Attached files

| file | filename |

|---|---|

| 8-K - ROCK-TENN COMPANY 8-K - Rock-Tenn CO | a50088271.htm |

Exhibit 99.1

J P SMID J.P. Morgan Cap Conference November 30, 2011

Cautionary Statement Regarding Forward-Looking Information Statements in this presentation that do not relate strictly to historical facts are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements are based on our current expectations, beliefs, plans or forecasts and use words in this presentation such as will, estimate, trending, or refer to future time periods. You should not place undue reliance on any forward-looking statements as such statements involve risks, uncertainties, assumptions and other factors that could cause actual results to differ materially, including the following: our ability to integrate Smurfit-Stone or to achieve benefits from the Smurfit Acquisition, including, without limitation, synergies and performance improvements; expected levels of depreciation, corporate expenses, interest expense, income tax rates, federal NOL utilization, Black Liquor and AMT tax credit utilization, pension contributions, capital expenditures, commodity costs, maintenance outages, containerboard inventory builds; the level of demand for our products; our ability to successfully identify and make performance improvements; anticipated returns on our capital investments; possible increases in energy, raw materials, shipping and capital equipment costs; any reduction in the supply of raw materials; fluctuations in selling prices and volumes; intense competition; the potential loss of certain customers; adverse changes in general market and industry conditions and other risks, uncertainties and factors discussed in Item 1A "Risk Factors" and under the caption "Business — Forward-Looking Information" in our 2011 Annual Report on Form 10-K and by similar disclosures in any of our subsequent SEC filings. The information contained herein speaks as of the date hereof and we do not have or undertake any obligation to update such information as future events unfold. 2

Use of Non-GAAP Financial Measures and Reconciliations We have included financial measures that are not prepared in accordance with accounting principles generally accepted in the United States ("GAAP"). The non-GAAP financial measures presented are not intended to be a substitute for GAAP financial measures, and any analysis of non-GAAP financial measures should be used only in conjunction with results presented in accordance with GAAP and the reconciliations of non-GAAP financial measures to GAAP financial measures included in the Appendix to this presentation. 3

Disclaimer We may from time to time be in possession of certain information regarding RockTenn that applicable law would not require us to disclose to the public in the ordinary course of business, but would require us to disclose if we were engaged in the purchase or sale of our securities. This presentation shall not be considered to be part of any solicitation of an offer to buy or sell RockTenn securities. This presentation also may not include all of the information regarding RockTenn that you may need to make an investment decision regarding RockTenn securities. Any such investment decision should be made on the basis of the overall mix of information regarding RockTenn that is publicly available as of the date of such decision. 4

RockTenn’s Core Business Principles RockTenn will be the most respected company in our business by: Providing superior paperboard, packaging and marketing solutions for consumer products companies at very low costs RockTenn’s expanded network of mills and converting plants are cost-competitive with numerous opportunities to further optimize the combined system Investing for competitive advantage RockTenn’s and Smurfit-Stone’s assets are well-capitalized, with significant opportunities identified for further profit-improving investments Maximizing the efficiency of our manufacturing processes by optimizing economies of scale Acquisition significantly increases RockTenn’s opportunities for optimizing scale Systematically improving processes and reducing costs throughout the Company Acquisition combines RockTenn’s Six Sigma continuous improvement method with Smurfit-Stone’s Lean Manufacturing method to further optimize manufacturing and administrative processes Seeking acquisitions that can dramatically improve the business RockTenn views Smurfit-Stone’s virgin containerboard mill system as a key strategic asset giving the acquisition a compelling strategic rationale 5

RockTenn Overview On May 27, 2011, RockTenn closed on its acquisition of Smurfit-Stone A leader in North American packaging: One of the largest paper recyclers in North America 2nd largest producer of containerboard 2nd largest producer of coated recycled board Balanced fiber mix of 55% virgin and 45% recycled 4Q’11 Adjusted EPS of $1.70 (1) ; $0.55 (1) accretive on per share basis 4Q’11 Corrugated Packaging EBITDA margin of 15.6% (1) Conservatively financed with a Leverage Ratio of 2.61x (1) at September 30, 2011 Liquidity in excess of $1.1 billion Management team with strong record of creating value and integrating acquisitions Synergy targets of $150 million by the end of calendar 2012; estimated performance improvements of an incremental $400 million by the end of calendar 2013, incremental to $150 million synergy estimate Compelling valuation (1) See use of Non-GAAP Financial Measures and Reconciliations in the Appendix. 6

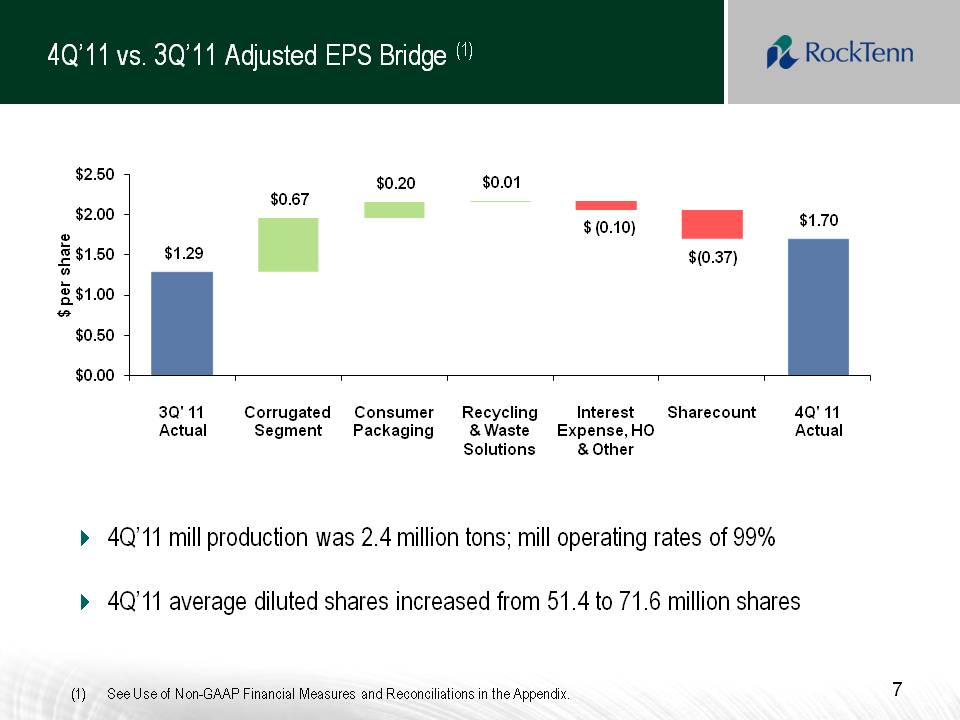

4Q’11 vs. 3Q’11 Adjusted EPS Bridge (1) $1.29 $0.67 $0.20 $0.01 $(0.10) $(0.37) $1.70 $2.50 $2.00 $1.50 $1.00 $0.50 $0.00 $ per share 3Q' 11 Actual Corrugated Segment Consumer Packaging Recycling & Waste Solutions Interest Expense, HO & Other Sharecount Q4’ 11 Actual 4Q’11 mill production was 2.4 million tons; mill operating rates of 99% 4Q’11 average diluted shares increased from 51.4 to 71.6 million shares (1) See Use of Non-GAAP Financial Measures and Reconciliations in the Appendix. 7

Overview of Integration Applying the RockTenn business model to the box plant system, driving product innovation, customer satisfaction (product quality and service) and low-cost manufacturing Creating a single RockTenn culture Identifying and executing on opportunities within the operating businesses Investing in the mill assets with low cost cost, high return projects Consolidating administration activities Leveraging purchasing opportunities Standardizing systems, functional activities and processes Significant opportunity to improve a solid business and participate in an attractive market 8

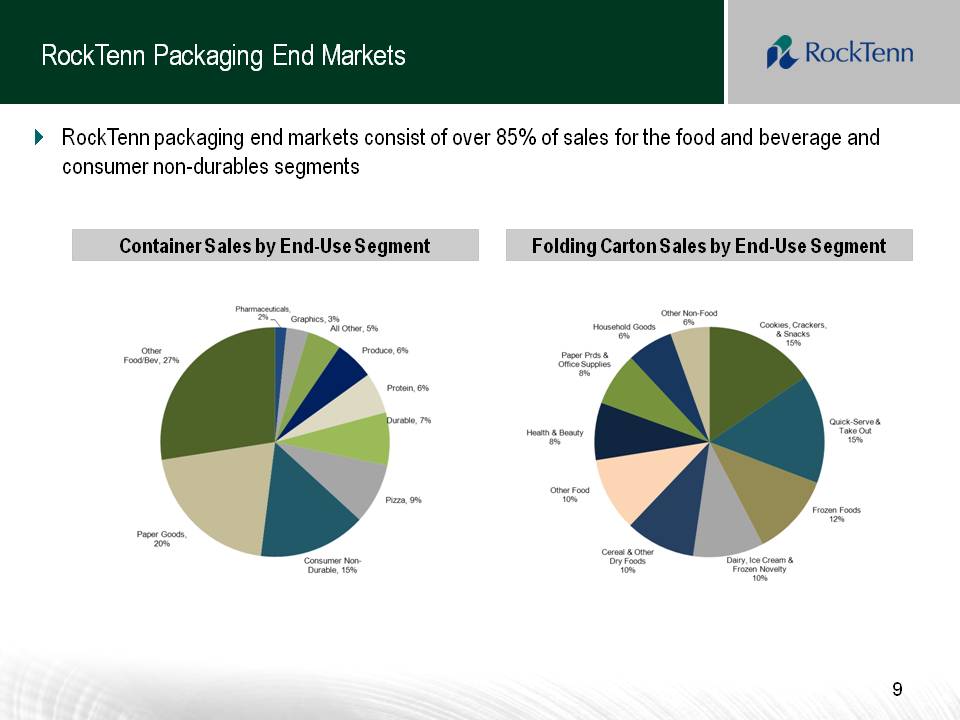

RockTenn Packaging End Markets RockTenn packaging end markets consist of over 85% of sales for the food and beverage and consumer non-durables segments Container Sales by End-Use Segment Other Food/Bev, 27% Paper Goods, 20% Consumer Non-Durable, 15% Pizza, 9% Durable, 7% Protein, 6% Produce, 6% All Other, 5% Graphics, 3% Pharmaceuticals 2% Folding Carton Sales by End-Use Segment Quick-Serve & Take Out 15% Cookies, Crackers, & Snacks 15% Frozen Foods 12% Dairy, Ice Cream & Frozen Novelty 10% Cereal & Other Dry Foods 10% Other Food 10% Health & Beauty 8% Paper Prds & Office Supplies 8% Household Goods 6% Other Non-Food 6% 9

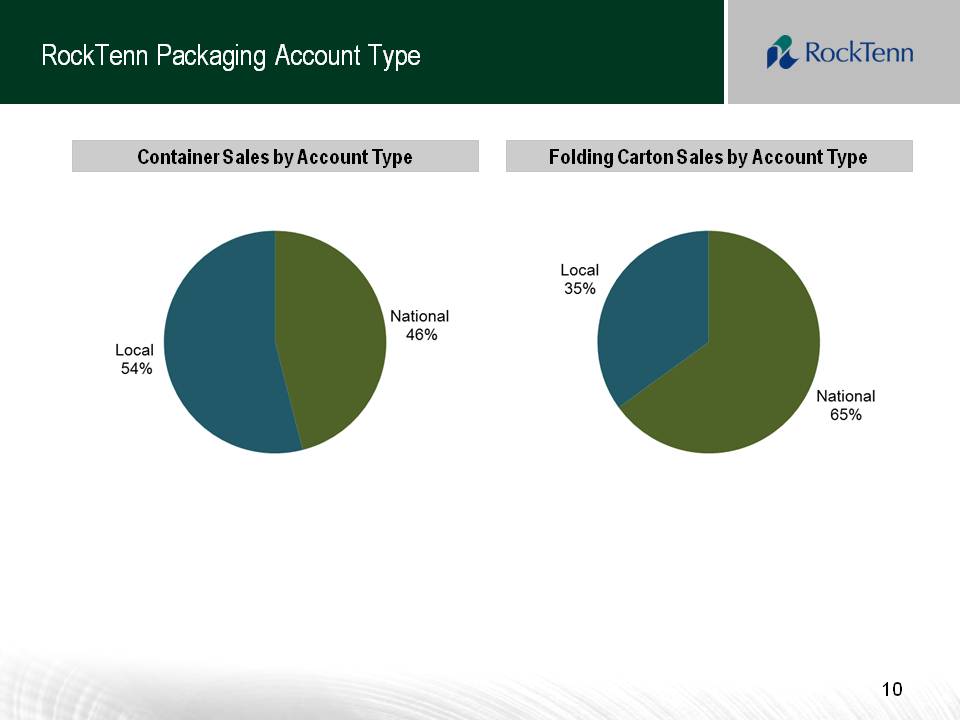

RockTenn Packaging Account Type Container Sales by Account Type Local 54% National 46% Folding Carton Sales by Account Type National 65% Local 35% 10

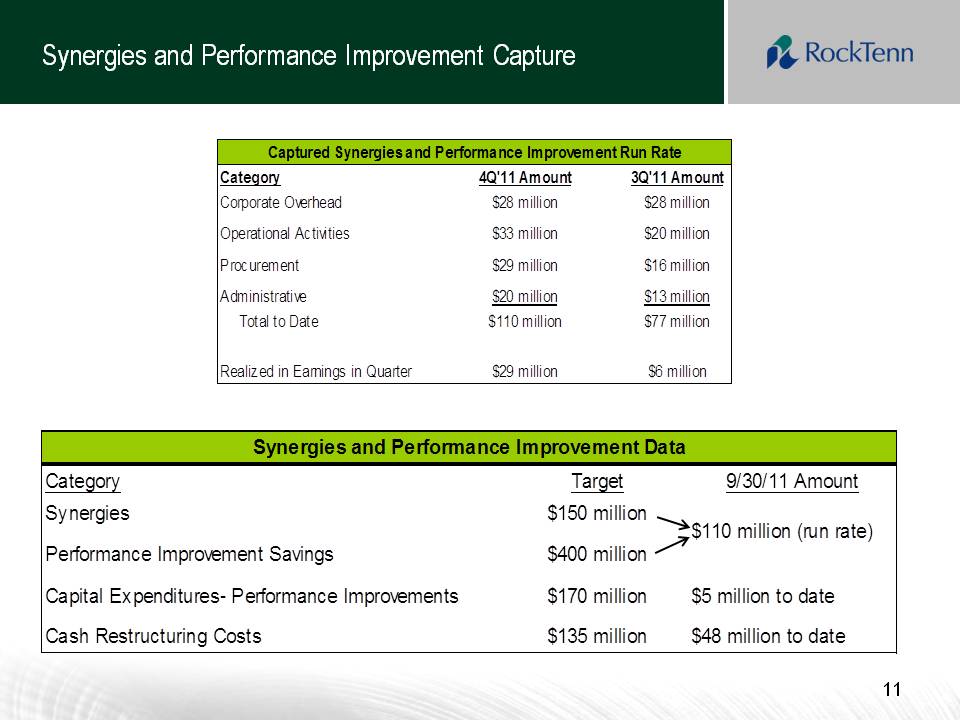

Synergies and Performance Improvement Capture Captured Synergies and Performance Improvement Run Rate Category 4Q'11 Amount 3Q'11 Amount Corporate Overhead $28 million $28 million Operational Activities $33 million $20 million Procurement $29 million $16 million Administrative $20 million $13 million Total to Date $110 million $77 million Realized in Earnings in Quarter $29 million $6 million Synergies and Performance Improvement Data Category Target 9/30/11 Amount Synergies $150 million Performance Improvement Savings $400 million $110 million (run rate) Capital Expenditures- Performance Improvements $170 million $5 million to date Cash Restructuring Costs $135 million $48 million to date 11

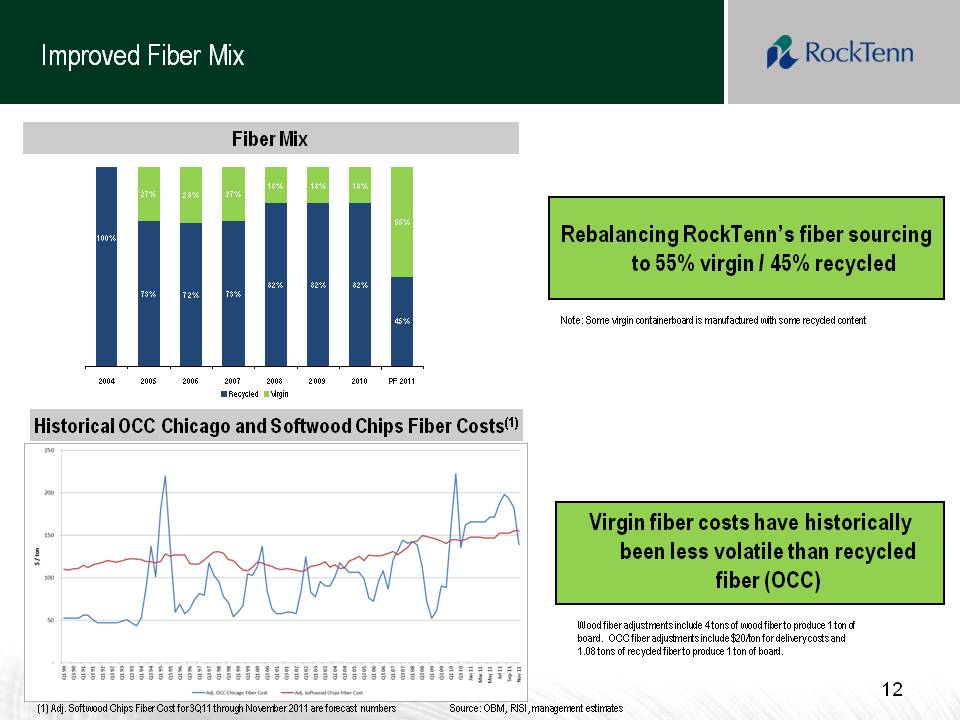

Improved Fiber Mix Fiber Mix Rebalancing RockTenn’s fiber sourcing to 55% virgin / 45% recycled Note: Some virgin containerboard is manufactured with some recycled content Historical OCC Chicago and Softwood Chips Fiber Costs(1) Virgin fiber costs have historically been less volatile than recycled fiber (OCC) Wood fiber adjustments include 4 tons of wood fiber to produce 1 ton of board. OCC fiber adjustments include $20/ton for delivery costs and 1.08 tons of recycled fiber to produce 1 ton of board. (1) Adj. Softwood Chips Fiber Cost for 3Q11 through November 2011 are forecast numbers Source: OBM, RISI, management estimates 12

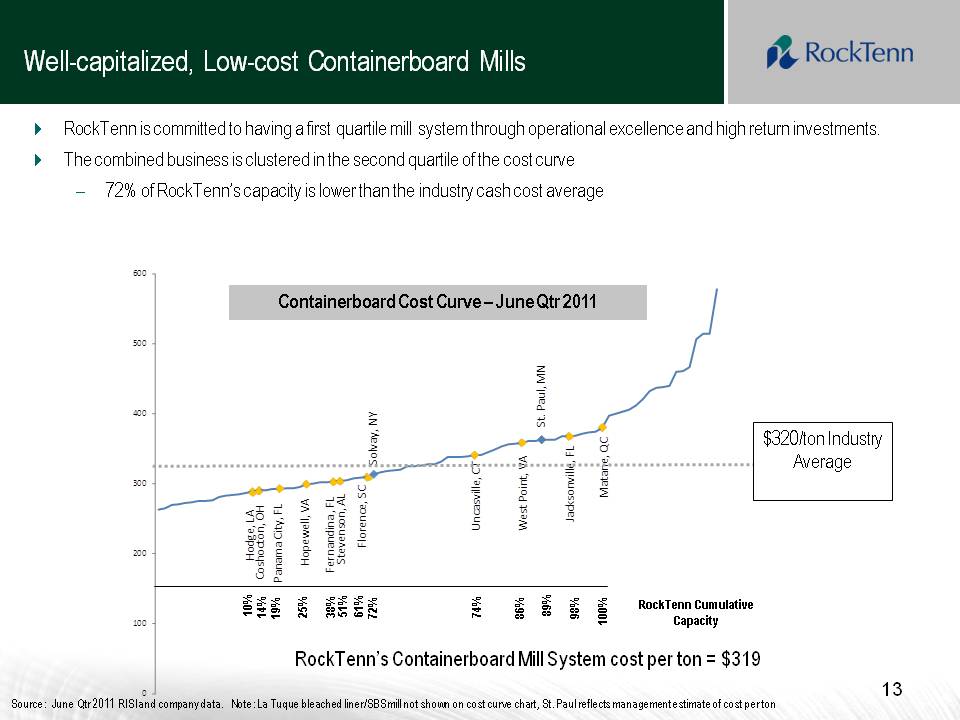

Well-capitalized, Low-cost Containerboard Mills RockTenn is committed to having a first quartile mill system through operational excellence and high return investments. The combined business is clustered in the second quartile of the cost curve 72% of RockTenn’s capacity is lower than the industry cash cost average Containerboard Cost Curve – June Qtr 2011 10% 14% 19% 25% 38% 51% 61% 72% 74% 86% 89% 98% 100% Hodge, LA Coshocton, OH Panama City, FL Hopewell, VA Fernandina, FL Stevenson, AL Florence, SC Solvay, NY Uncasville, CT West Point, VA St. Paul, MN Jacksonville, FL Matane, QC $320/ton Industry RockTenn Cumulative Capacity RockTenn’s Containerboard Mill System cost per ton = $319 Source: June Qtr 2011 RISI and company data. Note: La Tuque bleached liner/SBS mill not shown on cost curve chart, St. Paul reflects management estimate of cost per ton 13

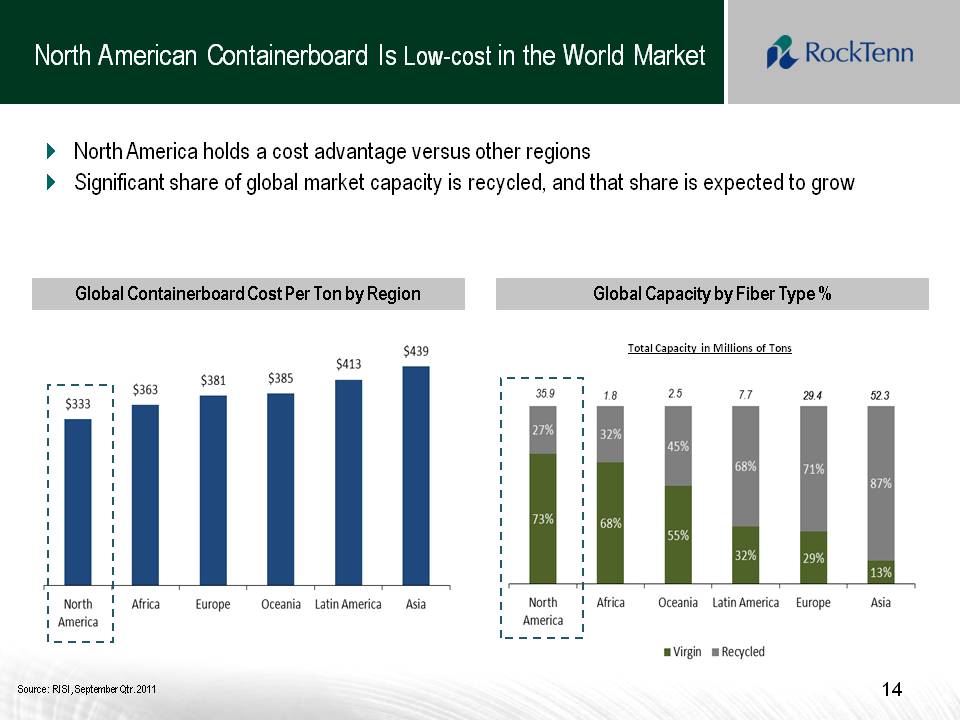

North American Containerboard Is Low-cost in the World Market North America holds a cost advantage versus other regions Significant share of global market capacity is recycled, and that share is expected to grow Global Containerboard Cost Per Ton by Region Global Capacity by Fiber Type % Total Capacity in Millions of Tons North America $333 Africa $363 Europe $381 Oceania $385 Latin America $413 Asia $439 North America 35.9 27% 73% Africa 1.8 32% 68% Oceania 2.5 45% 55% Latin America 7.7 68% 32% Europe 29.4 71% 29% Asia 52.3 87% 13% Virgin Recycled Source: RISI, September Qtr. 2011 14

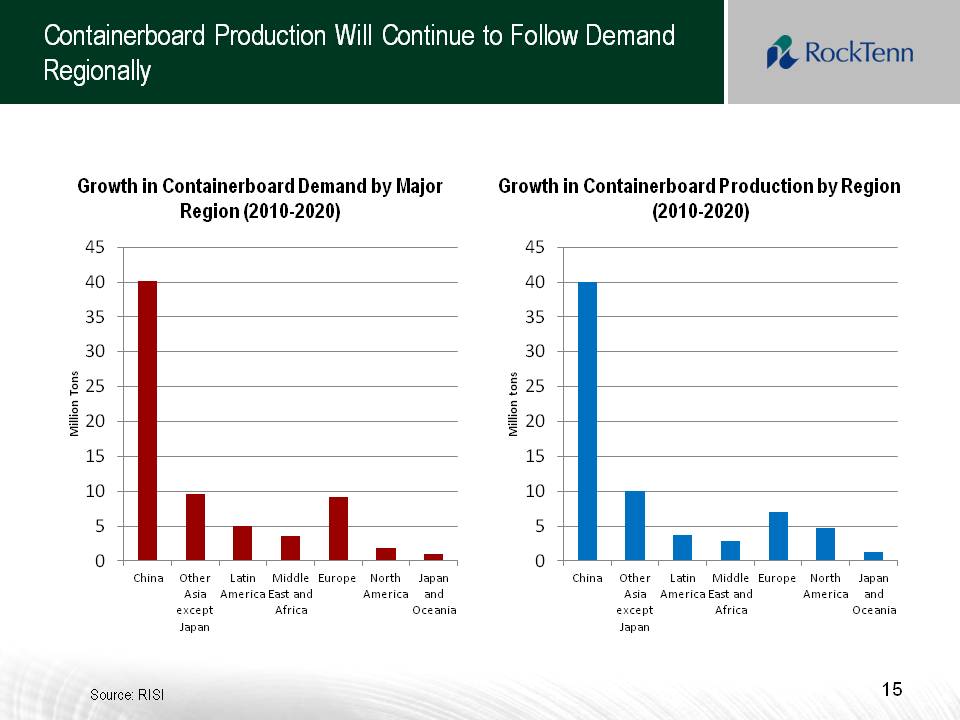

Containerboard Production Will Continue to Follow Demand Regionally Growth in Containerboard Demand by Major Region (2010 2020) Growth in Containerboard Production by Region (2010 2020) Million Tons Million tons 0 0 5 5 10 10 15 15 20 20 25 25 30 30 35 35 40 40 45 45 China China Other Asia except Japan Other Asia except Japan Latin America Latin America Middle East and Africa Middle East and Africa Europe Europe North America North America Japan and Oceania Japan and Oceania Source: RISI 15

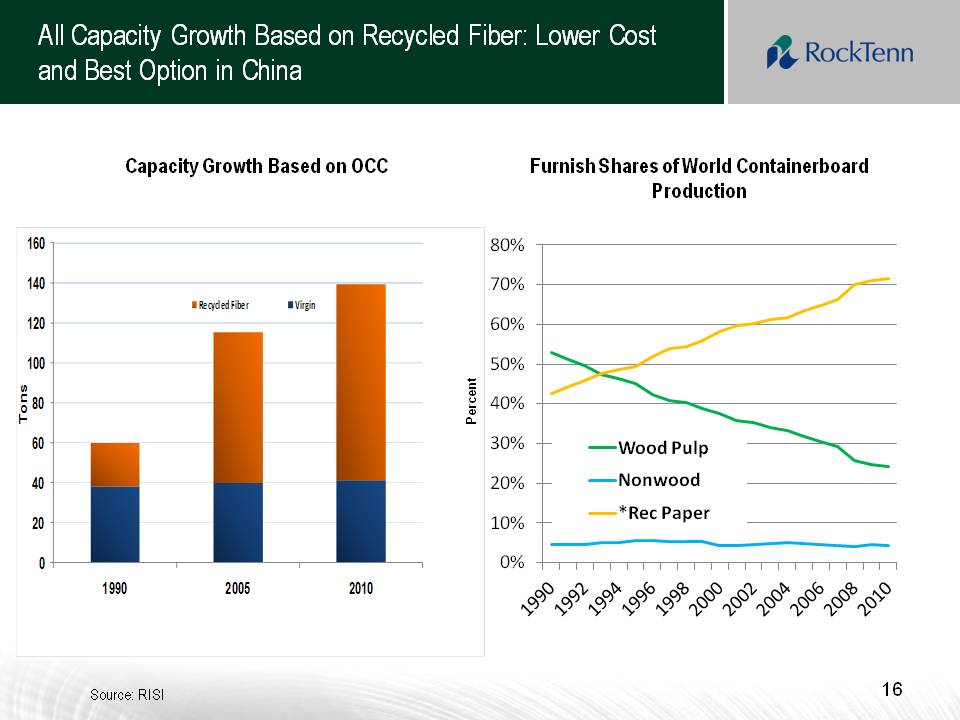

All Capacity Growth Based on Recycled Fiber: Lower Cost and Best Option in China Capacity Growth Based on OCC Furnish Shares of World Containerboard Production Recycled Fiber Virgin Wood Pulp Nonwood *Rec Paper Source: RISI 16

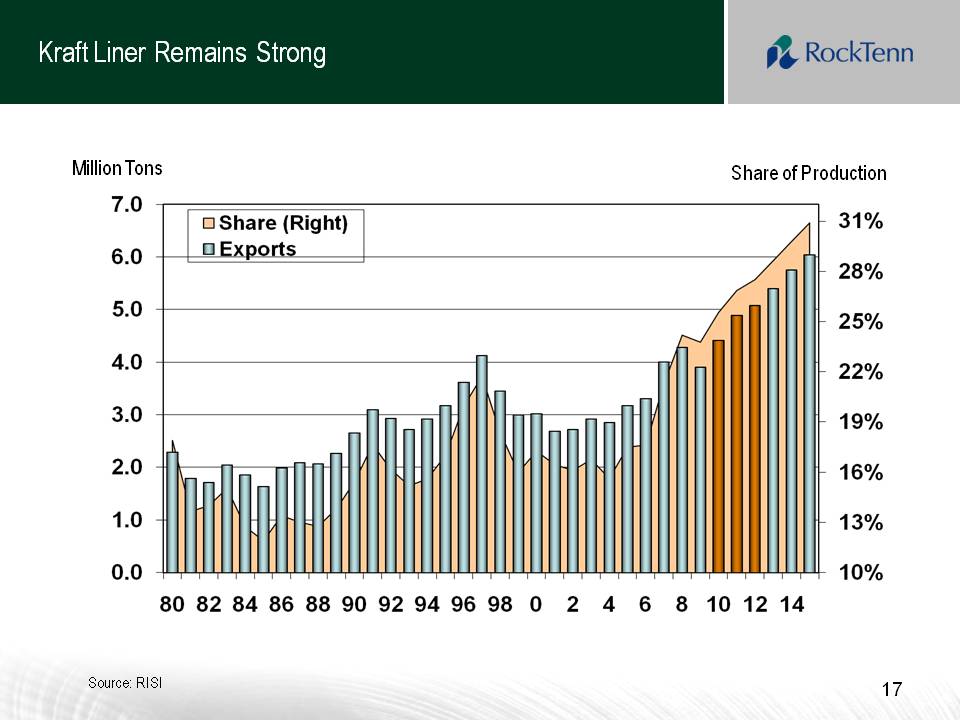

Kraft Liner Remains Strong Million Tons Share of Production Share (Right) Exports Source: RISI 17

Strategic Value of Virgin Containerboard Assets U.S. Containerboard box shipments growth since 2000 at approx. 1% below non-durable production; U.S. Containerboard production is globally low cost Approx. 70% of North American production is virgin Kraftliner content Approx. 30% of World production is virgin Kraftliner content; China is almost all recycled Global containerboard markets reflecting strong growth since 1980 and forecasted growth Asian production accounts for 46% of global production; North America at 20% China growth estimated at 40 million tons from 2010-2020 and will be all recycled content Global demand for virgin Kraftliner will increase substantially Continuing need for virgin content to fuel recycled fiber/OCC needs U.S. virgin containerboard export market is well positioned to help meet global needs U.S. South remains primary source with good potential for growth Weakness in U.S. dollar also fuels exports Source: RISI 18

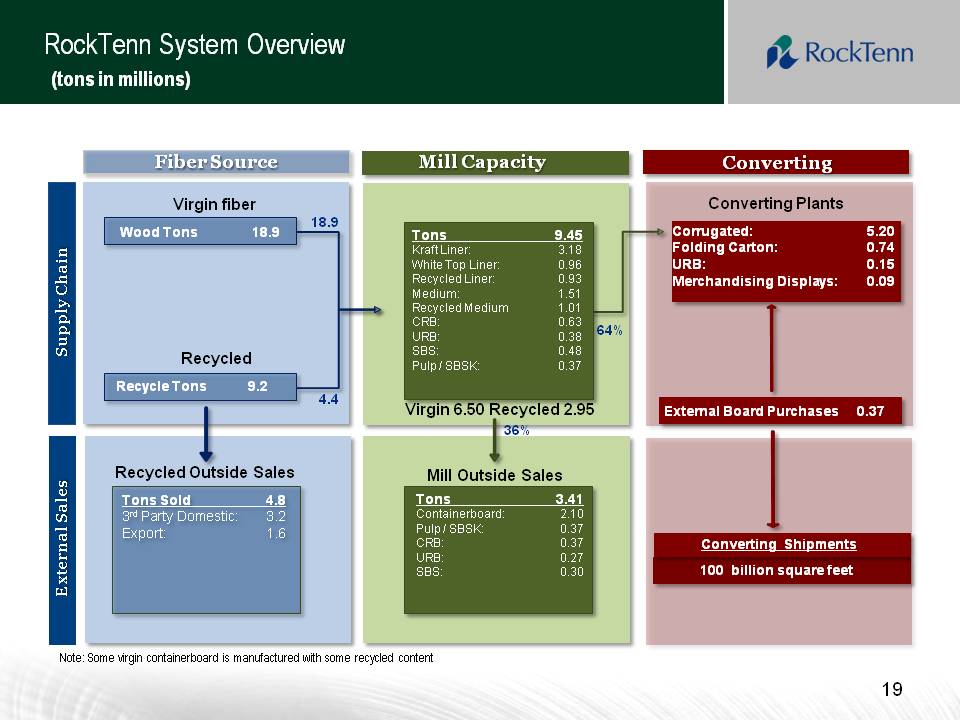

RockTenn System Overview (tons in millions) Fiber Source Mill Capacity Converting Supply Chain External Sales Converting Plants Corrugated: 5.20 Folding Carton: 0.74 URB: 0.15 Merchandising Displays: 0.09 External Board Purchases 0.37 Virgin fiber Wood Tons 18.9 18.9 Recycled Recycle Tons 9.2 4.4 Tons 9.45 Kraft Liner: 3.18 White Top Liner: 0.96 Recycled Liner: 0.93 Medium: 1.51 Recycled Medium 1.01 CRB: 0.63 URB: 0.38 SBS: 0.48 Pulp / SBSK: 0.37 64% Virgin 6.50 Recycled 2.95 36% Mill Outside Sales Tons 3.41 Containerboard: 2 10 Pulp / SBSK: 0.37 CRB: 0.37 URB: 0.27 SBS: 0.30 Recycled Outside Sales Tons Sold 4.8 3rd Party Domestic: 3.2 Export: 1.6 Converting Shipments 100 billion square feet Note: Some virgin containerboard is manufactured with some recycled content 19

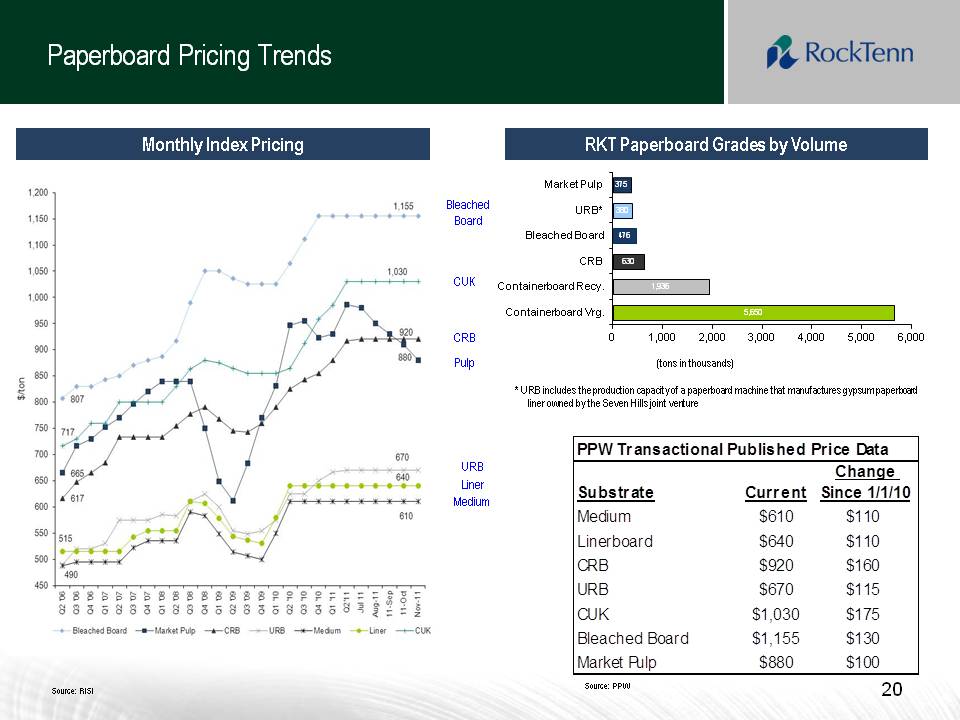

Paperboard Pricing Trends Monthly Index Pricing RKT Paperboard Grades by Volume Bleached Board CUK CRB Pulp URB Liner Medium (tons in thousands) * URB includes the production capacity of a paperboard machine that manufactures gypsum paperboard liner owned by the Seven Hills joint venture PPW Transactional Published Price Data Substrate Current Change Since 1/1/10 Medium $610 $110 Linerboard $640 $110 CRB $920 $160 URB $670 $115 CUK $1,030 $175 Bleached Board $1,155 $130 Market Pulp $880 $100 Source: RISI Source: PPW 20

Conclusion One of the largest paper recyclers in North America 2nd largest producer of containerboard in North America 2nd largest producer of coated recycled board in North America Significant ownership of strategically valuable virgin containerboard mills; balanced fiber mix of 55% virgin and 45% recycled Significant, quantified opportunities to improve results through cost reduction and capital investment Delivered results in first 4 months of ownership Management team with strong record of creating value and integrating acquisitions Compelling valuation See use of Non-GAAP Financial Measures and Reconciliations in the Appendix. 21

Appendix 22

Use of Non-GAAP Financial Measures and Reconciliations Below, we define the non-GAAP financial measures, provide a reconciliation of each non-GAAP financial measure to the most directly comparable financial measure calculated in accordance with GAAP, and discuss the reasons that we believe this information is useful to management and may be useful to investors. These measures may differ from similarly captioned measures of other companies in our industry. Non-GAAP Measures Our definitions of Credit Agreement EBITDA and Segment EBITDA may differ from other similarly titled measures at other companies. Credit Agreement EBITDA (as defined) and Adjusted EBITDA (as defined) are not defined in accordance with GAAP and should not be viewed as alternatives to GAAP measures of operating results or liquidity. RockTenn management believes that net income is the most directly comparable GAAP measure to Credit Agreement EBITDA (as defined) and Segment Income is the most directly comparable GAAP measure to Segment EBITDA. 23

Non-GAAP Measures: Credit Agreement EBITDA and Total Funded Debt (as defined) “Credit Agreement EBITDA” is calculated in accordance with the definition of “EBITDA” contained in the Company’s Credit Agreement. Credit Agreement EBITDA is generally defined as Consolidated Net Income plus: consolidated interest expense; consolidated tax expenses; depreciation and amortization expenses; charges and for financing fees and expenses and write-offs of deferred financing fees and expenses write expenses, remaining portions of OID on prepayment of indebtedness, premiums due in respect of prepayment of indebtedness, and commitment fees in respect of financing commitments; various charges and expenses related to, or incurred in connection with, the Smurfit-Stone acquisition; costs and expenses relating to the integration of Smurfit-Stone and the achievement of synergies relating to the Smurfit-Stone acquisition; certain run-rate synergies expected to be achieved due to the Smurfit-Stone acquisition; all non-cash charges; all cash charges and expenses for plant and other facility closures and other cash restructuring charges; labor disruption charges; officer payments associated with any permitted acquisitions; “black liquor” expenses; cash charges and expenses incurred in respect of the Chapter 11 bankruptcy proceeding and plan of reorganization of Smurfit-Stone; and all non-recurring cash expenses Smurfit non taken in respect of any multi-employer and defined benefit pension plan obligations that are related to plant and other facilities closures. For additional information on the calculation see our Credit Agreement, dated as of May 27, 2011, filed as Exhibit 10.1 to our Form 8-K, dated May 27, 2011. “Total Funded Debt” is calculated in accordance with the definition of “Total Funded Debt” contained in the Company’s Credit Agreement. Total Funded Debt is generally defined as aggregate debt obligations reflected in our balance sheet, less the hedge adjustments resulting from terminated and existing fair value interest rate derivatives or swaps, plus additional outstanding letters of credit not already reflected in debt, plus debt guarantees. 24

Non-GAAP Measures: Credit Agreement EBITDA and Total Funded Debt Our management uses Credit Agreement EBITDA and Total Funded Debt to evaluate compliance with RockTenn’s debt covenants and borrowing capacity available under its Credit Agreement. Management also uses Credit Agreement EBITDA as a measure of our Company’s core operating performance Management believes that investors also use these measures to evaluate the performance. Company’s compliance with its debt covenants and available borrowing capacity. Management also believes that investors use Credit Agreement EBITDA as a measure of our Company’s core operating performance. Borrowing capacity is dependent upon, in addition to other measures, the “Total Funded Debt/EBITDA ratio” or the “Leverage Ratio,” which is defined as Total Funded Debt divided by Credit Agreement EBITDA. 25

Non-GAAP Measures: Net Debt We have defined the non-GAAP measure Net Debt to include the aggregate debt obligations reflected in our balance sheet, less the hedge adjustments resulting from terminated and existing fair value interest rate derivatives or swaps, the balance of our cash and cash equivalents, restricted cash (which includes the balance sheet line items restricted cash and restricted cash and marketable debt securities) and certain other investments that we consider to be readily available to satisfy such debt obligations. Our management uses Net Debt, along with other factors, to evaluate our financial condition. We believe that Net Debt is an appropriate supplemental measure of financial condition and may be useful to investors because it provides a more complete understanding of our financial condition before the impact of our decisions regarding the appropriate use of cash and liquid investments. 26

Non-GAAP Measures: Adjusted Net Income and Adjusted Earnings Per Diluted Share We also use the non-GAAP measures “adjusted net income” and “adjusted earnings per diluted share”. Management believes these non-GAAP financial measures provide our board of directors, investors, potential investors, securities analysts and others with useful information to evaluate the performance of the Company because it excludes restructuring and other costs, net, the alternative fuel mixture credit and cellulosic biofuel producer credit and other specific items that management believes are not indicative of the ongoing operating results of the business. The Company and the board of directors use this information to evaluate the Company’s performance relative to other periods. 27

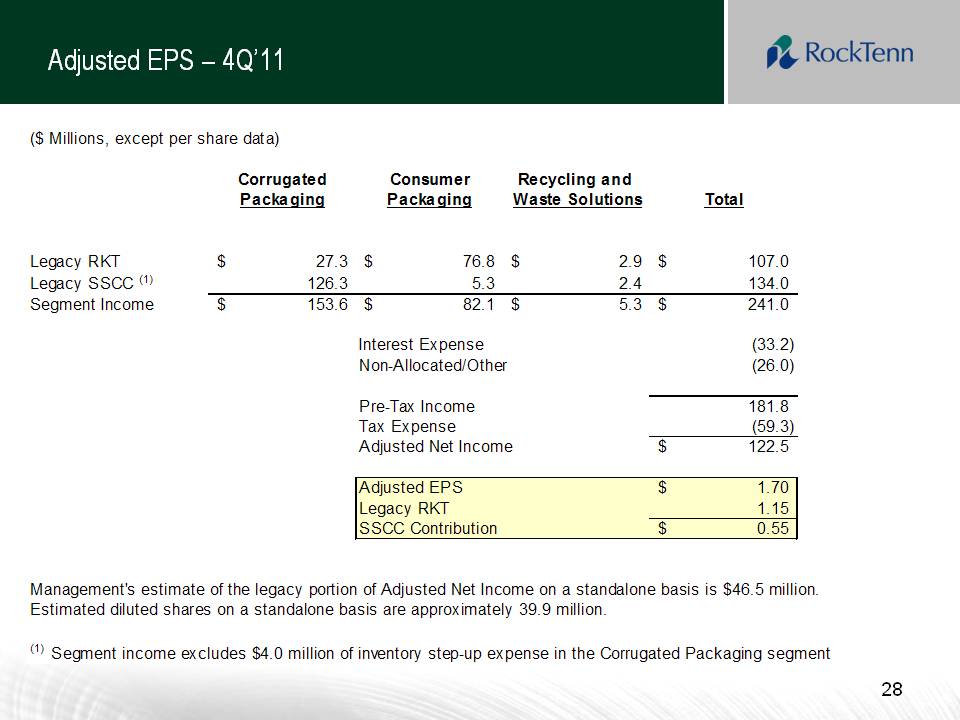

Adjusted EPS – 4Q’11 ($ Millions, except per share data) Corrugated Packaging Consumer Packaging Recycling and Waste Solutions Total Legacy RKT $ 27.3 $ 76.8 $ 2.9 $ 107.0 Legacy SSCC (1) 126.3 5.3 2.4 134.0 Segment Income $ 153.6 $ 82.1 $ 5.3 $ 241.0 Interest Expense (33.2) Non-Allocated/Other (26.0) Pre-Tax Income 181.8 Tax Expense (59.3) Adjusted Net Income $ 122.5 Adjusted EPS $ 1.70 Legacy RKT 1.15 SSCC Contribution $ 0.55 Management's estimate of the legacy portion of Adjusted Net Income on a standalone basis is $46.5 million. Estimated diluted shares on a standalone basis are approximately 39.9 million. (1) Segment income excludes $4.0 million of inventory step-up expense in the Corrugated Packaging segment 28

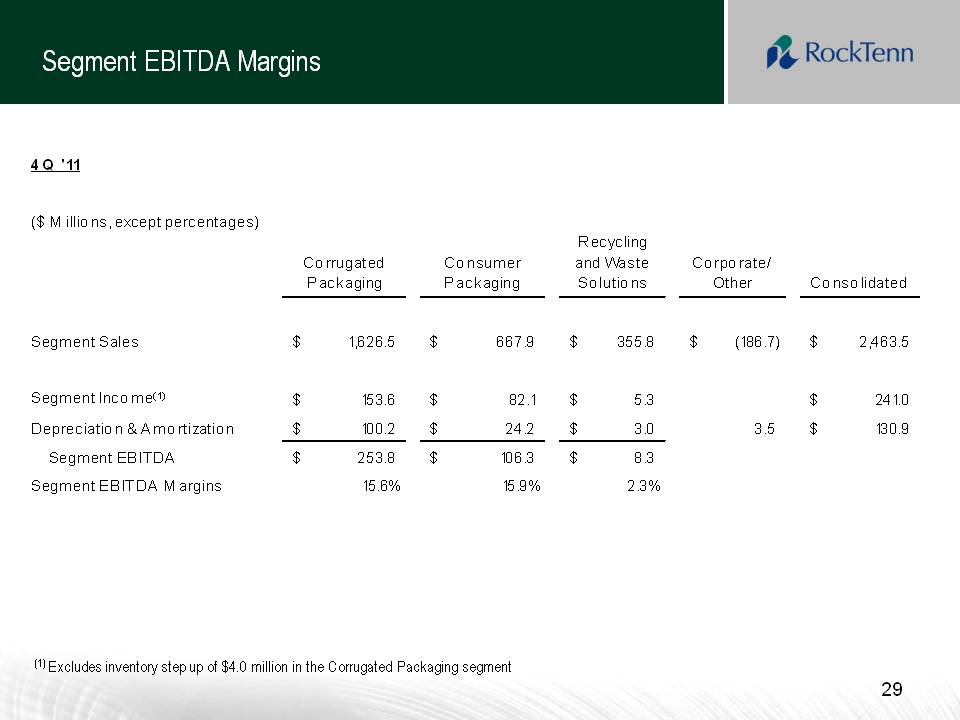

Segment EBITDA Margins 4Q '11 ($ Millions, except percentages) Corrugated Packaging Consumer Packaging Recycling and Waste Solutions Corporate/Other Consolidated Segment Sales $ 1,626.5 $ 667.9 $ 355.8 $ (186.7) $ 2,463.5 Segment Income(1) $ 153.6 $ 82.1 $ 5.3 $ 241.0 Depreciation & Amortization $ 100.2 $ 24.2 $ 3.0 $ 3.5 130.9 Segment EBITDA $ 253.8 $ 106.3 $ 8.3 Segment EBITDA Margins 15.6% 15.9% 2.3% (1) Excludes inventory step up of $4.0 million in the Corrugated Packaging segment 29

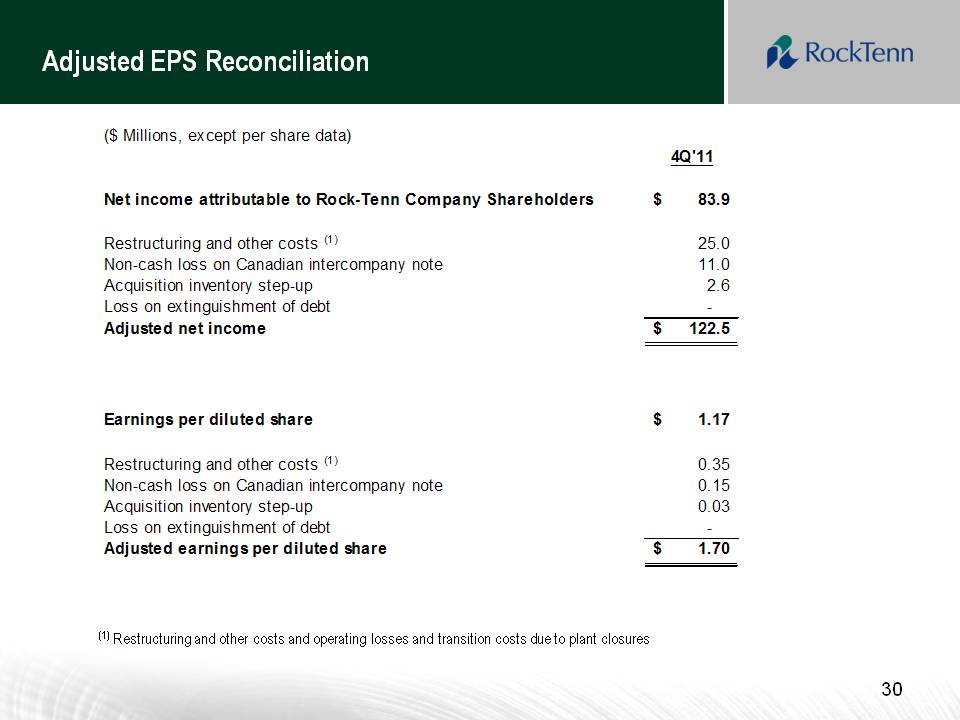

Adjusted EPS Reconciliation ($ Millions, except per share data) 4Q'11 Net income attributable to Rock-Tenn Company Shareholders $ 83.9 Restructuring and other costs (1) 25.0 Non-cash loss on Canadian intercompany note 11.0 Acquisition inventory step-up 2.6 Loss on extinguishment of debt - Adjusted net income $ 122.5 Earnings per diluted share $ 1.17 Restructuring and other costs (1) 0.35 Non-cash loss on Canadian intercompany note 0.15 Acquisition inventory step-up 0.03 Loss on extinguishment of debt - Adjusted earnings per diluted share $ 1.70 (1) Restructuring and other costs and operating losses and transition costs due to plant closures 30

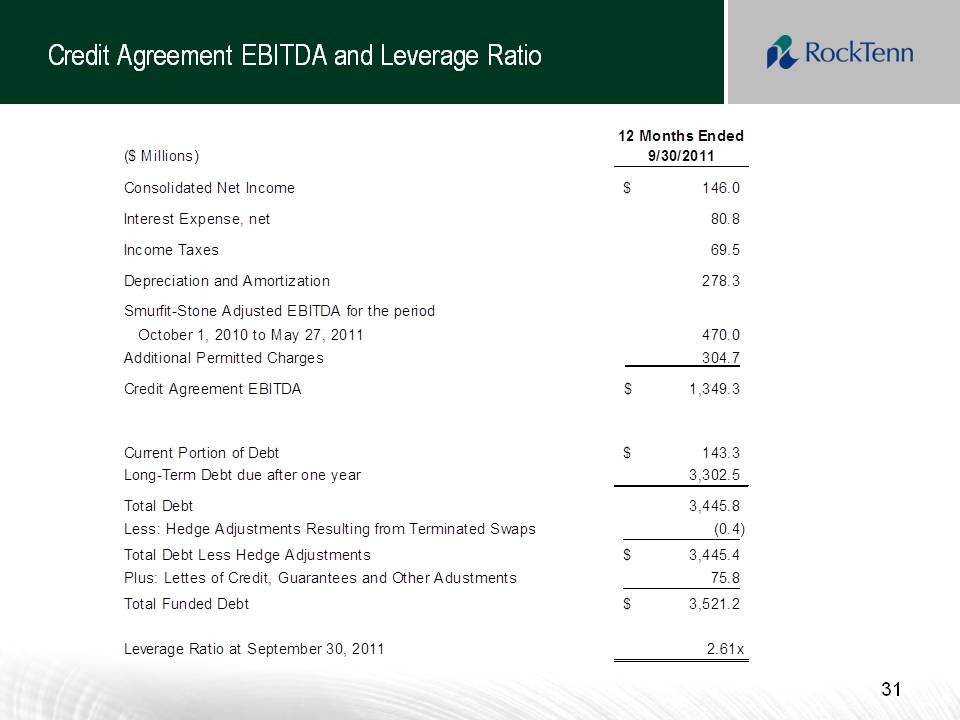

Credit Agreement EBITDA and Leverage Ratio ($ Millions) 12 Months Ended 9/30/2011 Consolidated Net Income $ 146.0 Interest Expense, net 80.8 Income Taxes 69.5 Depreciation and Amortization 278.3 Smurfit-Stone Adjusted EBITDA for the period October 1, 2010 to May 27, 2011 470.0 Additional Permitted Charges 304.7 Credit Agreement EBITDA $ 1,349.3 Current Portion of Debt $ 143.3 Long-Term Debt due after one year 3,302.5 Total Debt 3,445.8 Less: Hedge Adjustments Resulting from Terminated Swaps (0.4) Total Debt Less Hedge Adjustments $ 3,445.4 Plus: Lettes of Credit, Guarantees and Other Adustments 75.8 Total Funded Debt $ 3,521.2 Leverage Ratio at September 30, 2011 2.61x 31

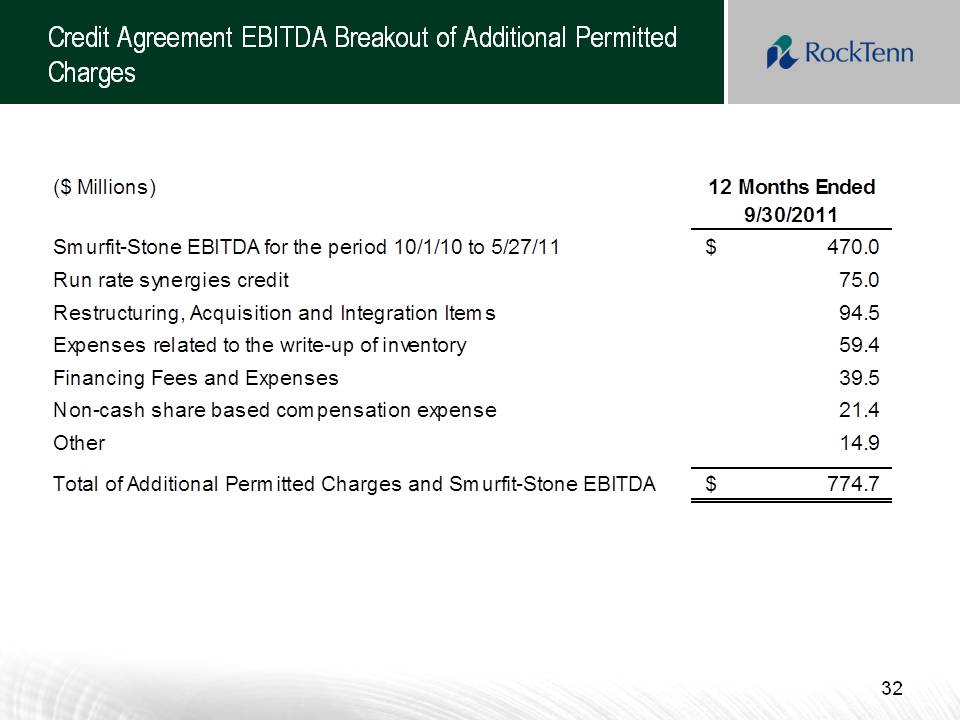

Credit Agreement EBITDA Breakout of Additional Permitted Charges ($ Millions) 12 Months Ended 9/30/2011 Smurfit-Stone EBITDA for the period 10/1/10 to 5/27/11 $ 470.0 Run rate synergies credit 75.0 Restructuring, Acquisition and Integration Items 94.5 Expenses related to the write-up of inventory 59.4 Financing Fees and Expenses 39.5 Non-cash share based compensation expense 21.4 Other 14.9 Total of Additional Permitted Charges and Smurfit-Stone EBITDA $ 774.7 32

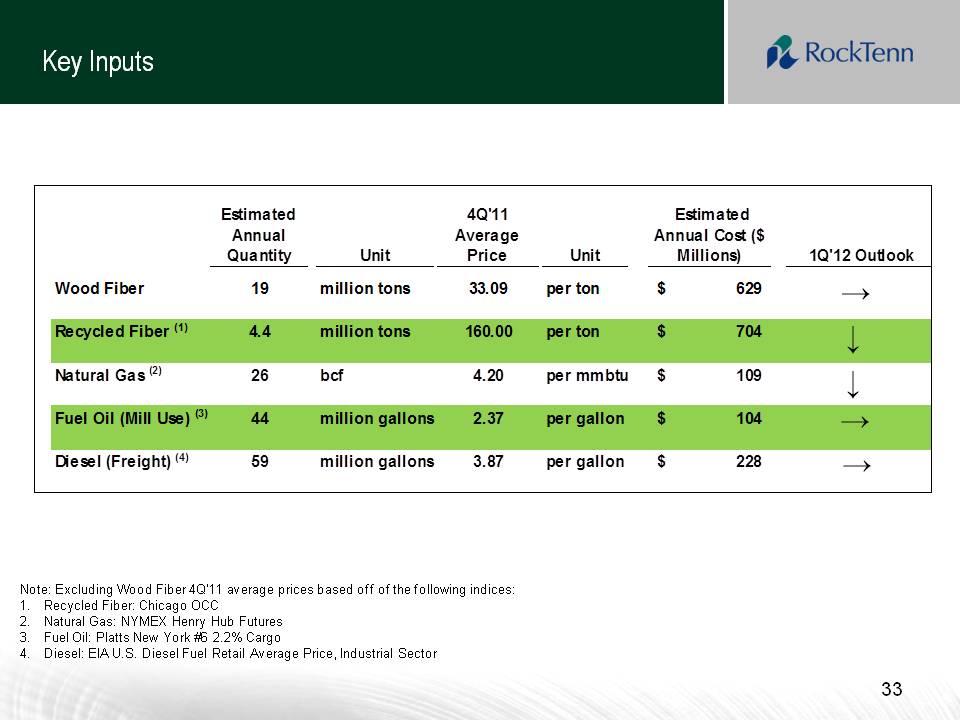

Key Inputs Estimated Annual Quantity Unit 4Q'11 Average Price Unit Estimated Annual Cost ($ Millions) 1Q'12 Outlook Wood Fiber 19 million tons 33.09 per ton $ 629 Recycled Fiber (1) 4.4 million tons 160.00 per ton $ 704 Natural Gas (2) 26 bcf 4.20 per mmbtu $ 109 Fuel Oil (Mill Use) (3) 44 million gallons 2.37 per gallon $ 104 Diesel (Freight) (4) 59 million gallons 3.87 per gallon $ 228 Note: Excluding Wood Fiber 4Q’11 average prices based off of the following indices: 1. Recycled Fiber: Chicago OCC 2. Natural Gas: NYMEX Henry Hub Futures 3. Fuel Oil: Platts New York #6 2.2% Cargo 4. Diesel: EIA U.S. Diesel Fuel Retail Average Price, Industrial Sector 33

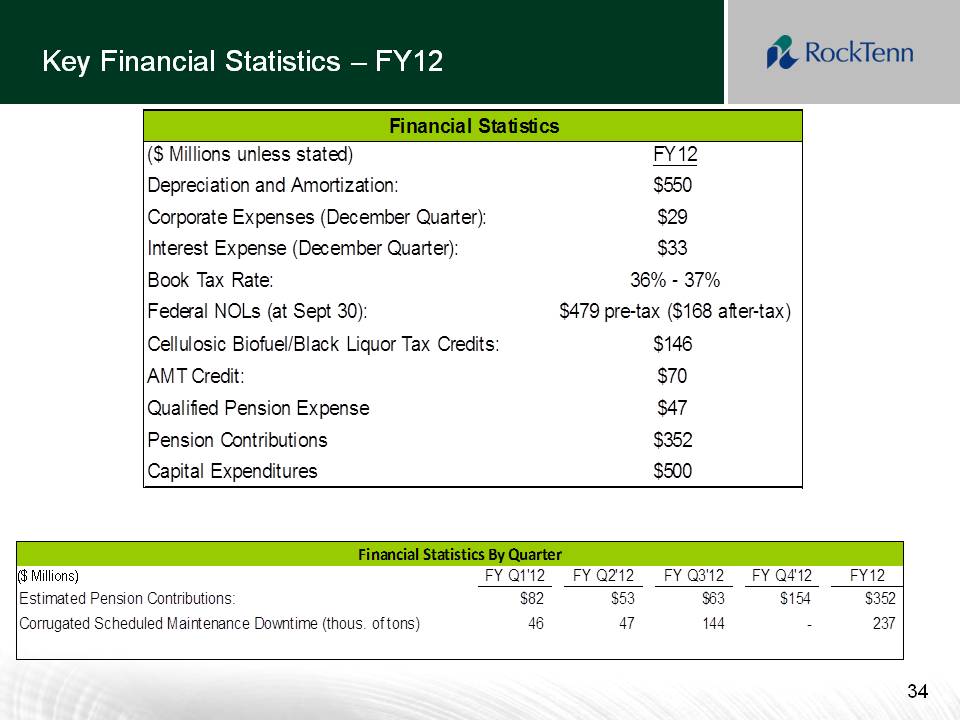

Key Financial Statistics – FY12 Financial Statistics ($ Millions unless stated) FY12 Depreciation and Amortization: $550 Corporate Expenses (December Quarter): $29 Interest Expense (December Quarter): $33 Book Tax Rate: 36% - 37% Federal NOLs (at Sept 30): $479 pre-tax ($168 after-tax) Cellulosic Biofuel/Black Liquor Tax Credits: $146 AMT Credit: $70 Qualified Pension Expense $47 Pension Contributions $352 Capital Expenditures $500 Financial Statistics By Quarter ($ Millions) FY Q1'12 FY Q2'12 FY Q3'12 FY Q4'12 FY12 Estimated Pension Contributions: $82 $53 $63 $154 $352 Corrugated Scheduled Maintenance Downtime (thous. of tons) 46 47 144 - 237 34