Attached files

Table of Contents

UNITED STATES SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

Form 10-K

x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the Fiscal Year Ended December 31, 2010

OR

¨ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission File Number: 1-7665

Lydall, Inc.

(Exact name of registrant as specified in its charter)

| Delaware |

06-0865505 | |

| (State or Other Jurisdiction of Incorporation or Organization) |

(I.R.S. Employer Identification No.) | |

| One Colonial Road, Manchester, Connecticut |

06042 | |

| (Address of principal executive offices) |

(Zip code) | |

Registrant’s telephone number, including area code: (860) 646-1233

Securities registered pursuant to Section 12(b) of the Act:

| Title of each class |

Name of each exchange on which registered | |

| Common Stock, $.10 par value |

New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ¨ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of the registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

|

Large accelerated filer ¨ |

Non-accelerated filer ¨ |

Accelerated filer x |

Smaller reporting company ¨ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

On June 30, 2010, the aggregate market value of the Registrant’s voting stock held by nonaffiliates was $126,451,703 based on the New York Stock Exchange closing price on that date. For purposes of this calculation, the Registrant has assumed that its directors and executive officers are affiliates.

On February 15, 2011, there were 17,133,751 shares of Common Stock outstanding, exclusive of treasury shares.

DOCUMENTS INCORPORATED BY REFERENCE

Part III incorporates information by reference to the definitive Proxy Statement to be distributed in connection with the Registrant’s Annual Meeting of Stockholders to be held on April 29, 2011.

The exhibit index is located on pages 38-40.

Table of Contents

INDEX TO ANNUAL REPORT ON FORM 10-K

Year Ended December 31, 2010

| Page Number |

||||||

| Item 1. |

1 | |||||

| Item 1A. |

4 | |||||

| Item 1B. |

8 | |||||

| Item 2. |

8 | |||||

| Item 3. |

9 | |||||

| Item 4. |

9 | |||||

| 10 | ||||||

| Item 5. |

11 | |||||

| Item 6. |

14 | |||||

| Item 7. |

Management’s Discussion and Analysis of Financial Condition and Results of Operations |

15 | ||||

| Item 7A. |

34 | |||||

| Item 8. |

34 | |||||

| Item 9. |

Changes in and Disagreements With Accountants on Accounting and Financial Disclosure |

35 | ||||

| Item 9A. |

35 | |||||

| Item 9B. |

36 | |||||

| Item 10. |

37 | |||||

| Item 11. |

37 | |||||

| Item 12. |

Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters |

37 | ||||

| Item 13. |

Certain Relationships and Related Transactions, and Director Independence |

37 | ||||

| Item 14. |

37 | |||||

| Item 15. |

38 | |||||

| 41 | ||||||

The information called for by Items 10, 11, 12, 13 and 14, to the extent not included in this document, is incorporated herein by reference to such information included in the Company’s definitive Proxy Statement to be filed with the Securities and Exchange Commission and distributed in connection with Lydall, Inc.’s 2011 Annual Meeting of Stockholders to be held on April 29, 2011.

Table of Contents

Lydall, Inc. and its subsidiaries are hereafter collectively referred to as “Lydall,” the “Company” or the “Registrant.”

Lydall, Inc. has been incorporated in Delaware since 1987 after originally being incorporated in Connecticut in 1969. The principal executive offices are located in Manchester, Connecticut. The Company’s subsidiaries design and manufacture specialty engineered filtration media, industrial thermal insulating solutions, automotive thermal and acoustical barriers, temperature-control equipment, medical filtration media and devices and biopharmaceutical processing components for thermal/acoustical, filtration/separation and bio/medical applications.

Lydall serves a number of markets. The Company’s products are primarily sold directly to customers through an internal sales force and external sales representatives and distributed via common carrier. The majority of products are sold to original equipment manufacturers and tier-one suppliers. The Company competes through high-quality, specialty engineered innovative products and exceptional customer service. Lydall has a number of domestic and foreign competitors for its products, most of whom are either privately owned or divisions of larger companies, making it difficult to determine the Company’s share of the markets served.

Thermal/Acoustical segment sales to the automotive market represented 53.0% of Lydall’s net sales in 2010, 51.3% in 2009 and 53.5% in 2008. Sales to Ford Motor Company were $35.0 million and $24.1 million, or approximately 10% of Lydall’s 2010 and 2009 net sales, respectively. Sales to Volkswagen were approximately 10% of net sales in 2008. Sales to Chrysler were approximately 10% of net sales in 2008. No other single customer accounted for more than 10% of the Company’s net sales in 2010, 2009 or 2008.

Foreign and export sales were 49.9% of net sales in 2010, 50.3% in 2009 and 53.2% in 2008. Export sales primarily to Europe, Asia, Mexico and Canada were $46.2 million, $28.8 million and $44.0 million in 2010, 2009 and 2008, respectively. Foreign sales were $122.4 million, $96.3 million and $118.5 million for the years ended December 31, 2010, 2009 and 2008, respectively. The increase in export sales during 2010 was primarily related to higher export sales to Canada, China and Mexico in the Performance Materials and Thermal/Acoustical segments as a result of markets beginning to recover from the global economic recession. The increase in foreign net sales during 2010 was primarily from the Germany automotive facility, included in the Thermal/Acoustical segment.

Foreign operations generated operating income of $11.0 million, $1.6 million and $8.3 million for the years ended December 31, 2010, 2009 and 2008, respectively. Total foreign assets were $94.1 million at December 31, 2010 compared with $97.6 million at December 31, 2009.

The Company’s Annual Reports on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and Proxy Statements are made available free of charge through the Investor Relations section of the Company’s Internet website at www.lydall.com after such material is electronically filed with, or furnished to, the Securities and Exchange Commission (the “Commission”) and are also available on the Commission’s website at www.sec.gov. Additionally, the public may read and copy any materials the Company files with the Commission at the Commission’s Public Reference room located at 100 F Street, N.E., Washington, D.C. 20549. The public may obtain information on the operation of the Public Reference Room by calling the Commission at 1-800-SEC-0330.

The Company’s Code of Ethics and Business Conduct for all employees and its Code of Ethics for the Chief Executive Officer, Senior Financial Officers and All Accounting and Financial Personnel can be obtained free of charge on the Company’s website under the Corporate Governance section or by contacting the Office of the General Counsel, P.O. Box 151, One Colonial Road, Manchester, CT 06045-0151.

SEGMENTS

The Company’s reportable segments are Performance Materials and Thermal/Acoustical. The Thermal/Acoustical segment reports the results of Lydall’s automotive businesses. The Performance Materials segment reports the results of the filtration and industrial thermal insulation businesses. All other businesses are aggregated in Other Products and Services (“OPS”).

1

Table of Contents

Performance Materials

The Performance Materials segment includes filtration media solutions for air, fluid power, industrial and life science applications and industrial thermal insulation solutions for building products, appliances, and energy and industrial markets.

Lydall air filtration products include LydAir®MG (Micro-Glass), LydAir®MB (Melt Blown), LydAir®SC (Synthetic Composite) and Arioso™ (Membrane Composite) media. These products constitute the critical media component of clean-air systems for applications in clean-space, commercial, industrial and residential HVAC, power generation, industrial processes and protection/respiratory devices. Lydall has leveraged its extensive technical expertise and applications knowledge into a suite of media products covering the vast liquid filtration landscape across the engine and industrial and life science fields. The LyPore® and activated carbon containing ActiPure® media series address a variety of application needs including hydraulic filters, air-water and air-oil coalescing, industrial fluid processes, diesel filtration, biopharmaceutical pre-filtration and clarification, diagnostic tests, and drinking water filtration. The Company also manufactures Lydall Solupor® specialty microporous membranes that are utilized in various markets and applications including batteries, fuel cells and supercapacitors, air and liquid filtration, and transdermal drug delivery. Solupor® membranes are based on ultra-high molecular weight polyethylene and incorporate an uncommon combination of mechanical strength, chemical inertness, and high porosity in a unique open structure.

The industrial thermal insulation business develops unique high performance nonwoven veils, papers, mats and specialty composites for the building products, appliance, and energy and industrial markets. The Manniglas® brand is diverse in its product application ranging from high temperature seals and gaskets in ovens and ranges to specialty veils for HVAC and cavity wall insulation. appLY™ Mat has been developed to expand Lydall’s high temperature technology portfolio for broad application into the appliance market and supplements the Lytherm™ product brand, traditionally utilized in the industrial market for kilns and furnaces used in metal processing. Lydall’s CryothermTM, CRS-WrapTM and CryoliteTM products are industry standards for state-of-the-art cryogenic insulation designs used by manufacturers of cryogenic equipment for liquid gas storage, piping and transportation.

Net sales from the Performance Materials segment represented 36.4% of Lydall’s net sales in 2010 compared with 39.4% in 2009 and 36.5% in 2008. Net sales generated by the international operations of the Performance Materials segment accounted for 29.8%, 29.8% and 27.6% of segment net sales in 2010, 2009 and 2008, respectively.

Thermal/Acoustical

The Thermal/Acoustical segment offers a full line of innovative engineered products to assist in noise and heat abatement within the transportation sector. Lydall products are found in the interior (Dash insulators), underbody (fuel tank, exhaust) and underhood (engine compartment) of cars, trucks, SUV’s, heavy duty trucks and recreational vehicles. Lydall’s patented products include ZeroClearance®, AMS®, Flexshield® and dBCore® comprising of organic and inorganic fiber composites as well as metal combinations.

Thermal/Acoustical segment net sales represented 53.0% of the Company’s net sales in 2010, 51.3% in 2009 and 53.5% in 2008. Net sales generated by international operations of the Thermal/Acoustical segment accounted for 46.2%, 51.4% and 52.4% of segment net sales in 2010, 2009 and 2008, respectively.

Other Products and Services

The components of OPS are Lydall’s Vital Fluids business and Affinity® temperature control equipment (“Affinity”) business.

The Vital Fluids business serves the life science industry offering specialty products for blood transfusion and cell therapy applications as well as Bio-Pak® single-use bioprocessing containers for containment of media, buffers and bulk intermediates used in biotech, pharmaceutical and diagnostic reagent manufacturing processes. Vital Fluids also offers Cell-Freeze®, a medical device used for cryogenic storage of peripheral blood stem cells. Its medical filter materials products are utilized in traditional blood filtration devices such as cardiotomy reservoirs and autotransfusion filters. Other products include specialty blood transfusion products, as well as medical filtration components used for surgical procedures.

The Affinity business designs and manufactures high precision, specialty engineered temperature-control equipment, including standard, configurable models, for demanding semiconductor, pharmaceutical, life sciences and industrial applications.

2

Table of Contents

OPS net sales were 11.1% of the Company’s net sales in 2010 compared with 9.6% in 2009 and 10.4% in 2008. Net sales generated by the international operations of OPS accounted for 7.9%, 6.2% and 6.1% of OPS net sales in 2010, 2009 and 2008, respectively.

OTHER INFORMATION

During 2011, the Company is implementing internal organizational changes in its Performance Materials and Vital Fluids businesses to better align the Company’s structure with its strategic direction. Lydall is integrating operational activities and realigning sales and marketing responsibilities within and across these two businesses. In 2011, the Company expects that the Vital Fluids business will be included in the operating results of the Performance Materials segment.

GENERAL BUSINESS INFORMATION

Lydall holds a number of patents, trademarks and licenses. While no single patent, trademark or license is critical to the success of Lydall, together these intangible assets are of considerable value to the Company.

The Company’s business is generally not seasonal; however, results of operations are impacted by shutdowns at its European operations and at its North American and European automotive customers that typically occur in the third and fourth quarters of each year. Lydall maintains levels of inventory and grants credit terms that are normal within the industries it serves. The Company uses a wide range of raw materials in the manufacturing of its products. The majority of raw materials used are generally available from a variety of suppliers.

The Company invested $8.7 million in 2010, $7.9 million in 2009 and $8.5 million in 2008, or approximately 3% of net sales for all years, in research and development to develop new products and to improve existing products. All amounts were expensed as incurred. Most of the investment in research and development is application specific. There were no significant customer-sponsored research and development activities during the past three years.

Backlog at January 31, 2011 was $55.7 million. Lydall’s backlog was $49.0 million at December 31, 2010, $26.3 million at December 31, 2009 and $18.0 million at December 31, 2008. Thermal/Acoustical segment backlog, comprising the global automotive business, included in Lydall’s backlog was $31.8 million, $12.2 million and $8.2 million at December 31, 2010, 2009 and 2008, respectively. Thermal/Acoustical backlog may be impacted by various assumptions, including future automotive production volume estimates, changes in program launch timing and changes in customer development plans. The Company believes that global automotive orders for a two month period represent a reasonable timeframe to be deemed as firm orders and included as Thermal/Acoustical segment backlog. The increase in Lydall’s backlog at December 31, 2010 compared with December 31, 2009 was due to a significant improvement in demand from customers beginning to recover from the global economic recession and market share gains in certain markets served by the Company. There are minimal seasonal aspects to Lydall’s backlog as of the end of the Company’s fiscal years.

No material portion of Lydall’s business is subject to renegotiation of profits or termination of contracts or subcontracts at the election of any governmental body.

Lydall believes that its plants and equipment are in substantial compliance with applicable federal, state and local provisions that have been enacted or adopted regulating the discharge of materials into the environment, or otherwise relating to the protection of the environment.

As of December 31, 2010, Lydall employed approximately 1,600 people. Four unions with contracts expiring on March 31, 2012 represent 67 employees in the United States. All employees at the facilities in France and the Netherlands are covered under a National Collective Bargaining Agreement. Certain salaried and all hourly employees in Germany are also covered under a National Collective Bargaining Agreement. Lydall considers its employee relationships to be satisfactory and did not have any actual or threatened work stoppages due to union-related activities in 2010.

There are no significant anticipated operating risks related to foreign investment law, expropriation, or availability of material, labor or energy. The foreign and domestic operations limit foreign currency exchange transaction risk by completing transactions in functional currencies whenever practical or through the use of foreign currency forward exchange contracts when deemed appropriate.

3

Table of Contents

The reader should carefully review and consider the risk factors discussed below. Any and all of these risk factors could materially affect the Company’s business, financial condition, future results of operations or cash flows and possibly lead to a decline in Lydall’s stock price. The risks, uncertainties and other factors described below constitute all material risk factors known to management as of the date of this report.

The Company’s Ability to Accurately Report its Financial Results may be Adversely Affected by the Lack of Effective Internal Controls and Procedures – At December 31, 2010, the Company had a material weakness in internal control over financial reporting. In connection with the preparation and filing of the third quarter 2010 Form 10-Q, the Company’s Chief Executive Officer and Chief Financial Officer concluded that the disclosure controls and procedures were not effective as of September 30, 2010 because of a material weakness in its internal control over financial reporting described in Item 4 of the Form 10-Q filed on November 5, 2010. As described in Item 9A of this Annual Report on Form 10-K, management believes that at December 31, 2010, enhancements have been made to strengthen the disclosure controls and procedures. Because the reliability of the internal control process requires repeatable execution, the successful remediation of this material weakness will require review and evidence of effectiveness prior to management concluding that the controls are now effective. Some of the enhancements that have been implemented by management in the fourth quarter of 2010 have not been in place for a sufficient period of time to demonstrate that their effectiveness is sustainable. Therefore, additional time is required to validate that the material weakness is fully remediated. Until management is able to ensure the effectiveness of the Company’s disclosure controls and procedures, the material weakness may materially adversely affect the Company’s ability to report accurately its financial information in a timely and reliable manner.

Worldwide Economic Cycles – Worldwide economic cycles affect the markets that the Company’s businesses serve and could affect demand for the Company’s products and impact profitability. Among other factors, disruptions in the global credit and financial markets, including diminished liquidity and credit availability, swings in consumer confidence and spending, unstable economic growth and fluctuations in unemployment rates could cause further economic instability and could have a negative impact on the Company’s results of operations, financial condition and liquidity and make it difficult to accurately forecast and plan future business activities. Demand for the Company’s products may be affected by continued uncertainty regarding the overall economic outlook for both U.S. and non-U.S. economies.

Quarterly Results – The Company’s quarterly results are subject to significant fluctuations. Operating results may fluctuate as a result of many factors, including size and timing of orders and shipments, loss of significant customers, product mix, technological change, operational efficiencies and inefficiencies, competition and general economic conditions. In addition, if revenues and asset utilization decrease, the absorption of the Company’s fixed costs will negatively impact gross margins.

Thermal/Acoustical Segment – Supplier to the Global Automotive Market – The Company’s Thermal/Acoustical segment, a vendor to the automotive market, accounted for approximately 53% of consolidated net sales in 2010. Approximately 54% of segment net sales were manufactured in North America and 46% were manufactured in Europe. Among other factors, the Company’s automotive business could be impacted by:

| • | Global economic uncertainties and swings in consumer spending; |

| • | A continuation of gross margin losses on fiber based products at its North American automotive facility. Fiber-based products were negatively impacted by higher manufacturing costs during 2010, including increases in raw material costs, abnormally high labor and overtime costs, material usage inefficiencies and excessive scrap on production lines, significant freight expediting and inspection costs; |

| • | The degree of success of actions aimed at improving the gross margins of fiber based products at the North American automotive facility as there is no assurance that depressed operating results for the Thermal/Acoustical segment will not continue in 2011; |

| • | An inability to satisfy the demand for the Company’s fiber-based products at the North American automotive facility, including on time delivery requirements, resulting in customer claims and contract penalties. Additionally, product quality could be impaired by the Company’s efforts to rapidly ramp up production necessary to satisfy a dramatic increase in demand; |

| • | Impairment of the Company’s relations with the automotive manufacturers and its status as an approved supplier to the automotive manufacturers as the result of the Company’s failure to satisfy current and expected demand and/or incur |

4

Table of Contents

| product quality issues. An impairment of the Company’s status as an approved supplier could result in the loss of future business; |

| • | The inability of the Company to realize the expected benefits from investments it has made in capital equipment to respond to the increased demand for the Company’s fiber-based automotive products; |

| • | Financial uncertainties faced by automakers and other automotive customers, as well as labor unrest and supply chain disruptions in the automotive industry; |

| • | The failure of an automaker to timely, or ever, pay the Company amounts owed, especially since receivables from automakers often comprise a material portion of overall account receivable; |

| • | The Company’s dependence on sales to large automotive manufacturers who have substantial bargaining power with respect to price, volume and other commercial terms. In the event customers obtain price decreases from Lydall, Lydall may not be able to offset such reduction by decreases in its costs of goods sold; |

| • | The sourcing by automotive OEM’s of parts from lower cost countries, in which Lydall does not operate. |

Restructurings and Cost Reduction Activities – During 2009, Lydall implemented certain measures to address slowdowns in the markets for most of its products, including a consolidation of facilities and headcount reductions. The Company cannot assure that, if production levels continue to increase, measures implemented in 2009 will not result in unforeseen costs, disruptions in operations or have other negative effects.

Manufacturing Efficiencies – The Company operates a number of manufacturing facilities. The equipment and systems necessary for such operations may break down, perform poorly or fail, causing fluctuations in manufacturing efficiencies. Such fluctuations could affect the Company’s ability to deliver products to customers on a timely basis, which could have a material adverse effect on the Company’s financial condition or results of operations.

Cyclical Business – Lydall’s Affinity business, which provides capital equipment for the semiconductor and other industries, experienced a significant increase in customer demand in 2010 and may not be able to satisfy this demand or otherwise deliver products on time. The Affinity business is subject to, and affected by, dramatic swings in demand in the historically cyclical semiconductor industry. As a result, it is possible that demand for Affinity products, which has recently increased, could significantly decrease in the future.

Liquidity and Capital Resources – The Company may not have adequate cash to fund its operating requirements. The principal source of liquidity is operating cash flows. In addition to operating cash flows, other significant factors that affect the overall management of liquidity include capital expenditures, investments in businesses, acquisitions, income tax payments, pension funding, outcomes of contingencies and availability of lines of credit and long-term financing. The Company’s liquidity can be impacted by the Company’s ability to:

| • | Manage working capital and the level of future profitability. The consolidated cash balance is impacted by capital equipment and inventory investments that may be made in response to changing market conditions; |

| • | Satisfy covenants and other obligations under its Domestic Credit Facility, which could limit or prohibit Lydall’s ability to borrow funds under the Domestic Credit Facility. Additionally, these debt covenants and other obligations could limit the Company’s ability to make acquisitions, incur additional debt, make investments, or consummate asset sales; |

| • | Obtain additional financing from other sources. |

Raw Material Pricing and Supply – Raw material pricing and supply issues could affect all of the Company’s businesses. The Thermal/Acoustical segment uses aluminum and other metals to manufacture most of its automotive heat shields. The Thermal/Acoustical and Performance Materials segments use various fibers in manufacturing its products. If the prices of these raw materials increase, the Company may not have the ability to pass incremental cost increases on to its customers, thus negatively impacting Lydall’s financial results. In addition, an interruption in the ability of the Company to source these materials could negatively impact operations and sales.

Energy Pricing – Increases in energy pricing can affect all of the Company’s businesses. Higher energy costs at the Company’s manufacturing plants or higher energy costs passed on from the Company’s vendors could impact each business’ profitability.

5

Table of Contents

International Operations – The Company believes that in order to be competitive and grow its businesses, it needs to maintain significant international operations. Foreign sales were $122.4 million, $96.3 million, and $118.5 million in 2010, 2009 and 2008, respectively. Operations outside the United States may be subject to inherent risks including political and economic conditions in various countries, unexpected changes in regulatory requirements, longer accounts receivable collection cycles and potentially adverse tax consequences.

Foreign Currency Exchange Rate Fluctuations – Transactions in non-functional currencies may be affected by exchange rate fluctuations. The Company’s primary currency exposure is to the Euro. The Company’s foreign and domestic operations limit foreign currency exchange transaction risk by completing transactions in functional currencies whenever practical or through the use of foreign currency forward exchange contracts when deemed appropriate. If the Company is not able to successfully hedge its currency exposure, changes in the rate of exchange between these foreign currencies and the U.S. dollar may negatively impact the Company. Additionally, translation of the results of operations and financial condition of its foreign operations into U.S. dollars may be affected by exchange rate fluctuations. The Company receives a material portion of its revenue from foreign operations. The Company’s reported results of operations and financial condition are subject to changes in the exchange relationship between the U.S. dollar and any applicable foreign currency. Such changes can affect the Company’s results of operations and assets and liabilities as reported in its financial statements.

Company Resources – The industries in which Lydall sells its products are highly competitive and many of the competitors are affiliated with entities that are substantially larger and that have greater financial, technical and marketing resources. The Company’s more limited resources and relatively diverse product mix may limit or impair its ability to capitalize on changes in technology, competition and pricing.

New Product Introductions – Improved performance and growth are partially dependent on new product introductions planned for the future. Delays in developing products and long customer qualification cycles may impact the success of new product programs. The degree of success of new product programs could materially impact the Company’s future results.

Product Performance – In the event that the Company’s products fail to perform as expected, the Company may be subject to warranty claims from its customers. If such failure results in, or is alleged to result in, bodily injury and/or property damage or other losses, the Company may be subject to product liability lawsuits, product recalls and other claims, any of which could have a material impact on results of operations and cash flows.

Strategic Initiatives – As part of Lydall’s business strategy, the Company continues to review various strategic and business opportunities to grow the business and evaluates the profitability and growth potential for each of its existing businesses. The Company cannot predict with certainty whether any recent or future strategic transactions will be beneficial to the Company. Future performance could be impacted by the Company’s ability to:

| • | Obtain adequate financing to fund strategic initiatives, which could be difficult to obtain; |

| • | Identify and effectively complete strategic transactions; |

| • | Successfully integrate and manage acquired businesses that involve numerous operational and financial risks, including difficulties in the assimilation of acquired operations, diversion of management’s attention from other business concerns, managing assets in multiple geographic regions and potential loss of key employees and key customers of acquired operations. |

Attracting and Retaining Key Employees – The Company’s success, in part, depends on key managerial, engineering, sales and marketing and technical personnel and its ability to continue to attract and retain additional personnel. The loss of certain key personnel could have a material, adverse effect upon the Company’s business and results of operations. There is no assurance that Lydall can retain its key employees or that it can attract competent and effective new or replacement personnel in the future.

Key Management Changes to Business Segments – In 2011, the Company is implementing internal organizational changes in its Performance Materials and Vital Fluids businesses. In order to better align the Performance Materials and Vital Fluids businesses with the Company’s strategic direction, Lydall is integrating operational activities and realigning sales and marketing responsibilities. The Company’s ability to effectively and efficiently implement these changes could impact these businesses’ operations and customer relations.

6

Table of Contents

Accounting Estimates – Estimates and assumptions may affect the reserves that the Company has established to cover uncollectible accounts receivable, excess or obsolete inventory, income tax valuation and fair market value write downs of certain assets and various liabilities. Actual results could differ from those estimates.

Lean Six Sigma Initiatives – The Company’s Lean Six Sigma program is intended to improve processes and work flow, improve customer service, reduce costs and leverage synergies across the Company to improve operating margins. There is no assurance that future Lean Six Sigma initiatives will result in improved operating margins.

Environmental Laws and Regulations – The Company is subject to federal, state, local, and foreign environmental, and health and safety laws and regulations that affect ongoing operations. In order to maintain compliance with such requirements, Lydall may incur increased capital costs and operating expenses. In addition, new laws and regulations, including legislation and regulation regarding climate change, discovery of previously unknown contamination, or the imposition of new clean-up requirements could require the Company to incur costs or become subject to new or increased liabilities that could have a material impact on results of operations and cash flows.

Intellectual Property – Lydall owns intellectual property, including patents and trademarks, which play an important role in helping the Company to maintain its competitive position in a number of markets. The Company is subject to risks with respect to (i) changes in the intellectual property landscape of markets in which it competes; (ii) the potential assertion of intellectual property-related claims against Lydall; (iii) the failure to maximize or successfully assert its intellectual property rights; and (iv) significant technological developments by others.

Legal Proceedings – The Company is involved in legal proceedings that, from time to time, are significant. These proceedings may include, without limitation, commercial or contractual disputes, intellectual property matters, personal injury claims and employment matters. No assurances can be given that such proceedings and claims will not have a material adverse impact on the Company’s results of operations and cash flows.

Tax Rate Changes – The Company is subject to risks with respect to changes in tax law and rates, changes in rules related to accounting for income taxes, or adverse outcomes from tax audits that may be in process in any of the jurisdictions in which the Company operates. In addition, certain jurisdictions have statutory rates greater than or less than the United States statutory rate. Changes in the mix and source of earnings between jurisdictions could have a significant impact on the overall effective tax rate in future periods.

Disruptions to the Company’s Operations Relating to Information Technology – The capacity, reliability and security of the Company’s information technology hardware and software infrastructure and the ability to expand and update this infrastructure in response to the Company’s changing needs are important to the operation of the businesses. Any failure of, or inadequacy in, the information technology infrastructure could harm Lydall’s businesses and negatively impact results of operations and cash flows.

The Company’s Ability to Effectively Upgrade Its Enterprise Resource Planning (“ERP”) System – In response to a review of its IT infrastructure, the Company has undertaken a project to upgrade its ERP system. The deployment, implementation and integration to a new version of its ERP system may not be managed in an efficient, timely and cost effective manner resulting in greater than anticipated costs and other operating difficulties.

Disruptions to the Company’s Operations – A major disruption caused by acts of war, global warming, terrorist attacks, the threat of domestic and international terrorist attacks, a natural disaster, a fire, or labor strikes and work stoppages at any of the Company’s facilities could result in a prolonged interruption of its business. Certain employees in the United States and Germany and all employees in France and the Netherlands are covered by one or more collective bargaining agreements. Widespread work stoppages or a major strike could have a direct negative impact on the Company’s ability to conduct business, continue production and on its operating results.

7

Table of Contents

Item 1B. UNRESOLVED STAFF COMMENTS

None

The principal properties of the Company as of December 31, 2010 are situated at the following locations and have the following characteristics:

| Location | Primary Business Segment/General Description | Type of Interest |

||||

| Hamptonville, North Carolina |

Thermal/Acoustical – Product Manufacturing |

Owned | ||||

| Yadkinville, North Carolina |

Thermal/Acoustical – Product Manufacturing |

Leased | ||||

| St. Johnsbury, Vermont |

Thermal/Acoustical – Formerly Product Manufacturing |

Leased | ||||

| Meinerzhagen, Germany |

Thermal/Acoustical – Product Manufacturing |

Owned | ||||

| Saint-Nazaire, France |

Thermal/Acoustical – Product Manufacturing |

Leased | ||||

| Green Island, New York |

Performance Materials – Specialty Media Manufacturing |

Owned | ||||

| Rochester, New Hampshire |

Performance Materials – Specialty Media Manufacturing |

Owned | ||||

| Saint-Rivalain, France |

Performance Materials – Specialty Media Manufacturing |

Owned | ||||

| Geleen, the Netherlands |

Performance Materials – Specialty Media Manufacturing |

Leased | ||||

| Heerlen, the Netherlands |

Performance Materials – Specialty Media Manufacturing |

Leased | ||||

| Winston-Salem, North Carolina |

Other Products and Services – Biomedical Products Manufacturing |

Leased | ||||

| Ossipee, New Hampshire |

Other Products and Services – Product Manufacturing |

Owned | ||||

| Manchester, Connecticut |

Corporate Office |

Owned | ||||

For information regarding lease obligations, see Note 17 to the Consolidated Financial Statements. Lydall considers its properties to be in good operating condition and suitable and adequate for its present needs. Except for the Company’s Vermont facility, all properties are being appropriately utilized consistent with experience and demand for the Company’s products. During 2009, the Company completed the consolidation of its Vermont manufacturing facility into its Hamptonville, North Carolina facility and ceased operations at the Vermont facility. Remaining lease payments for the Vermont facility will occur through the third quarter of 2011. In addition to the properties listed above, the Company has several leases for sales offices and warehouses in the United States, Europe and Asia.

8

Table of Contents

A suit was filed against a subsidiary of the Company on March 31, 2005, in the Vermont Superior Court by a safety equipment supplier, by and through its alleged assignee, a non-employee temporary worker, with respect to personal injuries allegedly suffered by the alleged assignee. The plaintiff alleges that the Company subsidiary removed safety equipment that would have prevented the injury. The Vermont Superior Court granted two motions for partial summary judgment filed by the Company. In December 2007, the plaintiff appealed to the Vermont Supreme Court. The Vermont Supreme Court issued an order on September 4, 2009, overturning the lower Court’s grant of summary judgment in the Company’s favor and remanding the case back to the Superior Court for further proceedings. On August 20, 2010, the Company filed a third party complaint against Stamp Tech asserting claims for breach of contract and negligence related to Stamp Tech’s installation of a safety device on the equipment that allegedly injured the plaintiff. The Company also claims that Stamp Tech is bound to defend and indemnify the Company for the plaintiff’s injuries. Stamp Tech filed an answer denying the Company’s claims on or about October 12, 2010 and a Motion to Dismiss the Company’s Third Party Complaint on January 12, 2011. A trial ready date has been set for March, 2011.

The Company believes that it has meritorious defenses to the above claim and intends to contest it vigorously. While it is not possible to predict or determine the outcome of the claim or to provide possible ranges of losses that may arise, the Company believes the losses associated with this action will not have a material adverse effect on the Company’s consolidated financial position or liquidity, but could possibly be material to its consolidated results of operations of any one period. As of December 31, 2010, there were no reserves recorded by the Company related to this claim because the Company believes a loss is not probable as the claim is without merit.

In addition to the above, from time-to-time the Company is subject to legal proceedings, claims and investigations that arise in the ordinary course of business such as, but not limited to, patent, employment, personal injury, commercial and environmental matters. Although there can be no assurance, the Company is not aware of any matters pending that are expected to be material with respect to the Company’s business, results of operations or cash flows.

9

Table of Contents

EXECUTIVE OFFICERS OF THE REGISTRANT

The executive officers of Lydall, Inc. or its subsidiaries, together with the offices presently held by them, their business experience since January 1, 2006, and their age as of March 1, 2011, the record date of the Company’s 2011 Annual Meeting, are as follows:

| Name | Age | Position and Date of Initial Employment | Other Business Experience Since 2006 | |||||

| Dale G. Barnhart |

58 | President, Chief Executive Officer (August 27, 2007) | Chief Executive Officer, Synventive Molding Solutions (March 2005 – August 2007), a provider of hot runner systems, machine nozzles, temperature controllers and sprue bushings for the injection molding industry. | |||||

| Erika G. Turner |

55 | Vice President, Chief Financial Officer and Treasurer (November 4, 2009) |

Chief Financial Officer, Superior Industries International (February 2008 – November 2009), a manufacturer of aluminum road wheels for sale to original equipment manufacturers; Chief Financial Officer and Vice President of Finance, Monogram Systems (July 2004 - February 2008), a supplier of cabin systems and equipment to the global aerospace industry. | |||||

| Mona G. Estey |

56 | Vice President, Human Resources (July 1, 2000); formerly Director, Human Resources (September 1, 1986) | Not applicable | |||||

| Paul G. Igoe |

48 | Vice President, General Counsel and Secretary (October 14, 2009) |

Associate General Counsel and Assistant Corporate Secretary, Teradyne, Inc. (June 2001 – September 2009), a supplier of automatic test equipment for the semiconductor industry. | |||||

| Peter M. Kurto |

45 | Vice President, Business Development and Sr. Vice President – Life Sciences (December 14, 2010); formerly Vice President – Business Development and Investor Relations (September 24, 2008) | Global Marketing Director, Imerys – Filtration Division (August 2006 – September 2008), a world leader in the supply of engineered minerals for liquid filtration applications; Intermediates Business Leader, General Electric Co. – Plastics Division (until August 2006), a major supplier of engineering thermoplastics to a diverse group of industries including automotive, electronics and appliances. | |||||

| James V. Laughlan |

38 | Chief Accounting Officer and Controller (March 29, 2010); formerly Principal Accounting Officer and Controller (December 4, 2007); formerly Controller (October 17, 2005) | Not applicable | |||||

10

Table of Contents

Item 5. MARKET FOR REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES OF EQUITY SECURITIES

PRICE RANGE OF COMMON STOCK AND DIVIDEND HISTORY

The Company’s Common Stock is traded on the New York Stock Exchange (“NYSE”) under the symbol LDL. Shares totaling 21,425,695 and 22,062,283 were traded during 2010 and 2009, respectively. The table below shows the range of reported sale prices on the NYSE Composite Tape for the Company’s Common Stock for the periods indicated. As of December 31, 2010, 5,130 stockholders of record held 17,163,201 shares of Lydall’s Common Stock, $.10 par value.

| High | Low | Close | ||||||||||

| 2010 |

||||||||||||

| First Quarter |

$ | 8.56 | $ | 5.21 | $ | 7.85 | ||||||

| Second Quarter |

9.36 | 7.22 | 7.64 | |||||||||

| Third Quarter |

8.21 | 6.51 | 7.36 | |||||||||

| Fourth Quarter |

9.04 | 6.91 | 8.05 | |||||||||

| 2009 |

||||||||||||

| First Quarter |

$ | 6.07 | $ | 1.93 | $ | 2.97 | ||||||

| Second Quarter |

4.67 | 2.83 | 3.40 | |||||||||

| Third Quarter |

6.00 | 2.82 | 5.26 | |||||||||

| Fourth Quarter |

6.54 | 4.45 | 5.21 | |||||||||

The Company does not pay a cash dividend on its Common Stock and the Company’s domestic credit facility entered into on March 11, 2009 prohibits the payment of a cash dividend.

The following table provides information about the Company’s Common Stock that may be issued upon exercise of options and rights under all of the Company’s existing equity compensation plans at December 31, 2010. The number of securities remaining available for issuance at December 31, 2010 was 466,918 and includes 296,213 shares that may be issued as restricted stock, performance shares and other stock awards.

| Plan Category | Number of securities to be issued upon exercise of outstanding options, warrants and rights (a) |

Weighted average exercise price of outstanding options, warrants and rights (b) |

Number

of plans (excluding |

|||||||||

| Equity compensation plans approved by security holders |

906,751 | $ | 8.62 | 466,918 | ||||||||

11

Table of Contents

ISSUER PURCHASES OF EQUITY SECURITIES

In August 2003, the Company’s Board of Directors approved a Stock Repurchase Program (“Repurchase Program”) to mitigate the potentially dilutive effects of stock options and shares of restricted and unrestricted stock granted by the Company. Under the Repurchase Program, shares may be purchased by the Company up to the quantity of shares underlying options and other equity-based awards granted after January 1, 2003 under shareholder approved plans. The Company’s domestic credit facility generally prohibits the Company’s ability to repurchase common stock of the Company, subject to certain stated exceptions.

Should the Company have the ability to engage in repurchase activity in the future, the Company would take advantage of the safe harbor protections afforded by Rule 10b-18 promulgated under the Securities Exchange Act of 1934 (“Exchange Act”), to engage in future repurchase activity in accordance with the provisions of the Exchange Act. As of December 31, 2010, there were 2,278,389 shares remaining available for purchase under the Repurchase Program. There was no repurchase activity under the Repurchase Program during 2010. Shares acquired by the Company during the quarter ended December 31, 2010 represent shares withheld by the Company pursuant to provisions in agreements with recipients of restricted stock granted under the Company’s equity compensation plans requiring the Company to withhold the number of shares having fair value equal to each recipient’s tax withholding due. The following table details the activity for the fourth quarter ended December 31, 2010.

| Period | Total Number of Shares Purchased |

Average Price per Share |

Total Number of Shares |

Maximum Number of |

||||||||||||

| Activity October 1, 2010 - October 31, 2010 |

1,568 | $ | 7.75 | — | 1,969,230 | |||||||||||

| Activity November 1, 2010 - November 30, 2010 |

788 | $ | 8.08 | — | 1,969,230 | |||||||||||

| Activity December 1, 2010 - December 31, 2010 |

11,767 | $ | 7.56 | — | 2,278,389 | |||||||||||

| Total |

14,123 | $ | 7.61 | — | 2,278,389 | |||||||||||

Unregistered Sales of Equity Securities and Use of Proceeds

Lydall sponsored an Employee Stock Purchase Plan (“the Plan”) that provided a method by which participating employees used voluntary, systematic payroll deductions to purchase shares of Lydall Common stock in open-market purchase transactions effectuated by a broker. The Plan was suspended by the Company on February 25, 2010 and no shares have been purchased for participants since February 1, 2010. The Plan included a Company matching contribution feature, pursuant to which the Company contributed an amount equal to 33 and 1/3 cents for each dollar contributed by a participating employee, up to a maximum of $150 per month. The broker accumulated the contributions and purchased shares of Company stock for participants in open market transactions on a monthly basis. The Company received no proceeds from the transactions. Nevertheless, because the Plan included a matching contribution feature, the Company may have been required to register the transactions under the Securities Act of 1933, and for many years, the Company prepared and filed appropriate registration statements on Form S-8. In connection with the preparation and filing of the Company’s 2009 Annual Report on Form 10-K, the Company concluded that a new registration statement should have been filed with respect to the Plan a number of years ago. During 2010, 2009 and 2008, an aggregate of approximately 123,000 shares of Company stock were acquired by participating employees pursuant to the Plan without having been registered. Because the transactions were not registered, certain Plan participants may have a right to rescind their transactions. Based on Lydall’s current stock price, the Company does not believe that any liability for rescission would be material to the Company’s consolidated financial position, results of operations or cash flows.

12

Table of Contents

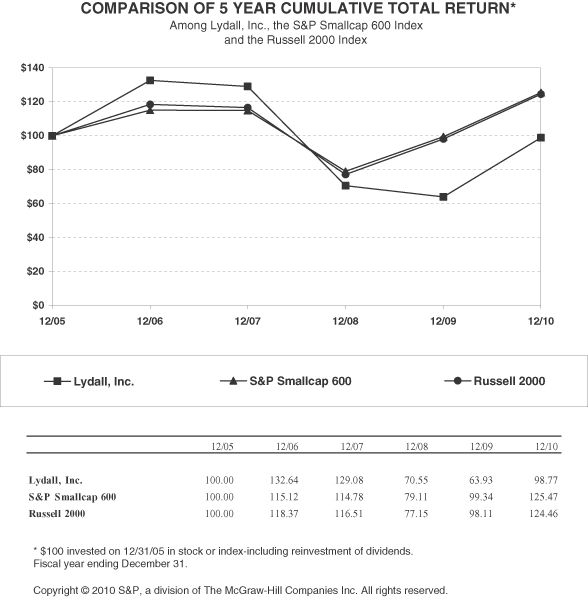

PERFORMANCE GRAPH

The following graph compares the cumulative total return on Lydall’s shares over the past five years with the cumulative total return on shares of companies comprising the Standard & Poor’s SmallCap 600 Index and the Russell 2000 Index. Cumulative total return is measured assuming an initial investment of $100 on December 31, 2005, including reinvestment of dividends. Due to the diversity of niche businesses that the Company participates in, it is difficult to identify a reasonable peer group or one industry or line-of-business index for comparison purposes. Thus, Lydall has chosen to compare its performance to the Standard & Poor’s SmallCap 600 Index and to the Russell 2000 Index.

13

Table of Contents

Item 6. SELECTED FINANCIAL DATA

FIVE-YEAR SUMMARY

| In thousands except per share amounts and ratio data | 2010 | Revised 2009 |

Revised 2008 |

Revised 2007 |

Revised 2006 |

|||||||||||||||

| Financial results from continuing operations |

||||||||||||||||||||

| Net sales |

$ | 338,007 | $ | 248,947 | $ | 305,716 | $ | 320,917 | $ | 306,121 | ||||||||||

| Income (loss) from continuing operations |

$ | 2,739 | $ | (14,572 | ) | $ | (6,031 | ) | $ | 8,196 | $ | 9,094 | ||||||||

| Common stock per share data |

||||||||||||||||||||

| Diluted income (loss) from continuing operations |

$ | .16 | $ | (.88 | ) | $ | (.37 | ) | $ | .50 | $ | .56 | ||||||||

| Diluted income from discontinued operations |

$ | — | $ | — | $ | .06 | $ | .03 | $ | .07 | ||||||||||

| Diluted net income (loss) |

$ | .16 | $ | (.88 | ) | $ | (.30 | ) | $ | .53 | $ | .63 | ||||||||

| Financial position |

||||||||||||||||||||

| Total assets |

$ | 231,888 | $ | 224,352 | $ | 235,452 | $ | 258,483 | $ | 241,173 | ||||||||||

| Working capital |

$ | 63,360 | $ | 60,599 | $ | 60,548 | $ | 63,506 | $ | 50,610 | ||||||||||

| Long-term debt, net of current maturities |

$ | 3,392 | $ | 5,220 | $ | 6,699 | $ | 8,377 | $ | 8,914 | ||||||||||

| Total stockholders’ equity |

$ | 155,455 | $ | 156,389 | $ | 166,140 | $ | 180,391 | $ | 161,516 | ||||||||||

| Property, plant and equipment |

||||||||||||||||||||

| Net property, plant and equipment |

$ | 88,236 | $ | 93,419 | $ | 101,592 | $ | 107,231 | $ | 103,469 | ||||||||||

| Capital expenditures |

$ | 12,001 | $ | 5,921 | $ | 12,037 | $ | 14,610 | $ | 11,182 | ||||||||||

| Depreciation |

$ | 13,650 | $ | 14,923 | $ | 15,867 | $ | 15,171 | $ | 15,130 | ||||||||||

| Performance and other ratios |

||||||||||||||||||||

| Gross margin |

17.1 | % | 13.3 | % | 20.5 | % | 22.5 | % | 22.3 | % | ||||||||||

| Operating margin |

1.4 | % | (7.1 | )% | (3.1 | )% | 4.7 | % | 4.4 | % | ||||||||||

| Current ratio |

2.2:1 | 2.5:1 | 2.7:1 | 2.4:1 | 2.2:1 | |||||||||||||||

| Total debt to total capitalization |

3.0 | % | 4.1 | % | 4.7 | % | 5.2 | % | 5.9 | % | ||||||||||

Please read Item 7 (Management’s Discussion and Analysis of Financial Condition and Results of Operations) and the Notes to the Consolidated Financial Statements for specific changes in the Company and the markets that provide context to the above data, including without limitation discussions concerning (i) how global economic uncertainties may affect the Company’s future results; (ii) business combinations and dispositions of business operations that affect the comparability of the data set forth above; and (iii) 2008 impairment charges recorded by the Company associated with goodwill and long-lived assets.

Please read Note 2 to the Consolidated Financial Statements which discloses the Company’s revision of previously reported financial results for 2009 and 2008. Financial results were primarily impacted by a revision to cost of sales and property, plant and equipment, net. Financial results for 2007 were also revised to reflect an adjustment primarily to income tax expense and deferred income taxes resulting in a reduction of income from continuing operations of approximately $0.4 million. The revision to 2006 financial results was to stockholders’ equity, as a revision impacted net income in a year prior to 2006.

14

Table of Contents

Item 7. MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS

CAUTIONARY NOTE CONCERNING FACTORS THAT MAY AFFECT FUTURE RESULTS

This report contains “forward-looking statements” within the meaning of Section 21E of the Securities Exchange Act of 1934, as amended. In general, any statements contained in this report that are not statements of historical fact may be deemed to be forward-looking statements within the meaning of Section 21E. All such forward-looking statements are intended to provide management’s current expectations for the future operating and financial performance of the Company based on current expectations and assumptions relating to the Company’s business, the economy and other future conditions. Forward-looking statements generally can be identified through the use of the words “believes,” “anticipates,” “may,” “plans,” “projects,” “expects,” “estimates,” “forecasts,” “predicts,” “targets,” and other similar expressions in connection with the discussion of future operating or financial performance. Because forward-looking statements relate to the future, they are subject to inherent risks, uncertainties and changes in circumstances that are difficult to predict. Accordingly, the Company’s actual results may differ materially from those contemplated by the forward-looking statements. Investors, therefore, are cautioned against relying on any of these forward-looking statements. They are neither statements of historical fact nor guarantees or assurances of future performance. Forward-looking statements in this Annual Report on Form 10-K include, among others, statements relating to:

| • | Overall economic and business conditions and the effects on the Company’s markets |

| • | Business strategies, synergies, or operating efficiencies, such as manufacturing inefficiencies at the Company’s North American automotive facility |

| • | The ability of the Company to improve gross margins of fiber based products at its North American automotive facility |

| • | Significant changes in the North American or European automotive markets |

| • | Future earnings and other measurements of financial performance |

| • | Future cash flow and uses of cash |

| • | Competitive factors in the industries and geographic markets in which the Company competes or may compete |

| • | The cost and availability of raw materials and energy |

| • | Product development and new business opportunities |

| • | Benefits realized from savings and operating efficiency improvements as a result of Lean Six Sigma and operational excellence initiatives |

| • | Estimates of restructuring costs and future savings to the Company |

| • | Future amounts of stock-based compensation expense |

| • | Pension plan assumptions and future expense and funding requirements |

| • | Future levels of indebtedness and capital spending |

| • | The Company’s ability to meet cash operating requirements |

| • | The Company’s ability to meet financial covenants in its domestic credit facility |

| • | The Company’s ability to remediate identified control deficiencies over financial reporting |

| • | The Company’s ability to earn fees for services to be rendered under a process technology license agreement |

| • | Future effective income tax rates and realization of deferred tax assets |

| • | Estimates of fair values of reporting units and long-lived assets used in assessing goodwill and long-lived assets for possible impairment |

| • | The expected outcomes of contingencies |

| • | Future repurchases of the Company’s common stock |

| • | Benefits expected to be realized from recent acquisitions, including the Company’s ability to complete the commercialization of the Arioso™ product |

15

Table of Contents

| • | Benefits expected to be realized from capital equipment investments in businesses |

| • | Future strategic acquisitions, joint ventures, alliances and licensing agreements |

All forward-looking statements are inherently subject to a number of risks and uncertainties that could cause the actual results of the Company to differ materially from those reflected in forward-looking statements. See Item 1A. Risk Factors for a description of identified risks. The occurrence of one or more of these risks, or other unidentified risks, could cause Lydall’s actual results to vary materially from recent results or from the anticipated future results.

Lydall does not undertake to update any forward-looking statement made in this report or that may from time to time be made by or on behalf of the Company.

OVERVIEW AND OUTLOOK

Lydall, Inc. and its subsidiaries (collectively, the “Company” or “Lydall”) design and manufacture specialty engineered filtration media, industrial thermal insulating solutions, automotive thermal and acoustical barriers, temperature-control equipment, medical filtration media and devices and biopharmaceutical processing components for thermal/acoustical, filtration/separation and bio/medical applications. Lydall principally conducts its business through two reportable segments: Performance Materials and Thermal/Acoustical with the majority of sales to customers in North America and Europe.

The Performance Materials segment reports results of the filtration and industrial thermal insulation businesses. Lydall’s filtration media products provide solutions for air, fluid power, industrial and life science applications and its industrial thermal insulation products provide solutions for building products, appliances, and energy and industrial markets.

The Thermal/Acoustical segment reports the results of the Company’s automotive businesses. Thermal/Acoustical products provide solutions to abate noise and heat in various types of automobiles. Lydall products shield several areas in automobiles from heat (thermal) and sound (acoustical) sources including the underbody, under hood and interior areas.

All other businesses are aggregated in Other Products and Services. OPS includes the Vital Fluids business and the Affinity® temperature control equipment business.

Revision of Prior Period Amounts

During the third quarter of 2010, the Company revised prior period financial statements due to errors detected in the third quarter of 2010. None of the revisions were considered material to the periods impacted, as disclosed in Note 2 to Notes to the Consolidated Financial Statements. All figures in Item 7 of this filing are provided as revised.

Highlights

Below are financial highlights comparing Lydall’s 2010 results to its 2009 results:

| • | Consolidated net sales increased by $89.1 million, or 35.8%, to a record annual amount of $338.0 million; |

| • | Foreign currency translation negatively impacted net sales growth by 2.6%; |

| • | Segment net sales (net of foreign currency translation) increased as follows: |

| – | Performance Materials segment increased by $27.2 million, or 27.7%; |

| – | Thermal/Acoustical segment increased by $55.8 million, or 43.6%; |

| – | Other Products and Services increased by $13.6 million, or 57.3%; |

| • | Gross margin percentage increased to 17.1% compared to 13.3%; |

| • | Consolidated operating income was $4.6 million, compared to an operating loss of $(17.8) million: |

| – | Performance Materials segment reported operating income of $17.2 million, compared to operating income of $7.6 million; |

16

Table of Contents

| – | Thermal/Acoustical segment reported operating income of $0.4 million, compared to an operating loss of $(10.3) million; |

| – | OPS reported operating income of $1.0 million, compared to an operating loss of $(2.5) million; |

| – | Corporate office expenses were $(14.0) million, compared with $(12.5) million; |

| • | Pretax income for 2010 was $3.9 million, compared to pretax loss of $(18.4) million; |

| • | Net income for 2010 was $2.7 million, or $.16 per share, compared to a net loss of $(14.6) million, or $(.88) per share; |

| • | Cash provided from operations was $10.7 million compared to $14.1 million. |

Operational and Financial Overview

The Company reported net sales of $338.0 million, a record annual amount, reflecting an increase of nearly $90 million, or 36%, compared to 2009. The combination of a recovery in most of the markets that Lydall serves as well as improved market share resulted in the significant increase in net sales in 2010. The 2010 operating income of $4.6 million, or 1.4% of net sales, was significantly depressed by the operating results of the Thermal/Acoustical segment, serving the automotive industry. In particular, the gross margin in 2010 was negatively impacted by the fiber-based product line of the North American automotive facility (“NA Auto”) starting towards the end of the second quarter of 2010, as production was rapidly ramped up to meet a sharp increase in customer demand. Although manufacturing improvements have been made in the fourth quarter of 2010, the Company estimates that $30.0 million of fiber based product net sales generated a gross margin loss of approximately $(5.0) million from June 1, 2010 through December 31, 2010.

Performance Materials Segment

The Performance Materials segment reported record net sales of $123.1 million in 2010, which represented an increase of 25.6% from 2009, and operating income of $17.2 million, or 14.0% of net sales. Gross margin and operating income as a percentage of net sales both increased primarily as a result of the significant increase in net sales and improved absorption of fixed costs.

Demand for filtration products by customers in the air filtration, fluid power and automotive and life science markets in 2010 rebounded dramatically as customers began recovering from the global economic recession. Also, in 2010, the industrial thermal insulation business benefited from significant improvement in capital project investments by customers in the cryogenic and electrical markets, increasing demand for the Company’s energy and industrial products.

The filtration and industrial thermal insulation businesses are in markets that the Company believes present long-term growth opportunities through expansion of existing products and through strategic transactions. With a strong backlog of orders, the segment is actively managing growth by selectively investing in capabilities to enhance processes and capacity. The segment has realigned manufacturing capabilities among its production sites, which has enabled improved optimization of existing capacity and created additional capacity to grow the business organically. Further, products and activities are continually evaluated for strategic fit, as evidenced by the sale of the electrical papers product line in 2010.

Performance Materials remains focused on fully commercializing the Arioso™ membrane composite media, which was developed based on technologies obtained through the Solutech acquisition in late 2008. Arioso™ provides advanced filtration media for respirator, clean room and industrial dust collection applications. Although product development and customer qualification have taken longer than originally planned, the Arioso™ product represents an important growth area and is expected to expand the Company’s market participation in the industrial air and life science arena.

Thermal/Acoustical Segment

The Thermal/Acoustical segment reported net sales of $179.1 million in 2010, an increase of 40.1% from 2009. Segment net sales were approximately 53% of the Company’s consolidated net sales in 2010, compared to approximately 51% of net sales in 2009. According to a published automotive market forecasting service, production of cars and light trucks in North America and Europe in 2010 increased by approximately 22%, or 5.5 million vehicles, compared to 2009, indicating that the Thermal/Acoustical segment increased market share through the introduction of new products and growth of the automotive platforms served. The same service predicts that production of cars and light trucks in North America and Europe in 2011 will grow again in the range of 3% – 5%. While automobile production improved significantly in 2010 and is expected to increase again in 2011, volatile market conditions, including fluctuations in consumer demand for automobiles, persist in the automotive market.

17

Table of Contents

The segment reported operating income in 2010 of $0.4 million compared with an operating loss of $(10.3) million in 2009. Beginning late in the second quarter of 2010, the segment has been impacted by negative gross margin from the fiber-based product line of the NA Auto facility. During the second half of 2010, the Company responded to a rapid acceleration of orders with a plant expansion, addition of new equipment, hiring and training of a significant number of new employees and fabrication of tooling, all while simultaneously increasing output to meet customers’ demand. As a result, the Company incurred abnormally high labor costs, material usage inefficiencies and excessive scrap on production lines, and freight expediting and inspection costs. Also, due to capacity constraints, the facility outsourced a portion of the processing of certain fibers at a premium. While the Company has undertaken a comprehensive improvement plan to stabilize this operation, the full impact of actions underway has not yet been fully realized. The operating loss of $(10.3) million in 2009 included $5.8 million of restructuring related charges associated with the NA Auto consolidation.

Other Products and Services

The Vital Fluids business, which serves the life science industry, reported net sales of $15.6 million in 2010, an increase of 6.6% compared to 2009, and operating results were essentially breakeven in 2010 compared to operating income of $0.2 million in 2009. During 2009 and 2010, the Company made capital investments in clean room space capacity and acquired biodisposable bag manufacturing equipment to support a strategic initiative to increase market share in the growing bioprocessing market. During 2010, the business initiated the qualification of products with a number of new customers. However, due to the lengthy period of time required for qualification, incremental revenues did not materialize in 2010. During 2011, the Vital Fluids business expects certain customers to begin to complete the qualification process initiated in 2010 and start to order biodisposable bags from the Company.

Throughout 2010, the Affinity business benefited from the recovery of capital equipment spending in the semiconductor industry as evidenced by an increase in net sales of $12.7 million, to $21.9 million, in 2010. The business has begun to realize sales from the “S-Series,” a configurable industrial chiller launched in 2010, which is expected to open several new markets in the future, including medical, analytical, scientific, and industrial. Service revenues in the chiller markets have grown as well and the business has gained profitability both through absorption of costs from higher revenues and from employing Lean principles to systematically improve gross margins.

Liquidity

At December 31, 2010, the Company had cash balances of $25.0 million and no borrowings under any existing credit facility. Consistent with the fourth quarter of 2010, the Company expects to be subject to a $5.0 million borrowing limit under its domestic credit facility throughout the first quarter of 2011 and possibly future periods because it does not expect to meet the fixed charge coverage ratio. At December 31, 2010, the Company’s foreign subsidiaries had various credit arrangements with banks totaling €7.0 million (approximately $9.4 million) with €5.9 million (approximately $7.9 million) available for borrowings, primarily restricted to borrowings at the respective foreign subsidiary.

The Company expects to fund its operating cash requirements from existing cash balances, cash generated by operations and from available borrowings, as needed, under its existing domestic credit facility and foreign credit facilities.

During 2010, the Company increased working capital, primarily inventory, in order to meet anticipated customer demand. At December 30, 2010, inventory increased by $11.0 million compared to levels at December 31, 2009, primarily from increases in raw material inventory. Also contributing to the increase in working capital were significant cash investments in automotive tooling inventory and tooling accounts receivable during 2010 in preparation of launches of new automotive parts in 2011. Typically, the Company is not reimbursed for tooling inventory until completion and customer approval of the tooling.

Outlook

At December 31, 2010, the Company’s backlog was significantly higher than December 31, 2009. Going into 2011, the top priority for the Company is to improve its operating results, particularly those of the Thermal/Acoustical segment.

As part of Lydall’s business strategy, the Company will continue to review various strategic and business opportunities to grow its businesses and evaluate the profitability and growth potential for each of its existing businesses.

18

Table of Contents

In 2011, the Company is implementing internal organizational changes in its Performance Materials and Vital Fluids businesses to better align the Company’s structure with its strategic direction. Lydall is integrating operational activities and realigning sales and marketing responsibilities within and across these two businesses. In 2011, the Company expects that the Vital Fluids business will be included in the operating results of the Performance Materials segment.

Throughout the Company, management expects that its Lean Six Sigma and operational excellence initiatives will assist in reducing costs, improving performance and customer service, and leveraging synergies across the Company.

The Company is also focused on continuing to remediate its material weakness in internal control over financial reporting as discussed in Item 9A. Controls and Procedures.

19

Table of Contents

CONSOLIDATED RESULTS OF OPERATIONS

Net Sales

| (in thousands of dollars) | 2010 | Percent Change |

2009 | Percent Change |

2008 | |||||||||||||||

| Net sales |

$ | 338,007 | 35.8 | % | $ | 248,947 | (18.6 | )% | $ | 305,716 | ||||||||||

The increase in 2010 net sales of $89.1 million, or 35.8%, compared with 2009, was primarily attributable to higher sales volumes from the Thermal/Acoustical segment of $51.3 million, or 40.1%, and the Performance Materials segment of $25.1 million, or 25.6%. Net sales of OPS increased by $13.6 million, or 57.3%, including an increase of $12.7 million from the Affinity business and $0.9 million from the Vital Fluids business. Foreign currency translation decreased net sales by $6.6 million, or 2.6%, for the current year, compared with 2009, impacting the Thermal/Acoustical segment by $4.5 million and the Performance Materials segment by $2.1 million.

The decrease in 2009 net sales of $56.8 million, compared with 2008, was primarily the result of lower net sales from the Company’s Thermal/Acoustical segment of $35.9 million, or 21.9%. Performance Materials segment net sales in 2009 decreased by $13.6 million, or 12.2%, compared to 2008. Net sales of OPS in 2009 decreased by $7.9 million, or 25.0%, compared to 2008, as net sales from the Vital Fluids business decreased by $2.0 million and net sales from the Affinity business decreased by $5.9 million. Foreign currency translation decreased net sales by $4.7 million in 2009, compared with 2008, impacting the Thermal/Acoustical segment by $3.2 million and the Performance Materials segment by $1.5 million.

Gross Margin

| (in thousands of dollars) | 2010 | Revised 2009 |

Revised 2008 |

|||||||||

| Gross margin |

$ | 57,873 | $ | 33,004 | $ | 62,766 | ||||||

| Percentage of sales |

17.1 | % | 13.3 | % | 20.5 | % | ||||||

The increase in gross margin percentage in 2010 compared to 2009 was attributable to improved gross margin percentages from both the Performance Materials and Thermal/Acoustical segments, as well as from the Affinity business included in OPS. The Performance Materials segment and Affinity business reported improved gross margin percentages primarily as a result of significantly higher net sales and the resulting improved absorption of fixed costs. The 2009 gross margin percentage included restructuring related charges of $5.7 million, or 230 basis points, associated with the NA Auto consolidation, included in the Thermal/Acoustical segment. Excluding these restructuring charges in 2009, the Thermal/Acoustical segment gross margin percentage increased marginally in 2010 compared to 2009 due to improvements in gross margin percentage for worldwide non-fiber based products from higher sales partially offset by higher per unit costs for fiber-based products at its NA Auto facility.