Attached files

| file | filename |

|---|---|

| EX-32.2 - Guanwei Recycling Corp. | v216754_ex32-2.htm |

| EX-10.4 - Guanwei Recycling Corp. | v216754_ex10-4.htm |

| EX-32.1 - Guanwei Recycling Corp. | v216754_ex32-1.htm |

| EX-31.1 - Guanwei Recycling Corp. | v216754_ex31-1.htm |

| EX-31.2 - Guanwei Recycling Corp. | v216754_ex31-2.htm |

| EX-10.10 - Guanwei Recycling Corp. | v216754_ex10-10.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

|

¨

|

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

For the fiscal year ended December 31, 2010

|

¨

|

TRANSITION REPORT UNDER SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

Commission File Number: 000-53825

GUANWEI RECYCLING CORP.

(Exact name of registrant as specified in its charter)

|

Nevada

|

98-0669936

|

|

|

(State or other jurisdiction

|

(I.R.S. Employer

|

|

|

of incorporation or organization)

|

Identification No.)

|

Rong Qiao Economic Zone, Fuqing City

Fujian Province,

People’s Republic of China 350301

(Address of principal executive offices) (Zip Code)

86-591 8539 2532

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act: None

Securities registered under Section 12(g) of the Act:

Common stock, par value $0.001 per share

(Title of class)

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

¨ Yes R No

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act.

o Yes R No

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

R Yes o No

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulations S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

o Yes R No

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. o

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

|

Large accelerated filer

|

o

|

Accelerated filer o

|

|

|

|

|

|

Non-accelerated filer

|

o (do not check if a smaller reporting company)

|

Smaller reporting company R

|

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act).

o Yes R No

Revenues for year ended December 31, 2010: $47,534,645.

The aggregate market value of the registrant’s voting common stock held by non-affiliates as of June 30, 2010 based upon the closing price reported for such date on the NASDAQ Capital Market was approximately $31,760,000.

As of March 25, 2011, there were 20,000,006 shares of the registrant’s common stock outstanding.

TABLE OF CONTENTS

|

PART I

|

|

|

|

|

|

Item 1. Business.

|

1

|

|

Item 1A. Risk Factors.

|

9

|

|

Item 2. Properties.

|

18

|

|

Item 3. Legal Proceedings.

|

18

|

|

PART II

|

|

|

Item 5. Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities.

|

19

|

|

Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations.

|

20

|

|

Item 8. Financial Statements and Supplementary Data.

|

28

|

|

Item 9. Changes in and Disagreements With Accountants on Accounting and Financial Disclosures.

|

28

|

|

Item 9A. Controls and Procedures.

|

28

|

|

PART III

|

|

|

Item 10. Directors, Executive Officers, and Corporate Governance.

|

30

|

|

Item 11. Executive Compensation.

|

33

|

|

Item 12. Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters.

|

34

|

|

Item 13. Certain Relationships and Related Transactions, and Director Independence.

|

36

|

|

Item 14. Principal Accounting Fees and Services.

|

37

|

|

PART IV

|

|

|

Item 15. Exhibits, Financial Statement Schedules.

|

39

|

PART I

Item 1. Business

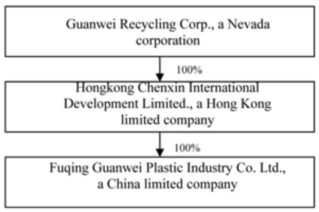

Except as otherwise indicated by the context, references in this Annual Report to “we”, “us”, “our” or the “Company” are to the consolidated businesses of Guanwei Recycling Corp. and its wholly-owned direct and indirect subsidiaries, Hongkong Chenxin International Development Limited, a Hong Kong limited company (“Chenxin”) and Fuqing Guanwei Plastic Industry Co. Ltd., a China limited company (“Guanwei”), except that references to “our Common Stock”, “our shares of Common Stock” or “our capital stock” or similar terms shall refer to the common stock, par value $0.001 per share, of Guanwei Recycling Corp., a Nevada corporation (the “Registrant”). “China” or “PRC” refers to the People’s Republic of China. References to “RMB” refer to the Chinese Renminbi, the currency of the primary economic environment in which the Company operates.

History and Organizational Structure

The Registrant was incorporated as MD Holdings Corp. on December 13, 2006 in Nevada, and was engaged in the business of providing traditional mortgage brokerage services through its wholly-owned subsidiary, MD Mortgage Corp., a Maryland Corporation (“MD Mortgage”). It was unsuccessful in developing a profitable business and ceased its operations effective December 31, 2008. On November 5, 2009, the Registrant consummated a share exchange transaction (the “Share Exchange”), pursuant to which the Registrant became the 100% parent of Chenxin and assumed the operations of Chenxin and its subsidiary, Guanwei. Prior to the Share Exchange, Chenxin was 100% owned by Fresh Generation Overseas Limited, a British Virgin Islands corporation (“Fresh Generation”). Pursuant to the Share Exchange, Fresh Generation became the holder of approximately 60% of our Common Stock. Additional information regarding the Share Exchange can be found in the Registrant’s Current Report on Form 8-K filed with the U.S. Securities and Exchange Commission (“SEC”) on November 6, 2009.

Guanwei was founded as a limited company in China in April 2005 with registered capital of RMB 5 million (approximately $0.62 million) and then increasing to RMB 10 million (approximately $1.46 million) in January 2006. Since inception, it has been principally engaged in the manufacture and distribution of low density polyethylene (“LDPE”) and other recycled plastics products, using imported raw material in the form of plastic waste. On November 22, 2008, Guanwei was acquired by Chenxin, a holding company incorporated in Hong Kong, and became a wholly-owned by foreign investment enterprise (“WOFIE”) under PRC law. Guanwei is the sole operating subsidiary of Chenxin.

On December 16, 2009, the Registrant filed Articles of Merger with the Secretary of State of the State of Nevada, pursuant to which the Registrant’s newly formed and wholly-owned subsidiary, Guanwei Recycling Corp., a Nevada corporation, merged with and into the Registrant. Upon the effectiveness of the merger, the name of the Registrant was changed from MD Holdings Corp. to Guanwei Recycling Corp. in accordance with Nevada Revised Statutes §92A.180. The Registrant effected the name change to better reflect the nature of its new business operations following the Share Exchange. The merger, along with the Plan of Merger and Articles of Merger, is disclosed in the Registrant’s Current Report on Form 8-K filed with the SEC on December 22, 2009. Effective December 28, 2009, the Registrant received a new trading symbol, GURC.OB, and a new CUSIP number for its Common Stock. On March 30, 2010, the Registrant’s Common Stock began trading on the NASDAQ Capital Market under the symbol “GPRC.”

The corporate structure of the Registrant is as follows:

1

The Registrant’s corporate offices are located at Rong Qiao Economic Zone, Fuqing City, Fujian Province, People’s Republic of China, 350301.

General Business Overview

The following is a description of the business operations of the Registrant, including its wholly-owned and sole operating subsidiary, Guanwei.

Based in Fuqing City, in the Fujian Province of China, Guanwei is one of few plastic recyclers in China to import primarily most of its raw materials (i.e. plastic waste) from foreign suppliers (primarily Germany), where the cost of processing plastic waste is significantly higher than in China. Guanwei’s products are sold to customers in a wide range of industries, including shoe manufacturing, architecture and engineering products, industrial equipment and supplies, and chemical and petrochemical manufacturing. Guanwei operates its business in compliance with the highest environmental standards in order to meet the stringent requirements of both German and Chinese authorities. In fact, on June 18, 2009, Umweltagentur Erftstadt, a provider of certification services, issued its audit report on the compliance of Guanwei's operations with German regulations regarding pollution and environmental controls. Based upon its audit, Umweltagentur Erftstadt determined that Guanwei should be issued a certificate (a “Compliance Certificate”) as to such compliance. Holding a Compliance Certificate permits a plastics recycler to purchase plastic waste directly from German suppliers.

The Company is organized as a single business segment and is committed to sourcing and developing innovative ideas and markets for recycled materials, and concentrates on transforming plastic waste into useful plastic grains. Its mission is to be an environmentally conscious, profitable manufacturer of plastics products of the highest quality. Guanwei procures raw material in the form of unrecycled plastic waste from its suppliers and uses this material to manufacture recycled plastic grains, which are then sold to manufacturers of consumer products in various industries. Guanwei specializes in the production of various recycled plastics products, the most important of which is LDPE. In the last four years, Guanwei has developed four distinct grades of LDPE plastic grains, which are sold to clients to be manufactured into a broad range of end products. Guanwei currently sells to over 300 customers in more than 10 industries, ranging from shoe manufacturing, architecture and engineering, industrial equipment and supplies, and chemical and petrochemical manufacturing. Guanwei’s LDPE products in particular are widely used in the manufacturing of chemical and functional fibers, and is the main raw material for shoe soles, insulation material, fire-proofing and water-proofing material, and foam.

Market and Industry

According to the Plastic Industry Statistics & Research Report (2008), since 2004, with national production capacity exceeding 20 million tons, China has become the second largest plastics products manufacturing country in the world after the United States. China’s plastics industry has benefited greatly from its low production and labor costs, as the manufacturing and recycling of plastics products have been outsourced from higher-cost countries to China and other low-cost countries. The lower production costs have allowed the plastics industry worldwide to experience strong growth in sales over the last several years. In the US and Europe, plastics industries out-perform overall manufacturing industries and are a strong force in international markets. According to the Plastic Industry Statistics & Research Report (2008), the worldwide average annual growth rate of the plastics industry from 1999 to 2005 was 5.02%, while the average GDP growth rate for the same period was 2.43%. In China, the growth rate of domestic plastic consumption from 2001 to 2005 exceeded 19% annually, while the Chinese GDP growth rate averaged 9.5% for the same period.

2

The Plastic Industry Statistics & Research Report (2008) further states that, in particular, China’s plastics manufacturing industry experienced an annual growth rate of greater than 18% from 1990 to 2001, and in 2008 the growth rate was 11%. According to the website of the Chinese national plastic industry (www.51plas.com), in 2007, 14,592 Chinese plastic manufacturers realized a total profit of RMB 802 billion (approximately $110 billion), and 16,300 manufacturers realized a total profit of RMB 964 billion (approximately $141 billion) in 2008. China consumed more than 50 million tons of plastics in 2008, 24% of which was produced by recycled plastics.

There are seven types of plastic polymers, each with specific properties, which are used worldwide for various packaging applications. Each group of plastic polymers can be identified by its Plastic Identification Code (PIC), which is usually a number or a letter abbreviation. The PIC appears inside a three-chasing arrow recycling symbol. The symbol is used to indicate whether the plastic can be recycled into new products. The PIC identification system was introduced by the Society of the Plastics Industry, Inc., which provides a uniform system for the identification of different polymer types and helps recycling companies to separate different plastics for reprocessing. Manufacturers of plastic products are required to use PIC labels in some countries/regions and can voluntarily mark their products with the PIC where there are no requirements. Consumers can identify the plastic types based on the codes usually found at the base or at the side of the plastic products, including food/chemical packaging and containers.

The seven types of plastics polymers used in packaging are listed in the chart below, along with a brief description of the properties and common applications of each. A more detailed description of each polymer type follows the chart.

|

Plastic

Identification Code

|

Type of plastic

polymer

|

Properties

|

Common Packaging Applications

|

|||

|

Polyethylene Terephthalate (PET, PETE)

|

Clarity, strength, toughness, barrier to gas and moisture.

|

Soft drink, water and salad dressing bottles; peanut butter and jam jars

|

|||

|

High Density Polyethylene (HDPE)

|

Stiffness, strength, toughness, resistance to moisture, permeability to gas.

|

Milk, juice and water bottles; trash and retail bags.

|

|||

|

Polyvinyl Chloride (PVC)

|

Versatility, clarity, ease of blending, strength, toughness.

|

Juice bottles; cling films; PVC piping

|

|||

|

Low Density Polyethylene (LDPE)

|

Ease of processing, strength, toughness, flexibility, ease of sealing, barrier to moisture.

|

Frozen food bags; squeezable bottles, e.g. honey, mustard; cling films; flexible container lids.

|

3

|

Polypropylene (PP)

|

Strength, toughness, resistance to heat, chemicals, grease and oil, versatile, barrier to moisture.

|

Reusable microwaveable ware; kitchenware; yogurt containers; margarine tubs; microwaveable disposable take-away containers; disposable cups and plates.

|

|||

|

Polystyrene (PS)

|

Versatility, clarity, easily formed

|

Egg cartons; packing peanuts; disposable cups, plates, trays and cutlery; disposable take-away containers;

|

|||

|

|

Other (often polycarbonate or ABS)

|

|

Dependent on polymers or combination of polymers

|

|

Beverage bottles; baby milk bottles; electronic casing.

|

Polyethylene terephthalate (PET)

PET is among the most-recycled polymers worldwide. Its barrier properties make it the material of choice for mineral water and carbonated drink bottles, and it can be recycled a number of times. The material is also used to make food trays, and is commonly found as a laminate in films. A high proportion of mixed bottles, typically PET combined with HDPE, are exported from China.

High-density polyethylene (HDPE)

HDPE is most commonly used for milk containers and bleach and other cleaning product containers, and is also found in films and some thin-gauge carriers and fresh produce bags. As with PET, price is dictated by quality and markets offer a wide range of prices according to the level of purity of the polymer. HDPE is a versatile polymer that can be manipulated to control transparency.

Polyvinyl chloride (PVC)

PVC is a popular polymer for a range of applications, including food packaging, where it is found in some thermoformed trays. It is also used in the manufacture of plastic wrapping film. PVC can contaminate some PET products, however, which impedes the collection and thus the recycling of PET. Through the introduction of reclamation facilities that focus solely on plastics and recycling plastic products, more color and polymer separation is possible, which would help develop the rates of recycling of all polymers, including PVC.

Low-density polyethylene (LDPE)

LDPE is used in food trays, but a more common application is in wrapping films and bags because it is very flexible. It is easily cleaned, has strong impact resistance and is unreactive at room temperature in the absence of a strong oxidizing agent. LDPE can withstand moderately high temperatures, does not absorb moisture and is chemical and corrosion resistant. LDPE’s tensile force is lower than that of HDPE and its resilience is higher. The collection of LDPE is particularly challenging given the relatively low-value of its end products, which can make the recycling of LDPE less cost-efficient, so its recycling rates are lower than other polymers.

4

Polypropylene (PP)

PP comprises a large proportion of mixed plastics products that are recycled for collection, other than plastic bottles. PP is widely used in packaging in food containers and trays, screw tops and as a film. It can be easily recovered and recycled into a wide range of applications. Its recycling rates are typically quite high.

Polystyrene (PS)

PS is found in yogurt containers and food trays, and in its expanded form, in protective packaging and hot drinks cups. Research has shown that PS comprises a small part of the waste stream, but as with other rigid packaging plastics, it is likely to form part of future mixed plastics recycling trials, which focus on new ways to recycle and to enhance the collection of recyclable products.

Recycling Awareness

There is a growing awareness in the global economy of issues surrounding waste management, and recycling processes and recycled products are being developed to address these issues. The advantages of recycling waste material, much of which consists of metal, paper, glass and plastic packaging, are being increasingly recognized by the global community. The environmental benefits of recycled plastics products are well known, and in addition, our management’s experience indicates that recycled plastics can be 40% cheaper than virgin polymers. Recycling rates in China vary among the different polymer types, but the overall trend for each polymer type is increasing.

Currently, most of the recycled plastics products manufactured in China use imported raw material in the form of plastic waste. We believe that there is great opportunity to further develop the plastics recycling market in China by relying on domestic suppliers of raw material. According to the Plastics Industry Statistics & Research Report (2008), in 2007, only approximately 14 million tons, or 24% of the total amount of plastic being consumed in China, was recycled. The total value of the unrecycled plastic waste in China is currently estimated to exceed RMB 28 billion (approximately $4.1 billion) per year. Guanwei has no current plans to use domestic suppliers as the waste classification and sorting techniques used abroad result in higher quality raw material.

Guanwei’s Recycling Process

Guanwei’s plastics recycling process begins with procuring raw material, which it sources primarily from Europe and China. All the raw material Guanwei purchases is previously unrecycled (i.e. virgin) plastic waste, making it a strong plastic that is most suitable in the manufacturing of Guanwei’s plastic grains.

The raw material is shipped directly from the supplier to Guanwei’s 64,000 square meter raw material storage and manufacturing plant in special containers which are approved by the Chinese government. Once in Guanwei’s facility, the plastic waste is then classified and sorted by hand based on polymer type and color. Guanwei has over 200 workshop employees who help sort raw material and who are paid per piece in order to increase productivity. Guanwei focuses on recycling of LDPE products, so the non-LDPE materials are sorted out first, which accounts for approximately 9% of the raw material. This non-LDPE material is packed and sold to manufacturers who specialize in plastic production using the respective materials.

After the LDPE material is sorted by color, it is sent to the smashing workshop, where it is smashed and cut into pieces by one of Guanwei’s eight smashing machines. The material is then washed and cleaned at least two to three times in order to eliminate impurities. This enhances the whiteness of the material, which results in a higher grade end-product. Once washed, the material is packed into square containers and sent to the plastic grain manufacturing area of the workshop, where there are 32 plastic grain machines. The material is fed into the grain machines, which break down the material and form it into small grains of recycled plastic, which are then sold to consumers in various manufacturing industries.

The waste water from the washing process is treated in Guanwei’s sewage treatment area, which comprises over 4,800 square meters. The water is discharged into rectangular sediment pools through a fence, which eliminates any large pieces of waste. Most of the inorganic suspended particles and insoluble organic material are separated out in the sedimentation pool. Each sediment pool has a sewage pumps for condensing the inorganic material into sludge, which is then dried and used as compost. The waste water is then run through a reaction pool, where the coagulant agents PAC and PAM are added. The water is then processed again in the sediment pool before it is sand filtered and run back to the workshop for re-use.

5

Products

Guanwei currently manufactures a number of recycled plastics products made from LDPE, and is one of the largest manufacturer of recycled LDPE in China. LDPE is easily processed and is defined by a density range of 0.910-0.940 g/cm3. It is moisture resistant and can withstand continuous temperatures of 175°F, and can withstand temperatures of nearly 200° F for short periods of time. LDPE is chemical and corrosion resistant. It has high resilience and low density, making it an extremely light weight and flexible plastic. It also meets food handling guidelines and is easily cleaned, and therefore it is ideal for food wraps and films.

LDPE can be produced in both translucent or opaque varieties, and the principal difference between virgin LDPE and recycled LDPE is that recycled LDPE cannot be completely transparent. Some manufacturers have strict color requirements, so they will not purchase recycled LDPE. However, recycled LDPE is attractive to manufacturers without color requirements, as the selling price of virgin plastic in China can be as high as RMB 16,500 (approximately $2,475) per ton, 40% higher than recycled LDPE.

Guanwei produces four types of LDPE plastic grains. The grade is determined by the color of the plastic grain, with higher grade denoting that the grain is whiter. Higher grade plastic grains are more expensive.

|

•

|

Grade A

|

This is a white LDPE grain and accounts for approximately 20% of Guanwei’s sales.

|

|

•

|

Grade B

|

This is a white LDPE grain and accounts for approximately 30% of Guanwei’s sales.

|

|

•

|

Grade C

|

This is a white LDPE grain and accounts for approximately 20% of Guanwei’s sales.

|

|

•

|

Grade D

|

This is a black LDPE grain and accounts for approximately 30% of Guanwei’s sales.

|

Currently, the demand for Guanwei’s products exceeds the amount Guanwei is able to produce. Therefore, Guanwei does not currently have any plans to develop new products. However, Guanwei intends to enhance its manufacturing process and increase its training of more skilled workers, and thereby increase productivity.

All of Guanwei’s products are manufactured in its 64,000 square meter storage and manufacturing facility located in Fuqing City. Guanwei has a sewage treatment area for processing the waste water used in the manufacturing process, which exceeds 4,800 square meters.

Raw Materials and Major Suppliers

Because an important step in the recycling of plastic waste is sorting and classifying the raw material, Guanwei obtains most of its raw material from foreign suppliers (primarily in Europe), where it can obtain raw material which consists solely of unrecycled plastic, and where the sorting and classification techniques are superior to those used in China. Guanwei’s primary suppliers during 2009 and 2010 are primarily located in Europe. Guanwei is one of the few plastics importer-manufacturers in China with a Compliance Certificate from Unweltagentur Erftstadt for meeting certain pollution and environmental standards, which allows Guanwei access to German suppliers. Guanwei has entered into certain long-term supply contracts with its suppliers in Europe to purchase raw materials at prices to be determined monthly.

The following table sets out our major suppliers of raw materials for recycled LDPE and non-LDPE materials for the fiscal years ended December 31, 2010 and 2009.

6

|

As a Percentage of Our

Purchases of Raw Materials

|

||||||||

|

Fiscal Year Ended

December 31,

|

||||||||

|

2010

|

2009*

|

|||||||

|

Supplier A

|

21.6

|

%

|

6.1

|

%

|

||||

|

Supplier B

|

19.7

|

%

|

46.5

|

%

|

||||

|

Supplier C

|

18.8

|

%

|

-

|

%

|

||||

|

Supplier D

|

11.7

|

%

|

10.4

|

%

|

||||

|

Supplier E

|

-

|

%

|

10.2

|

%

|

||||

|

Supplier F

|

-

|

%

|

13.0

|

%

|

||||

|

Supplier G

|

14.4

|

%

|

-

|

%

|

||||

|

|

* The percentages in this column differ from those disclosed for 2009 in the Annual Report on Form 10-K for the year ended December 31, 2009 (the “2009 10-K”) because the percentages in the 2009 10-K were by import agent, whereas the percentages in the table above are listed by individual suppliers.

|

The raw materials are transported to the port of Jiangyin in China by ocean freighters. As the importer of the raw materials, Guanwei covers the cost of shipping from the supplier to Guanwei’s facility. Each imported container weighs about 20 tons, and per container shipping costs between $635 - $1,750, including insurance. The raw materials are then transported from the port in Jiangyin to Guanwei’s facility by truck at a cost of approximately $135 per container. Each container is subject to an import tax imposed by the Chinese government of 6.5% of the value of the goods and is also subject to a value-added tax of 17%.

Importers of plastic waste into the PRC are subject to an import quota regulated by the Ministry of Environmental Protection. Guanwei has been approved for an import quota of 24,000 tons of plastic waste per year, and for a period of 10 years, Guanwei has been permitted use of the 35,000 tons per year import quota granted to Fuqing Huan Li Plastics Company Limited (“Huan Li”) at no cost pursuant to the agreement dated November 1, 2008. Huan Li has not had any significant operations since 2005, but its import quota remains valid. Chen Min, the Registrant’s Chief Executive Officer, is the Chief Executive Officer, Chairman of the Board of Directors, and legal representative, with the power to represent and act on behalf, of Huan Li.

Due to the fact that Huan Li has no material operations, Guanwei could apply for official transfer of Huan Li’s import quota to Guanwei. As Guanwei’s operations expand, the Company has applied to the relevant government agencies for an increase in its import quota for plastic waste. Pre-approval for the application has already been received from the Development Council of the Fuqing Rongqiao Economic Zone Authority and the application has been forwarded for further processing to the General Administration of Quality Supervision, Inspection and Quarantine of the PRC, the General Administration of the PRC and the Ministry of Environmental Protection of the PRC. It is anticipated that the full approval process will take approximately one year. If successful, the Company expects to increase its import quota to 150,000 tons from its current import quota of 24,000 tons in July 2011.

Product Sales, Distribution and Marketing

Guanwei has a sales team of six people, led by Mr. Gao Juguang, an industry veteran with over 15 years of plastic sales experience. The Company is focused on diversifying its client base and increasing its sales volume to the infrastructure-building industry. Mr. Gao and the sales team work toward these goals by developing new client relationships through site visits, personal telephone calls and presentations and presenting product samples to the potential customers. Guanwei also relies on word-of-mouth to strengthen its reputation and secure sales from local customers. Due to its product quality and reputation, Guanwei has experienced a great deal of success securing regular customers after their first usage of the products.

Guanwei sells its products directly to end-users of the plastic grains, many of whom contact Guanwei directly for pricing quotes. Guanwei does not advertise or promote its products heavily, as the demand for the products currently exceeds supply. The Fujian Province, where Guanwei’s manufacturing facilities are located, is one of the largest shoe-manufacturing bases in China. Guanwei sells between 30% to 50% of its product to these shoe manufacturers, many of whom are located within 200 km of Guanwei’s facilities.

All of Guanwei’s customers pre-pay for the products they purchase and the price includes all shipping and transportation costs. Guanwei typically sells its products on a purchase order basis, but occasionally enters into one-year supply agreements with customers. The purpose of such agreements is to set the prices at which products are to be sold to such customers during the following year. The customer base is spread across different geographic markets and industries, such as shoe manufacturing, construction material manufacturing (such as fire- and water-proofing material and plastic pipes), and outdoor furniture manufacturing. No single customer represents greater than five percent of our sales volume or net revenue. Guanwei does not foresee any difficulties in sales as it is well-insulated against fluctuating demands in any one industry and demand currently exceeds supply.

Competition

Guanwei has several competitive advantages over its competitors, including the following:

7

Experienced management team

Guanwei’s senior management team has extensive business and industry experience, which has been instrumental in the development of Guanwei’s strong supplier and customer relationships and manufacturing processes. For additional information regarding Guanwei’s management team, please see the description of directors and management later in this Annual Report.

Well-established manufacturing capabilities

In China, the vast majority of plastic recycling companies are small-scale craftsmen shops lacking the capacity to properly process raw materials, deal with sewage treatment issues and meet required environmental standards. In comparison, Guanwei has a large, 64,000 square meter storage and manufacturing facility in which it produces various plastics products, and also has a sewage treatment facility that is able to filter and process the waste products resulting from the manufacturing. Guanwei’s production capacity is currently 50,000 tons annually, based on two shifts. Adding one additional shift per day would allow Guanwei to reach a full capacity of 65,000 tons. In 2010, Guanwei sold 41,478 tons of manufactured recycled LDPE. Additionally, production costs for both of these companies are higher than Guanwei’s because they purchase their raw materials from wholesalers in Hong Kong, whereas Guanwei imports almost all of its raw materials directly from suppliers. Furthermore, Guanwei is the only LDPE importer in China with recycled plastic manufacturing capabilities, and one of the few plastics manufacturers in China with a Compliance Certificate from Umweltagentur Urftstadt for meeting certain pollution and environmental standards, as discussed further below.

Steady supply of imported raw material and no middlemen

Guanwei is a forerunner among imported plastic waste processors and plastic material manufacturers. It has a steady supply of raw material from suppliers located throughout Europe and elsewhere outside China. The imported raw material is of a high quality, allowing Guanwei to benefit from efficiencies in the manufacturing of its products. Additionally, Guanwei imports the raw material directly, which cuts costs that would otherwise be paid to an importer, and Guanwei is located near a major port, so freight costs are kept low.

Broad range of end-users

The Company sells its plastics products to over 300 customers in over 10 industries. Its products are used to produce a wide variety of end products, including shoe soles, outdoor furniture, and construction equipment. The Company intends to focus on expanding further into the construction equipment industry because the Chinese government’s stimulus plan has substantially increased infrastructure construction in China. The Company is well insulated from fluctuating market demands in any one industry due to its diverse client base.

Compliance Certificate From Umweltagentur Erftstadt Regarding German Environmental Standards

Umweltagentur Erftstadt provides certificates of approval for certain plastics manufacturers which meet strict German environmental standards. Manufacturers are subject to inspections relating to air, water and noise discharge. German suppliers are only allowed to sell plastics waste to manufacturers who have this certificate. Guanwei is one of only several Chinese importers and manufacturers with this Compliance Certificate.

Employees

Guanwei currently has 508 full-time employees working in the workshops and 37 employees in management positions. Guanwei has no part-time employees. We have a labor contract with each employee as required by law in the PRC. The labor contract mainly includes working content, contract period, working time, payment and other terms.

Costs and Effects of Compliance with Environmental Laws and Other Regulations

Currently, Guanwei’s manufacturing processes are in compliance with all Chinese laws and environmental standards. Guanwei is not aware of any other governmental approvals required for any of its products or manufacturing processes.

8

Research and Development

Guanwei does not currently have plans to develop new products because the demand for LDPE plastic grains already exceeds our manufacturing capabilities. As the performance was deemed unsatisfactory, Guanwei has abandoned the test-use of Ethylene-Propylene-Diene Monomer (EPDM), which is a cleaning solvent which was being tested in 2009 for use as an additive in the smashing and cleaning process to improve the cleanliness of the end product. There are nominal costs associated with our research and development activities.

Item 1A. Risk Factors.

The financial condition, business, operations, and prospects of the Company involve a high degree of risk. You should carefully consider the risks and uncertainties described below, which constitute the material risks relating to the Company, and the other information in this Annual Report. If any of the following risks are realized, the Company’s business, operating results and financial condition could be harmed and the value of the Company’s stock could suffer. This means that investors and shareholders of the Company could lose all or a part of their investment.

RISKS RELATING TO THE PEOPLE’S REPUBLIC OF CHINA

The operations of Guanwei, our sole operating subsidiary, are wholly conducted in China. Accordingly, its businesses, financial condition and results of operations may be influenced by the political, economic and legal environments in the PRC and by the general state of the PRC economy.

Certain Political and Economic Considerations Relating to China Could Adversely Affect Our Company.

The PRC is transitioning from a planned economy to a market economy. While the PRC government has pursued economic reforms since its adoption of the open-door policy in 1978, a large portion of the PRC economy is still operating under five-year plans and annual state plans. Through these plans and other economic measures, such as control on foreign exchange, taxation and restrictions on foreign participation in the domestic market of various industries, the PRC government exerts considerable direct and indirect influence on the economy. Many of the economic reforms carried out by the PRC government are unprecedented or experimental, and are expected to be refined and improved.

Other political, economic and social factors can also lead to further readjustment of such reforms. This refining and readjustment process may not necessarily have a positive effect on our operations or future business development. Our operating results may be adversely affected by changes in the PRC’s economic and social conditions as well as by changes in the policies of the PRC government, such as changes in laws and regulations (or the official interpretation thereof), measures which may be introduced to control inflation, changes in the interest rate or method of taxation, and the imposition of additional restrictions on currency conversion.

PRC regulations relating to the establishment of offshore special purpose companies by PRC residents and the acquisitions of PRC companies by foreign entities may create regulatory uncertainties and subject our PRC resident beneficial owners to personal liability, limit our ability to inject capital into our PRC subsidiaries, limit our ability to increase registered capital or distribute profits to us, or may otherwise adversely affect us.

On August 8, 2006, six PRC regulatory agencies namely, the PRC Ministry of Commerce (“MOFCOM”), the State Assets Supervision and Administration Commission (“SASAC”), the State Administration for Taxation, the State Administration for Industry and Commerce, the China Securities Regulatory Commission (“CSRC”), and the State Administration of Foreign Exchange (“SAFE”), jointly adopted the Regulations on Mergers and Acquisitions of Domestic Enterprises by Foreign Investors (the “New M&A Rules”), which became effective on September 8, 2006, as amended on June 22, 2009. The New M&A Rules significantly revised China’s regulatory framework governing onshore-to-offshore restructurings and foreign acquisitions of domestic enterprises. The New M&A Rules signify greater PRC government attention to cross-border merger, acquisition and other investment activities, by confirming MOFCOM as a key regulator for issues related to mergers and acquisitions in China and requiring MOFCOM approval of a broad range of merger, acquisition and investment transactions. Further, the New M&A Rules establish reporting requirements for acquisition of control by foreigners of companies in key industries, and reinforce the ability of the Chinese government to monitor and prohibit foreign control transactions in key industries.

Among other things, the New M&A Rules provide that where a domestic company, enterprise or natural person intends to take over its domestic affiliated company in the name of an offshore company which it lawfully established or controls, it shall be subject to the examination and approval of the MOFCOM. Additionally, the New M&A Rules include new provisions that purport to require that an offshore special purpose vehicle, or SPV, formed for listing purposes and controlled directly or indirectly by PRC companies or individuals must obtain the approval of the CSRC prior to the listing and trading of such SPV’s securities on an overseas stock exchange. However, the application of this PRC regulation remains unclear regarding the scope and applicability of the CSRC approval requirement.

We are committed to complying with and to ensuring that our beneficial owners who are subject to the New M&A Rules will comply with the relevant rules. However, we cannot assure you that all of our current or future beneficial owners who are PRC residents will comply with our request to make or obtain any applicable registrations or comply with these rules. Any failure by any of our current or future beneficial owners to comply with relevant requirements under this regulation could subject us to fines or sanctions imposed by the PRC government. If the MOFCOM, CSRC or another PRC regulatory agency subsequently determines that the approval of this regulatory agency is required for any of our relevant transactions or acquisitions, we may face sanctions by such regulatory agency. If this happens, these regulatory agencies may impose fines and penalties on our operations in the PRC, limit our operating privileges in the PRC, delay or restrict the repatriation of the proceeds from this offering into the PRC, restrict or prohibit payment or remittance of dividends to us or take other actions that could have a material adverse effect on our business, financial condition, results of operations, reputation and prospects, as well as the trading price of our shares.

In October 2005, SAFE issued a public notice that took effect on November 1, 2005, known as Circular No. 75, concerning the use of offshore holding companies in mergers and acquisitions in China. The public notice Circular No.75 provides that if a PRC resident intends to establish or control an SPV, or an offshore company controlled by PRC residents intends to acquire a PRC company, such acquisition will be subject to registration with the relevant foreign exchange authorities.

9

Circular No. 75 also suggests that registration with the relevant foreign exchange authorities is required for any sale or transfer by PRC residents of shares in an offshore holding company that owns an onshore company. PRC residents must each submit a registration form to the local SAFE branch with respect to their ownership interests in the offshore company, and must also file an amendment to such registration if the offshore company experiences material events, such as changes in the share capital, share transfer, mergers and acquisitions, spin-off transactions or use of assets in China to guarantee offshore obligations.

We are committed to complying with and to ensuring that our beneficial owners who are subject to Circular No. 75 will comply with the relevant rules. However, we cannot assure you that all of our current or future beneficial owners who are PRC residents will comply with our request to make or obtain any applicable registrations or comply with these rules. Any failure by those PRC beneficial owners to file any such registration form or amendments could subject us to sanctions imposed by the PRC government or/and limit the ability of a PRC company to remit its profit, dividends and other proceeds to offshore entities.

The Chinese Government Exerts Substantial Influence Over The Manner In Which We Must Conduct Our Business Activities Which Could Adversely Affect Our Company.

China only recently has permitted provincial and local economic autonomy and private economic activities. The Chinese government has exercised and continues to exercise substantial control over virtually every sector of the Chinese economy through regulation and State ownership. Our ability to operate in China may be harmed by changes in its laws and regulations, including those relating to taxation, import and export tariffs, environmental regulations, land use rights, property and other matters. We believe that our operations in China are in material compliance with all applicable legal and regulatory requirements. However, the central or local governments of these jurisdictions may impose new, stricter regulations or interpretations of existing regulations that would require additional expenditures and efforts on our part to ensure our compliance with such regulations or interpretations.

Accordingly, government actions in the future, including any decision not to continue to support recent economic reforms and to return to a more centrally planned economy or regional or local variations in the implementation of economic policies, could have a significant effect on economic conditions in China or particular regions thereof, and could require us to divest ourselves of any interest we then hold in China.

The Chinese Legal System Has Inherent Uncertainties That Could Limit The Legal Protections Available To You.

Guanwei’s contractual arrangements in China are governed by the laws of the PRC. China’s legal system is based upon written statutes. Prior court decisions may be cited for reference but are not binding on subsequent cases and have limited value as precedents. Since 1979, the Chinese legislative bodies have promulgated laws and regulations dealing with economic matters such as foreign investment, corporate organization and governance, commerce, taxation and trade. However, because these laws and regulations are relatively new, and because of the limited volume of published decisions and their non-binding nature, the interpretation and enforcement of these laws and regulations involve uncertainties, and therefore you may not have legal protections for certain matters in China.

Because Our Assets Are Located In China, Any Dividends Of Proceeds From Liquidation Is Subject To The Approval Of The Relevant Chinese Government Agencies.

Our assets are located inside China. Under the laws governing foreign invested enterprises in China, dividend distribution and liquidation are allowed but subject to special procedures under the relevant laws and rules. Any dividend payments will be subject to the decision of our Board of Directors and subject to foreign exchange rules governing such repatriation. Any liquidation is subject to both the relevant government agency’s approval and supervision as well as the foreign exchange control. This may generate additional risk for our investors in case of dividend payments and liquidation.

Future Inflation In China May Inhibit Our Activity To Conduct Business In China.

In recent years, the Chinese economy has experienced periods of rapid expansion and high rates of inflation. During the past twenty years, the rate of inflation in China has been as high as 24.1% in 1994 and as low as -1.4% in 1999 (according to National Bureau of Statistics of China). These factors have led to the adoption by Chinese government, from time to time, of various corrective measures designed to restrict the availability of credit or regulate growth and contain inflation. While inflation has been more moderate since 1995, high inflation may in the future cause the Chinese government to impose controls on credit and/or prices, or to take other action, which could inhibit economic activity in China and thereby harm our business operations.

10

Capital Outflow Policies In China May Hamper Our Ability To Pay Dividends To Shareholders In The United States.

The PRC has adopted currency and capital transfer regulations. These regulations require that we comply with complex regulations for the movement of capital. Although Chinese governmental policies were introduced in 1996 to allow the convertibility of RMB into foreign currency for current account items, conversion of RMB into foreign exchange for capital items, such as foreign direct investment, loans or securities, requires the approval of the State Administration of Foreign Exchange. We may be unable to obtain all of the required conversion approvals for our operations, and Chinese regulatory authorities may impose greater restrictions on the convertibility of the RMB in the future. Because all of our current revenues and most of our future revenues will be in RMB, any inability to obtain the requisite approvals or any future restrictions on currency exchanges will limit our ability to fund our business activities outside China or to pay dividends to our shareholders.

Currency Conversion And Exchange Rate Volatility Could Adversely Affect Our Financial Condition.

The PRC government imposes control over the conversion of RMB into foreign currencies. Under the current unified floating exchange rate system, the People’s Bank of China (PBOC) publishes an exchange rate, which we refer to as the PBOC exchange rate, based on the previous day’s dealings in the inter-bank foreign exchange market. Financial institutions authorized to deal in foreign currency may enter into foreign exchange transactions at exchange rates within an authorized range above or below the PBOC exchange rate according to market conditions.

Pursuant to the Foreign Exchange Control Regulations of the PRC issued by the State Council which came into effect on April 1, 1996, and the Regulations on the Administration of Foreign Exchange Settlement, Sale and Payment of the PRC which came into effect on July 1, 1996, regarding foreign exchange control, conversion of RMB into foreign exchange by Foreign Investment Enterprises (“FIEs”), for use on current account items, including the distribution of dividends and profits to foreign investors, is permissible. FIEs are permitted to convert their after-tax dividends and profits to foreign exchange and remit such foreign exchange to their foreign exchange bank accounts in the PRC. Conversion of RMB into foreign currencies for capital account items, including direct investment, loans, and security investment, is still under certain restrictions. On January 14, 1997, the State Council amended the Foreign Exchange Control Regulations and added, among other things, an important provision, which provides that the PRC government shall not impose restrictions on recurring international payments and transfers under current account items.

Enterprises in the PRC (including FIEs) which require foreign exchange for transactions relating to current account items, may, without approval of the State Administration of Foreign Exchange, or SAFE, effect payment from their foreign exchange account or convert and pay at the designated foreign exchange banks by providing valid receipts and proofs.

Convertibility of foreign exchange in respect of capital account items, such as direct investment and capital contribution, is still subject to certain restrictions, and prior approval from the SAFE or its relevant branches must be sought.

Since 1994, the exchange rate for RMB against the United States dollars has remained relatively stable, most of the time in the region of approximately RMB 8.28 to US$1.00. However, in 2005, the Chinese government announced that would begin pegging the exchange rate of the Chinese RMB against a number of currencies, rather than just the U.S. Dollar. As our operations are primarily in China, any significant revaluation of the RMB may materially and adversely affect our cash flows, revenues and financial condition. For example, to the extent that we need to convert United States dollars into RMB for our operations, appreciation of this currency against the United States dollar could have a material adverse effect on our business, financial condition and results of operations. Conversely, if we decide to convert RMB into United States dollars for other business purposes and the United States dollar appreciates against this currency, the United States dollar equivalent of the RMB we convert would be reduced.

The Value Of Our Securities Will Be Affected By The Foreign Exchange Rate Between U.S. Dollars And Renminbi.

The value of our Common Stock will be affected by the foreign exchange rate between U.S. dollars and RMB, and between those currencies and other currencies in which our sales may be denominated. For example, to the extent that we need to convert U.S. dollars into RMB for our operational needs and should the RMB appreciate against the U.S. dollar at that time, our financial position, the business of the Company, and the price of our Common Stock may be harmed. Conversely, if we decide to convert our RMB into U.S. dollars for the purpose of declaring dividends on our Common Stock or for other business purposes and the U.S. dollar appreciates against the RMB, the U.S. dollar equivalent of our earnings from our China operations would be reduced.

11

You May Experience Difficulties In Effecting Service Of Legal Process, Enforcing Foreign Judgments Or Bringing Original Actions In China Based On United States Or Other Foreign Laws Against Us.

We conduct our operations in China and most of our assets are located in China. In addition, some of our directors and executive officers reside within China. As a result, it may not be possible to effect service of process within the United States or elsewhere outside China upon such directors or executive officers, including with respect to matters arising under U.S. federal securities laws or applicable state securities laws. Moreover, our Chinese counsel has advised us that China does not have treaties with the U.S. and many other countries that provide for the reciprocal recognition and enforcement of judgment of courts. As a result, recognition and enforcement in China of judgments of a court of the U.S. or any other jurisdiction in relation to any matter may be difficult or impossible.

Our Significant Amount Of Deposits In Certain Banks and Financial Institutions In China May Be At Risk If These Banks Go Bankrupt During Our Deposit Period.

At December 31, 2010, we had approximately US$17.2 million on deposit with banks and financial institutions in China, which constitutes approximately all of our total cash. The terms of these deposits are, in general, up to twelve (12) months. Historically, deposits in Chinese banks and financial institutions are secure due to the state policy on protecting depositors’ interests. However, China promulgated a new Bankruptcy Law in August 2006, which became effective on June 1, 2007, which contains a separate article expressly stating that the State Council may promulgate implementation measures for the bankruptcy of Chinese banks and financial institutions based on the Bankruptcy Law. Under the new Bankruptcy Law, a Chinese bank or financial institution may go bankrupt. In addition, since China’s concession to WTO, foreign banks have been gradually permitted to operate in China and have been severe competitors against Chinese banks and financial institutions in many aspects, especially since the opening of RMB business to foreign banks in late 2006. Therefore, the risk of bankruptcy of those banks and financial institutions in which we have deposits has increased. In the event of bankruptcy of one of the banks or financial institutions which holds our deposits, we are unlikely to recover our deposits back in full since we are unlikely to be classified as a secured creditor based on PRC laws.

We Are Subject To The United States Foreign Corrupt Practices Act.

We are required to comply with the United States Foreign Corrupt Practices Act, which generally prohibits United States companies from engaging in bribery or other prohibited payments to foreign officials for the purpose of obtaining or retaining business. In addition, we are required to maintain records that accurately and fairly represent our transactions and have an adequate system of internal accounting controls. Foreign companies, including some that may compete with us, are not subject to these prohibitions, and therefore may have a competitive advantage over us. Corruption, extortion, bribery, pay-offs, theft and other fraudulent practices occur from time-to-time in the PRC, particularly in our industry since it deals with contracts from the Chinese Government, and our executive officers and employees have not been subject to the United States Foreign Corrupt Practices Act prior to the completion of the Share Exchange. If our competitors engage in these practices they may receive preferential treatment from personnel of some companies, giving our competitors an advantage in securing business or from government officials who might give them priority in obtaining new licenses, which would put us at a disadvantage. We can make no assurance that our employees or other agents will not engage in such conduct for which we might be held responsible. If our employees or other agents are found to have engaged in such practices, we could suffer severe penalties and other consequences that may have a material adverse effect on our business, financial condition and results of operations.

RISKS RELATING TO OUR BUSINESS

We Cannot Predict Whether We Will Meet Internal or External Expectations Of Future Performance.

We believe that our future success depends on our ability to significantly increase revenue from processing recycled plastic wastes. Accordingly, our prospects must be considered in light of the risks, expenses and difficulties frequently encountered by companies with a limited operating history. These risks include our ability to:

|

|

•

|

develop new and innovative processing methods, including processes which increase production yield;

|

|

|

•

|

respond effectively to competitive pressures and address the effects of strategic relationships or corporate combinations;

|

12

|

|

•

|

maintain our current, and develop new, strategic relationships with customers and suppliers;

|

|

|

•

|

increase awareness of our products and continue to build customer loyalty; and

|

|

|

•

|

attract and retain qualified management, consultants and employees.

|

We Cannot Assure You That Our Organic Growth Strategy Will Be Successful.

One of our growth strategies is to grow organically through increasing the sale of our products by increasing our output volume and entering new markets in China and internationally. However, many obstacles to increasing our market share and entering such new markets exist, including, but not limited to, costs associated with increasing market share and entering into such markets and attendant marketing efforts. We cannot, therefore, assure you that we will be able to successfully overcome such obstacles and establish our products in any additional markets. Our inability to implement this organic growth strategy successfully may have a negative impact on our ability to grow and on our future financial condition, results of operations or cash flows.

Our Business And Growth Could Suffer If We Are Unable To Hire And Retain Key Personnel That Are In High Demand.

We depend upon the continued contributions of our senior management and other key personnel, including external experts and advisers. The loss of the services of any of our executive officers or other key personnel could have a material adverse effect on our business, operations, revenues or prospects. We do not maintain key man insurance on the lives of these individuals at present. As we plan to expand, we will have to attract managerial staff. We may not be able to identify and retain qualified personnel due to our lack of understanding of different cultures and lack of local contacts. This may impede any potential expansion. Our future success will also depend on our ability to attract and retain highly skilled and qualified technical, engineering, managerial, finance, marketing, security and customer service personnel in China. Qualified individuals are in high demand, and we may not be able to successfully attract, assimilate or retain the personnel we need to succeed.

We May Not Be Able To Manage Our Expanding Operations Effectively, Which Could Harm Our Business.

We anticipate expanding our business as we address growth in our customer base and market opportunities. In addition, the geographic dispersion of our operations as a result of overall internal growth requires significant management resources that our locally-based competitors do not need to devote to their operations. In order to manage the expected growth of our operations and personnel, we will be required to improve and implement operational and financial systems, procedures and controls, and expand, train and manage our growing employee base. Further, our management will be required to maintain and expand our strategic relationships necessary to our business. We cannot assure you that our current and planned personnel, systems, procedures and controls will be adequate to support our future operations. If we are not successful in establishing, maintaining and managing our personnel, systems, procedures and controls, our business will be materially and adversely affected.

If We Need Additional Capital To Fund Our Growing Operations, We May Not Be Able To Obtain Sufficient Capital And May Be Forced To Limit The Scope Of Our Operations.

We may experience increased capital needs and we may not have enough capital to fund our future operations without additional capital investments. Our capital needs will depend on numerous factors, including (i) our profitability; (ii) the success of our competitors; (iii) the amount of our capital expenditures; and (iv) new investments. We cannot assure you that we will be able to obtain capital in the future to meet our needs. If we cannot obtain additional funding, we may be required to:

|

|

•

|

reduce our investments;

|

|

|

•

|

limit our expansion efforts; and

|

|

|

•

|

decrease or eliminate capital expenditures.

|

13

Such reductions could materially adversely affect our business and our ability to compete. Even if we do find a source of additional capital, we may not be able to negotiate terms and conditions for receiving the additional capital that are acceptable to us. Any future capital investments could dilute or otherwise materially and adversely affect the holdings or rights of our existing shareholders. We cannot give you any assurance that any additional financing will be available to us, or if available, will be on terms favorable to us.

We Depend On A Limited Number Of Suppliers For A Majority Of Our Supplies. The Inability To Secure Raw Materials Could Affect Our Production Output And Reduce Our Revenues.

For the years ended December 31, 2010 and 2009, 74% and 89% of our raw material was purchased from three major suppliers, respectively. Failure to maintain good relationships with our current suppliers or to develop a new supply source of raw materials could negatively affect our ability to obtain the raw materials used in our products in a timely manner. If we are unable to obtain ample supplies of raw material from our existing suppliers or develop alternative supply sources, we may be unable to satisfy our customers’ orders which could materially and adversely affect our revenues and our relationship with our customers. Furthermore, we are dependent on our suppliers for the timely delivery of materials that we require for our operations. Should our suppliers fail to deliver such materials on time, and if we are unable to source these materials from alternative suppliers on a timely basis, our revenue and profitability could be adversely affected.

The Success Of Our Business Is Heavily Dependent Upon Our Ability To Secure Raw Plastic.

Our ability to generate revenue depends upon our ability to secure raw plastic. There is a world-wide market for these materials, and the Company faces competition from other low-cost users. To the extent that we are unable to secure enough raw plastic, our business, financial condition and results of operations will be materially adversely affected.

The Chinese Government Limits The Amount Of Plastic Waste Which May Be Imported, And As Such, We May Not Be Able To Import Sufficient Raw Materials.

The Chinese government limits the amount of plastic waste which may be imported into China. Although we have not experienced difficulties obtaining and renewing our import license in the past, we cannot guarantee the license will be approved in the future. If we fail to obtain the import license, we may have to use domestically supplied plastics wastes for our manufacturing. Domestic plastic wastes are typically poorly sorted, so utilizing the domestic raw material increase production costs.

Our Production Costs And Revenues Are Impacted By Increases In The Cost Of Labor, Shipping And Other Expenses.

The manufacturing of recycled plastics is highly labor-intensive as all raw material classification is done by hand. A sharp increase of in pay or a mandatory welfare/insurance contribution by employers would cause an increase in production costs and would reduce our profit margin. Additionally, as all of the raw material used in our manufacturing is imported, an increase in the freight costs of importing such material would increase our production costs and thus negatively impact our revenues.

We Are Dependent On Use Of An Import Quota Granted To Us By Another Company, The Loss Of Which Could Materially Affect Our Ability To Secure High Quality Raw Materials For Our Manufacturing Processes.

In the PRC, imports of plastic waste are subject to an import quota regulated by the Ministry of Environmental Protection. We have been approved for an import quota of 24,000 tons of plastic waste per year. We have also been permitted to use of the 35,000 tons per year import quota granted to Huan Li. Huan Li has not had any significant operations since 2005, but its import quota remains valid. Chen Min, our Chief Executive Officer, is the Chief Executive Officer, Chairman of the Board of Directors, and legal representative with the power to represent and act on behalf, of Huan Li.

Although we have not previously experienced difficulties with regard to Huan Li permitting us to use its import quota, there can be no guarantee that the import quota will be available to us in the future. Huan Li can rescind its grant to us of the import quota at any time. If we are unable to use Huan Li’s import quota, our business, financial condition and results of operations would be materially adversely affected. Without the import quota we may have to purchase domestically supplied plastic waste for our manufacturing processes. Domestic plastic waste is typically poorly sorted, which increases our production costs and most of the plastic waste available domestically has already been recycled, and it therefore has a lower tensile force which would negatively impact the quality of our products.

14

We May Be Classified As A Passive Foreign Investment Company, Which Could Result In Adverse U.S. Tax Consequences To U.S. Investors.

Based upon the nature of our income and assets, we may be classified as a passive foreign investment company, or PFIC, by the United States Internal Revenue Service for U.S. federal income tax purposes. This characterization could result in adverse U.S. tax consequences to you. For example, if we are a PFIC, our U.S. investors will become subject to increased tax liabilities under U.S. tax laws and regulations and will become subject to more burdensome reporting requirements. The determination of whether or not we are a PFIC is made on an annual basis, and those determinations depend on the composition of our income and assets, including goodwill, from time to time. We intend to operate our business so as to minimize the risk of PFIC treatment, however you should be aware that certain factors that could affect our classification as PFIC are out of our control. For example, the calculation of assets for purposes of the PFIC rules depends in large part upon the amount of our goodwill, which in turn is based, in part, on the then market value of our shares, which is subject to change. Similarly, the composition of our income and assets is affected by the extent to which we spend the cash we have raised on acquisitions and capital expenditures. In addition, the relevant authorities in this area are not clear and so we operate with less than clear guidance in our effort to minimize the risk of PFIC treatment. Therefore, we cannot be sure whether we are not and will not be a PFIC for the current or any future taxable year. In the event we are determined to be a PFIC, our stock may become less attractive to U.S. investors, which may negatively impact the price of our common stock.

Environmental Compliance And Remediation Could Result In Substantially Increased Capital Requirements And Operating Costs Which Could Adversely Affect Our Business

Guanwei is subject to numerous Chinese provincial and local laws and regulations relating to the protection of the environment. These laws continue to evolve and are becoming increasingly stringent. The ultimate impact of complying with such laws and regulations is not always clearly known or determinable because regulations under some of these laws have not yet been promulgated or are undergoing revision. Our consolidated business and operating results could be materially and adversely affected if Guanwei were required to increase expenditures to comply with any new environmental regulations affecting its operations. We could, in the future, incur a material liability resulting from the costs of complying with environmental laws, environmental permits or any claims concerning noncompliance, or liability from contamination.

We cannot predict what environmental legislation or regulations will be enacted in the future, how existing or future laws or regulations will be administered or interpreted or what environmental conditions may be found to exist at our facilities or at third-party sites for which we are liable. Enactment of stricter laws or regulations, stricter interpretations of existing laws and regulations or the requirement to undertake the investigation or remediation of currently unknown environmental contamination at our own or third-party sites may require us to make additional expenditures, some of which could be material.

If Environmental Regulation Enforcement Is Relaxed, The Demand For Our Products May Decrease.

The demand for our services is substantially dependent upon the public’s concern with, and the continuation and proliferation of, the laws and regulations governing the recycling of plastic. A decrease in the level of public concern, the repeal or modification of these laws, or any significant relaxation of regulations relating to the recycling of plastic would significantly reduce the demand for our services and could have a material adverse effect on our operations and financial condition.

We Face Competition From Other Companies, Which Could Force Us To Lower Our Prices, Thereby Adversely Affecting Our Operating Margins, Financial Condition, Cash Flows And Profitability.

The markets in which we operate are highly competitive, and this competition could harm our business, results of operations, cash flow and financial condition. We believe that one significant competitive factor for our products is selling price. Although we do not aspire to be the lowest cost provider but rather the highest value provider to our customers, we could be subject to adverse results caused by our competitors’ pricing decisions. If we do not compete successfully, our business, operating margins, financial condition, cash flows and profitability could be adversely affected.

15

Our Sales Are Dominated By Sales in China Which Could Have An Adverse Effect On Our Business

For each of the two fiscal years ended December 31, 2010 and 2009 almost all of our sales were derived from customers in China. We expect that the domestic market in China will continue to be our major market. Our business is therefore heavily dependent on the demand for plastics in China and the domestic market prices of LDPE. In the event that there is any material adverse change in the level of the demand of raw material for plastic products in China or if there are a significant price fluctuations in China, our performance could be adversely affected.

RISKS RELATING TO OUR COMMON STOCK

Our Common Stock Price May Be Volatile And Could Decline In The Future.

The stock market in general and the market price for other companies based in the PRC have experienced extreme stock price fluctuations. In some cases, these fluctuations have been unrelated to the operating performance of the affected companies. Many companies in China have experienced dramatic volatility in the market prices of their common stock. We believe that a number of factors, both within and outside of our control, could cause the price of our Common Stock to fluctuate, perhaps substantially. Factors such as the following could have a significant adverse impact on the market price of our Common Stock:

|

|

•

|

announcements of technological innovations by us or our competitors;

|

|

|

•

|

our ability to obtain additional financing and, if available, the terms and conditions of the financing;

|

|

|

•

|

our financial position and results of operations;

|

|

|

•

|

litigation;

|

|

|

•

|

period-to-period fluctuations in our operating results;

|

|

|

•

|

changes in estimates of our performance by any securities analysts;

|

|

|

•

|

new regulatory requirements and changes in the existing regulatory environment;

|

|

|

•

|

the issuance of new equity securities in a future offering;

|

|

|

•

|

changes in interest rates;

|

|

|

•

|

changes in environmental standards;

|

|

|

•

|

market conditions of securities traded on the NASDAQ;

|

|

|

•

|

investor perceptions of us and the plastics recycling industry generally; and

|

|

|

•

|

general economic and other national conditions.

|

The Trading Market In Our Common Stock Is Limited And May Cause Volatility In The Market Price.

Our Common Stock is currently quoted on the NASDAQ Capital Market under the symbol “GPRC”. The quotation of our Common Stock on the NASDAQ Capital Market does not assure that a meaningful, consistent and liquid trading market currently exists, and in recent years such market has experienced extreme price and volume fluctuations that have particularly affected the market prices of many smaller companies like us. Thus, the market price for our Common Stock is subject to volatility and holders of Common Stock may be unable to resell their shares at or near their original purchase price or at any price. In the absence of an active trading market:

|

|

•

|

investors may have difficulty buying and selling or obtaining market quotations;

|

16

|

|

•

|

market visibility for our Common Stock may be limited; and

|

|

|

•

|

a lack of visibility for our Common Stock may have a depressive effect on the market for our Common Stock.

|

We May Have Difficulty Raising Necessary Capital To Fund Operations As A Result Of Market Price Volatility For Our Shares Of Common Stock.