Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - C&J Energy Services, Inc. | d298546d8k.htm |

C&J Energy Services, Inc.

Investor Presentation

February 9, 2012

Exhibit 99.1 |

Forward-Looking Statements

Certain

statements

and

information

in

this

presentation

may

constitute

“forward-looking

statements”

within

the

meaning

of

Section

27A

of

the

Securities

Act

of

1933,

as

amended,

Section

21E

of

the

Securities

Exchange

Act

of

1934,

as

amended,

and

the

Private

Securities

Litigation

Reform

Act

of

1995.

The

words

“believe,”

“expect,”

“anticipate,”

“plan,”

“intend,”

“foresee,”

“should,”

“would,”

“could”

or

other

similar

expressions

are

intended

to

identify

forward-looking

statements,

which

are

generally

not

historical

in

nature.

These

forward-looking

statements

are

based

on

our

current

expectations

and

beliefs

concerning

future

developments

and

their

potential

effect

on

us.

While

management

believes

that

these

forward-looking

statements

are

reasonable

as

and

when

made,

there

can

be

no

assurance

that

future

developments

affecting

us

will

be

those

that

we

anticipate.

All

comments

concerning

our

expectations

for

future

revenues

and

operating

results

are

based

on

our

forecasts

for

our

existing

operations

and

do

not

include

the

potential

impact

of

any

future

acquisitions.

Our

forward-looking

statements

involve

significant

risks

and

uncertainties

(some

of

which

are

beyond

our

control)

and

assumptions

that

could

cause

actual

results

to

differ

materially

from

our

historical

experience

and

our

present

expectations

or

projections.

Known

material

factors

that

could

cause

our

actual

results

to

differ

from

our

projected

results

are

described

in

our

filings

with

the

Securities

and

Exchange

Commission

(“SEC”),

including

but

not

limited

to

the

final

prospectus

dated

July

29,

2011

(File

No.

333-173177)

relating

to

our

initial

public

offering

and

Quarterly

Report

on

Form

10-Q

for

the

period

ended

September

30,

2011.

All

readers

are

cautioned

not

to

place

undue

reliance

on

forward-looking

statements,

which

speak

only

as

of

the

date

hereof.

We

undertake

no

obligation

to

publicly

update

or

revise

any

forward-looking

statements

after

the

date

they

are

made,

whether

as

a

result

of

new

information,

future

events

or

otherwise.

Non-GAAP Financial Measures

We

use

both

GAAP

and

certain

non-GAAP

financial

measures

to

assess

performance.

Generally,

a

non-GAAP

financial

measure

is

a

numerical

measure

of

a

company's

performance,

financial

position

or

cash

flows

that

either

excludes

or

includes

amounts

that

are

not

normally

excluded

or

included

in

the

most

directly

comparable

measure

calculated

and

presented

in

accordance

with

GAAP.

C&J

management

believes

that

these

non-GAAP

measures

provide

useful

supplemental

information

to

investors

in

order

that

they

may

evaluate

our

financial

performance

using

the

same

measures

as

management.

These

non-GAAP

financial

measures

should

not

be

considered

as

a

substitute

for,

or

superior

to,

measures

of

financial

performance

prepared

in

accordance

with

GAAP.

In

evaluating

these

measures,

investors

should

consider

that

the

methodology

applied

in

calculating

such

measures

may

differ

among

companies

and

analysts.

Reconciliation

of

non-GAAP

results

to

GAAP

results

for

historic

periods

can

be

found

on

slide

35

of

this

presentation

and

in

our

filings

with

the

SEC,

as

applicable.

2

Disclaimer |

Company Overview |

4

Founded by current Chairman and CEO Josh Comstock

Well-positioned to benefit from many of the most important trends in drilling

and completion Focused on complex, technically demanding completions that

deliver superior returns Operates modern, high-pressure rated

equipment Integrated manufacturing capabilities

Recent rapid growth through penetration of prominent E&P customers

Unique financial business model through “take-or-pay plus”

contracts that combine visibility

with spot upside optionality

C&J is a Differentiated Energy Services Company |

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

5

Josh

Comstock

founded C&J

Introduced stand-

alone pressure

pumping services

Ordered first

hydraulic

fracturing fleet

Added 5 coiled tubing units, bringing total to 13

Geographic expansion into East Texas

Launched hydraulic fracturing service

Contracted Fleets 1 and 2

Ordered Fleets 3, 4 and 5

Evolution of C&J

Introduced

coiled tubing

services

C&J Timeline

Key Customers

Closed Total Acquisition

Coiled tubing count reaches 18 units

Contracted Fleets 3, 4, 5 and 6

Ordered Fleets 7, 8, 9

2012

Ordered 6 additional

coiled tubing units |

6

C&J Investment Highlights

Operational

expertise in

service-

intensive

basins

Visible revenue

growth

Modern, high-

specification

equipment

High-quality

service

Focused on technically-demanding, service-intensive basins

Generate higher revenue per unit of horsepower relative to peers

Customized solutions through extensive front-end technical analysis and

planning

Design

engineers

and

job

supervisors

involved

throughout

project

execution

Exclusive focus on high-pressure rated equipment (all rated up to 15,000

psi) Modern fracturing fleet, all entered into service in the past four

years Acquisition of Total provides specialized, in-house manufacturing

capability Substantial hydraulic fracturing and completion services

experience Vested executive team with significant ownership

Experienced

management

Scheduled equipment deliveries to support sustained growth

Term contracts provide visibility with flexibility for spot market upside

|

Industry Trends |

Ongoing development of existing and emerging unconventional resource basins

-

Increased horizontal drilling

-

Greater service intensity

Strong North American supply-demand fundamentals

-

Increased demand for expertise to execute complex completions

-

High levels of asset utilization and constrained supply growth

Spread of North American unconventional drilling and completion techniques

-

Conventional field redevelopment applications

-

Emerging international opportunities

8

Key Industry Themes Driving C&J Opportunity |

Source:

Unconventional

Drilling

data

as

of

September

2011

and

Baker

Hughes

Rig

Count

data

as

of

November

04,

2011.

Strong Drilling Outlook Drives Completion Demand

9

Significant increase in rig count and horizontal drilling activity

Increased service intensity of horizontal wells |

10

Source: Goldman Sachs Equity Research, management estimates.

Note: Dark blue bars denote current C&J basin of operation.

Advances in Completion Techniques Driving Demand

Average Fracturing Stages Per Well

Average Horsepower Per Well (000’s of HP)

40

38

30

25

11

Haynesville

Eagle

Ford

Granite

Wash

Other

Unconventional

Median

Conventional

16

16

12

13

3

Haynesville

Eagle

Ford

Granite

Wash

Other

Unconventional

Median

Conventional |

11

Favorable Supply / Demand Fundamentals

Continued increase in horizontal drilling

Longer laterals

Growing number of fracturing stages per well

Improved drilling efficiencies

High-pressure environments

Customized approach to the completion of

complex, technically demanding wells

Redevelopment of conventional fields

Older equipment not well-suited to meet

demanding completion requirements

Significant increase in attrition and

maintenance downtime

-

24-hour continuous service

-

More aggressive sand / proppant use

-

More demanding operating conditions in

higher pressure formations

Supply chain constraints in obtaining new

equipment

Limited industry experience executing the

most complex completions

Demand-Side Drivers

Supply-Side Drivers |

Business Overview |

13

Overview of Service Offerings

Services

Hydraulic

Fracturing

Pressure

Pumping

Coiled Tubing

Provide highly customized services for

technically challenging basins

Engineering staff offers extensive

front-end technical evaluation

Demonstrated efficiency gains to client

allows for premium pricing

Ability to handle heavy-duty jobs across

a wide spectrum of environments

Leverage CT business to expand into

additional fracturing opportunities

Provides various functions associated

with well completion and well servicing

Diverse portfolio of value-added

services

Routinely performed in conjunction with

coiled tubing services

Often provides advanced knowledge of

potential coiled tubing work

Focus on most

complex projects in

most challenging

basins |

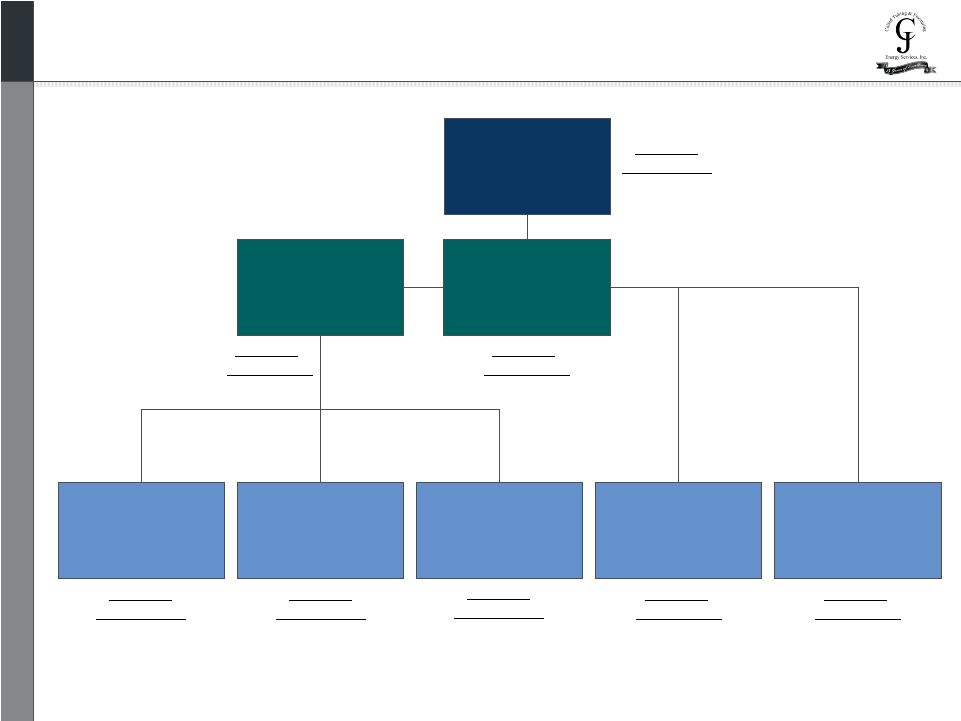

14

Highly Experienced Management Team

Josh Comstock

Founder,

Chairman and CEO

Randy McMullen

EVP,

CFO and Treasurer

Brett Barrier

COO

John Foret

VP, Coiled Tubing

Billy Driver

VP, Hydraulic

Fracturing

Brandon

Simmons

VP, Coiled Tubing

Pat Winstead

VP, Marketing

Ted Moore

VP, General Counsel

Industry

Experience

20+ years

Industry

Experience

20+ years

Industry

Experience

10+ years

Industry

Experience

20+ years

Industry

Experience

25+ years

Industry

Experience

18+ years

Industry

Experience

25+ years

Industry

Experience

9+ years |

15

Modern, High-Specification Equipment

Currently operates six modern 15,000 psi pressure rated hydraulic fracturing fleets

with aggregate of 206,000 horsepower

–

Specifically designed to handle well completions with long lateral segments and

multiple fracturing stages in high pressure formations

Also owns a fleet of 18 coiled tubing units, 21 double-pump pressure pumps

and 9 single-pump pressure pumps

–

Additional 6 coiled tubing units and ancillary equipment to be delivered in

the second half of 2012 for

deployment to new geographic basins –

20 of the 24 coiled tubing units will be 2-inch dimension

Vertical integration through acquisition of Total E&S

(“Total”) Premium Hydraulic Fracturing Fleets

Current Fleets

Year Built

On-Time Delivery

Number of Pressure Pumps

Horsepower Capacity

1

2007

17

34,000

2

2010

12

24,000

3

2010

16

32,000

4

2011

20

40,000

5

2011

16

32,000

6

2011 / 2012

22

44,000

Expected Fleets

Expected Delivery Date

On-Time Delivery

Number of Pressure Pumps

Horsepower Capacity

7

2Q 2012

16

32,000

8

3Q 2012

16

32,000

9

4Q 2012

16

32,000

Total

151

302,000 |

Company

Coiled

Tubing

Hydraulic

Fracturing

Chesapeake

Encana

Samson

Petrohawk

EOG

Shell

Devon

Plains Exploration

EXCO

Penn Virginia

Company

Coiled

Tubing

Hydraulic

Fracturing

Chesapeake

Apache

Forest Oil

Cordillera

Newfield

Unit

Penn Virginia

16

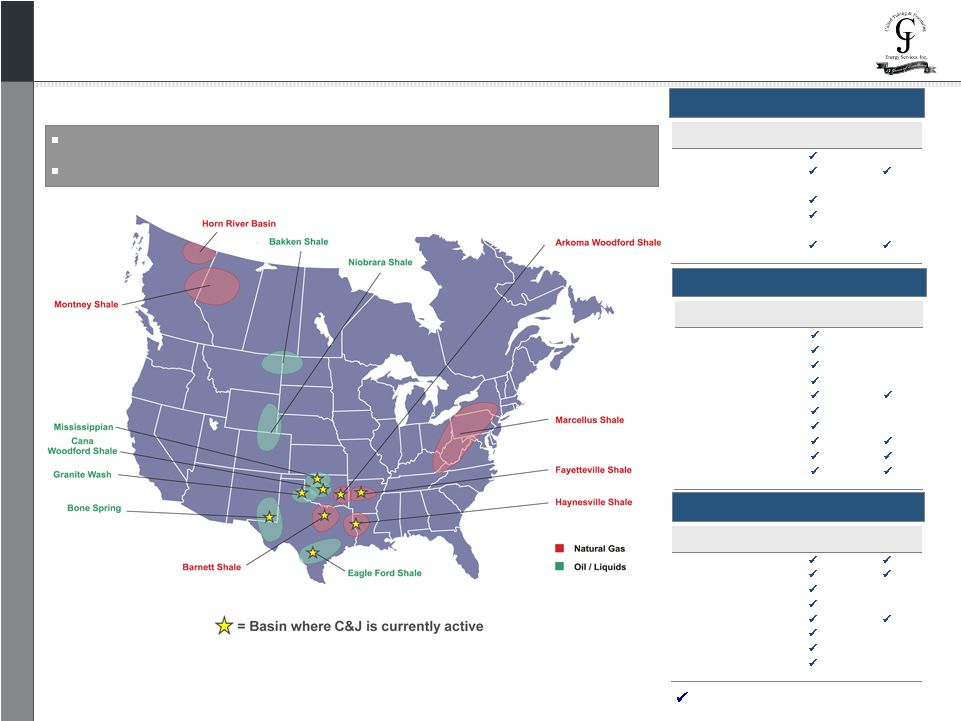

Geographically Focused in Attractive Basins

= C&J Customer Relationship

Granite Wash

Company

Coiled

Tubing

Hydraulic

Fracturing

Chesapeake

EOG

Petrohawk

Newfield

Anadarko

Shell

SM Energy

ConocoPhillips

Eagle Ford Shale

Haynesville Shale

Existing relationships provide platform for future growth

Prominent shales are in reach of C&J’s existing service centers

|

Offer customized solutions on

a job-by-job basis

Engineers and fleet managers

onsite throughout process

Culture of flexibility and

collaboration

Completed thousands of

fracturing stages in Eagle

Ford and Haynesville

Operating team with 20+

years of in-basin experience

Relationships with several

proppant and chemical

suppliers

Technical proficiency and

front-end analysis

The Result is Enhanced Economics for Our Customers

Superior

customer

service

New, highly

capable

equipment

Exceptional

execution

High-quality

service

provider

Minimize cycle time and limit

pump downtime

Design fluids that perform well

in various environments

Focus on maintaining

performance data that is used

to supplement and increase

effectiveness of future

assignments

We Offer an Attractive Value Proposition to Our Customers

All fracturing fleets less than 4

years old; rated for 15,000 psi

Optimized configuration of fleet

according to basin specific

requirements

Custom-designed equipment

maximizes efficiency and

durability

Specific competence in

fracturing fluid design and local

application

17 |

Current Service

Offerings Customer

Stand Alone

Pressure Pumping

Coiled Tubing

Hydraulic

Fracturing

Term Frac Contract

18

Relationships with Industry Leaders

(Through mid-2012)

(Through mid-2012)

(Through early 2013)

(Through mid-2014)

(Through mid-2013)

Large operators have embraced C&J’s technical capabilities

(Early 2014) |

19

Outperformance Through Efficiency

Pre-job best

practices

Pumping

procedures

Motivated

workforce

Rig-up

flexibility

More frequent communication with customers during well design process

Continuity

of

technical

staff

to

avoid

repetition

and

save

customers’

time

Lab fluids testing in advance for optimal well design

Develop best layout for job site to maximize Hydration Unit and Blender

performance Organize crew into focused teams to complete multiple tasks

simultaneously Conduct field fluid tests during rig process to confirm lab

results Engineers

and

blender

operators

on

site

during

rig

up

to

“jump

start”

technical

review

Real-time monitoring of equipment to spot potential problems early

On-site maintenance of pump units as soon as each one is offline

Proactive replacement of wear items rather than waiting for a failure

Streamline paperwork requirements to allow supervisors to focus on efficiency and

planning

Empowering employees and promoting best practices produces a proud and highly

motivated workforce |

20

Strategy for Continued Growth

Capitalize on growth in development of shale and other resource plays

Leverage customer relationships to geographically expand

–

Further expansion into new geographic basins

–

Evaluating opportunities to expand operations into new areas throughout the

U.S. Pursue additional term hydraulic fracturing contracts

–

Currently seeking term contracts for Fleets 7, 8 and 9

Maintain flexibility to pursue spot market work

–

Retains upside revenue potential at prevailing market rates

|

Financials |

22

Key Drivers of Financial Performance

Business Model

Financial Model

Visibility

Growth

Vertical integration

Risk management

Hourly rates under take-or-pay contracts

Spot market optionality

Utilization drives model

Balance sheet strength |

23

Significant Historical Growth

Adjusted EBITDA ($mm)

Revenue ($mm)

Revenue ($mm)

1

Assumes

timely

delivery

of

Fleets

6

–

8. |

24

Strong Margin Profile

EBITDA Margin¹

Annual

Quarterly

1

EBITDA margin based on Adjusted EBITDA.

Margins driven by utilization, not price |

25

More demanding wells drive higher hourly rates and higher revenues from

chemicals and proppant

More frac stages per well keep fleets onsite longer, allowing more pumping hours

per month

Demonstrated

shorter

time

per

completion

permits

us

to

negotiate

premium

rates

with customers

Less redundant pumping capacity boosts utilization

Average monthly revenue per unit of horsepower:

-

$331 in 2010

-

$387 YTD September 30, 2011

ROCE of 43% in 2010 and 47% YTD September 30, 2011

Operational Strategy Drives Strong Financial Performance

Regional

focus

and

operating

efficiency

generate

higher

revenues

per

unit

of

horsepower |

26

Contract Coverage for Fracturing Fleets

2011

2012

Operating Regions

Q1

Q2

Q3

Q4

Q1

Q2

Q3

Q4

Fleet 1

Haynesville/Eagle

Ford/Granite wash

Fleet 2

Eagle Ford

Fleet 3

Eagle Ford

Fleet 4

Eagle Ford

Fleet 5

Eagle Ford

Fleet 6

Permian

Fleet 7

(Uncontracted)

Fleet 8

(Uncontracted)

Fleet 9

(Uncontracted)

Fleet Under Contracts

Expected Delivery of Future Fleets

Delivery 2Q 2012

Delivery 2Q 2012

Fracturing Term Contracts Provide Visible Growth

Delivery 4Q 2012 |

27

Overview of Term Contracts

•

1 –

3 year contract life

•

Revenues under term contracts are derived from:

–

Mandatory monthly payments for minimum hours

–

Pre-agreed amounts for each hour of service in excess of the contracted

minimum

–

Service charge to customers for chemicals and proppant materials

•

Take or pay

•

Optionality to deploy equipment when not utilized

•

Contractual protections for term |

28

Total E&S Acquisition Facilitates Growth Strategy

Total E&S is a manufacturer of hydraulic fracturing equipment, coiled

tubing, pressure

pumping

and

other

equipment

used

in

the

energy

services

industry

and one of C&J’s largest suppliers of machinery and equipment

–

Acquisition closed April 28, 2011

–

Aggregate purchase price of approximately $33.0mm

–

Received $5.4mm cash as part of acquisition, for net transaction

value of $27.5mm

–

$25.0mm financed through incremental revolver borrowings

–

Remainder funded through cash on hand

Strategic benefits include

–

Internal control over supply chain

–

Significantly reduces exposure to third-party supply constraints

–

Shorter cycle times for the delivery of new equipment and replacement parts

–

Provides for greater potential control of costs associated with new

equipment –

Acquisition has reduced C&J’s procurement costs from Total

–

Ability to delay, or indefinitely postpone, delivery time of equipment

–

Platform for R & D, continued equipment design improvements

|

Strong Balance Sheet and Liquidity

Flexible balance sheet with strong liquidity position

–

$200mm revolving credit facility

29

1

Summary Capital Structure, as of 9/30/2011

($ in thousands)

Reported

Cash and Cash Equivalents

$

50,640

Long-term Debt

Five-Year $200mm Credit Facility

Total Long-Term Debt

Shareholders' Equity

$

338,312

Total Capitalization

$

338,312

$

$

0

1

The credit facility remains undrawn today, leaving the full $200.0 million available

for borrowing. 0 |

30

C&J Investment Highlights

Operational

expertise in

service-

intensive

basins

Visible revenue

growth

Modern, high-

specification

equipment

High-quality

service

Focused on technically-demanding, service-intensive basins

Generate higher revenue per unit of horsepower relative to peers

Customized solutions through extensive front-end technical analysis and

planning

Design

engineers

and

job

supervisors

involved

throughout

project

execution

Exclusive focus on high-pressure rated equipment (all rated up to 15,000

psi) Modern fracturing fleet, all entered into service in the past four

years Acquisition of Total provides specialized, in-house manufacturing

capability Substantial hydraulic fracturing and completion services

experience Vested executive team with significant ownership

Experienced

management

Scheduled equipment deliveries to support sustained growth

Term contracts provide visibility with flexibility for spot market upside

|

Appendix |

Income Statements

32

Year Ended December 31,

Nine Months

Ended September 30,

($ in thousands except per share amounts)

2007

2008

2009

2010

2010

2011

Statement of Operations Data

Revenue

$28,022

$62,441

$67,030

$244,157

$158,361

$538,403

Cost of Sales

14,227

42,401

54,242

154,297

102,872

318,949

Gross Profit

$13,795

$20,040

$12,788

$89,860

$55,489

$219,454

Selling, General and Administrative Expenses

7,427

8,950

9,533

17,998

11,384

36,219

Loss (Gain) on Sale / Disposal of Assets

129

397

920

1,571

1,582

(20)

Operating Income

$6,239

$10,693

$2,335

$70,291

$42,523

$183,255

Other Income (Expense)

Interest Income

$50

$5

$4

$9

$7

$1

Interest Expense

(5,786)

(6,913)

(4,712)

(17,350)

(13,451)

(3,825)

Lender Fees

(341)

(511)

(391)

(322)

(97)

(42)

Loss on early extinguishment of debt

–

–

–

–

–

(7,605)

Other Income

–

–

–

163

106

3

Other Expense

(17)

(68)

(52)

(150)

(47)

(1)

Total Other Expenses

$(6,094)

$(7,487)

$(5,151)

$(17,650)

$(13,482)

$(11,469)

Income (Loss) Before Income Taxes

$145

$3,206

$(2,816)

$52,641

$29,041

$171,786

Provision (Benefit) for Income Taxes

868

2,085

(386)

20,369

11,271

63,189

Net Income (Loss)

$(723)

$1,121

$(2,430)

$32,272

$17,770

$108,597

Basic Net Income (Loss) per Share

$(0.02)

$0.02

$(0.05)

$0.70

$0.38

$2.24

Diluted Net Income (Loss) per Share

(0.02)

0.02

(0.05)

0.67

0.37

2.18

(Unaudited) |

Cash

Flows 33

Year Ended December 31,

Nine Months

Ended September 30,

2006

2007

2008

2009

2010

2010

2011

Statement of Cash Flows Data

Capital Expenditures

$9,282

$30,152

$21,526

$4,301

$44,473

$18,647

$106,471

Cash Flow Provided by (Used in)

Operating Activities

$855

$8,377

$8,611

$12,056

$44,723

$27,769

$141,190

Investing Activities

(108,760)

(30,054)

(20,673)

(4,254)

(43,818)

(18,622)

(131,312)

Financing Activities

106,700

21,305

11,921

(6,733)

734

(3,217)

37,945

(Unaudited) |

Balance Sheets

34

As of December 31,

As of

September 30

($ in thousands)

2006

2007

2008

2009

2010

2011

Balance Sheet Data

Cash and Cash Equivalents

$622

$250

$109

$1,178

$2,817

Accounts Receivable, Net

5,557

4,409

13,362

12,668

44,354

Inventories, Net

440

581

861

2,463

8,182

Property, Plant and Equipment, Net

31,593

57,991

71,441

65,404

88,395

Total Assets

$111,467

$133,711

$155,212

$150,231

$226,088

Accounts Payable

690

1,705

6,519

10,598

13,084

Long-term Debt and Capital Lease Obligations,

Excluding Current Portion

51,700

56,773

25,041

60,668

44,817

Total Stockholders' Equity

$56,265

$66,797

$68,099

$65,799

$109,446

(Unaudited)

$50,640

88,678

26,954

188,782

$462,475

51,298

–

$338,312 |

EBITDA Reconciliation

35

Note:

EBIT,

EBITDA

and

Adjusted

EBITDA

are

non-GAAP

financial

measures,

and

when

analyzing

C&J’s

operating

performance,

investors

should

use

EBIT,

EBITDA

and

Adjusted

EBITDA

in

addition

to,

and

not

as

an

alternative

for,

operating

income

and

net

(loss)

income

(each

as

determined

in

accordance

with

GAAP).

C&J

uses

EBIT,

EBITDA

and

Adjusted

EBITDA

as

supplemental

financial

measures.

EBIT

is

defined

as

net

income

(loss)

before

interest

expense

(net)

and

income

taxes.

EBITDA

is

EBIT

adjusted

for

depreciation

and

amortization.

Adjusted

EBITDA

is

EBITDA

further

adjusted

for

certain

other

items

which

are

not

indicative

of

future

performance

or

cash

flow,

including

lender

fees,

other

non-operating

expenses

and

loss

on

sale/disposal

of

property,

plant

and

equipment.

C&J

believes

EBIT,

EBIDA

and

Adjusted

EBITDA

are

useful

supplemental

indicators

of

its

performance.

EBIT,

EBITDA

and

Adjusted

EBITDA,

as

used

and

defined

by

C&J,

may

not

be

comparable

to

similarly

titled

measures

employed

by

other

companies

and

are

not

measures

of

performance

calculated

in

accordance

with

GAAP.

Year Ended December 31,

Nine Months

Ended September 30,

(Unaudited)

($ in thousands)

2008

2009

2010

2010

2011

Net Income (Loss)

$1,121

$(2,430)

$32,272

$17,770

$108,597

Interest Expense, Net

6,909

4,708

17,341

13,444

3,824

Provision (Benefit) for Income Taxes

2,085

(386)

20,369

11,271

63,189

Depreciation and Amortization

8,836

9,828

10,744

7,855

15,640

EBITDA

$18,951

$11,720

$80,726

$50,340

$191,250

Adjustments to EBITDA

Loss on early extinguishment of debt

-

-

-

-

7,605

Loss (Gain) on Sale / Disposition of Property,

Plant & Equipment

397

920

1,571

1,582

(20)

Adjusted EBITDA

$19,348

$12,640

$82,297

$51,922

$198,835 |