Attached files

| file | filename |

|---|---|

| EX-23.1 - EXHIBIT 23.1 - TENGION INC | ex23-1.htm |

| EX-32.2 - EXHIBIT 32.2 - TENGION INC | ex32-2.htm |

| EX-31.1 - EXHIBIT 31.1 - TENGION INC | ex31-1.htm |

| EX-23.2 - EXHIBIT 23.2 - TENGION INC | ex23-2.htm |

| EX-32.1 - EXHIBIT 32.1 - TENGION INC | ex32-1.htm |

| EX-31.2 - EXHIBIT 31.2 - TENGION INC | ex31-2.htm |

| EX-10.29 - EXHIBIT 10.29 - TENGION INC | ex10-29.htm |

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

| [X] |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

For the fiscal year ended December 31, 2010

OR

| [ ] |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

|

For the transition period from _____ to _____

Commission file number 001-34688

|

Tengion, Inc.

(Exact name of registrant as specified in its charter)

|

|

|

Delaware

(State or other jurisdiction of incorporation or organization)

|

20-0214813

(I.R.S. Employer Identification No.)

|

|

2900 Potshop Lane, Suite 100

East Norriton, PA 19403

(Address of principal executive offices)

(610) 292-8364

(Registrant’s telephone number, including area code)

|

|

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes [ ] No [X]

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes [ ] No [X]

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes [X] No [ ]

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes [ ] No [ ]

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K [X]

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer or a non-accelerated filer, as defined in Rule 12b-2 of the Exchange Act.

Large accelerated filer [ ] Accelerated filer [ ] Non-accelerated filer [X] Smaller reporting company [ ]

Indicate by check mark whether the registrant is a shell company, as defined in Rule 12b-2 of the Exchange Act. Yes [ ] No [X]

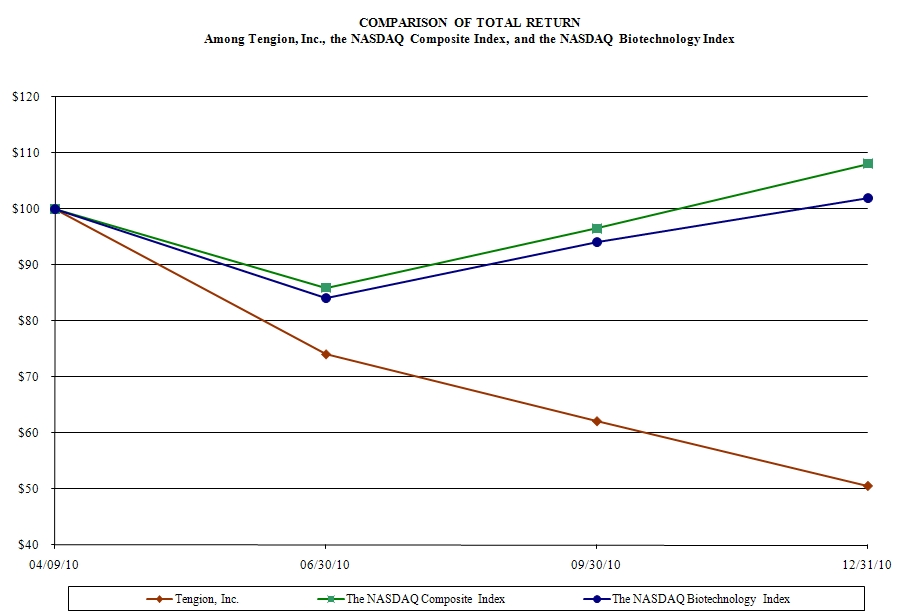

The aggregate market value of the registrant’s common stock held by non-affiliates of the registrant as of June 30, 2010 was $24,737,900. This calculation excludes 5,704,657 shares held on June 30, 2010 by directors, executive officers, and one holder of more than 10% of the registrant’s common stock. As of March 24, 2011, there were 23,471,249 shares of the registrant’s common stock outstanding.

TENGION, INC.

FORM 10-K

INDEX

|

Part I

|

||

|

Item 1.

|

Business

|

|

|

Item 1A.

|

Risk Factors

|

|

|

Item 1B.

|

Unresolved Staff Comments

|

|

|

Item 2.

|

Properties

|

|

|

Item 3.

|

Legal Proceedings

|

|

|

Item 4.

|

(Removed and Reserved)

|

|

|

Part II

|

||

|

Item 5.

|

Market for Registrant’s Common Equity, Related Stockholder Matters

|

|

|

and Issuer Purchases of Equity Securities

|

||

|

Item 6.

|

Selected Financial Data

|

|

|

Item 7.

|

Management’s Discussion and Analysis of Financial Condition and

|

|

|

Results of Operations.

|

||

|

Item 7A.

|

Quantitative and Qualitative Disclosures about Market Risk

|

|

|

Item 8.

|

Financial Statements and Supplementary Data

|

|

|

Item 9.

|

Changes in and Disagreements with Accountants on Accounting

|

|

|

and Financial Disclosure

|

||

|

Item 9A.

|

Controls and Procedures

|

|

|

Item 9B.

|

Other Information

|

|

|

Part III

|

||

|

Item 10.

|

Directors, Executive Officers and Corporate Governance

|

|

|

Item 11.

|

Executive Compensation

|

|

|

Item 12.

|

Security Ownership of Certain Beneficial Owners and Management

|

|

|

and Related Stockholder Matters

|

||

|

Item 13.

|

Certain Relationships and Related Party Transactions, and Director

|

|

|

Independence

|

||

|

Item 14.

|

Principal Accounting Fees and Services

|

|

|

Part IV

|

||

|

Item 15.

|

Exhibits and Financial Statement Schedules

|

|

|

Signatures

|

||

Tengion® and the Tengion logo® are our registered trademarks and Tengion Neo-Urinary Conduit™, Tengion Neo-Kidney™, Tengion Neo-Kidney Augment™, Tengion Neo-Vessel™, Tengion Neo-Vessel Replacement™, Tengion Neo-Bladder Replacement™, Neo-Bladder Augment™, Tengion Organ Regeneration Platform™ and Organ Regeneration Platform™ are our trademarks. Other names are for informational purposes only and may be trademarks of their respective owners.

PART I

Item 1. Business

Overview

We believe we are the only regenerative medicine company focused on discovering, developing, manufacturing and commercializing a range of neo-organs, which we define as products composed of living cells, with or without synthetic or natural materials, implanted into the body to incorporate, replace or regenerate a damaged tissue or organ. We currently create these functional neo-organs using a patient’s own cells, or autologous cells, in conjunction with our Organ Regeneration Platform. We believe our proprietary product candidates harness the intrinsic regenerative pathways of the body to regenerate a range of native-like organs and tissues. Our neo-organs are designed to avoid the need to substitute other tissues of the body for a purpose to which they are poorly suited. In addition, our product candidates are intended to eliminate the need for donor organs and the administration of anti-rejection medications. We produce neo-organs in our scalable manufacturing facilities using efficient and repeatable proprietary processes, and have implanted neo-organs in our clinical trials. Building on our clinical and preclinical experience, we are initially leveraging our Organ Regeneration Platform to develop our Neo-Urinary Conduit for bladder cancer patients who are in need of a urinary diversion. We intend to develop our technology to address unmet medical needs in urologic, renal, and other diseases and disorders.

Regenerative medicine is an interdisciplinary field combining expertise in developmental biology, medicine and engineering with the goal of restoring native-like organ and tissue function. The premise of regenerative medicine is that the body has the intrinsic capacity to heal and regenerate. Liver tissue, for example, will naturally regenerate following partial resection. In many situations, however, the appropriate conditions that facilitate the regenerative process in the body may not be present for reasons such as the absence of appropriate gene expression or the presence of an underlying disease process. Regenerative medicine seeks to provide the necessary stimulus, environment or foundation to promote the body’s innate regenerative capacity. While the FDA has approved regenerative medicine products for skin applications and repair of selected cartilage defects, we believe that we are the only company using regenerative medicine to harness the body’s ability to regenerate a range of functional, native-like organs and tissues.

Our Organ Regeneration Platform has enabled us to develop our product candidates from proof of concept to first-in-man clinical trials in as short as 24 months. Our technology has been applied in two Phase II clinical trials for our Neo-Bladder Augment. Recent advances in our platform technology have enabled us to significantly simplify our process of manufacturing neo-organs, which we believe will allow us to address new and larger market opportunities. Our lead product candidate, our Neo-Urinary Conduit, is intended to replace the use of bowel tissue in bladder cancer patients requiring a non-continent urinary diversion after bladder removal surgery, or cystectomy. We are able to manufacture our Neo-Urinary Conduit using a proprietary process that takes four weeks or less and uses only smooth muscle cells derived from a routine fat biopsy. We are currently conducting a Phase I clinical trial for our Neo-Urinary Conduit in bladder cancer patients.

We were incorporated in Delaware in 2003. Our corporate headquarters are located at 2900 Potshop Lane, Suite 100, East Norriton, Pennsylvania and our telephone number is (267) 960-4800.

Our Organ Regeneration Platform

Our Organ Regeneration Platform is based on extensive work that began in the early 1990s at Children’s Hospital Boston and Massachusetts Institute of Technology, and continued at the Wake Forest Institute for Regenerative Medicine and our company. Our proprietary approach involves the use of a combinatorial method, testing different combinations of cell type and scaffold material. We believe this approach enables us to accurately identify the combination of various cell types and scaffold materials for a specific organ necessary to elicit a regenerative response and guides our decisions for subsequent rounds of testing. We own or license over 30 U.S. patents and patent applications and over 100 international patents and filings related to our Organ Regeneration Platform and product candidates.

The organ regeneration process enabled by our proprietary Organ Regeneration Platform involves the following steps:

|

|

·

|

Isolation and expansion of progenitor cells. Our autologous organ regeneration process begins with our receipt of a small tissue sample, generally obtained by a routine biopsy of the patient. This sample is then sent to our pilot manufacturing facility in North Carolina where our scientists engage in a specialized process to isolate the necessary committed progenitor cells, of one or more types as needed, that form the basis of the target organ’s or tissue’s essential function. Committed progenitor cells have been programmed by the body to become specific cell types, but are not yet developed into a single cell type, retaining the ability to promote regeneration. We obtain the requisite progenitor cells from various sources. For example, for our Neo-Urinary Conduit, we select smooth muscle progenitor cells from a small sample of adipose, or fat tissue. In the case of our Neo-Kidney Augment, we obtain a tissue sample through a small gauge needle biopsy of the kidney. We then use our proprietary cell growth process to grow, or expand, the specifically isolated progenitor cells ex vivo, or outside of the body, until an adequate number of cells are produced.

|

|

|

·

|

Seeding and growth. Once we have completed our cell expansion process, we separately place, or seed, these cell populations on a bioabsorbable scaffold. Depending upon the type of neo-organ being created, we use biomaterials for the scaffold that, when combined with the isolated and expanded cell populations, promote the desired regenerative outcome. We select the type of material based upon our knowledge of the organ or tissue we are seeking to regenerate and extensive testing to determine the optimal material characteristics, treatment and shape that will encourage cell growth and catalyze the body’s regenerative power. Composition and design of the biomaterials are important elements of our technology that help to ensure native-like tissue regeneration and ease of delivery through, where possible, minimally invasive surgical procedures.

|

2

We then place the bioabsorbable scaffold, seeded with the cell populations, in a bioreactor, or a closed container used for enhancing biological growth under controlled conditions. Further manipulation and handling of the neo-organ is done without removal from the bioreactor, which greatly reduces the risk of contamination. The expanded cell populations attach to the biomaterials and begin to form appropriate cellular and tissue layers for the neo-organ, until ready for implantation.

|

|

·

|

Implantation. The neo-organ is typically shipped from our manufacturing facility via a standard overnight courier service and delivered directly to the patient’s surgeon in as short as four weeks after we receive the patient’s biopsy. Each surgeon implanting our neo-organs will be trained and provided with specific procedures and protocols based on general surgical techniques to implant the neo-organ in the patient.

|

|

|

·

|

Regeneration. Based on data from preclinical and clinical studies, we believe that the neo-organ serves as a template for the body to regenerate native-like organs and tissues. Blood vessels and nerves grow into the implanted neo-organ and the scaffold is gradually absorbed by the body. In preclinical tests, we have observed that the newly grown tissue integrates with its surroundings and becomes substantially indistinguishable over time from the native organ. We have also observed that, in this regenerative process, the body regulates the growth and development of the organ to ensure that it is not under- or over-developed.

|

Our Strategy

Our goal is to become the leading regenerative medicine company focused on the development and commercialization of neo-organs for a variety of diseases and disorders. To achieve this objective, we intend to:

|

|

·

|

Advance the Tengion Neo-Urinary Conduit. We are devoting a significant portion of our resources and business efforts to completing the development of our lead product candidate, the Neo-Urinary Conduit. We have an active IND and are currently conducting a Phase I clinical trial in bladder cancer patients who require removal of their bladders and are in need of a urinary diversion.

|

|

|

·

|

Leverage our Organ Regeneration Platform to develop additional neo-organs. We believe our technology is broadly applicable to other indications including certain types of urologic, renal, gastrointestinal and vascular diseases. We have generated significant proprietary know-how and intellectual property in the development and manufacture of our various product candidates. We plan to continue to apply our technologies to other neo-organs as treatments for other conditions, such as our Neo-Kidney Augment for patients with advanced chronic kidney disease, or CKD.

|

3

|

|

·

|

Become a fully integrated company, developing, manufacturing and commercializing neo-organs. We believe our scalable manufacturing facilities will position us well for the commercialization of our product candidates. We believe a small direct sales force will be sufficient to market to the specialty surgeons for our targeted indications in North America and Europe.

|

|

|

·

|

Selectively pursue strategic partnerships to accelerate and maximize the potential of our product candidates and technology while preserving significant commercial rights. We intend to selectively pursue strategic partnership opportunities that we believe may allow us to accelerate the development or maximize the value of our product candidates and technology by leveraging the scientific, clinical development, manufacturing, commercialization and/or financial strengths of leading biotechnology and pharmaceutical companies while still preserving significant commercial rights.

|

Product Pipeline

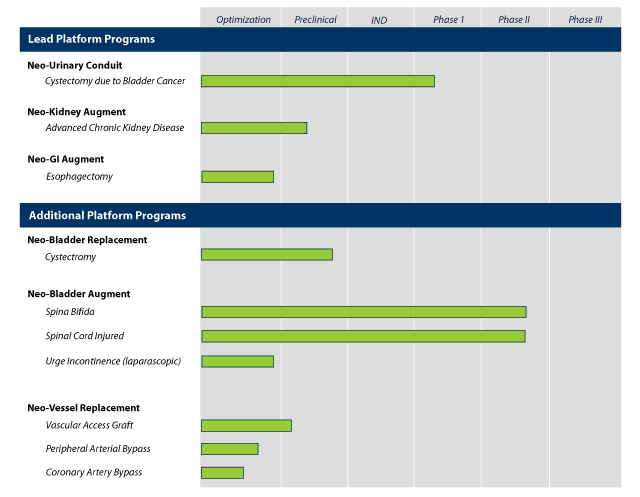

Leveraging our Organ Regeneration Platform, we are currently developing the following product candidates with potential applications in urologic, renal, gastrointestinal and vascular diseases:

4

Urologic Product Candidates

We believe that there will be numerous opportunities for our technology across a variety of medical conditions. We are focusing on the development of product candidates to target applications where the current standard of care involves surgical procedures to replace diseased bladder tissue through the use of bowel tissue harvested from the patient. According to the Agency for Healthcare Research and Quality in the United States and similar government data sources in Europe, we estimate there are a total of approximately 28,000 such procedures performed every year in the United States and the European Union. We have developed a portfolio of product candidates in this area, with clinical experience in two product candidates.

We currently have two product candidates for the treatment of patients who require removal of their bladder in connection with the treatment of bladder, abdominal or pelvic cancer, or other severe bladder disease. Our Neo-Urinary Conduit, for which we have an active IND and are currently conducting a Phase I clinical trial, is a combination of bioabsorbable materials and autologous smooth muscle cells that are isolated and expanded ex-vivo by our scientists. We believe our Neo-Urinary Conduit will develop into physiologically functional tissue with a structure, diverting urine from the ureters to an ostomy bag. Similarly, our Neo-Bladder Replacement, for which we believe we have completed all preclinical development necessary to prepare an IND, is a combination of bioabsorbable materials and autologous smooth muscle cells cultured by our scientists that we believe will serve as a functioning bladder, eliminating the need for an ostomy bag, for patients who have their bladders removed due to cancer. We also have a product candidate, our Neo-Bladder Augment, for the treatment of neurogenic bladder, or dysfunctional bladder due to some form of neurologic disease or condition, for which treatment often requires an augmentation of the bladder in order to relieve high bladder pressure and incontinence. While we have conducted two Phase II clinical trials of this product candidate, we currently are not actively developing our Neo-Bladder Augment and are directing the majority of our resources toward the development of our Neo-Urinary Conduit and other development programs in our pipeline.

We believe that our urologic product candidates, which use autologous cells and develop into functional bladder tissue, will avoid many of the complications associated with using bowel tissue in urologic procedures.

5

Market Overview

The table below indicates the number of urologic surgical procedures performed per year in the United States and the European Union for our targeted indications.

|

Estimated Surgical Procedures Per Year

|

United States(1)

|

European Union(2)

|

||

|

Urinary Conduit

|

||||

|

Cancer

|

9,300

|

10,800

|

||

|

Other

|

1,700

|

2,300

|

||

|

Total

|

11,000

|

13,100

|

||

|

Bladder Replacement

|

700

|

900

|

||

|

Bladder Augment

|

||||

|

Spina Bifida

|

380

|

350

|

||

|

Spinal Cord Injury

|

140

|

130

|

||

|

Other

|

680

|

620

|

||

|

Total

|

1,200

|

1,100

|

||

|

Total Surgical Procedures

|

12,900

|

15,100

|

_______________________

Sources:

|

(1)

|

US: Agency for Healthcare Research and Quality.

|

|

(2)

|

EU: Government data sources for the United Kingdom, France and Germany; other EU countries estimated from population census.

|

Bladder Cancer

According to the National Cancer Institute, bladder cancer is the sixth most common form of cancer in the United States. The American Cancer Society estimates there were 71,000 new cases of bladder cancer diagnosed in the United States in 2009, and 14,000 deaths. The European Cancer Observatory estimates that there were over 100,000 new cases of bladder cancer in Europe in 2006. In the United States, there are approximately 10,000 cases per year of bladder cancer requiring bladder removal, according to data compiled from a 2005 National Inpatient Sample, or NIS, performed by the Healthcare Cost and Utilization Project, or HCUP, a family of healthcare databases and related software tools and projects developed through a federal-state-industry partnership and sponsored by the Agency for Healthcare Research and Quality.

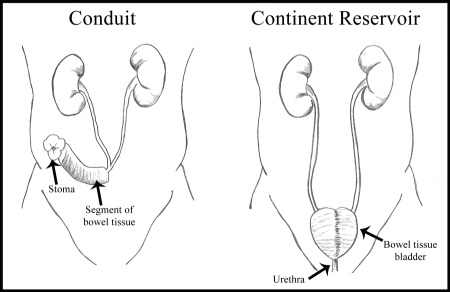

Following removal of a bladder, patients require some form of urinary diversion. Most patients are currently treated by using a segment of bowel tissue to construct a conduit for urine to exit from the body. In its simplest form, the reconstruction involves creating a tubular structure out of bowel tissue and then connecting it to the ureters at one end and the skin at the other in a procedure that was pioneered in the 1930s. Urine output is not controlled and the patient wears a collection device at all times.

The other diversionary option for patients is the creation of a continent reservoir which is most commonly a bladder-shaped pouch fashioned from bowel tissue, to which the ureters and urethra are connected. We believe that less than 10% of the urinary diversions performed after bladder removal are bladder replacements and the remaining diversions are urinary conduits, based upon data compiled from a 2005 NIS performed by HCUP. There are multiple factors that affect the decision concerning which form of post-bladder removal urinary diversion is optimal for a given patient, including stage of disease, health and mental status, manual dexterity, physique and, importantly, patient preference.

6

The graphic below illustrates two urinary diversion options for patients who require bladder removal.

Limitations of Current Therapies

There are many complications associated with surgery to remove or repair the bladder, such as adhesions and obstructions. In the case of traditional surgery to construct a conduit for urine to exit from the body into an ostomy bag, complications such as ureteral detachment, ureteral stricture and hydroureter / hydronephrosis, or swelling in the ureters or kidneys resulting from the backup of urine, are related to the attachment of the ureters to the conduit. Other complications, such as stomal stenosis, involve the attachment of the conduit to the abdominal wall.

While there is variation across procedures and patient types, there are risks and complications common to all procedures that rely on harvesting bowel tissue and placing it in the urinary tract. These complications may include:

|

|

·

|

Bowel complications. Bowel surgery required to harvest tissue for reconstructive use can result in complications, such as prolonged recovery of bowel function, ileus (temporary bowel paralysis), obstructions, leaks and fistulas. Because vitamin B12 is absorbed in the bowel tissue, the loss of tissue can result in anemia and neurologic abnormalities. Additionally, malabsorption of salts and lipids can lead to diarrhea. Patients with neurogenic bladder are prone to bowel movement problems even before surgery and the removal of bowel tissue may either exacerbate existing conditions or create new motility problems. These conditions further contribute to the substantial physical and psychological morbidity in these patients.

|

7

|

|

·

|

Absorption issues. Use of bowel tissue often leads to electrolyte and metabolic imbalances, which can cause bone loss. Certain drugs taken by the patient may be reabsorbed by the implanted bowel tissue, potentially leading to unintended toxic levels. The exposure of intestinal surface to urine also results in the inappropriate absorption of ammonium, chloride and hydrogen ions as well as potassium loss, leading to chronic metabolic imbalances or abnormalities.

|

|

|

·

|

Infection. Persistent and recurrent infections are common in patients with bowel tissue reconstruction. For example, based upon an article entitled “Long Term Outcome of Ideal Conduit Diversion” by S. Madersbacher, et. al., which appeared in the Journal of Urology in 2003, as many as 23% of patients with bowel tissue conduits have recurrent urinary tract infections, or UTIs, and according to “Use of intestinal segments in urinary diversion” by D. M. Dahl and W. S. McDougal in Campbell-Walsh Urology in 2007, approximately 10% to 17% of bowel tissue conduit patients have UTIs that reach the kidney. Bacteria normally found in bowel tissue can serve as a source of infection and septic complications when repositioned into the urinary tract. One of the consequences of persistent infection is the development of stones, hard masses which can cause pain, bleeding, obstruction of urine or infections.

|

|

|

·

|

Mucus. Bowel tissue repositioned in the urinary tract secretes mucus into the urine. Mucus increases the risk of stone formation and the viscosity of urine, and in the case of bladder augments, may require bladder irrigation and more frequent catheterization.

|

|

|

·

|

Cancer. Malignancy, although rare, is a well-recognized complication following enterocystoplasty and other reconstructive surgeries that incorporate bowel segments into the genitourinary tract. This is of greatest concern in the population of spina bifida patients receiving a bladder augment because of the young age of the patients at the time of surgery.

|

Patients requiring some form of urinary diversion with today’s standard of care are at risk of complications associated with the use of bowel tissue as well as those associated with the surgery to harvest the bowel tissue.

Our Solutions

Our Neo-Urinary Conduit and Neo-Bladder Replacement are being developed to address unmet needs in patients who require removal of their bladder in connection with treatment for bladder, abdominal or pelvic cancer or other severe bladder diseases. We believe our product candidates have the potential to be the clinical treatment of choice for the majority of these conditions.

8

The Tengion Neo-Urinary Conduit

Our Neo-Urinary Conduit is a combination of autologous cells and bioabsorbable scaffold that is intended to catalyze regeneration of a native bladder tissue conduit, passively transporting urine from the ureters, through a stoma, or hole in the abdomen, into a standard ostomy bag. We expect that it will be a safe and effective alternative to the creation of a urinary diversion from bowel tissue after bladder removal. Our Neo-Urinary Conduit is intended to avoid complications such as bowel obstruction, urine absorption, infection and mucus secretion associated with the use of bowel tissue in the urinary tract, as well as the potential surgical issues that arise from the procedure involved in harvesting bowel tissue. We produce our Neo-Urinary Conduit using smooth muscle cells from a routine fat biopsy and not cells from the diseased bladder, eliminating the risk of reintroducing cancerous cells from the bladder into the patient.

We produce our Neo-Urinary Conduit for our Phase I clinical trial at our cGMP qualified clinical production facility using our Organ Regeneration Platform. We are able to deliver our Neo-Urinary Conduit in four weeks or less after we receive the patient’s fat biopsy. This timing is consistent with the clinical practice of bladder removal in these patients. To create our Neo-Urinary Conduit, we isolate the smooth muscle cells from the biopsy, expand the cells ex vivo and then seed them onto a bioabsorbable scaffold, which is composed of biomaterials similar to those used in bioabsorbable sutures. Each surgeon implanting one of our Neo-Urinary Conduits will be trained in and receive specific procedures and protocols based on routine surgical techniques to implant our Neo-Urinary Conduit in the patient. We have an active IND and are currently conducting a Phase I clinical trial for the treatment of bladder cancer patients who require bladder removal.

Preclinical History and Background of the Tengion Neo-Urinary Conduit

Our preclinical studies utilized various large animal models for bladder removal and implantation of our product candidate. In these studies, animals receiving our product candidate underwent bladder removal and the animals’ ureters were attached to one end of our Neo-Urinary Conduit using bioabsorbable sutures and the other end was connected to the skin in the abdominal wall, providing an outlet for urine to flow out of the body.

Principal observations of our Neo-Urinary Conduit in preclinical animal models have shown that:

|

|

·

|

Implantation of our Neo-Urinary Conduit created from fat-derived smooth muscle cells results in the formation of a functional conduit.

|

|

|

·

|

By three months post-implantation the scaffold is no longer present and is replaced by a tri-layered native-like bladder tissue consisting of urothelium, submucosa and smooth muscle cells.

|

|

|

·

|

There is no evidence of abnormal cell growth, tissue development or adverse immune response, or adverse systemic effects in response to the biomaterials, autologous cells, or our Neo-Urinary Conduit.

|

9

|

|

·

|

Our Neo-Urinary Conduit regenerates native-like bladder tissue with complete mucosal lining at the ureteral and skin junctions. The function of the regenerated bladder tissue is similar to native bladder tissue in that it allows elimination of urine in a water-tight fashion and does not absorb urine or secrete mucus or electrolytes.

|

These preclinical animal studies suggest that by using current standards of clinical care and specific surgical and post-operative procedures associated with urinary conduits, our Neo-Urinary Conduit may be safe and effective for treating patients who have had their bladders removed.

Clinical Development Plan

We have an active IND for our Neo-Urinary Conduit and commenced a Phase I study in March 2010. The program is designed to provide data to support the use of our Neo-Urinary Conduit in patients who are undergoing bladder removal due to bladder cancer.

This trial is an open-label, single-arm study which is currently expected to enroll up to ten patients. This trial is designed to assess the safety and preliminary efficacy of the Neo-Urinary Conduit. This trial is also intended to allow our investigators to optimize the surgical procedure and post-surgical care with respect to implantation of the Neo-Urinary Conduit. Our clinical investigators may, as necessary, modify the surgical technique based upon the experience gained by prior patients enrolled. A limited number of clinical centers will be utilized to minimize variations in surgical technique and provide the most controlled setting in which the surgical approach is optimized through working with a clinical investigator. We have designed the trial to provide for at least an eight-week interval between implantations of the Neo-Urinary Conduit to allow for close observation and assessment of any treatment and/or procedure-related complications, post-operative recovery, tolerability and safety before proceeding to the next patient. We are working with clinical investigators who have expertise in the surgical treatment of bladder cancer and significant experience performing bladder removals and urinary diversions. This study does not have a control group as the surgical procedure, post-operative care and other clinical parameters preclude the possibility of blinding treatment options.

The primary safety and efficacy assessment of our Neo-Urinary Conduit will be made at 12 months post-implantation and patients will be followed for an additional 48 months in order to assess long term safety and durability. During this first year, however, patients will be seen frequently by the study investigator and/or designated clinical team: every one to two weeks after hospital discharge through week eight, and then at month 3, 6, 9 and 12. Imaging, either CT scan or ultrasound, will be performed at three-month intervals for the first year to examine the neo-organ’s structure, patency and identify any obstructions or other abnormalities. This frequent evaluation and the open-label nature of this study will provide us significant ongoing feedback throughout the study.

The Tengion Neo-Bladder Replacement

Like our Neo-Urinary Conduit, we believe that our Neo-Bladder Replacement will enable patients to avoid the complications associated with removal of bowel tissue and its subsequent use as a bladder replacement. In today’s practice, a continent reconstructed bladder, made from bowel tissue, is attempted in fewer than 10% of patients undergoing bladder removal, or cystectomy. The approach is limited by the various complications associated with using bowel tissue, as well as patient considerations, including the risk of requiring chronic catheterization, and the high frequency of urinary leakage and night time incontinence. Our Neo-Bladder Replacement, when implanted in the body, is intended to serve as a template that recruits other cells to develop a regenerated bladder.

10

Preclinical History and Background of the Tengion Neo-Bladder Replacement

We have conducted preclinical studies of our Neo-Bladder Replacement in large animals to serve as an autologous urinary reservoir. Animals receiving our product candidate underwent urethral-sparing bladder removal. The urethra and ureters were attached using bioabsorbable sutures to our Neo-Bladder Replacement. Principal observations of our Neo-Bladder Replacement in large animal models have shown that:

|

|

·

|

All animals demonstrate continence upon removal of the urethral catheter 21 days after surgery.

|

|

|

·

|

Implantation of our Neo-Bladder Replacement created from only smooth muscle cells results in the formation of a compliant and functional bladder, with demonstrated nerve growth into the tissue.

|

|

|

·

|

The regenerated bladder capacity achieves volumes that were typical of native-bladder volumes, and in instances where there was significant growth of the animal, the regenerated bladder capacity increases to accommodate the animal’s body size.

|

|

|

·

|

By three months post-implantation, the bioabsorbable scaffold is no longer present and is replaced by a tri-layered native-like bladder tissue consisting of urothelium, submucosa and smooth muscle cells.

|

|

|

·

|

By six months post-implantation, the functionality of the neo-bladder tissue is consistent with native bladder tissue as demonstrated by functional imaging, physiological assessments of bladder capacity and compliance, and response to pharmacological stimuli in a manner consistent with native bladder tissue.

|

|

|

·

|

There is no evidence of abnormal cell growth, tissue development, immune response or adverse systemic effects in response to the biomaterials, autologous cells, or our Neo-Bladder Replacement.

|

Based on the results of our preclinical animal studies, we believe that our Neo-Bladder Replacement may provide patients with a functional replacement bladder enabling them to void urine, with no need for a stoma or ostomy bag.

11

The Tengion Neo-Bladder Augment

We have conducted two open-label, multi-center Phase II clinical trials of our Neo-Bladder Augment for the treatment of neurogenic bladder resulting from spina bifida in pediatric patients and neurogenic bladder resulting from spinal cord injury in adult patients. We terminated enrollment of our clinical trial in adult, spinal cord injured patients early as a result of enrollment challenges. Our Neo-Bladder Augment, which is based upon an earlier iteration of our technology requiring a biopsy be obtained from the patient’s bladder, is intended to supplement the patient’s existing bladder and promote regeneration of healthy bladder tissue in patients suffering from neurogenic bladder. Certain of the patients in our Phase II clinical trials experienced serious adverse events that, at the time of their occurrence, were deemed by the respective clinical investigator to be clinically relevant and probably related to our product candidate or the implantation procedure. In response to certain of these serious adverse events, in February 2009, the FDA placed our IND on clinical hold. We conducted a thorough review of the safety events of these patients including the details of each event, the background medical history of these patients, the timing of the events relative to the implantation of our Neo-Bladder Augment and the background rate of similar events in patients receiving the current standard of care, enterocystoplasty. We submitted a complete response to the clinical hold setting forth our analysis in June 2009 and the FDA released the clinical hold in July 2009, with no recommended changes to our protocol, product candidate or implantation procedure. In addition, we have seen limited efficacy of our Neo-Bladder Augment in patients. As of the 36-month clinical follow-up of our pediatric patients, three of the ten patients continue to demonstrate sustained clinical benefit from our product candidate. With respect to adult patients, as of the 24-month clinical follow-up, three of the six patients continue to demonstrate sustained clinical benefit from our product candidate.

As the primary end-point for this trial was one year, we are currently in the long-term follow-up phase of these trials. We currently are not actively developing our Neo-Bladder Augment and are directing the majority of our resources toward the development of our Neo-Urinary Conduit and Neo-Kidney Augment. We may, in the future, determine to terminate the trials involving our Neo-Bladder Augment, so as to further conserve our resources for use on our lead product candidates.

Other Product Opportunities

The Tengion Neo-Kidney Augment

Our Neo-Kidney Augment is being developed to prevent or delay dialysis by increasing renal function in patients with advanced chronic kidney disease, or CKD. Our Neo-Kidney Augment is based on our proprietary technology, which is expected to use the patient’s cells, procured by a needle biopsy of the patient’s kidney, to create an implantable product candidate that can catalyze the regeneration of functional kidney tissue.

Market Overview and Limitations of Current Therapies

According to the 2010 Annual Report of the United States Renal Data System, or the USRDS, which is funded by the National Institutes of Health, or NIH, there are over 30 million people in the United States with chronic kidney disease. Patients with end stage renal disease, or ESRD, have CKD that has progressed to a point of little to no kidney function. These patients require dialysis or a kidney transplant to survive. According to the USRDS, $27 billion in Medicare costs each year are attributable just to ESRD patients. ESRD is associated with an approximate 20% mortality rate per year, with the average life expectancy of a patient on dialysis in 2007 of approximately 5.9 years. In addition, bone loss and anemia is a common complication of advanced CKD, mainly due to an inability of the kidneys to produce enough Vitamin D and erythropoietin, a hormone that controls red blood cell production.

12

Dialysis extends the lives of patients with ESRD, but has many limitations, including infections, hernias and the need to undergo the procedure up to three times per week. Kidney transplantation remains the most desirable and cost-effective form of kidney replacement therapy at this time; however, there is a chronic shortage of organs with only 18,000 kidneys available for transplant in 2008. In addition to the high cost of organ procurement and the subsequent surgery, kidney transplant patients also require a lifetime of drug therapy to prevent organ rejection. There is a clear need for a product that can prevent or delay the need for dialysis or kidney transplant in patients with advanced CKD.

Our Solution

Through our Organ Regeneration Platform, we have isolated and characterized the effects of different kidney cells and combinations of cells on various aspects of kidney function. We have identified a specific combination of renal cells that provides the foundation for the Neo-Kidney Augment and are currently optimizing the formulation to achieve the desired product profile. We obtain cells through a routine needle biopsy of the kidney and using our Organ Regeneration Platform, we are able to produce our Neo-Kidney Augment grown from these cells in as short as four weeks from biopsy receipt. This product development program has demonstrated function in multiple animal models to date and we have also isolated and characterized the necessary cells from healthy and diseased human kidneys, which we believe supports translation of this approach to human patients.

We have assessed the regenerative capabilities of the Neo-Kidney Augment in a rodent model of chronic kidney disease in which renal failure is induced by removal of approximately 80% of the kidney tissue. These studies extend up to six months post-treatment and have demonstrated that animals implanted with our Neo-Kidney Augment have prolonged survival with no additional supportive care. Stabilization and improvement in renal function are evident within several weeks after implantation and continue for the duration of the studies. In these studies, we have seen improvement or stabilization of various biomarkers including certain proteins, lipids, bone remodeling and vitamin levels, as well as organism-level improvements in weight gain and blood pressure.

In late 2009, we began a preclinical study in a rodent model of chronic, progressive renal failure that develops due to obesity, diabetes, and hypertension – three common co-morbid conditions often seen in patients with renal failure. This study demonstrated that our proprietary therapeutic approach, using specific regenerative cells isolated from diseased kidney tissue, can provide significant improvements in several parameters of kidney function, including filtration, urine concentration, and electrolyte balance, as well as a significant reduction in blood pressure. At one year of age, which is approaching end-of-life in this aggressive model, the treated animals demonstrated improved kidney function, delayed disease progression, and better survival compared to the age- and disease-matched untreated control animals.

13

In 2010, we presented additional data using four different animal models of chronic kidney disease. In all four studies, diseased kidney function was improved by the selected regenerative cells which form the active biological component of our Neo-Kidney Augment. In these studies, renal function was shown to be enhanced as early as seven weeks after implantation and was associated with improvements to kidney filtration, urinary protein loss, and urine concentrating ability. Systemic functions controlled by the kidney were also improved including metabolic condition (electrolyte and mineral balance), blood pressure, weight gain and correction of anemia. Improved survival was demonstrated in two animal models which were followed up to one year. In one animal study, selected regenerative cells taken from human kidneys were able to improve kidney function of chronically diseased kidneys.

The Tengion Neo-GI Augment

Leveraging our cumulative learnings from producing tubular neo-organs, such as our Neo-Urinary Conduit, we have begun early development work on our Neo-GI Augment. This product candidate is composed of smooth muscle cells, obtained from a routine fat biopsy, seeded on one of our proprietary bioabsorbable scaffolds, that can be used as a tubular or patch implant to accommodate patient needs. Our objective is to demonstrate that our Neo-GI Augment regenerates esophageal and intestinal tissues.

Our Solution

We have defined in-vitro testing models for our Neo-GI Augment, as well as the necessary cell function assays. Using our combinatorial approach we have also identified potential scaffold prototypes. We have observed extended survival times in animals with esophageal damage following implantation of our Neo-GI Augment. We believe our Neo-GI Augment may offer benefits in other gastrointestinal diseases.

The Tengion Neo-Vessel Replacement

Our Neo-Vessel Replacement targets various blood vessel applications including vascular access grafts, or arterio-venous, or AV, shunts, for patients with ESRD undergoing hemodialysis treatment, and for vessel replacement for patients undergoing coronary or peripheral artery bypass procedures. Our technology will use smooth muscle cells isolated from fat tissue and endothelial cells isolated from blood samples, which are expanded ex vivo and then seeded onto a bioabsorbable scaffold in the shape of a blood vessel.

Our Solution

We believe our Neo-Vessel Replacement may prove to be a more effective alternative to artificial AV grafts. In preclinical studies, our Neo-Vessel Replacement has shown similarities to natural blood vessels and does not become infected to the same extent as synthetic AV graft materials. Further, our Neo-Vessel Replacement may prove to be a superior treatment for patients undergoing a coronary or peripheral artery bypass. Based upon the initial preclinical studies performed to date, we believe this product candidate may eliminate the need to harvest arteries or veins from elsewhere in the patient’s body which will simplify the surgical procedure and avoid potential complications arising from operating on healthy tissue.

14

In large mammal preclinical studies using our Neo-Vessel Replacement as an AV graft, the regenerated vessel has shown similarities to natural blood vessels and reduced rates of infections compared to synthetic AV graft materials. Our Neo-Vessel Replacement has also undergone feasibility testing for the purpose of renal dialysis access. In six-month studies using clinically relevant protocols, we have observed that our Neo-Vessel Replacement retained a native-like ability to remodel, maintained its structural integrity and did not become infected to the same extent as synthetic AV graft materials, despite weekly access with a needle. In large animal studies, our Neo-Vessel Replacements have also been shown to remain open and resist blood clotting when used for carotid artery reconstruction. In addition, we have observed that this product candidate responds to pharmacologic stimuli and expands and contracts in a similar manner to normal blood vessels.

Manufacturing

We believe our product manufacturing capability provides us with a competitive advantage. We manufacture our product candidates in facilities specifically designed for the production of patient-specific materials and have implemented quality control systems to ensure our manufacturing processes and facilities comply with applicable current good manufacturing processes, or cGMP, current Good Tissue Practices, or cGTP, and medical device quality systems regulations, or QSR standards. We have exercised these manufacturing and quality control processes while producing materials for preclinical and clinical studies and have established a significant knowledge base relating to the manufacture of our product candidates. This knowledge base is maintained in a set of standard operating procedures that detail the techniques and standards for manufacturing. All of our production technicians are trained and certified in these procedures to ensure consistency in manufacturing.

Manufacturing of product candidates for our existing preclinical and clinical studies is conducted in our pilot manufacturing facility in Winston-Salem, North Carolina. The pilot manufacturing facility contains approximately 38,400 square feet of laboratories, offices, and clean room manufacturing space. We expect to manufacture early stage product candidates through Phase II clinical trials at this facility. We have also designed and constructed a commercial manufacturing facility, which is located at our headquarters in East Norriton, Pennsylvania. This facility contains approximately 30,000 square feet of technical and manufacturing space and 15,000 square feet of office space. Commencing on March 1, 2011, we also began leasing an additional 35,000 square feet of warehouse space, which ultimately will provide us with space for further expansion. We are currently subleasing this additional warehouse space to a third party. We expect to manufacture product candidates for Phase III clinical trials in this facility and to license this facility for commercial manufacturing of our product candidates. As a result of our business decision to focus our resources on our Neo-Urinary Conduit, activities that were under way to prepare this facility to commence manufacturing operations were temporarily halted in March 2009 and we are currently maintaining this facility in a condition that will enable us to complete these activities and commence manufacturing operations. We anticipate this commercial manufacturing facility can become fully operational following completion of these activities, including all necessary validation, certification and staffing requirements, which we believe can be accomplished in approximately 12 months.

15

Both facilities are designed to segregate the manufacturing and laboratory areas from the administrative portions of the building. The facilities are also designed to prevent cross-contamination of patient specific materials and to provide physical segregation while processing these materials. Our products are manufactured as individual units using disposable processing materials for storage and containment of the product. We do not face many of the traditional challenges of biopharmaceutical companies in maintaining batch quality as manufacturing is scaled up to commercial quantities because our batch size remains consistent at one unit and because the core manufacturing processes remain consistent regardless of production volume. We believe our existing facility infrastructure is sufficient to meet the initial commercial demand for our products and we can increase production capacity by installing additional equipment into existing space and by constructing additional manufacturing space within our existing facilities.

Sales and Marketing

We believe the product candidates we are currently developing will be used primarily by a relatively small number of specialty surgeons at hospitals in North America and the European Union. We intend to explore building the necessary marketing and sales infrastructure necessary to market and sell our current product candidates, if approved by the FDA, as well as hire other personnel to train physicians on the surgical techniques used with our product candidates. We will also explore the possibility of entering into strategic partnerships for the development and marketing our product candidates.

Intellectual Property

We have established a patent position surrounding our product candidates in regenerative medicine. As of December 31, 2010, we owned or had licenses to 22 issued U.S. patents, 20 of which are exclusive and two of which are non-exclusive, 34 U.S. patent applications and over 100 international patents and patent applications. The patent portfolio owned by the Company relates to the composition, design and methods of manufacture for our Neo-Urinary Conduit, Neo-Bladder Replacement and Neo-Bladder Augment product candidates, as well as technological advances associated with our Neo-Vessel Replacement, Neo-GI Augment, and Neo-Kidney Augment development programs. The licensed patent portfolio relates to technology developed by scientists and researchers associated with Childrens’ Medical Center Corporation and Wake Forest University Health Sciences. Also included within our portfolio are patents that address an array of regenerative medicine and tissue engineering technologies and product candidates outside the scope of our current product pipeline. In addition to our patent portfolio, we have developed proprietary information, trade secrets and know-how in the development and manufacture of neo-organs. We are committed to protecting our intellectual property position and to aggressively pursue our patent portfolio as well as the protection of our proprietary information, know-how and trade secrets.

16

Our Patent Portfolio

Our urologic product candidates currently include our Neo-Urinary Conduit, our Neo-Bladder Replacement, and our Neo-Bladder Augment. Our urologic-related patent portfolio is currently composed of 13 issued U.S. patents; 4 granted European patents, which have been validated in 12 European countries; 12 issued patents in other foreign jurisdictions; 6 pending U.S. non-provisional patent applications; 3 pending U.S. provisional patent applications; 2 pending Patent Cooperation Treaty, or PCT, applications; and 8 pending foreign patent applications, all of which relate to a PCT application. We have licensed all of the issued patents. We own 5 of the U.S. non-provisional patent applications, the PCT application, the U.S. provisional patent applications and 5 of the foreign patent applications. We have licensed all of the other pending applications.

The issued U.S. patents, which will expire between 2011 and 2020, contain claims directed to organ constructs, cell-matrix structures, organ scaffolds, and laminarly organized luminal organ or tissue structure constructs; methods of making the same, and methods of treatment using the same. If claims in the pending U.S. patent applications covering urinary conduit constructs, methods for producing the same, and methods of treatment using the same; methods of treatment using laminarly organized luminal organ or tissue structure constructs; and methods for correcting tissue defects in urological structures, are allowed, they would expire between 2014 and 2030. The granted European patents, which will expire between 2018 and 2020, contain claims directed to organ constructs, cell-matrix structures, organ scaffolds, and laminarly organized luminal organ or tissue structure constructs; and methods of making and using the same. The pending PCT, foreign and U.S. provisional applications contain claims directed to urinary conduit constructs, organ constructs, cell-matrix structures, organ scaffolds, and laminarly organized luminal organ or tissue structure constructs; methods of making and using the same; and rational design of regenerative medicine products. These patent applications, if issued, will expire between 2019 and 2030.

Our gastrointestinal (GI) development program is our Neo-GI Augment. Our GI-related patent portfolio is currently composed of 5 pending U.S. provisional patent applications, each of which is owned by us. If claims issue from patent applications filed claiming benefit of the provisional applications, they will expire in 2031.

Our renal development program is our Neo-Kidney Augment. Our renal-related patent portfolio is currently composed of 11 issued U.S. patents; 4 granted European patents, which have been validated in 12 European countries; 8 issued patents in other foreign jurisdictions; 4 pending U.S. non-provisional patent applications; 10 pending U.S. provisional patent applications; 2 pending PCT applications; and 15 pending foreign patent applications, all of which relate to a PCT application. We have licensed all of the issued patents. We own 2 of the U.S. non-provisional patent applications, the PCT application and the U.S. provisional applications. We have licensed all of the other pending applications.

The issued U.S. patents, which will expire between 2011 and 2020, contain claims directed to prosthetic kidneys, organ constructs, cell-matrix structures, organ scaffolds; methods of making the same, and methods of treatment using the same. If claims in the pending U.S. patent applications covering renal cell preparations and augmentation constructs, methods for producing the same, and methods of treatment using the same, are allowed, they would expire between 2019 and 2030. The granted European patents, which will expire between 2017 and 2020, contain claims directed to prosthetic kidneys, organ constructs, cell-matrix structures, organ scaffolds; and methods of making and using the same. The pending PCT, foreign and U.S. provisional applications contain claims directed to renal cell preparations and augmentation constructs, methods for producing and using the same; and rational design of regenerative medicine products. These patent applications, if issued, will expire between 2019 and 2030.

17

Our vascular development program is our Neo-Vessel Replacement. Our vessel-related patent portfolio is currently composed of 2 issued U.S. patents, 1 pending U.S. non-provisional patent application and 1 pending PCT application. We have licensed each of the issued patents. We own each of the pending applications. The issued U.S. patents, which will expire between 2015 and 2016, contain claims directed to cell-matrix constructs and methods of making the same. If claims in our pending U.S. and PCT patent applications covering tissue engineering scaffolds having a mechanical response to stress and strain substantially similar to that of a response by a native blood vessel, and methods of making the same, are allowed, they would expire in 2029.

Confidential Information and Inventions Assignment Agreements

We require our employees, consultants and members of our research and development advisory board to execute confidentiality agreements upon the commencement of employment, consulting or collaborative relationships with us. These agreements provide that all confidential information developed or made known during the course of the relationship with us be kept confidential and not disclosed to third parties except in specific circumstances. In the case of employees, the agreements provide that all inventions resulting from work performed for us, utilizing our property or relating to our business and conceived or completed by the individual during employment shall be our exclusive property to the extent permitted by applicable law.

License Agreements and Research Agreements

Exclusive License Agreement with Children’s Medical Center Corporation

In October 2003, we entered into a license agreement with Children’s Medical Center Corporation, or CMCC, for the license of certain patent rights and intellectual property rights owned or controlled by CMCC related to tissue engineering technology. The CMCC patent rights include patent rights owned by CMCC, as well as CMCC’s right to sublicense certain patent rights owned or controlled by Massachusetts Institute of Technology, or MIT. Under the terms of this license agreement, CMCC has granted us exclusive worldwide, sublicensable licenses under certain of CMCC’s patent rights related to implantable matrices for the development and commercialization of tissue engineered products for human and animal therapeutics in the subfields of genitourinary, vascular tissue, nervous tissue, trachea and other subfields later agreed upon by us and CMCC. Our license from CMCC is exclusive in all subfields for patent rights related to organ constructs; cell matrix structures; laminarly organized luminal organ or tissue structure constructs; prosthetic kidneys; kidney augmenting constructs; stents; reproductive organs and tissue structure constructs; as well as methods for making and using the same. Our license to CMCC’s patent rights related to implantable cartilaginous structures, implantable genitourinary cell-seeded matrices, and mammalian urothelial cell preparation is non-exclusive, except in the genitourinary subfield where the license is exclusive. Our license to CMCC’s patent rights relating to organ decellularization is non-exclusive for all subfields covered by the license agreement. Under the license agreement, we were also granted a non-exclusive, non-sublicensable, non-transferable license to certain CMCC biological materials and know-how related to unpatented manufacturing and scientific information, except that such license may be sublicensed or transferred to our affiliates and contractors for purposes specified in the license agreement. CMCC has retained a royalty-free, non-exclusive right to practice, use and license to other academic and nonprofit research organizations to practice and/or use the patent rights and licensed products for research, educational, clinical and/or charitable purposes only.

18

We are required under the license agreement to use reasonably diligent efforts, as defined in the license agreement, to bring one or more licensed products to market as soon as practicable and to obtain all necessary government approvals for the manufacture, use, sale and distribution of licensed products. If we fail to meet the diligence requirements set forth in the license agreement, we may be required under certain circumstances to grant a sublicense to a third party chosen by CMCC relating to the licensed product or subfield for which we have failed to meet our diligence obligations.

Under the license agreement, we are required to make payments to CMCC for accrued and continuing patent prosecution costs and also upon the achievement of certain development and sales milestones as well as certain consideration received from a sublicensee. If we develop and obtain regulatory approval of a licensed product in each of the four subfields, we will be required to pay CMCC development milestones aggregating approximately $6.9 million. Also, if cumulative net sales of all licensed products reach a certain level, we will be required to make a one-time sales milestone payment of $2.0 million. We have previously paid a license issue fee of $175,000 and $350,000 of development milestones to CMCC and as of December 31, 2010, we did not owe any milestone payments to CMCC under the license agreement. A portion of the milestone payments we make will be credited against our future royalty payments. We must pay CMCC royalties in the mid-single digit range based on net sales of licensed products as defined in the agreement by us, our affiliates and our sublicensees, which royalties will be reduced for certain amounts we are required to pay to license patents or intellectual property from third parties and under certain circumstances if there is a competing product. No royalties will be payable with respect to sales of licensed products in countries where there is no valid patent claim, unless we advised CMCC not to file for patent protection in that country and later choose to market and sell licensed products in such country. The license agreement, and our obligation to pay royalties terminates on the later of the expiration, on a country-by-country basis, of the last patent right and October 2018.

Either party may terminate the license agreement upon 90 days prior written notice upon a material, unremedied breach or default of the other party. CMCC may terminate the agreement immediately upon our insolvency or as otherwise provided in the agreement and also upon 45 days prior written notice for our failure to pay royalties due in a timely manner. We may terminate at any time, with or without cause, upon six months prior written notice and payment to CMCC of accrued amounts due and a $50,000 termination fee.

19

Wake Forest University Health Sciences License Agreement

In January 2006 we entered into a license agreement with Wake Forest University Health Sciences, or WFUHS, which was amended in May 2007, for the license of WFUHS’s intellectual property (including know-how) related to research performed by WFUHS employee, Dr. Anthony Atala, a former employee of the Children’s Hospital Boston, an affiliate of CMCC, and the inventor or co-inventor on certain inventions and patents held by CMCC, which are licensed to us under our license agreement with CMCC.

In January 2006, we entered into a research agreement with WFUHS, which was amended in September 2006. Under the research agreement, WFUHS agreed to perform sponsored research in return for quarterly payments. The sponsored research involves the experiments and studies set out in annual research plans and milestones established under the agreement. In September 2010, we extended the agreement for an additional three-year period commencing January 1, 2011. Either party may terminate the agreement upon a material, uncured breach by the other party upon 30 days written notice. We may terminate the agreement at any time, with or without cause, upon 90 days prior written notice.

Under the terms of this amended license agreement, WFUHS has granted us a worldwide, exclusive, sublicensable license to make, use and sell products covered by certain of WFUHS’s patent rights that relate to improvements of the existing inventions and patents included in the patent rights licensed to us under our license agreement with CMCC, or the improvement patents, and to new development inventions and patents arising out of the performance of a separate agreement, the WFUHS Research Agreement, or the new development patents, in the fields of human and animal organs, tissues and tissue-engineered and regenerative medicine directed to their functions in the subfields of genitourinary tissue, kidney tissue, cardiovascular tissue and nervous tissue. This license agreement also granted us a non-exclusive, worldwide, sublicensable license to certain know-how related to unpatented manufacturing and scientific information provided by WFUHS. Our license to patents claiming inventions conceived after the expiration or other termination of the WFUHS Research Agreement may be terminated at any time by WFUHS following expiration or other termination of the WFUHS Research Agreement. Under the terms of the May 2007 amendment to the license agreement, we may elect to provide funding for research activities under the WFUHS Research Agreement directed to products that would be covered by the new development patents. If we elect to provide such funding we are required to provide a minimum of $1 million in annual funding, provided that we may decide within our discretion to reduce the amount of such annual funding by increments of $200,000. If we reduce the annual funding we are required to give up our rights to a license under one subfield for each $200,000 incremental reduction in the annual funding. We reduced our annual funding commitment for 2010 to $800,000 and agreed to give up our rights to a license under the trachea tissue subfield pursuant to this provision.

We are obligated to use commercially reasonable efforts to bring licensed products to market. If WFUHS believes that we have failed to comply with this obligation and an arbitrator agrees with WFUHS, we will be required to enter into a sublicense for the relevant product or grant WFUHS the right to enter into a sublicense for the that product. We are not required to make any milestone payments to WFUHS related to the development or commercialization of the licensed products. In addition, we are required to meet certain time deadlines with respect to initiating the first human clinical trial, filing for marketing approval with the FDA and achieving the first commercial sale in the United States with respect to the first product covered by the new development patents in each subfield. If we fail to meet any of these deadlines, WFUHS may, in its sole option, terminate our license with respect to such product covered by the new development patents.

20

Under the license agreement, we also issued WFUHS a warrant to purchase 3,200 shares of our common stock through January 1, 2016 at an exercise of $2.32 per share and are required to pay WFUHS a percentage of certain consideration received from a sublicensee. We are required to pay certain license maintenance fees with respect to each product covered by new development patents, commencing two years after we initiate the first animal study conducted under cGLP, with respect to such product. These license maintenance fees, which are in the low six figure range with respect to each product, will be creditable against royalties we are obligated to pay to WFUHS for such product. In addition, we are required to pay WFUHS royalties in the low- to mid-single digit range based on net sales of licensed products in all countries. With respect to any product covered by an improvement patent, our obligation to pay royalties to WFUHS terminates upon the later of the expiration, on a product-by-product basis, of the last to expire patent covering such product and the date that is 15 years from the first commercial sale of such product, provided that no such royalty is payable more than seven years after expiration of the last-to-expire patent covering such product.

With respect to any licensed product that is not covered by an improvement patent, our obligation to pay royalties to WFUHS terminates, on a product-by-product basis, on the date that is five years from the first commercial sale of such product, provided that the first commercial sale occurs prior to January 1, 2021 (for each day after January 1, 2021 that the first commercial sale does not occur, the five-year period is reduced by one day).

Pursuant to the terms of the amended license agreement, we have provided $2.8 million of funding for research activities under the WFUHS research agreement through December 31, 2010. We have made no other payments under the license agreement with WFUHS.

The agreement continues in effect on a country-by-country basis until the later of the expiration of the last to expire new improvement patent and January 1, 2021, unless earlier terminated as provided in the agreement. We may terminate the license agreement at any time, with or without cause, upon 90 days prior written notice. WFUHS may terminate the license agreement upon our default in paying a license fee or providing a report required to be provided under the license agreement, our material breach or our making a knowingly false report, upon 45 days prior written notice, provided that we may cure such default or breach within the 45-day period.

21

Medtronic Right of First Refusal and Right of First Negotiation Agreement

On March 1, 2011, we entered into a Right of First Refusal and Right of First Negotiation Agreement with Medtronic, Inc. pursuant to which we granted Medtronic a right of first refusal to the license, sale, assignment, transfer or other disposition by us of any material portion of intellectual property (including patents and trade secrets) or other assets related to our Neo-Kidney Augment program (an NKA transaction) until October 31, 2013. Additionally, from November 1, 2013 through July 1, 2014, Medtronic will have a right of first negotiation with respect to an NKA transaction, with an option to convert that right of first negotiation to a right of first refusal. Medtronic made a $7 million investment in our common stock along side other investors in a private placement consummated on March 4, 2011. In consideration for receiving rights under the Right of First Refusal and Right of First Negotiation Agreement, Medtronic agreed to receive a warrant to purchase 25% fewer shares of common stock that otherwise would have been issued to Medtronic pursuant to the terms of the private placement. In the event of a change in control, and without any obligation on our part, the agreement and all Medtronic’s rights pursuant thereto will automatically terminate in all respects and be of no further force and effect.

Competition

Our industry is subject to rapid and intense technological change. While we do not believe we currently have any commercial competitors who are developing autologous organs and tissues for the target populations that we are addressing, we face, and will continue to face, intense competition from medical device, pharmaceutical, biopharmaceutical and biotechnology companies, as well as numerous academic and research institutions and governmental agencies who are generally engaged in tissue engineering and regenerative medicine activities or funding, both in the United States and abroad. In addition, there are companies and academic institutions developing drugs, medical devices and surgical techniques to treat many of the medical conditions our product candidates are designed to treat.

Regenerative Medicine

While we are, to our knowledge, the only regenerative medicine company presently developing a range of neo-organs for implant that are designed to regenerate into functional organs and tissues, there are some companies that are researching and developing regenerative cell-based products or therapies, which may seek to address the medical indications that our neo-organ product candidates seek to address. The companies include Cytograft, Tissue Engineering, Inc., Osiris Therapeutics, Inc., Integra Life Sciences, Inc., Pervasis Therapeutics, Inc., LifeCell (a division of Kinetic Concepts, Inc.) and Genzyme. In addition, several large pharmaceutical companies with much greater resources have demonstrated a strategic interest in regenerative medicine, including Sanofi Aventis, Johnson & Johnson, Pfizer and Celgene.

Bladder Treatment

We expect that our Neo-Urinary Conduit and Neo-Bladder Replacement will compete with the current standard of care, which is the use of bowel tissue to create a urinary diversion.

22

Companies that are researching, developing and marketing products to treat bladder dysfunction include Allergan, which is developing Botox for bladder dysfunction; Speywood Biopharma, which is developing Dysport for bladder dysfunction; and Medtronic, which is marketing Interstim for bladder dysfunction. Further, many large pharmaceutical companies market anticholinergenic medications, such as Detrol and Ditropan, which can be used to treat bladder dysfunction.

Many of the companies competing against us have financial and other resources substantially greater than our own. In addition, many of our competitors have significantly greater experience in testing therapeutic products, obtaining FDA and other marketing approvals of products, and marketing and selling those products. Accordingly, our competitors may succeed more rapidly than we will in obtaining FDA approval for products and achieving widespread market acceptance.

We expect to compete based upon, among other things, our intellectual property portfolio, substantial process know-how with respect to scalable manufacturing capabilities and the efficacy and safety profile of our product candidates. Our ability to compete successfully will depend, in part, on our continued ability to attract and retain skilled and experienced scientific, clinical development and executive personnel, to develop viable autologous neo-organs.

Government Regulation

Regulation by governmental authorities in the United States and other countries is a significant factor in the development, manufacture, commercialization and reimbursement of our neo-organs. All of the products we are seeking to develop will require marketing approval, or licensure, by governmental agencies prior to commercialization. In particular, human therapeutic products are subject to rigorous preclinical and clinical testing, approval and marketing regulations promulgated by the FDA and similar regulatory authorities in other countries. Various governmental statutes and regulations also govern or influence testing, manufacturing, quality control, safety, labeling, packaging, storage and record keeping related to such products and their marketing. State, local and other authorities may also regulate manufacturing facilities used for our neo-organs. The process of obtaining these approvals and the subsequent compliance with appropriate statutes and regulations require the expenditure of substantial time and money, and there can be no guarantee that approvals will be granted.

FDA Approval Process

Our neo-organs will require approval from the FDA and corresponding agencies in other countries before they can be marketed. The FDA regulates human therapeutic products in one of three broad categories: biologics, drugs, or medical devices. Our product candidates that are currently under development are combination products having features of both a biologic and a medical device. The FDA has determined that the primary mode of action for our Neo-Urinary Conduit is cellular and, therefore, they will be regulated as biologics. We currently believe other neo-organs that we develop will also be regulated as biologics and will therefore require approval via a Biologics License Application, or BLA. The FDA regulates biological products under both the Federal Food, Drug, and Cosmetic Act and the Public Health Service Act, and implementing regulations for both statutes. The FDA generally requires the following steps for pre-market approval or licensure of a new biological product:

23

|

|

·

|