Attached files

| file | filename |

|---|---|

| 8-K - 8-K - BORGWARNER INC | d310702d8k.htm |

Exhibit 99.1

BorgWarner Inc

February 2012

| D E A R S H A R E H O L D E R | ||||

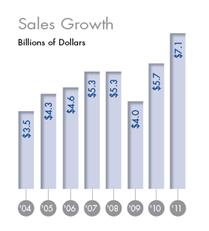

| The year 2011 was a very good year for BorgWarner. Global automotive production grew a modest 3% in 2011 compared with 2010. During that same period, BorgWarner sales grew 26%, outperforming the industry by a wide margin. Our strategy to focus on improving fuel economy, emissions and performance is clearly a winning approach. | ||||

|

|

The industry began the year with cautious optimism, but struggled to gain momentum. In March, a natural disaster devastated parts of Japan and ground industrial activity to a halt. At the time, it was known that vehicle production would be lost, the impact of which was measurable, and, therefore, somewhat understood. However, the impact of a crippled Japanese supply base, which supplies key components to the industry around the world, was not well understood. The uncertainty caused worst case scenarios to be contemplated and action plans to be developed. Despite our best efforts to contribute to the recovery, most of us outside of Japan were relegated to watching and waiting. During that period, I was inspired by the resilience of the Japanese people. Their resolve and the speed of their recovery was remarkable. In the end, the ingenuity of the industry prevailed. Alternative sources were found and product plans were adjusted to accommodate for scarce parts. The impact to BorgWarner was moderate.

China took measures to cool down their fast-growing economy in 2011. In addition to measures taken on a broad scale, the automotive sector was directly impacted by reduced government-sponsored incentives for vehicle sales in addition to limiting vehicle registration in some of the major cities. Vehicle production slowed down as a result, but the adoption of advanced powertrain technology did not. China was our fastest growing market in 2011 and I expect this to continue going forward for many years to come.

During the second half of 2011, the industry was focused on Europe and the potential impact of its sovereign debt crisis. Speculation was rampant and downside risk weighed on the minds of investors. Europe is an important market for our company. At more than 50% of our total revenue, it is our largest market, and leads the world in advanced powertrain development. Clearly, developments in the European economy and its automotive industry are meaningful to us. However, despite the heightened concerns, as I write this letter, the European automotive industry continues to grow and, more importantly, continues to adopt advanced powertrain technology at a rapid pace, driving above-market growth for BorgWarner.

| |

|

|

| The bright spot in the automotive industry in 2011 was North America. Light vehicle production grew 9%, outpacing the rest of the world. Another key development in North America was the U.S. government’s bold step toward instituting globally competitive fuel economy standards. It is expected that by 2025, automakers will have to achieve average corporate fuel economy standards of | We continue to deliver industry-leading stockholder returns. In 2011, our share price reached a new all-time high of $82.28, but eventually gave way to market uncertainty surrounding Europe, and ended the year at $63.74, down 11% from 2010. A decline in share price is a disappointing result for a year in which we achieved record operating performance, but to put things |

AWD segment as the market continues to shift toward FWD-based AWD vehicles. The acquisition adds industry leading FWD/AWD technologies, with a strong European customer base, to our existing Drivetrain portfolio. This enables BorgWarner to provide our global customers a broader range of AWD solutions to meet their vehicle needs. | ||

| “We believe that the industry will remain focused on improved fuel economy and lower emissions for many years to come, and that our products, and the new technologies that we are developing for the future, will play a crucial role in the industry’s evolution.” | ||||

| 54.5 miles per gallon for their fleets. These new standards will set into motion a tremendous amount of development work that will accelerate the adoption of advanced powertrain technology. In fact, the work has already begun. This should be a major growth catalyst for BorgWarner.

Record-setting Performance

Once again, it was a record setting year for BorgWarner on a number of different fronts. From an operational performance standpoint, our revenue of $7.1 billion and our earnings of $4.45 per diluted share were new highs for the company. It is also noteworthy that our operating income margin, a key measure of profitability, was 11.2% in 2011, also a new record. |

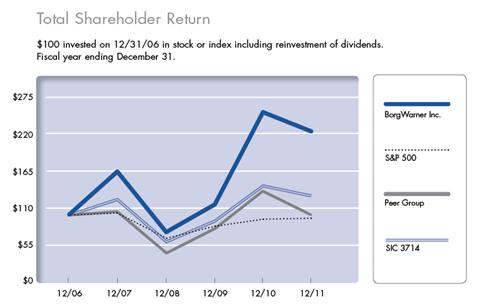

in perspective, our industry peers, on average, ended the year down 31%. Furthermore, total shareholder return for BorgWarner stockholders over the last five years was 122%, compared with 1% for our peer group and -1% for the S&P 500, providing outstanding results for you, our stockholders.

The Benefits of a Strong Balance Sheet

During the year, our strong balance sheet and cash flow enabled us to execute two important initiatives:

• We acquired Haldex Traction Systems, a leader in advanced front-wheel drive (“FWD”), all-wheel drive (“AWD”) technology. The deal is expected to accelerate our growth in the global |

• We repurchased approximately 5 million shares in 2011, most of which are intended to be used to settle our convertible debt obligations in April of 2012.

All of this was done while maintaining our investment grade credit rating, a clear signal that our balance sheet remains strong and provides opportunities for the future.

The growing importance of improved fuel economy and reduced emissions is driving significant growth and capital investment for us around the globe. We are currently installing capacity in North America, South America, Eastern Europe and Asia to support our growth in every major product area.

| ||

|

B O R G W A R N E R S T O C K H O L D E R S L E T T E R 2 0 1 1

|

| Accelerating Growth

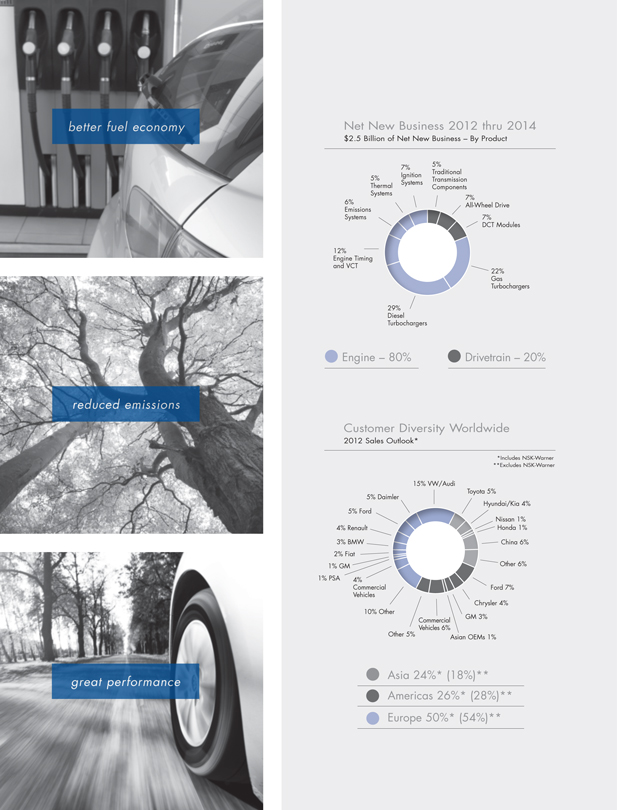

In the fall, we announced our backlog of $2.5 billion of net new business over the next three years (2012-2014), another record for our company. This backlog encompasses some of the most promising technologies and geographies in the auto sector and is representative of how BorgWarner is leading the way in important global powertrain developments. From a product perspective, turbochargers, engine timing systems, variable cam timing, and dual-clutch transmission modules are BorgWarner’s largest growth drivers. We continue to generate important new business in each of these product families.

|

| |||

| Turbochargers for gasoline engines represent a significant share of the turbocharger backlog, which reflects the growing global trend toward downsized turbocharged gasoline engines to address fuel efficiency and emissions reductions. For example, Ford selected BorgWarner’s leading gasoline turbocharger technology for its new four-cylinder EcoBoost engine and for rear-wheel drive trucks featuring its new six-cylinder EcoBoost engine. The six-cylinder EcoBoost engine has been a tremendous success for Ford while the highly anticipated 2.0-liter EcoBoost engine is launching on the 2012 Ford Edge and 2012 Ford Explorer.

Diesel turbochargers for both on-road and off-road commercial vehicles are also an important part of our backlog. Last year, we announced that we are supplying our latest B-series generation turbocharger to DEUTZ for its newly-designed, 6.1-liter six-cylinder heavy-duty diesel engine used in agricultural machinery. And, more recently, we announced |

that we are supplying turbochargers for the new Mercedes-Benz 12.8-liter six-cylinder in-line BlueEFFICIENCY engine, the first in its class to meet upcoming Euro 6 emissions standards. The top twenty-five customers of our three-year net new business include six commercial vehicle customers.

Another important launch last year was our variable cam timing technology on Subaru’s new 2.5- and 2.0-liter, Boxer engines. The 2.5-liter engine features BorgWarner’s award-winning Cam Torque Actuated technology (“CTA”), while the 2.0-liter engine introduces BorgWarner’s CTA technology with a new mid position lock, an innovation named as a finalist in the 2011 Automotive News PACE Awards. Our innovations in variable cam timing technology allow more precise control over intake and exhaust valve timing for better fuel economy and lower emissions. According to Subaru, the new four-cylinder 2.5- and 2.0-liter engines improve fuel economy 4 to 10 percent, respectively, compared |

with previous models, and meet U.S. Super Ultra Low Emissions Vehicle (SULEV) and Euro 5 emissions standards.

Another exciting development for BorgWarner is our growing business in China. The rapid adoption of leading powertrain technologies in the world’s fastest growing automotive market has created a tremendous opportunity for BorgWarner. In addition to our success with Chinese-Western OEM joint ventures, we have developed relationships with the leading domestic Chinese OEMs that are now bringing new technologies to China. For example, in 2011, Great Wall Motor Company launched its first self-designed diesel engine featuring a BorgWarner variable turbine geometry turbocharger. This is the first variable turbine geometry turbocharger available in China. In 2012, our dual-clutch transmission technology will make its Chinese debut with Shanghai Automotive, also a first for a Chinese automaker. | ||

| Additionally, our other product technologies continue to grow around the world. Fans and fan drives, emissions systems, traditional transmission components and AWD devices are all meaningful contributors to our backlog of net new business. Notably, we are supplying transmission components, including friction plates and roller one-way clutches, for Hyundai’s new 8-speed automatic rear-wheel drive transmission. We are supplying our electronically controlled Visctronic fans to Freightliner for its Cascadia trucks, a first for Class 8 commercial trucks in North America, and our Torque-On-Demand® transfer case drives the new 2.2-liter Tata Aria, the first four-wheel drive cross-over vehicle in India. At the same time, we are launching new transfer cases for AWD Ram Trucks in 2011.

The regional mix of our backlog of net new business is aligned with the pace of advanced technology adoption around the world. Forty-five percent of the backlog is in Europe which remains the epicenter of advanced development for internal combustion engines, fuel economy and emissions improvements. Thirty-five percent is in Asia, which continues to expand in importance because of its rapid growth and its demand for leading edge technologies. Twenty percent of our backlog is in North America, where we see intensified customer focus on programs aimed at improved fuel economy and lower emissions.

The Road Ahead

Looking ahead, we expect 2012 to be another great year for BorgWarner. Global vehicle production growth will continue, although we expect European production to decline in 2012 compared with 2011. Despite this, it should be another record year for BorgWarner as we continue to outpace the industry. |

In 2012, BorgWarner expects to increase sales in every major region of the world, including Europe, due to our strategic focus on improving fuel economy and lowering emissions.

We expect to post sales and earnings records in 2012. Furthermore, we expect to reach a higher operating income margin in 2012 than a year ago. Last year, our full year operating income margin reached 11.2%. In 2012, we expect that margin to be 11.5% or better. The expectation of improved margins can be attributed to restructuring actions taken in 2008 and 2009 combined with an ongoing focus on operating efficiency.

As we consider the longer term, we believe that understanding the foundation of our past success, and applying those principles to today’s strategic initiatives, are the keys to our future success. On that basis, our senior leadership has validated eight Enterprise Strategies that will guide BorgWarner to 2020:

Enterprise Strategies

• Accelerate the pace of INNOVATION and product leadership into new technologies, markets and geographic regions

• Consistently drive profitable sales GROWTH at least 10 percentage points above the global industry growth rate

• Be the supplier / strategic partner of choice for our CUSTOMERS, while meeting our company objectives |

• Realize a QUALITY operating system that focuses on zero defects

• Continuously improve the STRUCTURAL EFFICIENCY of BorgWarner

• Ensure we have the right TALENT in the right locations at the right time

• Protect, nurture and sustain the unique and successful CULTURE of BorgWarner

• Supplement organic growth with MERGERS & ACQUISTIONS to achieve our product, technology, customer and geographic goals

These strategies have been the cornerstone of BorgWarner’s success for many years, and continue to be energized for the future.

We spend a lot of time thinking about the direction of our industry and our role in it. We believe that the industry will remain focused on improved fuel economy and lower emissions for many years to come, and that our products, and the new technologies that we are developing for the future, will play a crucial role in the industry’s evolution. Staying focused on the future while executing operational excellence today is a winning formula for achieving one of our ultimate goals, which is to maximize your total stockholder returns.

Timothy M. Manganello Chairman and Chief Executive Officer |

| ENGINE Group |

The Engine Group develops air management strategies and products to optimize engines for fuel efficiency, reduced emissions and enhanced performance. BorgWarner’s expertise in engine timing systems, boosting systems, ignition systems, air and noise management, cooling and controls is the foundation for this collaboration.

| |||||

|

|

K E Y T E C H N O L O G I E S

| |||||

| Chain Products Global leader in the design and manufacture of chain systems for engine timing, automatic transmissions and torque transfer, including four- and all-wheel drive applications. Engine chain systems include chains, sprockets, tensioners, control arms and guides, and variable cam timing devices.

Emissions Systems A global leader in the design and supply of exhaust gas recirculation (EGR) systems, secondary air |

systems (SAS), and advanced actuators for enhanced engine performance, fuel economy, and reduced emissions.

Thermal Systems Systems for thermal management designed to improve engine cooling, and reduce emissions and fuel consumption.

Turbochargers Leading designer and manufacturer of turbochargers and boosting systems for passenger cars, light trucks and |

commercial vehicles. Systems enhance fuel efficiency, reduce emissions and enhance vehicle performance.

BERU Systems A worldwide leading supplier of diesel cold-start technology and a leading European manufacturer of ignition technology for gasoline vehicles. Electronics and sensor technology provide more comfort and stability for applications in various engine and vehicle functions. | ||||

| ||||||

| DRIVETRAIN Group |

The Drivetrain Group harnesses a legacy of more than 100 years as an industry innovator in transmission and all-wheel drive technology. The group is leveraging its understanding of powertrain clutching technology to develop interactive control systems and strategies for all types of torque management.

| |||||

|

|

K E Y T E C H N O L O G I E S

| |||||

| Torque Management Leading global designer and producer of torque distribution and management systems, including iTrac® Torque Management devices for front-wheel drive vehicles and transfer cases for rear-wheel drive applications. These systems enhance stability, security and drivability of passenger cars, | crossover vehicles, SUVs and light trucks.

Transmission Products A global designer and manufacturer of automatic transmission components and modules and supplier to virtually every major automatic transmission manufacturer in the world. Friction and mechanical products include dual clutch |

modules, friction clutch modules, friction plates, transmission bands, torque converter clutches, one-way clutches and torsional vibration electro-hydraulic solenoids for standard and high pressure hydraulic systems, transmission solenoid modules and dual clutch control modules. | ||||

| ||||||

BorgWarner will provide its full financial report electronically as part of its environmental initiative to conserve resources and reduce costs. For more information on the company’s financial performance and sustainability initiatives, please visit our website at borgwarner.com.