Attached files

| file | filename |

|---|---|

| EX-32.1 - China Energy Recovery, Inc. | v218935_ex32-1.htm |

| EX-21.1 - China Energy Recovery, Inc. | v218935_ex21-1.htm |

| EX-31.2 - China Energy Recovery, Inc. | v218935_ex31-2.htm |

| EX-31.1 - China Energy Recovery, Inc. | v218935_ex31-1.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, DC 20549

FORM 10-K

(Mark One)

|

x

|

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

For the fiscal year ended December 31, 2010

or

|

¨

|

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

For the transition period from to

Commission file number 000-53283

CHINA ENERGY RECOVERY, INC.

(Exact Name of Registrant as Specified in its Charter)

|

Delaware

|

90-0459730

|

|

|

(State or Other Jurisdiction of

Incorporation or Organization)

|

(I.R.S. Employer

Identification No.)

|

|

7F, No. 267 Qu Yang Road

Hongkou District, Shanghai

China

|

200081

|

|

|

(Address of Principal Executive Offices)

|

(Zip Code)

|

| Registrant's telephone number, including area code +86 (0)21 5556-0020 |

Securities registered pursuant to Section 12(b) of the Act:

|

Title of Each Class

|

Name of Each Exchange on Which Registered

|

|

|

NONE

|

Securities registered pursuant to Section 12(g) of the Act:

|

Common stock, par value $0.001

|

|

(Title of Class)

|

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

Yes ¨ No x

NOTE – Checking the box above will not relieve any registrant required to file reports pursuant to Section 13 or 15(d) of the Exchange Act from their obligations under those Sections.

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

Yes x No o

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ¨ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405) is not contained herein, and will not be contained, to the best of registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of "large accelerated filer," "accelerated filer" and "smaller reporting company" in Rule 12b-2 of the Exchange Act. (Check one):

|

Large accelerated filer

|

¨

|

Accelerated filer

|

¨

|

|

Non-accelerated filer

|

¨

|

Smaller reporting company

|

x

|

(Do not check if a smaller reporting company)

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act).

Yes ¨ No x

The aggregate market value of the voting and non-voting common equity held by non-affiliates is $11,983,530 [as computed by reference to the price at which the common equity was last sold, or the average bid and asked price of such common equity, as of the last business day of the registrant's most recently completed first fiscal quarter.]

Number of shares outstanding of the registrant's common stock as of March 31, 2011:

30,956,651 shares of Common Stock, $0.001 par value per share

DOCUMENTS INCORPORATED BY REFERENCE

None

Table of Content

|

PART I

|

3 | ||||

|

Item 1

|

Business

|

3 | |||

|

Item 1A

|

Risk Factors

|

18 | |||

|

Item 1B

|

Unresolved Staff Comments

|

29 | |||

|

Item 2

|

Properties

|

30 | |||

|

Item 3

|

Legal Proceedings

|

30 | |||

|

Item 4

|

[Reserved]

|

30 | |||

|

PART II

|

31 | ||||

|

Item 5

|

Market for Registrant's Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities

|

31 | |||

|

Item 6

|

Selected Financial Data

|

32 | |||

|

Item 7

|

Management's Discussion and Analysis of Financial Condition and Results of Operations

|

33 | |||

|

Item 7A

|

Quantitative and Quantitative Disclosures about Market Risk

|

49 | |||

|

Item 8

|

Financial Statements and Supplementary Data

|

50 | |||

|

Item 9

|

Changes in and Disagreements with Accountants on Accounting and Financial Disclosure

|

84 | |||

|

Item 9A

|

Controls and Procedures

|

84 | |||

|

Item 9B

|

Other Information

|

86 | |||

|

PART III

|

87 | ||||

|

Item 10

|

Directors, Executive Officers and Corporate Governance

|

87 | |||

|

Item 11

|

Executive Compensation

|

89 | |||

|

Item 12

|

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters

|

91 | |||

|

Item 13

|

Certain Relationships and Related Transactions, and Director Independence

|

92 | |||

|

Item 14

|

Principal Accountant Fees and Services

|

92 | |||

|

PART IV

|

93 | ||||

|

Item 15

|

Exhibits and Financial Statement Schedules

|

93 |

2

CAUTIONARY NOTE REGARDING FORWARD LOOKING STATEMENTS

This Annual Report on Form 10-K and other materials we will file with the U.S. Securities and Exchange Commission (the "SEC") contain, or will contain, disclosures which are forward-looking statements. Forward-looking statements include all statements that do not relate solely to historical or current facts, such as, but not limited to, the discussion of economic conditions in market areas and their effect on revenue growth, the discussion of our growth strategy, the potential for and effect of future governmental regulation, fluctuations in global energy costs, the effectiveness of our management information systems, and the availability of financing and working capital to meet funding requirements, and can generally be identified by the use of words such as "may," "believe," "will," "expect," "project," "estimate," "anticipate," "plan" or "continue." These forward-looking statements are based on our management's current plans and expectations and are subject to certain risks and uncertainties that could cause actual results to differ materially from historical results or those anticipated. These risks and uncertainties include, but are not limited to: our limited operating history; our ability to effectively market our products and services; the loss of key personnel; our inability to attract and retain new qualified personnel; our capital needs and the availability of and costs associated with potential sources of financing; adverse effects of the current turmoil in the credit markets; adverse effects of the current depressed global economic conditions; our inability to increase manufacturing capacity to meet demand; economic conditions affecting manufacturers of energy recovery systems and the industry segments they serve; our dependence on certain customer segments; difficulties associated with managing future growth; our failure to protect our intellectual property rights; allegations of claims of infringements of intellectual property rights brought against us; the loss of our ability to sell and install energy recovery systems made by third parties or such systems manufactured by us under licenses from third parties; fluctuations in currency exchange rates; our failure to comply with applicable environmental regulations; increased competition in our industry; our exposure to litigation from performing work on our customers' properties; an increase in warranty claims; our liability for injuries caused by our products; our inability to cover damages owed by insurance; fluctuations in energy prices resulting in fluctuating demand for our products and services; risks related to our corporate structure, such as our inability to control our affiliated entities and conflicts of interest between our Chief Executive Officer’s duties to us and to our affiliated entities; the uncertainties associated with the environmental, economic, political and legal conditions in China and changes thereof; the adverse effect of governmental regulation and other matters affecting energy recovery system manufacturers; Chinese restrictions on foreign currency exchange transactions; restrictions on foreign investments in China; ineligibility for and expiration of current Chinese governmental incentives; natural disasters and health related concerns; the development of an active trading market for our common stock; the loss of coverage of our common stock by securities analysts; the failure of our complying with securities laws in private placements; our common stock being a penny stock; a sudden increase in the number of shares of our common stock in the market as a result of Rule 144 sales or conversion or exercise of derivative securities, and our failure to maintain adequate internal controls over financial reporting.

These forward-looking statements speak only as of the date of this Annual Report on Form 10-K. Except as required by law, we undertake no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise. You should also read, among other things, the risks and uncertainties described in the section of this Annual Report on Form 10-K entitled "Risk Factors."

PART I

Item 1 Business

Overview of Our Business

China Energy Recovery, Inc. (the "Company," "we," "us," or "our") is headquartered in Shanghai, China, and, through its subsidiaries and affiliates, is in the business of designing, fabricating, implementing and servicing industrial energy recovery systems. The Company's energy recovery systems capture industrial waste energy for reuse in industrial processes or to produce electricity and thermal power, thereby allowing industrial manufacturers to reduce their energy costs, shrink their emissions and generate sellable emissions credits. A majority of the manufacturing takes place at the Company's leased manufacturing facilities in Shanghai, China. The Company transports the manufactured systems in parts via truck, train or ship to the customers' facilities where the system is assembled and installed. The Company has primarily sold energy recovery systems to chemical manufacturing plants to reduce their energy costs by increasing the efficiency of their manufacturing equipment. Since inception, the Company has installed over 122 energy recovery systems both in China and internationally. The Company mainly sells its energy recovery systems and services directly to customers.

3

Our History

Unless otherwise noted, the disclosures about our history reflect the Company's capital structure as of the time of the occurrences described and do not take into account subsequent stock splits or other adjustments to the Company's capital structure.

We incorporated in the State of Maryland in May 1998 under the name Majestic Financial, Ltd. We changed our name to Commerce Development Corporation, Ltd. in April 2002. Effective June 5, 2007, we changed our name to MMA Media Inc.

On January 24, 2008, we entered into a Share Exchange Agreement (the "Share Exchange Agreement") with Poise Profit International, Ltd., a private British Virgin Islands corporation ("Poise Profit"), and Poise Profit's shareholders pursuant to which we agreed to acquire all of the issued and outstanding shares of Poise Profit's common stock in exchange for the issuance of 41,514,179 shares of our common stock (on a post-1-for-9 stock split basis approved by our board of directors in connection with entering into the Share Exchange Agreement) to Poise Profit's shareholders (the "Share Exchange").

On January 25, 2008, we entered into and closed an Asset Purchase Agreement with MMA Acquisition Company, a Delaware corporation, pursuant to which we sold substantially all of our assets to MMA Acquisition Company in exchange for MMA Acquisition Company's assuming a substantial majority of our outstanding liabilities. The transferred assets consisted of letters of intent for the proposed acquisitions of MMAWeekly.com, dated June 9, 2007, and Blackbelt TV, Inc., dated July 16, 2007, and all shares of common stock in Blackbelt TV, Inc. we owned, among other things. The total book value of the assets acquired was approximately $317,000. The assumed liabilities consist of accounts payable, convertible debt, accrued expenses and shareholder advances of approximately $360,000.

Effective February 5, 2008, we changed our name to China Energy Recovery, Inc. and conducted a 1-for-9 reverse stock split of our issued and outstanding capital stock pursuant to which each nine shares of our common stock issued and outstanding on the record date of February 4, 2008 were converted into one share of our common stock. We had 84,922,000 shares of common stock issued and outstanding immediately prior to the reverse stock split and 9,435,780 shares thereafter.

On April 15, 2008, we closed the Share Exchange pursuant to which we acquired all of the issued and outstanding shares of Poise Profit's common stock in exchange for the issuance of 41,514,179 shares of our common stock to Poise Profit's stockholders. Upon the closing of the Share Exchange, Poise Profit became our wholly-owned subsidiary and our business operations consisted of those of Poise Profit's wholly-owned subsidiary, HAIE Hi-tech Engineering (Hong Kong) Company, Limited ("Hi-tech"), incorporated in the Hong Kong Special Administration Region, China.

Also on April 15, 2008 and as a condition to closing of the Share Exchange, we entered into Securities Purchase Agreements (the "Securities Purchase Agreement") with 25 accredited investors pursuant to which we issued and sold an aggregate of 7,874,241 units at a price per unit of $1.08 with each unit consisting of one share of our Series A Convertible Preferred Stock, par value $0.001 per share, and one warrant to purchase one-half of one share of our common stock at an exercise price of $1.29 per share (the "Financing"). Thus, at the closing of the Financing, we issued 7,874,241 shares of our Series A Convertible Preferred Stock to the investors and we also issued warrants to the investors for the purchase of an aggregate of 3,937,121 shares of our common stock for an aggregate purchase price of $8,504,181. After the April 16, 2008 1-for-2 reverse stock split described below, the warrants are exercisable into 1,968,561 shares of common stock at an exercise price of $2.58.

4

As a result of the closing of the Share Exchange on April 15, 2008, our new business operations consist of those of Poise Profit's Chinese subsidiary, Hi-tech, which were subsequently transferred to CER (Hong Kong) Holdings Limited (“CER Hong Kong”) as described in Item 1 Business - Organizational Structure and Subsidiaries. CER Hong Kong is principally engaged in designing, marketing, licensing, fabricating, implementing and servicing industrial energy recovery systems capable of capturing industrial waste energy for reuse in industrial processes or to produce electricity and thermal power.

On April 16, 2008, we conducted a 1-for-2 reverse stock split of our issued and outstanding capital stock pursuant to which each two shares of our common stock issued and outstanding on the record date of April 15, 2008 were converted into one share of our common stock. We had 50,949,959 shares of common stock issued and outstanding immediately prior to the reverse stock split and 25,474,980 shares thereafter.

Starting in the summer of 2008, we began a reorganization of our corporate structure as further described under the caption "Organizational Structure and Subsidiaries" below.

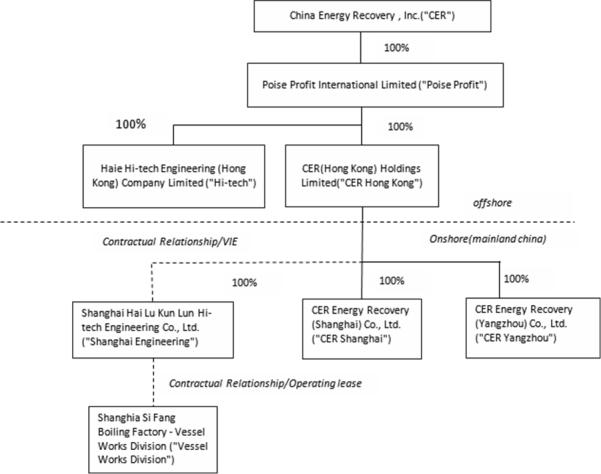

Organizational Structure and Subsidiaries

After closing of the Share Exchange, our organizational structure reflected Chinese limitations on foreign investments and ownership in Chinese businesses. Generally, these limitations prevent a U.S. corporation from owning directly certain types of Chinese businesses. Instead, a U.S. corporation can obtain the benefits and risk of equity ownership of a Chinese business either by being a part-owner of a Chinese joint venture or by entering into fairly extensive and complicated contractual relationships with Chinese companies wholly-owned by Chinese owners. At that time, and still to a significant extent, our business relied on contractual relationships. However, we began a corporate reorganization process in the summer of 2008 to gradually move our assets and operations from affiliated entities with which we have only contractual relationships into wholly-owned subsidiaries. Until our reorganization is complete, our corporate structure will reflect a combination of control via direct ownership and contractual arrangements.

Poise Profit, a wholly-owned subsidiary of the Company, was incorporated on November 23, 2007 under the laws of the British Virgin Islands. Poise Profit, in turn, owns 100% of the issued and outstanding equity interests in Hi-tech and CER (Hong Kong) Holdings Limited ("CER Hong Kong"). Historically, all of our operations were conducted through Hi-tech via contractual arrangements with affiliated Chinese entities, but we are in the process of transferring our assets and operations from Hi-tech to CER Hong Kong and its wholly-owned subsidiary CER Energy Recovery (Shanghai) Co., Ltd. ("CER Shanghai"). As part of our reorganization, CER Hong Kong was incorporated on August 13, 2008 under the laws of the Hong Kong Special Administrative Region, China and was originally jointly owned by Mr. Qinghuan Wu, one of our directors and our Chairman of the Board and Chief Executive Officer, and his spouse, Mrs. Jialing Zhou, who is one of our directors. On December 3, 2008, Mr. Qinghuan Wu and Mrs. Zhou transferred ownership of CER Hong Kong to Poise Profit. CER Shanghai was incorporated on November 11, 2008 as a wholly foreign-owned enterprise in Shanghai, China. After our reorganization is complete, CER Shanghai will be our primary operating entity in China and CER Hong Kong will be our primary holding entity holding all equity interests in our Chinese subsidiaries, including CER Shanghai. While we are gradually transferring our current assets and operations to CER Shanghai, we plan that CER Shanghai will enter into the majority of all new business contracts.

At the time of the closing of the Share Exchange, Hi-tech owned 90% of a joint venture called Shanghai Haie Investment Consultation Co., Ltd. ("JV Entity"), a company organized in Shanghai, China, providing investment consultancy services, enterprise management consultancy services and marketing policy planning services to third-party customers as well as affiliates. The remaining 10% was owned by Shanghai Engineering. In compliance with the new Chinese regulation effective January 2008, on June 16, 2008, JV Entity's board of directors approved a plan to dissolve JV Entity. The application for dissolution was approved by the Chinese governmental authority in July 2008. We dissolved JV Entity on September 1, 2008 and its assets, in the form of an initial capital contribution from Hi-tech, were returned to Hi-tech on September 18, 2008.

5

Before December 3, 2008, all of our operations were conducted through Hi-tech and its affiliated companies. Hi-Tech was engaged in the marketing and sale of energy recovery systems which were designed, manufactured and installed by affiliated companies. Hi-tech had entered into contractual relationships with two entities incorporated in Shanghai, China: Shanghai Hai Lu Kun Lun Hi-tech Engineering Co., Ltd. ("Shanghai Engineering") and Shanghai Xin Ye Environmental Protection Engineering Technology Co., Ltd. ("Shanghai Environmental"). Each of Shanghai Engineering and Shanghai Environmental was considered a "variable interest entity" and their respective financial information was consolidated with Hi-tech's pursuant to the Accounting Standard Codification (“ASC”) 810-10. Hi-tech entered into contractual relationships with Shanghai Engineering and Shanghai Environmental to comply with Chinese laws regulating foreign-ownership of Chinese companies. Shanghai Engineering is engaged in the business of designing, manufacturing and installing energy recovery systems. All manufacturing is done by Vessel Works Division pursuant to a cooperative manufacturing agreement between Shanghai Engineering and Vessel Works Division's parent, Shanghai Si Fang Boiler Factory ("Shanghai Si Fang"), as further described below. Vessel Works Division holds important permits for the manufacturing and installation of boilers used in our energy recovery systems. Shanghai Environmental is not an operating company but it served in the past as a vehicle for arranging sales and maximizing tax benefits. We did not use Shanghai Environmental for these purposes during our 2010 fiscal year and do not intend to do so in the future, hence we dissolved Shanghai Environmental in 2010. Shanghai Engineering is owned jointly by Mr. Qinghuan Wu, our Chairman of the Board and Chief Executive Officer, and his spouse, Mrs. Jialing Zhou, who is one of our directors.

On December 3, 2008, as a part of our reorganization, all of the material contracts between Hi-tech and Shanghai Engineering and between Hi-tech and Shanghai Environmental were transferred to CER Hong Kong. Since that date, CER Hong Kong has been engaged in the marketing and sale of energy recovery systems which are designed, manufactured and installed by its subsidiaries and affiliated companies. These material contractual relationships consist of:

|

·

|

Consulting Services Agreements - These agreements allow CER Hong Kong to manage and operate Shanghai Engineering and Shanghai Environmental, and collect the respective net profits of each company. Under the terms of the agreements, CER Hong Kong is the exclusive provider of advice and consultancy services to Shanghai Engineering and Shanghai Environmental, respectively, related to the companies' general business operations, human resources needs and research and development, among other things. In exchange for such services, each of Shanghai Engineering and Shanghai Environmental must pay to CER Hong Kong such company's respective net profits. CER Hong Kong will own all intellectual property rights developed or discovered through research and development in the course of providing services under the agreements but will grant a license to use such intellectual property back to the respective company if necessary to conduct the business. Each of Shanghai Engineering and Shanghai Environmental are required to cause their respective shareholders to pledge such shareholders' equity interests in the respective companies to secure the fee payable by Shanghai Engineering and Shanghai Environmental, respectively, under the agreements. The agreements contain affirmative covenants requiring each of Shanghai Engineering and Shanghai Environmental to take certain actions, such as (but not limited to) delivering periodic financial reports to CER Hong Kong. The agreements also contain negative covenants preventing each of Shanghai Engineering and Shanghai Environmental from taking certain actions such as (but not limited to) issuing equity, incurring indebtedness and changing its business. The agreements are effective until terminated and they may be terminated by CER Hong Kong for any or no reason and by either party for reasons explicitly set forth in the agreements, including (but not limited to) a breach by the other party or the other party's becoming bankrupt or insolvent. The parties may not assign or transfer their rights or obligations under the respective agreements without the prior written consent of the other party, except that CER Hong Kong may assign its rights or obligations under the agreements to an affiliate.

|

6

|

·

|

Proxy Agreements - CER Hong Kong has entered into proxy agreements with all of the shareholders of each of Shanghai Engineering and Shanghai Environmental under which the shareholders have vested their voting power of the companies in CER Hong Kong and agreed to not transfer the shareholders' respective equity interests in the two companies to anyone but CER Hong Kong or its designee(s). The agreements do not have an expiration date. CER Hong Kong has the right to terminate each of the agreements upon 30 days' written notice but the shareholders may not terminate the agreements without CER Hong Kong's consent.

|

|

·

|

Option Agreements - The parties to each of these agreements are CER Hong Kong, Shanghai Engineering, Shanghai Environmental, respectively, and all of the shareholders of each of Shanghai Engineering and Shanghai Environmental, respectively. The shareholders of each of Shanghai Engineering and Shanghai Environmental have granted CER Hong Kong or its designee(s) the irrevocable right and option to acquire all or a portion of such shareholders' equity interests in the two companies. The shareholders have also agreed not to grant such an option to anyone else. The purchase price for a shareholder's equity interests will be equal to such shareholder's original paid-in price for such equity interest. Pursuant to the terms of the agreements, the shareholders and each of Shanghai Engineering and Shanghai Environmental have agreed to certain restrictive covenants to safeguard CER Hong Kong's rights under the respective agreement. The agreements expire 10 years from execution unless renewed. CER Hong Kong may freely assign its rights and obligations under the agreements upon written notice to Shanghai Engineering, Shanghai Environmental and the shareholders, respectively. Shanghai Engineering, Shanghai Environmental and the shareholders, respectively, may not assign their rights or obligations under the respective agreements without the prior written consent of CER Hong Kong.

|

|

·

|

Equity Pledge Agreements - The parties to each of these agreements are CER Hong Kong, Shanghai Engineering, Shanghai Environmental, respectively, and all of the shareholders of each of Shanghai Engineering and Shanghai Environmental, respectively. The shareholders of each of Shanghai Engineering and Shanghai Environmental have pledged all of their respective equity interests in the two companies to CER Hong Kong to guarantee each of Shanghai Engineering and Shanghai Environmental performance of these companies' respective obligations under the Consulting Services Agreements. The pledge expires two years after the obligations under the Consulting Services Agreements described above are fulfilled. CER Hong Kong has the right to collect any and all dividends paid on the pledged equity interests. Pursuant to the terms of the agreements, the shareholders and each of Shanghai Engineering and Shanghai Environmental have agreed to certain restrictive covenants to safeguard CER Hong Kong's rights under the respective agreement. Upon an event of default under the agreements, CER Hong Kong may vote, control, sell or dispose of the pledged equity interests and may require the shareholders to pay all outstanding and unpaid amounts due under the Consulting Services Agreement. Pursuant to the terms of the agreements, the shareholders have agreed to certain restrictive covenants to safeguard CER Hong Kong's rights under the respective agreement. CER Hong Kong may freely assign its rights and obligations under the agreements upon written notice to the shareholders. The shareholders may not assign their rights or obligations under the respective agreements without the prior written consent of CER Hong Kong.

|

All of Shanghai Engineering’s manufacturing activities are conducted through a Leasing and Operation Agreement, a form of cooperative manufacturing agreement, originally effective as of May 1, 2003 and subsequently renewed and amended with a state-owned enterprise, Shanghai Si Fang. Pursuant to the agreement, Shanghai Si Fang leases certain land use rights, buildings and fixed assets (lease elements) in one of its subsidiaries, Vessel Works Division, and provides management services and licenses the “Si Fang” brand and manufacturing license (non-lease elements) of Vessel Works Division to Shanghai Engineering. Because the arrangement contains both the lease and non-lease elements, the quarterly payment is allocated between the lease and non-lease deliverables. The lease elements are classified and accounted for as operating leases and the lease expense is recorded on a straight-line basis. The non-lease elements are accounted for as prepayment for management and licensing fees and the payment is amortized on a straight-line basis over each contractual period.

7

Shanghai Engineering does not have a variable interest in Vessel Works Division through this agreement as the arrangement is established between Shanghai Engineering and Shanghai Si Fang. Shanghai Engineering does not have any contractual or ownership interest in Vessel Works Division, and therefore, Shanghai Engineering does not have variable interests in Vessel Works Division.

The arrangement, however, may result in Shanghai Engineering having a variable interest in Shanghai Si Fang, but as Shanghai Si Fang is a state-owned enterprise that has substantive operations other than this lease and operation arrangement, Shanghai Engineering is not the primary beneficiary of Shanghai Si Fang.

In August 2009, CER Hong Kong entered into a series of contracts with Yangzhou (Yizheng) Automobile Industrial Park Administration Committee, a government entity of the City of Yangzhou, Jiangsu Province, China, to acquire a tract of land on which CER Hong Kong plans to build a new manufacturing facility. Phase one construction of the plant was completed and began operating in January 2011. Phase two is under construction and anticipated to be completed in 2012. As a result, the company’s production function is now split between Vessel Works Division and CER Yangzhou. We are in the process of transferring the production function from Vessel Works Division to CER Yangzhou and expect to be finished by end of April 2011.

The following is an organizational chart setting forth the current status of the Company's subsidiaries and affiliated companies as of December 31, 2010:

8

Industry Overview

Global demand is increasing for innovative environmental protection and renewable energy solutions for sustainable economic growth. Modern industrial nations and emerging markets today are faced with the growing challenge of reducing and controlling air pollution emissions that present serious health risks to national populations, cross international borders, and damage the environment. Increased energy consumption has forced governments and industries to invest in improving energy efficiency and alternative forms of power generation and conservation. As the global power generation industry and manufacturing industries increase their focus on improving efficiency and mitigating the environmental impact of their processes, we believe that energy recovery systems will play a major role in improving the output that can be obtained from current supplies.

Energy recovery systems can salvage the majority of the wasted energy from excess heat that industrial manufacturing facilities and power plants release into the atmosphere in the form of hot exhaust gases or high pressure steam by converting the heat into electricity (often through steam driven generator turbines) which can be used in industrial processes, thereby lowering energy costs. In addition, energy recovery systems can also capture harmful pollutants that would otherwise be released into the environment from certain industrial processes. These reduced emissions can also help companies meet environmental regulations. Energy recovery systems may also be used in heat recovery applications whereby excess heat may be used to heat buildings and water. Examples of end-users of this type of energy recovery system include hospitals and schools that may heat their buildings and water with excess heat generated by their own large electrical equipment. This type of energy recovery system is less complicated and requires significantly less technical qualifications to build than the industrial energy recovery systems described above as it is essentially redirecting the heat generated by one system into other on-site systems. As a result, this type of energy recovery system is cheaper to build and the barriers to entry into this market are lower than in the market for industrial energy recovery systems. Our business focuses on energy recovery systems for industrial applications.

We believe that energy recovery systems represent a large-scale, environmentally friendly and economically feasible form of power generation and tool for improving energy efficiency. Compared with other alternative forms of power, such as solar, wind or biomass, we believe that energy recovery systems are dramatically more affordable for technology capable of delivering power on the scale necessary for industrial clients. In our opinion, energy recovery systems are cost competitive even with large-scale, traditional power sources such as coal, fossil fuels and nuclear power, but have the added benefit of reducing pollution and greenhouse gas emissions.

According to recent studies from the U.S. Department of Energy and the U.S. Environmental Protection Agency, energy recovery systems could generate nearly 200 gigawatt ("GW") new power, equivalent to approximately 20% of current U.S. power generation capacity. The European Union is a significant user of energy recovery systems, with 104 GW installed power generating capacity. Germany and Italy have the most installed capacity at 16 GW and 13 GW, respectively.

We have developed and commercialized our proprietary customized energy recovery technologies and solutions to cost-effectively reduce pollution and capture the waste heat released by our customer's industrial processes. Our energy recovery systems can help our customers improve their energy use efficiency. For example, our energy recovery systems applied in sulfuric acid manufacturing processes can produce as much as three times the usable energy from the same fuel by recovering otherwise lost energy and reusing it in the manufacturing processes directly or to further generate electrical power, which may allow customers to slash energy expenditures by up to two-thirds. Additionally, these systems can reduce harmful emissions resulting from certain types of sulfuric acid manufacturing processes that otherwise would have been released into the atmosphere. Other benefits include our customers' ability to sell carbon credits, reduction of flue gas and equipment sizes of all flue gas handling equipment such as fans, stacks, ducts, and burners, and a reduction in auxiliary energy consumption.

The most notable target customers for our energy recovery systems are major types of industrial manufacturing facilities, such as chemical plants, petrochemical plants, paper manufacturing plants, oil refineries, etc. These types of customers generally operate manufacturing equipment that release waste heat into which our energy recovery systems can be implemented and integrated to capture such waste heat for direct reuse or, if connected with steam-driven turbines, to produce electricity.

9

In March 2010, the Chinese People's Political Consultative Conference (“CPPCC”) and National People's Congress (“NPC”) convened, during which the number one proposal on low carbon: Suggestion On Promotion of Low Carbon Life and Improve Social Sustainable Development, proposed by Jiu San Society, was highly received by the NPC and CPPCC; over 10% proposals of CPPCC and NPC were related to low carbon issues. The Government Work Report of 2009, issued by Premier Wen Jiabao, addressed that Energy Saving and Environmental Protection is one of the nine principal focuses of the government in 2010, which means low carbon will be a State Strategy in the near future. The issues mentioned above implied that the energy saving industry should experience significant growth over the next few years. Furthermore, at the Copenhagen Climate Conference, Premier Wen Jiabao announced that China would decrease carbon emission by 40%-45% in 2020, as compared with 2005, which is further evidence that the energy saving industry should experience significant growth in the near future in China, which should benefit CER to in growing its business in the domestic Chinese market.

Global Market Overview

The world currently faces fundamental problems with its energy supply, which are due primarily to the reliance on fossil fuels. The economic prosperity of the wealthiest nations in the twentieth century was built on a ready supply of inexpensive fossil fuel and developing nations have continued in the twenty-first century to consume fossil fuel reserves at an ever increasing rate. This has led to worldwide reserve depletions, indicating that both oil and gas are likely to be effectively exhausted before the end of this century. Only coal reserves are expected to last into the next century. Yet even if fossil fuel supplies were unconstrained, their continued use poses its own problems. All fossil fuel combustion produces carbon dioxide, which appears to result in the warming of the earth's atmosphere with profound environmental implications across the globe.

These problems have resulted in the realization that the world must both increase the efficiency of its utilization of fossil fuels and decrease its reliance upon them. Environmental issues related to fossil fuel combustion arose first during the 1980s with the advent of acid rain, a product of the sulfur and nitrogen emissions from fossil fuel combustion. Power plants were forced by legislation and economic measures to control these emissions. However it is the recognition of global warming that presents the most serious challenge because carbon dioxide exists at much higher levels in the fuel gases of power plants and major types of industrial manufacturing facilities than sulfur dioxide and nitrogen oxides.

Although renewable energy capacity offers a hedge against major price rises because most renewable technologies exploit a source of energy that is freely available, many renewable technologies today still rely on government subsidies to make them competitive. Governments may also impose penalties upon companies, such as carbon trading schemes, which discourage the use of fossil fuels or increase its costs by imposing stringent emissions limits.

Given the international concerns regarding global warming and pollution and the need to more efficiently utilize fossil fuels, we believe that there exists substantial worldwide demand and a growing market for technologies that can enable companies to generate greater amounts of energy from the same supply of fossil fuels and that also reduce the amount of harmful emissions that would otherwise be released from the combustion of those fossil fuels. These technologies, including energy recovery systems, could benefit companies by both reducing energy costs and mitigating possible emissions penalties.

China Market Overview

Booming economic growth and rapid industrialization has spurred demand for electric power in China over the previous few years. For example, by the end of 2010, China's total installed generating capacity reached 960GW, an increase of more than 10% over the capacity at the end of 2009. Due to the expansion of energy intensive industrial sectors such as steel, cement, coal, petrol and chemicals, China's energy consumption has been growing faster than the country's gross domestic product ("GDP") and thus causing a shortage of electricity and coal and blackouts in over 20 of the country's 32 provinces, autonomous regions and municipalities. With the rapid modernization and industrialization of the country's economy, according to the International Energy Agency, China needs to add 1,300 GW to its electricity-generating capacity, more than the total installed capacity currently in the United States, to meet its demands over the next several years. We predict that the result of this massive increase in electric generation capacity will be a rapid rise in harmful emissions. China has already surpassed the United States to become the world's largest emitter of greenhouse gases, and the country faces enormous challenges from the pollution brought about by its energy needs.

10

In 2010, China's primary energy consumption was 3.25 billion tons of standard coal, an increase of 6% compared to that of 2009. China has become one of the world's major energy consumers. However, China has tried to reduce energy intensity to some extent. The energy consumption per GDP fell 4%. It is predicted that China will reach total electricity consumption of 4.6 trillion kwh, an increase of 9.5%; coal consumption of over 3.5 billion tons; crude oil consumption of 0.46 billion tons; natural gas consumption will maintain rapid growth and the total consumption is expected to reach 120-130 billion cubic meters.

The Chinese government principally encourages the setup of large-scale companies in energy intensive industries such as chemicals, petrol and coal. Therefore we would expect a general decrease in the number of smaller-scale companies in this related industry. We intend to develop the market opportunities to cooperate with these large companies for our future development.

In October 2010, the State Council announced that China will continue to focus on supporting and developing the strategic new industries, such as energy-saving, new energy, high-side equipment manufactory industries. The government encourages energy recycling and recovery to increase the efficiency of energy utilization. The goal is to increase the GDP of such strategic new industries to 8% and 15% of the total GDP, for the years ending 2015 and 2020, respectively.

In November 2010, the State Council approved development plans for energy-saving and environmental protection industries. The government addressed the support of development of high-efficiency energy-saving techniques and equipment, including our waste-heat energy recovery systems. We predicted that China will launch a series of technological and fiscal support policies to further promote the healthy growth of such industries.

In December 2010, a Chinese senior government official reiterated at the Cancun Conference that China intends to fulfill the goal of reducing the intensity of carbon dioxide emissions per unit of GDP in 2020 by 40 to 45 percent compared with 2005 levels, in order to address global climate change. From 2001 to 2005, the 10th five year plan, China realized an annual increase of GDP by 9.8% with increase of energy by10.4%. From2006 to 2010, the 11th five years, China realized an annual increase of GDP by 10.2% with increase of energy by 6.8%, which represented China’s rapid growth in investment of new energy and great improvement in energy utilization efficiency.

China would include the low-carbon targets in the 12th five-year plan for national economic development (2011-2015) to build an energy-saving, ecologically friendly society, the commission said.

In February 2011, Ministry of Industry and Information Technology announced that China will continue to encourage the energy-saving industries, to accelerate the development of recycling economics, recovery industries and energy-saving equipments. The supporting measures will be launched in order to reduce energy utilization and mitigate the release of harmful emissions.

Competitive Markets and Competition

Competition in the energy recovery system industry generally is divided by segment following the differentiation between low-grade energy recovery systems used for heat recovery applications (lower power extraction/generation capacity) and high-grade energy recovery systems used in industrial applications (higher power extraction/generation capacity).

Most of the players in the market are engineering firms that produce low-grade energy recovery systems for heat recovery applications mainly used by schools, hospitals and similar facilities. These products are generally undifferentiated and require lower levels of capital to develop. This type of energy recovery system is less complicated and requires significantly less technical qualifications to build than high-grade industrial energy recovery systems. As a result, this type of energy recovery system is cheaper to build and the barriers to entry into this market are lower than in the market for industrial energy recovery systems.

11

High-grade energy recovery systems for industrial applications, like ours, require large amounts of capital investment and high levels of expertise resulting in barriers to entry to most prospective market entrants. Because energy recovery systems of this type are highly customized based on the particular customer's need, manufacturers mainly compete based on their respective engineering capabilities. The manufacturers of industrial energy recovery systems generally fall into one of the following classifications:

|

|

1

|

Companies that specialize exclusively in energy recovery systems and account for the majority of the larger and more advanced production of energy recovery systems; and

|

|

|

2

|

Major equipment manufacturers for which energy recovery systems are not a key focus but which have the necessary resources to build effective systems.

|

Barriers to entry for the production of high grade energy recovery systems have resulted in a majority of the global sales for energy recovery systems being generated by a few large players. These industry participants focus on large scale projects leaving many intermediate opportunities for companies such as ours. The largest of these global players include Babcock-Hitachi (Japan), Foster Wheeler (USA), and Mitsubishi Heavy Industries (Japan). The major players in China include Dong Fang Boiler Group, Wuhan Boiler, Hangzhou Boiler Group, and Anshan Boiler.

We are principally engaged in designing, manufacturing, installing and servicing fully-customized energy recovery systems. While most of our competitors only offer one or two off-the-rack models, we develop products across varying specifications to best suit each customer's needs and objectives. Our products can recycle as much as 70% of the energy that would otherwise have been lost.

We believe that our products enable our customers to achieve substantial gains in energy efficiency and we continue to carry out research and development activities along with the design and engineering activities for customers’ projects to enhance efficiencies and decrease environmental impact. We employ approximately 100 highly trained engineers in our engineering team and are planning to hire more.

We have targeted our products at industrial sectors with significant amounts of waste heat. These sectors include:

|

|

¨

|

Chemical and Petrochemical Industries;

|

|

|

¨

|

Paper Manufacturing;

|

|

|

¨

|

Refining Industry; and

|

|

|

¨

|

Coking Industry.

|

We differentiate ourselves from our competitors by specializing in energy recovery systems and being one of the few players in the market capable of providing engineering, procurement and construction ("EPC") services for waste heat recovery (as further described below under the caption "Products and Technology"). Although we have the capacity and ability to provide EPC services, it was relatively rare that a customer requested such services. For example, we entered into three EPC contracts in 2007 and 2008. The number of EPC contracts increased to four and eight in 2009 and 2010, respectively. The revenue generated from EPC contracts increased from 43.6% to 56.2% of the total revenue in year 2010. We believe that we are currently a dominant player in energy recovery systems to sulfuric acid manufacturers in China. We believe that energy recovery systems for sulfuric manufacturing are the most difficult to design and engineer due to the strong corrosive character of the sulfuric acid.

By the end of 2010, phase one of our newly built first class manufacturing facility in Yangzhou, China was completed. Starting from 2011, our new facility will significantly boost our production capability, lower the production costs and provide us the opportunity to expand our participation as a supplier of high-performance energy recovery systems to industry located in China and around the world.

Design and Engineering

Our primary design and engineering facility is located in Shanghai, China. The facility employs approximately 100 engineers. Approximately 70 of the engineers engage in project design, customizing the energy recovery systems to meet the individual needs of various industries. The others manage our production processes at the facility. We believe that our engineering team is highly experienced and accomplished in its field.

12

Manufacturing

We operated a manufacturing facility, owned by Shanghai Si Fang through Shanghai Engineering in Shanghai, China. The facility occupies approximately 10 acres (4 hectares) of land with approximately 9,000 square meters of manufacturing space and storage. We employed a team of 230 skilled workers, technicians and quality assurance personnel at the manufacturing facility. Our employees utilize a vast array of equipment including lathes, drills, metal cutting machines, forging equipment, handling equipment (cranes), welding machines, and testing equipment. A majority of the equipment is leased from Shanghai Si Fang pursuant to the cooperative manufacturing agreement described above. This equipment will remain the property of Shanghai Si Fang when the agreement expires. Shanghai engineering does not own the facility but leases it from Shanghai Si Fang.

In August 2009, we started to build our new manufacturing base in Yangzhou Auto Industry Park, Jiangsu Province. The new factory will occupy approximately 37.5 acres (15 hectares) of land with approximately 90,000 square meters of manufacturing space and storage., with a total investment is about $60 million. Total registered capital of the Yangzhou Company is $20 million. One special railway is planned from Yizheng railway station leading directly to the plant. Meanwhile, there are three ports adjoining the Park: Yangzhou Port, Yizheng Liquid Dock of Nanjing Port Inc. and Yihua Port. Our objective is to construct a facility for the manufacturing of energy-saving and highly effective waste heat boilers, and also for the manufacturing of pressure vessels and other equipment, forming the capability of manufacturing Level-A boilers and Class I, II and III pressure vessels. Our plan is to establish CER (Yangzhou) as a world-class international manufacturing facility of waste heat equipment, in both products and technology. We plan to make highly efficient energy-saving products, using advanced manufacturing processes and equipment, We intend for this manufacturing facility to embody a completely new look of a modern factory, thus making the Company more competitive, while promoting the development of the local economy and further exploiting the manufacturing advantages in renewable energy equipment and waste heat recovery core equipment. In January 2011, phase one construction of the plant was completed. The phase one facility is about 14,000 square meters. Many advanced pieces of equipment have been installed in the new factory. The new facility significantly expands our ability to accept new orders and will speed delivery of large-scale waste heat systems for new and retro-fitted industrial plants located in China and overseas.

As a result, our production facilities are currently contained in both Vessel Works Division and CER Yangzhou. We will complete the transfer of the production function from Vessel Works Division to CER Yangzhou at the end of April 2011. Phase two is under construction and anticipated to be complete in 2012.

Marketing and Sales

We market and sell our products worldwide through our direct sales force, which is based in Shanghai, China. Our marketing programs include industrial conferences, trade fairs, sales training, and trade publication advertising. Our sales and marketing groups work closely with our design and engineering, and manufacturing groups to coordinate our product development activities, product launches and ongoing demand and supply planning. Primarily we sell our products directly to the end users of our energy recovery systems, but we also sell energy recovery systems to leading engineering firms who in turn sell them to their end users.

We plan on entering into marketing partnerships and licensing deals that will enable us to reach a boarder segment of the market. We believe that there is significant opportunity in international markets such as the Middle East, the United States, Europe and Latin America, and we intend to enter these markets through partnerships. Additionally, we will look to expand into new industrial sectors through partnerships with leading engineering firms that specialize in specific industry groups.

13

Products and Technology

We have four main service offerings available to our customers, of which the first three generate the majority of our revenue stream:

|

|

¨

|

Fabrication. We have highly-trained manufacturing teams capable of building high quality energy recovery systems in a timely fashion. All of our energy recovery systems are of modular design with a high degree of factory assembly. With modular construction, site welds on heat exchanger pressure parts are kept to a minimum. We design all energy recovery systems we manufacture to protect our brand. We collect a one-time fee for the fabrication of each of our units. Of the approximately 110 unique customers who have purchased energy recovery systems from us, more than 25% of them have also purchased some of the other three major services that we offer which are auxiliary to our fabrication services, or have returned to us for new projects.

|

|

|

¨

|

Design. Our primary product line of energy recovery systems can be designed to meet the specific needs of our customers. We typically focus on heavy industrial applications. In addition to the designing of energy recovery systems for our own customers, we occasionally are approached by and contract with third party manufacturers or engineering firms to design systems for their customers. This offers a peripheral revenue stream to supplement our core operations. We employ a flexible pricing scheme when designing for third parties that depends upon the size, application and deadline of the proposed energy recovery system.

|

|

|

¨

|

Implementation and EPC Projects. Similar to the revenue model employed for our design services, we either package the implementation (installation) of our energy recovery system with the design and fabrication of our units, or outsource this function to third party manufacturers for a service charge; this allows smaller third party manufacturers to convert fixed costs to variable costs, while offering us an ancillary revenue stream. We do not perform implementation services on a stand-alone basis. We also possess the resources, expertise and capabilities to act as the lead engineering procurement and construction contractor, overseeing the implementation of energy recovery systems for our customers. EPC services involve the whole process of the construction of projects from design, development, engineering, manufacturing up to installation.

|

|

|

¨

|

Maintenance. Our team is responsible for the overall maintenance of the energy recovery systems we install. In the event that major repairs are needed, the maintenance team is capable of rebuilding the equipment in order to repair or replace any necessary components. The maintenance team is contracted to service our own as well as other manufacturers' energy recovery systems. Our maintenance team charges an hourly fee for its services.

|

Our energy recovery systems represent a fully-customizable technology capable of meeting the varying needs of a diversified customer base. The systems are capable of recycling up to 70% of the energy that would otherwise be lost in customers' industrial processes, in many cases allowing our customers to recover their costs of the energy recovery system in energy savings within one to three years. The energy recovery systems can also capture and eliminate harmful particles, carbon dioxide, sulfur dioxide and other pollutants where the main industrial facilities release such harmful emissions.

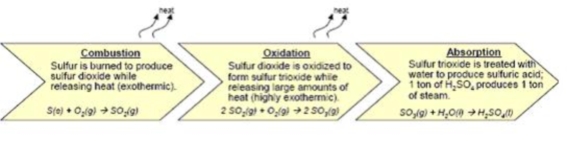

Our energy recovery systems are suitable for use in a wide range of industries, including chemical processing, papermaking, and oil and ethanol refining. The core technology is easily adaptable to meet a variety of different size facilities and types of plant design. Below is an illustration of our technology as it is implemented in the sulfuric acid production industry.

|

|

¨

|

Traditional Sulfuric Acid Production Process. The production of sulfuric acid involves highly exothermic chemical reactions. Most of the heat is released into the atmosphere through cooling towers without capturing any of the energy contained therein. Some of the heat from the production process is captured as steam, which the manufacturer can use to, for example, generate electricity. Without the use of an energy recovery system, the production of one ton of sulfuric acid will produce approximately one ton of steam.

|

14

|

|

¨

|

Sulfuric Acid Production Process with Energy Recovery System. The incorporation of an energy recovery system increases the manufacturer's ability to extract energy from the production process such that the production of one ton of sulfuric acid can produce between 1.3 and 1.65 tons of steam. In so doing, 94% of the heat that would have otherwise been released to the atmosphere is utilized to provide a larger quantity of steam that can be used in industrial applications. The harnessed steam can be used for various applications, most commonly to drive generator turbines to produce electricity. Doing so decreases the manufacturer's demand for externally produced energy as the manufacturer instead can use internally produced energy resulting from the energy recovery system's increased production and utilization of steam.

|

Customers

We have provided approximately 110 unique customers with energy recovery systems, and more than 25% of these customers have purchased multiple other products and services from us such as design and implementation services. Our customers are mainly industrial manufacturers, such as chemical plants, paper manufacturers and industrial engineering firms. Our energy recovery systems are currently deployed and being deployed in a variety of international markets, including Saudi Arabia, Egypt, Pakistan, Korea, Vietnam and Malaysia, as well as in 20 of China's 32 provinces, including Yunnan, Jiangsu, Shandong, Sichuan, Hunan and Hubei.

Because of the nature and long life of our energy recovery systems, a majority of our sales are from new customers when comparing our customer base from year to year. However, we do receive repeat business from previous customers, especially those in China, when they are expanding their capacities or building new plants. For the years ended December 31, 2009 and 2010, our five largest customers accounted for 69% and 60% of our sales, respectively. Receivables from these five customers were 66% and 5% of total accounts receivable at December 31, 2009 and 2010, respectively. Our large customers may not be the same from year to year. It represents the revenue recognized in excess of the amount billed based on the percentage of completion method. Therefore, we do not believe that we are dependent upon any specific major customer to continue our current level of sales.

Intellectual Property and Other Proprietary Rights

The Chinese State IPR Office has authorized and granted the following patents to Shanghai Engineering and CER Shanghai on various components of our energy recovery systems:

|

Patent Type

|

Patent Name

|

Expiration Date

|

||

|

Utility model

|

Drum-type sectional ache fire tube boiler made by sulphur

|

5/6/2013

|

||

|

Utility model

|

Double drum-type fire tube exhaust-heat boiler which shares one steam dome

|

11/6/2013

|

||

|

Utility model

|

Improvement of tube compensator breed which makes ache fume

|

11/6/2013

|

||

|

Utility model

|

Improvement of protective casing tube

|

11/6/2013

|

||

|

Utility model

|

Triple drum-type fire tube exhaust-heat boiler which shares one steam dome

|

1/30/2015

|

||

|

Utility model

|

Spray pump synthesizing tower

|

8/30/2017

|

||

|

Invention

|

Chlorosulfonic acid preparation new craftwork and equipment

|

8/30/2017

|

||

|

Utility model

|

Cement kiln forced-circulated waste heat recovery boiler

|

4/2/2019

|

||

|

Utility model

|

The center pipe smoke double disc regulator

|

4/16/2019

|

||

|

Utility model

|

|

Steam air reactor

|

|

3/28/2020

|

15

CER Shanghai has submitted the following patent applications to the Chinese State IPR Office, which are currently pending authorization:

|

Patent Type

|

Patent Name

|

Application Date

|

||

|

Utility model

|

Feed water type diluter

|

6/2/2010

|

||

|

Utility model

|

Inspection device for leaking

|

6/2/2010

|

||

|

Utility model

|

Steam drainage device

|

6/2/2010

|

Research and Development

We are focused on a strategy of utilizing our research and development capabilities to continuously improve the waste heat and emissions capture technology of our energy recovery systems. Our research and development efforts focus specifically on maximizing efficiency and reliability while minimizing the cost to customers. We have currently been focusing our efforts on new products with immediate demand in the markets such as capturing and reducing emissions released in various industrial processes, such as sulfur dioxide (a byproduct in sulfuric acid processes) and alkali (a byproduct in paper-making processes). We maintain strong relationships with many professional engineering firms in China that can provide technical support in the development process.

We employ approximately 100 highly trained engineers at our Shanghai, China facilities who are engaged in refining the core technology for our energy recovery systems, developing our intellectual property rights, enhancing energy efficiencies and decreasing environmental impact for our customers. Our engineers carry out development activities alongside with the design work for our customers’ projects and the expenses associated with our research and development activities are passed along to our customers as part of the price paid for our products and services. However, since expenses incurred in research and development are immaterial, we do not record research and development expenses as a separate line item in our financial statements. Shanghai Engineering has a portfolio of core Chinese patents on various components of our energy recovery systems as described above.

Our Business Strategy

We have established a three-phase growth strategy:

|

|

¨

|

Phase One. During the first phase of our growth strategy, we will continue to fulfill our current orders while growing our domestic Chinese business. During this time, we intend to establish long-term strategic purchasing agreements with suppliers that provide key raw materials.

|

|

|

¨

|

Phase Two. The second phase of our growth strategy involves increased expenditures that will support our growth. We have completed the first phase of the construction of our first owned manufacturing facility, which we believe will increase our profit margins and efficiency. We also intend to invest in specialized equipment to further increase the efficiency of our manufacturing process. While these capital expenditures are underway, we expect to incur separate (unrelated to any particular customer project) research and development expenditures to support an expansion into new sectors, such as coke refining and cement, including adding more specialized talents to our engineering and design team. We also anticipate recruiting an international sales and marketing team to assist in international market expansion.

|

|

|

¨

|

Phase Three. In the third phase of our growth strategy, we plan to complete the second phase of the construction of our first owned manufacturing facility to meet future demand. We also anticipate expanding our EPC business by continuing to increase the size of our engineering and design team. Finally, we intend to increase our international marketing efforts in the Middle East, Europe and the United States during this phase.

|

16

Raw Materials and Principal Suppliers

We do not currently have any long-term supply agreements. We do not believe that we are reliant on our current suppliers. We believe that we could substitute other suppliers if needed. Our five largest suppliers (by value) supplied approximately 29% of our raw materials in 2010.

Employees

As of December 31, 2010, we had approximately 470 employees, all of who are full time employees. Of these, approximately 100 are engineering and technical personnel. We expect to continue to add additional personnel, especially engineers, in 2011 and beyond to support our anticipated growth.

None of our employees is covered by a collective bargaining agreement. Each of our managerial, sales and administrative employees has entered into a standard form of employment agreement. All of our personnel who have access to our confidential information and technical know-how have entered into a separate agreement that contains covenants not to compete for 24 months following termination of employment and to maintain the confidentiality of certain proprietary information. We believe that our employee relations are good.

Governmental Regulation

The manufacture of boilers and pressure vessels used in our energy recovery systems is subject to licensing requirements imposed by the Chinese national government, as well as regional and local governments, depending on the type of license needed. Shanghai Si Fang conducted all our manufacturing operations before 2011 and obtained all required licenses. In January 2011, CER Yangzhou also obtained all required licenses and will take over all our manufacturing function starting approximately in May 2011. Boilers and pressure vessels manufactured without such licenses are not allowed to be sold in China. To qualify for a license, a manufacturer must (a) be a legal entity registered with the local government; (b) have a production facility, equipment, technical expertise, and inspection and testing capabilities suitable for producing boilers and pressure vessels; (c) establish and maintain an effective quality assurance system; and (d) manufacture the boilers and pressure vessels in accordance with the requirements of the applicable safety and technical standards.

Our operations are also subject to governmental regulations applicable to any business such as general permitting, licensing and registration. For example, the installation of energy recovery systems at our clients' locations requires a construction project building permit from the applicable regional government.

Compliance with Environmental Laws

We belong to what is known as the "machinery manufacturing industry" in China which industry is considered not to generate exhaust gas, waste liquor or waste residue during manufacturing. Therefore, generally, our manufacturing operations are not subject to any material environmental regulations.

The installation and construction of our energy recovery systems at our clients' locations are subject to environmental laws applicable to construction projects generally. As part of the procedure for obtaining a construction project building permit, we must submit an environmental impact statement for each construction project which assesses the pollution the projects is likely to produce, its impact on the environment, and which stipulates preventive and curative measures. The issuance of a building permit is conditioned on the approval of the environmental impact statement.

17

There are emissions standards applicable to the operation of coal-burning, oil-burning or gas-fired boilers (China National General Standard GWPB 3-1999). We do not believe that these emission standards are applicable to the boilers included within our energy recovery systems because our boilers are not independently emitting any emissions as they are being heated by industrial processes as opposed to by coal, oil or gas.

Item 1A Risk Factors

There are numerous and varied risks that may prevent us from achieving our goals, including those described below. You should carefully consider the risks described below and the other information included in this Annual Report on Form 10-K, including our financial statements and related notes. Our business, financial condition and results of operations could be harmed by any of the following risks. If any of the events or circumstances described below were to occur, our business, financial condition and results of operations could be materially adversely affected. As a result, the trading price of our common stock could decline, and investors could lose part or all of their investment.

Risks Related to Our Business

Our limited operating history may not serve as an adequate basis to judge our future prospects and results of operations.

Our limited operating history and the unpredictability of our industry make it difficult for investors to evaluate our business and future operating results. An investor in our securities must consider the risks, uncertainties and difficulties frequently encountered by companies in new and rapidly evolving markets. The risks and difficulties we face include challenges in accurate financial planning as a result of limited historical data and the uncertainties resulting from having had a relatively limited time period in which to implement and evaluate our business strategies as compared to companies with longer operating histories.

Our dependence on a limited number of customer segments may cause significant fluctuations or declines in our revenues.

We currently sell a substantial portion of our energy recovery systems to companies in either the chemical or paper manufacturing sectors. Consequently, any one of the following events may cause material fluctuations or declines in our revenues and have a material adverse effect on our results of operations:

|

|

¨

|

Decreased demand for the products of these manufacturing sectors;

|

|

|

¨

|

Advances in the manufacturing processes of these sectors that could eliminate the economic feasibility of our technology; and

|

|

|

¨

|

Failure to successfully implement our systems for one or more customers within a particular sector could adversely affect the reputation of our products and services have as a viable option for other companies within that sector.

|

We face risks associated with the marketing, distribution and sale of our energy recovery systems, and if we are unable to effectively manage these risks, they could impair our ability to expand our business.

The marketing, distribution and sale of our products expose us to a number of risks, including, but not limited to:

|

|

¨

|

Increased costs associated with maintaining marketing efforts in various parts of China and various countries;

|

|

|

¨

|

Marketing campaigns that are either ineffective or negatively perceived in one or more countries and/or across one or more industry sectors;

|

|

|

¨

|

Difficulty and cost relating to compliance with the different commercial and legal requirements of the overseas markets in which we offer our products;

|

|

|

¨

|

Inability to obtain, maintain or enforce intellectual property rights; and

|

18

|

|

¨

|

Trade barriers such as export requirements, tariffs, taxes and other restrictions and expenses, which could increase the prices of our products and make us less competitive in some countries.

|

If we are unable to manage these risks, we may be unable to expand our business into new countries or industries, or expansion may become costlier than expected.

The success of our business depends on our ability to attract highly qualified personnel without whom we would be unable to maintain the quality of our services, and our ability to retain them, including senior management and other key personnel who may terminate their employment with us at any time causing us to lose experienced personnel and to expend resources in securing qualified replacements.

We depend substantially on the current and continued services and performance of our senior management and other key personnel. Loss of the services of any of such individuals would adversely impact our operations. In addition, we believe that our technical personnel represent a significant asset and provide us with a competitive advantage over many of our competitors and that our future success will depend upon our ability to hire and retain these key employees and our ability to attract and retain other skilled financial, engineering, technical and managerial personnel. As our industry continues to grow, we expect increased competition for qualified personnel. In the event that we are unable to retain or attract the same level of qualified personnel as in the past on the current terms of employment, we may face higher labor costs or lower productivity. If our productivity or the quality of the services we provide decrease, our business may suffer negative consequences such as a reduction in our rate of securing and completing customer engagements. Increased costs of labor and reduced throughput would negatively affect our profitability.

We do not have currently any employment agreements with our key personnel, including our chief Executive Officer; therefore such key personnel may voluntarily terminate their employment at any time. There is no guarantee that we will be able to retain the services of these, or other, individuals on reasonable terms or at all. We do not currently maintain any "key man" life insurance with respect to any of such individuals.

Our inability to obtain capital, use internally generated cash, or use shares of our capital stock or debt to finance future expansion efforts could impair the growth and expansion of our business.