Attached files

| file | filename |

|---|---|

| 8-K - 8-K - Novelis Inc. | d253369d8k.htm |

| EX-99.1 - EX-99.1 - Novelis Inc. | d253369dex991.htm |

Novelis Second Quarter 2012

Earnings Conference Call

Philip Martens

President and Chief Executive Officer

Steve Fisher

Senior Vice President and Chief Financial Officer

Brighter Ideas with Aluminum

November 9, 2011

Exhibit 99.2 |

2

Safe Harbor Statement

Forward-Looking Statements

Statements made in this presentation which describe Novelis' intentions, expectations, beliefs or

predictions may be forward-looking statements within the meaning of securities laws.

Forward-looking statements include statements preceded by, followed by, or including the words "believes,"

"expects," "anticipates," "plans," "estimates," "projects,"

"forecasts," or similar expressions. Examples of such statements in this presentation are our

stated view regarding our ability to generate free cash flow this fiscal year, our target Adjusted

EBITDA for fiscal 2012 our projections for aluminum demand, our projected liquidity levels,

expected cost savings from plant closures and anticipated increases to our production capacity from our

debottlenecking initiatives. Novelis cautions that, by their nature, forward-looking

statements involve risk and uncertainty and that Novelis' actual results could differ

materially from those expressed or implied in such statements. We do not intend, and we disclaim any obligation, to update any

forward-looking statements, whether as a result of new information, future events or

otherwise. Factors that could cause actual results or outcomes to differ from the results

expressed or implied by forward-looking statements include, among other things: changes in the prices and availability of

aluminum (or premiums associated with such prices) or other materials and raw materials we use; the

capacity and effectiveness of our metal hedging activities, including our internal used

beverage cans (UBCs) and smelter hedges; relationships with, and financial and operating conditions

of, our customers, suppliers and other stakeholders; fluctuations in the supply of, and prices for,

energy in the areas in which we maintain production facilities; our ability to access financing

for future capital requirements; changes in the relative values of various currencies and the effectiveness of

our currency hedging activities; factors affecting our operations, such as litigation, environmental

remediation and clean-up costs, labor relations and negotiations, breakdown of equipment

and other events; the impact of restructuring efforts in the future; economic, regulatory and political factors

within the countries in which we operate or sell our products, including changes in duties or tariffs;

competition from other aluminum rolled products producers as well as from substitute materials

such as steel, glass, plastic and composite materials; changes in general economic conditions

including deterioration in the global economy, particularly sectors in which our customers operate;

changes in the fair value of derivative instruments; cyclical demand and pricing within the

principal markets for our products as well as seasonality in certain of our customers’ industries; changes in

government regulations, particularly those affecting taxes, environmental, health or safety

compliance; changes in interest rates that have the effect of increasing the amounts we pay

under our principal credit agreement and other financing agreements; the effect of taxes and changes in tax rates;

and our indebtedness and our ability to generate cash. The above list of factors is not

exhaustive. Other important risk factors included under the caption "Risk

Factors" in our Annual Report on Form 10-K for the fiscal year ended March 31, 2011 and our Quarterly Report on Form 10-Q for the

fiscal quarter ended June 30, 2011 are specifically incorporated by reference into this

presentation.

Non-GAAP Financial Measures

This presentation contains non-GAAP financial measures as defined by SEC rules. We think

that these measures are helpful to investors in measuring our financial performance and

liquidity and comparing our performance to our peers. However, our non-GAAP financial measures may

not be comparable to similarly titled non-GAAP financial measures used by other companies.

These non-GAAP financial measures have limitations as an analytical tool and should not be

considered in isolation or as a substitute for GAAP financial measures. We have included reconciliations of

each of these measures to the most directly comparable GAAP measure. In addition, a more

detailed description of these non-GAAP financial measures used in this presentation,

together with a discussion of the usefulness and purpose of such measures, is included as Exhibit 99.2 to our

Current Report on Form 8-K furnished to the SEC with our earnings press release. |

DETAILED FINANCIAL PERFORMANCE

NOVELIS STRATEGY

QUESTIONS AND ANSWERS

FINANCIAL HIGHLIGHTS & OUTLOOK

3

Agenda |

4

4 |

5

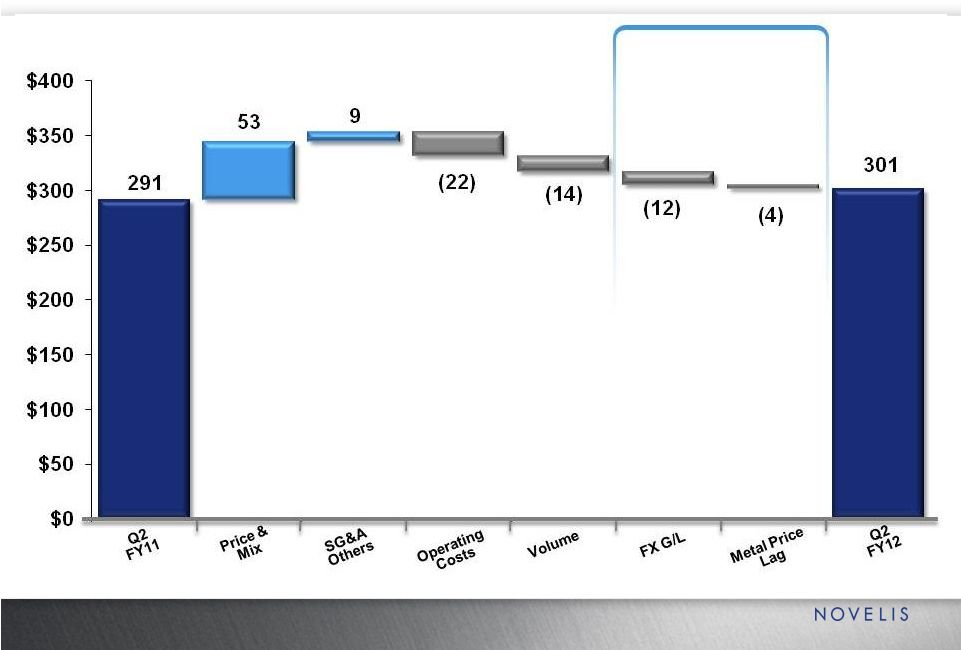

(Q2FY12 vs. Q2FY11)

Continued Strong Performance

Shipments Down 2% to 720 Kilotonnes

Net Sales Up 14% to $2.9 Billion

Strong Adjusted EBITDA Up 3% to $301 Million

Free Cash Flow Before CapEx of $237 Million

Liquidity of $993 Million

Net Income of $120 Million

Second Quarter Financial Highlights |

6

FY12 Targets

Adjusted EBITDA $1.10 -

$1.15B

Free Cash Flow before CapEx of

$600 -

$700M

CapEx of $550 -

$600M Primarily

for Strategic Investments

On Track to

Achieve

Record FY12

Results |

7

Strong & Predictable Results

Competitive Advantages in this Market

Recession Resistant

Growth in Emerging Markets

Increasing Substitution

Low Exposure to True Commodity Type Product

and |

8 |

9

Shipments & Sales

Shipments by Region

Total Company

Sales (Billions) •

Shipments (Kt)

Solid Global Demand

$1.0

$1.5

$2.0

$2.5

$3.0

$3.5

Shipments

Sales

Q2FY12

Q2FY11

2.5

2.9

200

350

500

650

800

Q2FY11

Q2FY12

0

50

100

150

200

250

300

South

America

Asia

Europe

North

America

(2%)

0%

(4%)

(3%) |

10

Adjusted EBITDA/Shipments

Adjusted Pre-Tax Income*

EBITDA, Shipments and Pre-Tax Income

Strong EBITDA –

Up 3% on Shipment Decrease of 2%

EBITDA

&

Pre-Tax

Income

(Millions)

•

Shipments

(Kt)

Shipments

Adjusted EBITDA

* Adjusted Pre-Tax Income excludes restructuring charges,

unrealized gains/losses on derivatives, gain/loss on sale of assets, gain on litigation.

$0

$40

$80

$120

$160

Q2FY11

Q2FY12

$200

$225

$250

$275

$300

$325

$350

Q2FY11

Q2FY12

291

301

137

128

0

150

300

450

600

750

900 |

11

(Millions)

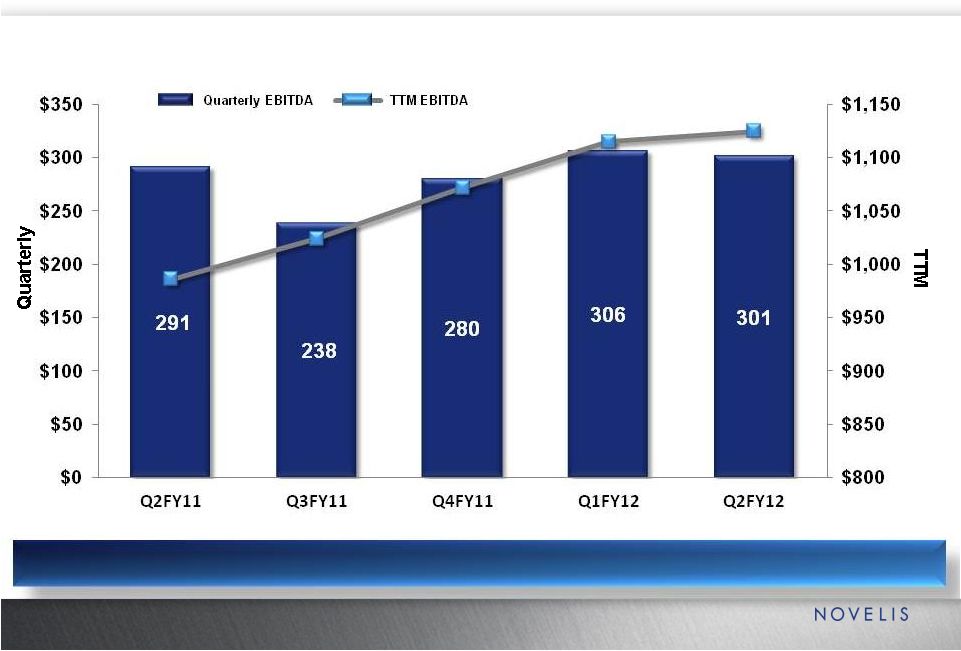

Adjusted EBITDA Trend

Driving Consistent & Predictable Results |

12

Less Controllable

Business Variables

Adjusted EBITDA

Q2FY11 vs. Q2FY12 (Millions) |

13

(Millions)

Free Cash Flow Before CapEx

Expect to Generate ~$600-700 Million for FY12 |

(Millions)

Capital Expenditures

Focused on Strategic Investments

CapEx Plan:

CapEx plan

Back-end Weighted

Strategic

Investments of

~$410-$460M

Maintenance

Investments of

~$140M

FY11

FY12

~550-600

$0

$100

$200

$300

$400

$500

$600

$700

234

107

48

67

23

Q1

Q2

FY

14 |

15 |

16

Source: Novelis Estimates and March 2011 CRU

Long-Term Global Trends in Aluminum Demand

Electronics & High-End

Specialties

Beverage Can

Automotive

~25%

~25%

~6%

~6%

~4-5%

~4-5%

Strong Long-Term Outlook

Long-term

(CY11-16)

16 |

17

Committed to Capitalizing on Strong Market Growth and

Solidifying Market Leadership Through Expansion

Novelis Long-Term Strategy

Long-Term Strategic Investments

Long-Term Strategic Investments

Brazil Mill Expansion

Asia Mill Expansion

North America Mill Expansion

17 |

18

Brazil

Mill

Expansion

–

Status

Update

Expansion Project

Additional

Capacity

Product

Segment

Annual Beverage

Can Growth of

7% for S.A. over

the next 5 years

~$300M

Halfway

Through

Expansion –

On Track & On

Budget

On Track

for

Incremental

Capacity of

~220kt by

End of CY

2012

Investment &

Status |

19

Brazil Mill Expansion

Cold Mill 3 Foundation

Pre-assembling

Cold Mill stands

Line-D Casting Center

Foundation

19 |

20

Brazil –

Additional Investment

New Recycling Line

Adds Recycling

Capacity of

~190 kts of UBC

and scrap, brings

total recycling

capacity to

~390 kts

~$30M

Late

CY2013

Additional Capacity

Investment

& Status

Benefits

•

Drives Towards 80%

Recycled Content

Goal

•

Ensures Metal

Supply

•

Reduces Costs

20 |

21

Korea

Mill

Expansion

–

Status

Update

Expansion Project

Investment

& Status

Additional

Capacity

Product

Segment

Annual FRP

Growth of 8% for

Asia over the next

5 years

~$400M

Broke Ground

in Q2

On Track

for

Incremental

Capacity of

~350kt by

End of

CY 2013

21 |

22

North

America

Mill

Expansion

–

Status

Update

22

Expansion Project

Investment &

Status

Additional

Capacity

Product

Segment

Strong Double

Digit Annual Auto

Sheet Growth in

N.A. over the next

5 years

On Track for

Incremental

Capacity of

~200kt by

Mid CY 2013

~$200M

Broke Ground

in Q2 |

23

Source: Ducker Worldwide and The Aluminum Association, Oct. 2011

Government Regulation Driving Aluminum Demand

0

100

200

300

400

500

600

1975

1980

1985

1990

1995

2000

2005

2010

2015

2020

2025

Driven by Castings

23

Driven by Sheet

Aluminum Content in Pounds per Light Vehicle -

History and Forecast -

Aluminum Content Growth to be Driven by Sheet Starting 2015

|

24

Summary

Performance Remains Solid Across Four Operating

Regions

Planning to Achieve Record FY12 Adjusted EBITDA of

$1.10 -

$1.15B

Making Headway on Global Investments:

•

Three Large Mill Expansions on Track & Budget

•

Global Recycling Initiatives on Track & Budget

24 |

25 |

26 |

27

Income Statement Reconciliation to Adjusted EBITDA

(in $ m)

Q1

FY10

Q2

FY10

Q3

FY10

Q4

FY10

FY 10

Q1

FY11

Q2

FY11

Q3

FY11

Q4

FY11

FY11

Q1

FY12

Q2

FY12

Net Income (loss) Attributable to Our Common

Shareholder

143

195

68

(1)

405

50

62

(46)

50

116

62

120

-

Interest, net

(40)

(41)

(42)

(41)

(164)

(36)

(37)

(42)

(79)

(194)

(73)

(73)

-

Income tax (provision) benefit

(112)

(87)

(48)

(15)

(262)

(15)

(56)

(33)

21

(83)

(59)

7

-

Depreciation and amortization

(100)

(92)

(93)

(99)

(384)

(103)

(104)

(100)

(97)

(404)

(89)

(81)

-

Noncontrolling interests

(18)

(19)

(13)

(10)

(60)

(9)

(11)

(11)

(13)

(44)

(15)

(10)

EBITDA

413

434

264

164

1,275

213

270

140

218

841

298

277

-

Unrealized gain (loss) on derivatives

299

254

62

(37)

578

(47)

1

9

(27)

(64)

26

(1)

-

Realized gain on derivative

instruments not included in

segment income

-

-

-

-

-

-

-

4

1

5

2

-

-

Loss on early extinguishment of debt

-

-

-

-

-

-

-

(74)

(10)

(84)

-

-

-

Proportional consolidation

(16)

(17)

2

(21)

(52)

(10)

(11)

(10)

(14)

(45)

(13)

(12)

-

Restructuring charges, net

(3)

(3)

(1)

(7)

(14)

(6)

(9)

(20)

1

(34)

(19)

(11)

-

Others costs, net

9

1

1

(3)

8

13

(2)

(7)

(13)

(9)

(4)

-

Adjusted EBITDA

124

199

200

232

755

263

291

238

280

1,072

306

301

Other Income (expense) Included in Adjusted

EBITDA

-

Metal price lag

(30)

(10)

3

2

(35)

9

19

-

(3)

25

5

15

-

Foreign currency remeasurement

5

13

(6)

4

16

(22)

20

1

9

8

(8)

-

-

Purchase accounting

52

49

42

(2)

141

(3)

(4)

(3)

(3)

(13)

(3)

(3)

-

Can price ceiling, net

(54)

(54)

(20)

-

(128)

-

-

-

-

-

-

- |

28

Free Cash Flow

(in $m)

FY10

FY11

FY12

Q1

Q2

Q3

Q4

Full

Year

Q1

Q2

Q3

Q4

Full

Year

Q1

Q2

Cash Provided by (used

in) Operating Activities

256

195

179

214

844

22

102

94

236

454

(115)

171

Cash Provided by (used

in) Investing Activities)

(233)

(196)

(55)

0

(484)

27

(2)

(39)

(99)

(113)

(79)

(40)

Less: Proceeds from

Sales of Fixed Assets

(3)

(1)

0

(1)

(5)

(15)

(3)

(10)

(3)

(31)

0

1

Free Cash Flow

20

(2)

124

213

355

34

97

45

134

310

(194)

130 |

29

Explanation of Other Income (Expenses)

Included in our Adjusted EBITDA

1) Metal Price Lag Net of Related Hedges:

On certain sales contracts we experience timing differences on the pass through of

changing aluminum prices from our suppliers to our customers. Additional

timing differences occur in the flow of metal costs through moving average inventory

cost values and cost of goods sold. This timing difference is referred to as Metal

Price Lag. We have a risk management program in place to minimize impact of

this “lag”. 2) Foreign Currency Remeasurement Net of Related

Hedges: All non-functional currency denominated Working Capital and Debt

gets remeasured every period by the period end exchange

rates.

This

impacts

our

profitability.

Like

Metal

Price

Lag,

we

have

a

risk

management

program

in

place

to

minimize impact of such Remeasurement.

3) Purchase Accounting:

Following our acquisition, the consideration and transaction costs paid by Hindalco

in connection with the transaction were “pushed down”

to us and were allocated to the assets acquired and the liabilities assumed. These

allocations are amortized over

periods,

impacting

our

profitability.

A

significant

portion

of

such

amortizations

pertain

to

ceiling

contracts.

4) Can Price Ceilings:

Some sales contracts contained a ceiling over which metal prices could not be

contractually passed through to certain customers. This negatively impacted

our margins and cash flows when the price we paid for metal was above the ceiling

price contained in these contracts. These contracts expired December 31,

2009. |