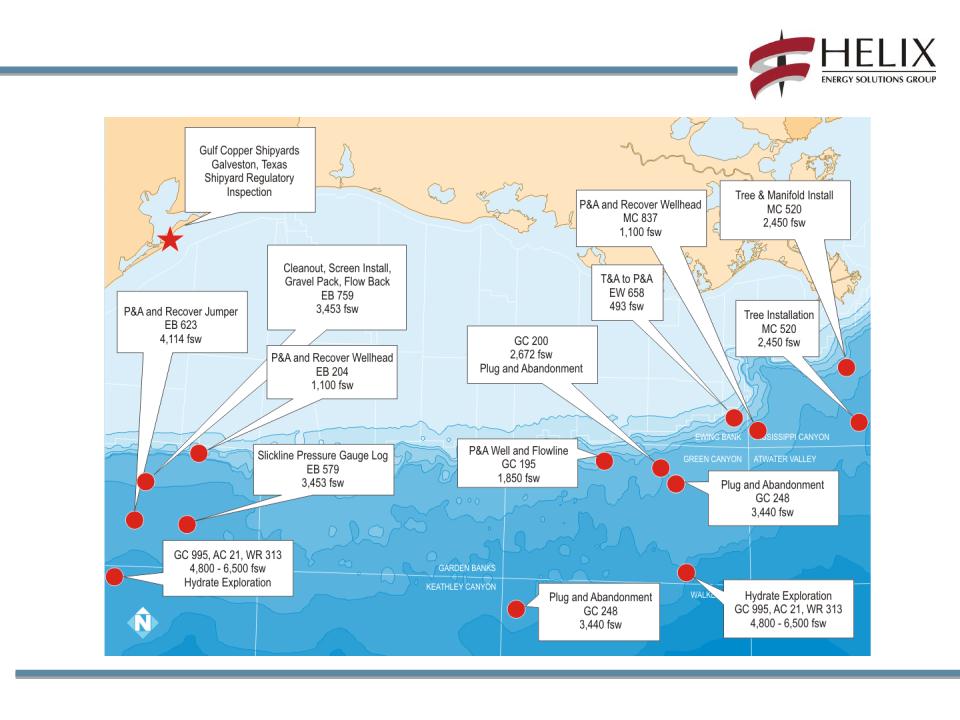

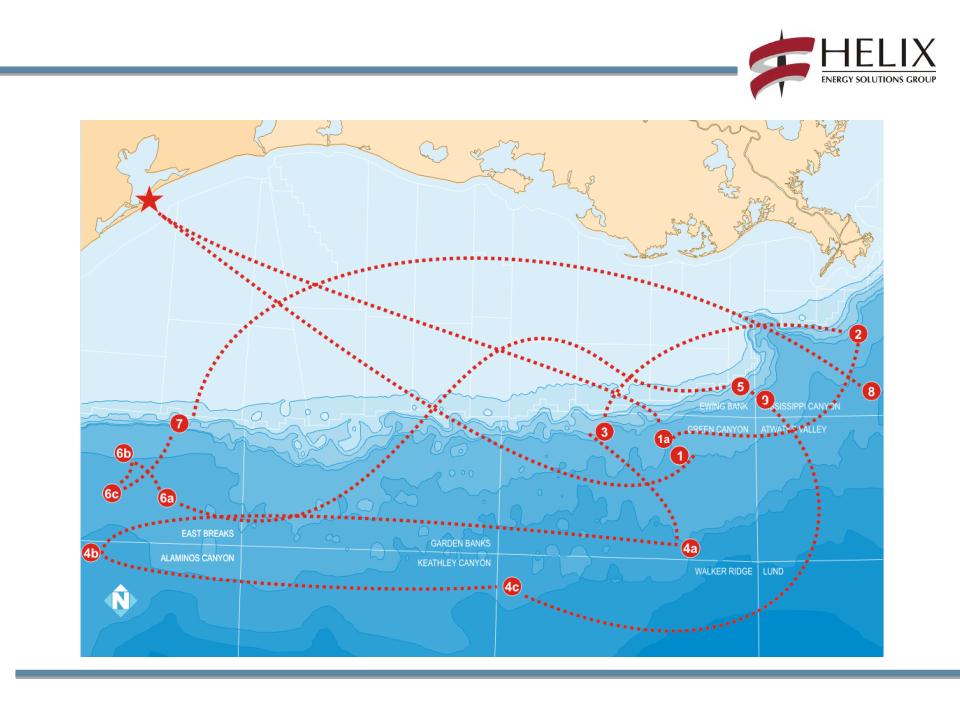

Campaign Based

• Shared costs across BU’s, fields and operators

• Reduced transit time

• Minimal port and duty costs

Construction Support

• Ability to carry out construction and well intervention

• Lift and/or transport heavy equipment from port to location, install via

crane or drill pipe, assist platform operation

crane or drill pipe, assist platform operation

Emergency Response

• Offshore fire fighting, diving and ROV support

• Ready availability, construction, accommodation, intervention and

general operations support

general operations support

Where the Value is Found

Operational overview - Seawell North Sea

The Client objective was to maximise

the operational functionality of the

MSV Seawell in order to complete the

following well workscopes:

the operational functionality of the

MSV Seawell in order to complete the

following well workscopes:

•Mechanical repair/well

maintenance/integrity

maintenance/integrity

•Production logging

•Mechanical repair/well maintenance;

tree change-out; well integrity

tree change-out; well integrity

•Well suspension operations

(temporary abandonment)

(temporary abandonment)

•3 x well P&A and wellhead removal

•Pumping - scale-squeeze operations

Operational overview - Seawell North Sea

• In field 16 days Highlander Field

• In field 16 days Tartan Field

• In field 14 days Enoch / South Wood

• In field 17 days Claymore

• In field 9 days Tweedsmuir

5 1/8” SIL in the MSV Seawell Derrick

Seawell Operation summary

• Number of well locations = 7

• Water depth range = 90 - 141m

• Full demobilisation of 5 1/8” SIL in order to mobilise 7 1/16” SIL for TNT

• Total days = 68

• Vessel off-hire 0 days

• Wait on Weather 9.5 days

• Uptime 58.1 days

• Well-work completed:

• 4 Interventions (Well Maintenance & Production Enhancement)

• 3 wells P&A’d (Decommissioning)

• All the above workscopes were supported with Saturation Diving operations

• All procedures developed and work supported by in-house WOUK project engineers

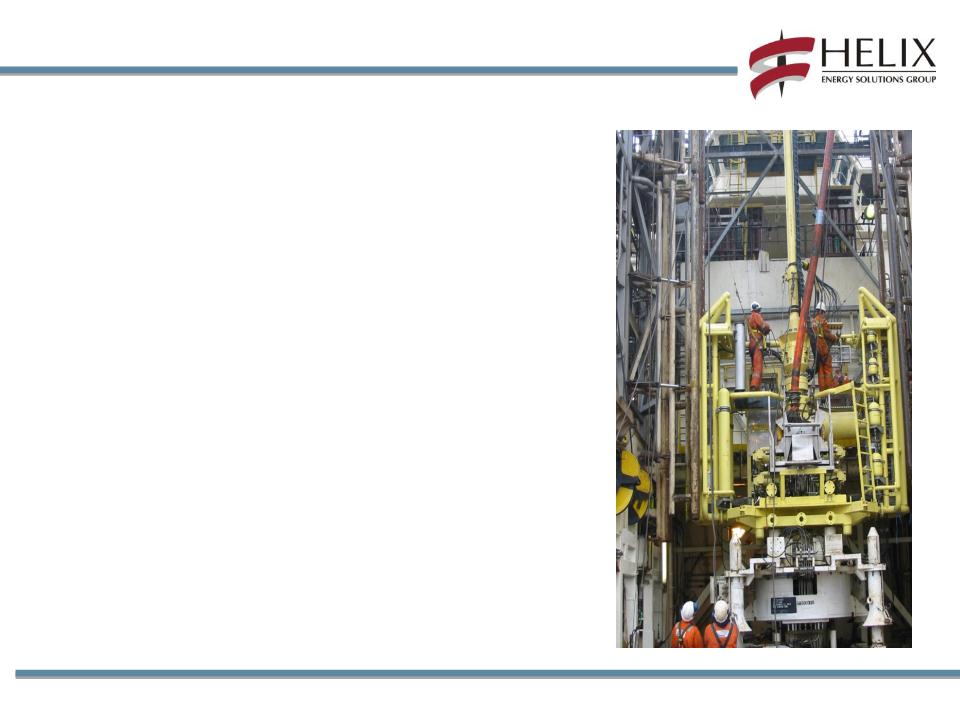

Q4000 Gulf of Mexico Snapshot

Q4000 Gulf of Mexico Snapshot

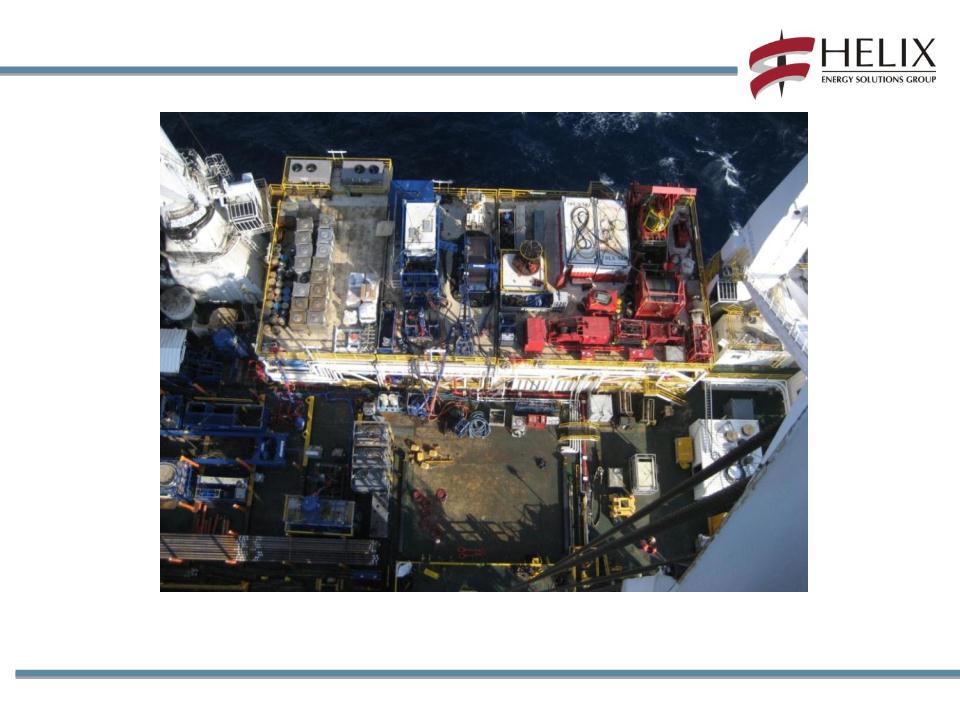

Q4000 Deck Layout for Well Stimulation

Deck Space- More is Better

Drilling module roofs with complete coiled tubing system, E

-Line, Slick Line, fluids and second WROV system

-Line, Slick Line, fluids and second WROV system

Intervention Deck Space and Positioning

• Coil-tubing Lift Frame

• Intervention Riser Package

• Flowhead

• H4 Connector

• Riser

• 3rd Party Service Equipment

Critical Components Remain Onboard

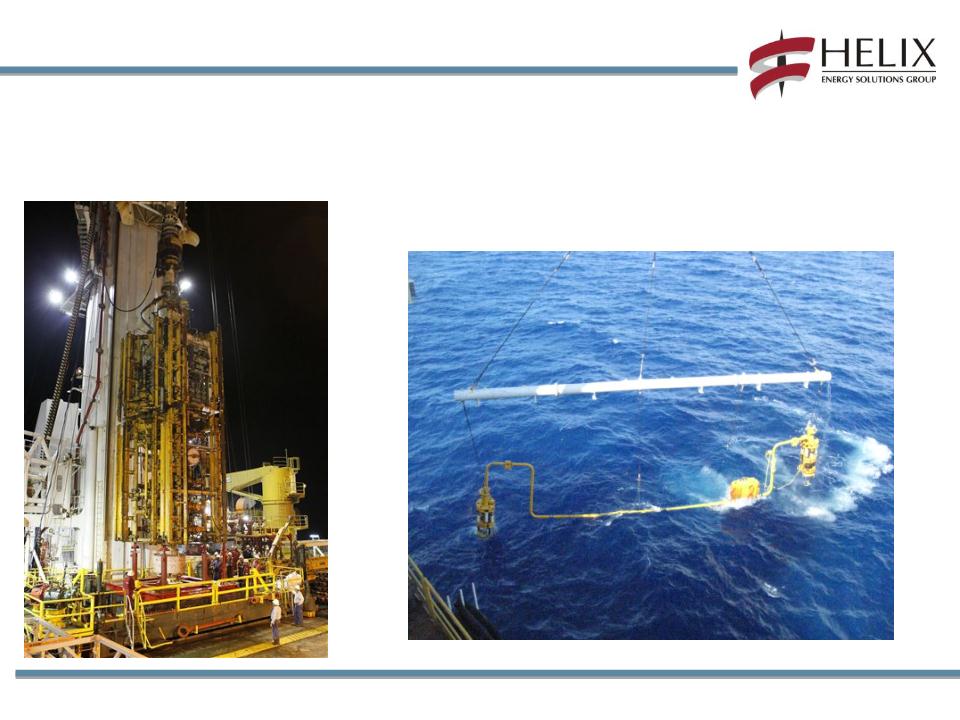

280 MT Manifold being deployed

Construction - Dock to Seabed

• Seabed debris recovery

• Debris cap recovery and

reinstall

reinstall

• Flowline plug and burial

Flowline clean out

Flowline clean out

• Jumper disconnect and

recovery

recovery

Construction - Concurrent Operations

Static Kill

Oil & Gas Burn

Dynamic Kill

SIMOPS

Q4000 Versatility and Capabilities

Summary

• A unique combination of specialized skills and equipment

• A clear understanding of Client value

• Recognition of operational technical limits

• The means, ability and experience to manage and control diverse assets and

personnel effectively and reliably

personnel effectively and reliably

Helix Well Ops Provides