UNITED STATES SECURITIES

AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 1O-K

(Mark One)

| x |

Annual report pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

For the fiscal year ended December 31, 2009

or

| ¨ |

Transition report pursuant to Section 13 or 15(d) of the Securities Act of 1934 |

For the transition period from to

Commission File Number 001-09781 (0-1052)

MILLIPORE CORPORATION

(Exact name of registrant as specified in its charter)

|

|

|

| Massachusetts |

|

04-2170233 |

| (State or Other Jurisdiction of Incorporation or Organization) |

|

(I.R.S. Employer Identification No.) |

|

|

| 290 Concord Road, Billerica, MA |

|

01821 |

| (Address of principal executive offices) |

|

(Zip Code) |

(978) 715-4321

(Registrant’s telephone number, including area code)

SECURITIES REGISTERED PURSUANT TO SECTION 12(B) OF THE ACT:

|

|

|

| Title of Class |

|

Name of Exchange on Which Registered |

| Common Stock, $1.00 Par Value |

|

New York Stock Exchange, Inc. |

SECURITIES

REGISTERED PURSUANT TO SECTION 12(G) OF THE ACT: NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405

of the Securities Act. x Yes ¨ No

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. ¨ Yes x

No

Indicate by check mark whether the registrant: (1) has filed all reports

required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing

requirements for the past 90 days. x Yes ¨ No

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be

submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). ¨ Yes ¨

No

Indicate by check mark if disclosure of delinquent filers pursuant to

Item 405 of Regulation S-K is not contained herein and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of Form 10-K or any amendment to this

Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer, or a smaller reporting company. See definition of “large accelerated filer,”

“accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

x Large accelerated filer ¨ Accelerated filer ¨ Non-accelerated filer ¨

Smaller reporting company

(Do not check if smaller reporting company)

Indicate by check mark whether the registrant is a shell company (as defined in Exchange Act Rule 12b-2 of the Act). ¨ Yes x No

The aggregate market value of Common

Stock held by non-affiliates of the registrant, based upon the closing sale price of the registrant’s Common Stock on July 2, 2009, the last business day of its most recently completed second fiscal quarter, as reported on the New York

Stock Exchange, was approximately $2,985,884,480. Shares of Common Stock held by each executive officer and director and by each person known to beneficially own more than 5 percent of the outstanding Common Stock have been excluded in that such

persons may be deemed to be affiliates. This determination of affiliate status is not necessarily a conclusive determination for other purposes.

As of

February 23, 2010, 56,029,332 shares of the registrant’s Common Stock were outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

|

|

|

| Document Definitive Proxy Statement for the 2010 Annual Meeting |

|

Incorporated into Form 10-K

Part III |

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

1 |

Table

of Contents

|

|

|

| 2 |

|

MILLIPORE FORM 10-K 2009

|

PART I

|

|

|

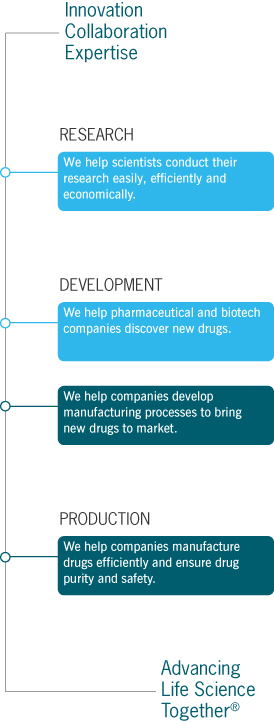

| MILLIPORE IS A GLOBAL LEADER IN THE LIFE SCIENCE TOOLS MARKET. TOGETHER WITH OUR CUSTOMERS, WE HELP TO ADVANCE THE RESEARCH, DEVELOPMENT AND PRODUCTION OF DRUGS. |

|

|

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

3 |

PART I

Summary

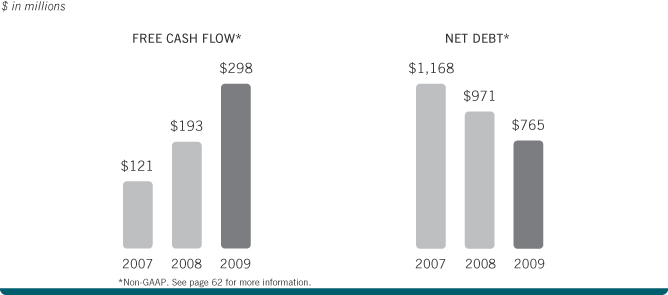

Millipore is a global leader in the life science tools market. Together with our customers, we help to advance the research, development, and production of drugs. Our innovative products and services are used to support life science

research, drug discovery, process development, drug manufacturing, and quality assurance. We help customers to improve laboratory productivity and workflows, prioritize potential drugs, optimize manufacturing productivity, and support commercial

scale manufacturing.

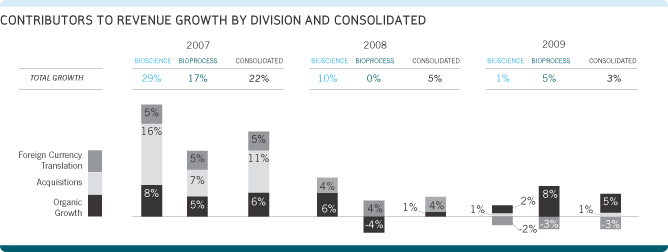

We manage our business globally and are organized in two operating divisions. Our Bioscience Division provides products and

technologies to support life science research and development activities. Our Bioprocess Division provides products and services to support pharmaceutical and biotechnology manufacturing.

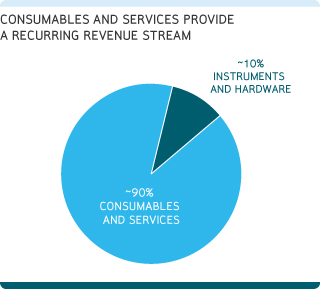

The breadth of our product offering and our global scale make us a strategic supplier to the life science industry and provide us with access to many different segments of the market. Our products and services are

primarily used by a diverse, global customer base including biotechnology and

pharmaceutical companies, academic institutions and research laboratories. In addition, we derive most of our revenues from consumable products. These attributes allow us to target growth on a

number of dimensions and make our business less susceptible to economic downturns, which we experienced in 2009.

Our History

Millipore Corporation was formed as a Massachusetts corporation in 1954. During much of our history, we have developed and sold products based on our

proprietary filtration and other separations technologies to a variety of industries. In 2001, we made a strategic decision to focus primarily on the life science markets. Beginning in 2005, we began implementing a strategy that sharpened our focus

on the fast growing biopharmaceutical manufacturing and life science research markets. During this time, we have made acquisitions to transform Millipore into a larger and more innovative company. These acquisitions expanded the products and

services we offer and complemented our brand, sales force, and customer relationships.

|

|

|

| 4 |

|

MILLIPORE FORM 10-K 2009

|

PART I

Our Business

OVERVIEW

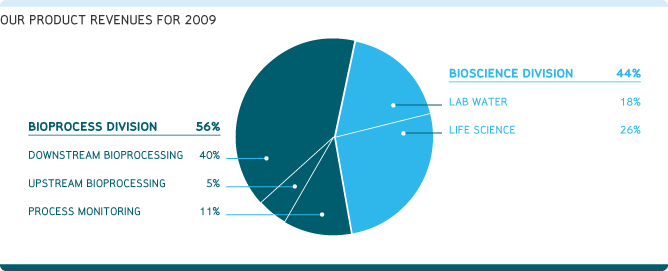

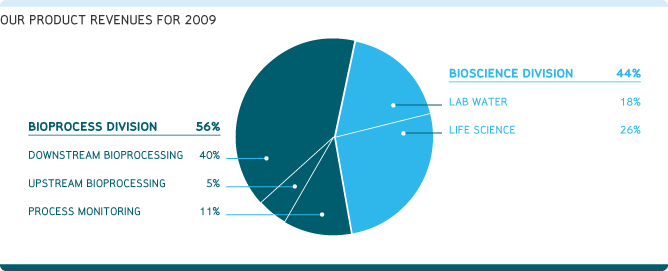

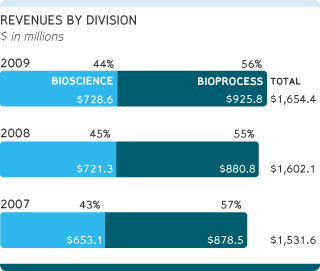

We compete in the life science tools market and focus on serving the needs of life science researchers and

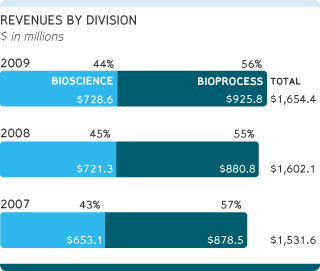

biopharmaceutical manufacturers. We are organized in two operating divisions: Bioscience and Bioprocess. Our Bioscience Division, which contributed approximately 44% of our 2009 revenues, improves laboratory productivity and work flows by providing

innovative products and technologies for life science research. Our Bioprocess Division, which contributed approximately 56% of our 2009 revenues, helps pharmaceutical and biotechnology companies develop their manufacturing processes, optimize their

manufacturing productivity, and ensure the quality of drugs.

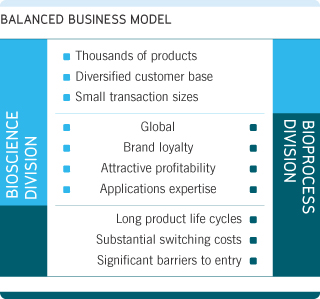

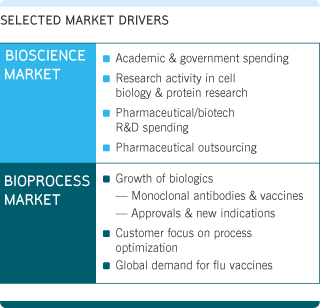

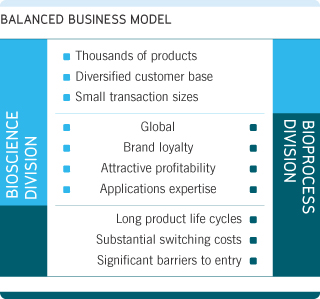

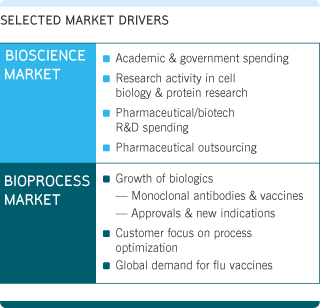

We believe both divisions have attractive business models and share a number of

characteristics in common, such as a premium brand, a global presence, a highly qualified sales force, and substantial technical expertise. They also possess a number of characteristics that are unique to the specific markets they serve, which we

list in the table on the right. The unique characteristics of our Bioprocess and Bioscience divisions provide us with a balanced and resilient business.

Our business is well-diversified across different life science end-markets, product lines and geographies. We sell

thousands of different products, and we are continually developing and/or acquiring new proprietary products and technologies to advance our businesses. Most of our products are consumables that are used, disposed, and replaced, such as reagent kits

or filtration cartridges.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

5 |

PART I

Because of the differing applications required by each of our target markets, we believe our business benefits from specialized

expertise and market focus. Accordingly, we have aligned our business to better address each of these markets. The following describes more specifically the principal markets in which we compete.

LABORATORY/LIFE SCIENCE RESEARCH MARKETS

Industry Background

As researchers seek to understand complex biological systems and identify and

characterize new therapeutic targets, the market demand for tools and services that improve productivity and efficiency in the laboratory has grown.

|

|

|

| 6 |

|

MILLIPORE FORM 10-K 2009

|

PART I

These researchers are conducting complex and expensive research to help them fundamentally understand the science of

biology — what occurs inside the human body. This research is required to feed the pipeline of biologics, cell-based vaccines, and other therapeutic and diagnostic products in development.

Researchers have come under increasing competitive and economic pressure to screen and identify new drugs with more speed and accuracy. In particular, the rapid growth

in the development of new biotechnology drugs has brought a heightened focus on protein research, including protein identification and characterization. Additionally, academic researchers are under pressure to increase the speed with which they

publish their research in scientific journals in order to compete for public and private funding of their research projects. Laboratory markets have also grown with the increase in concerns about new public health threats.

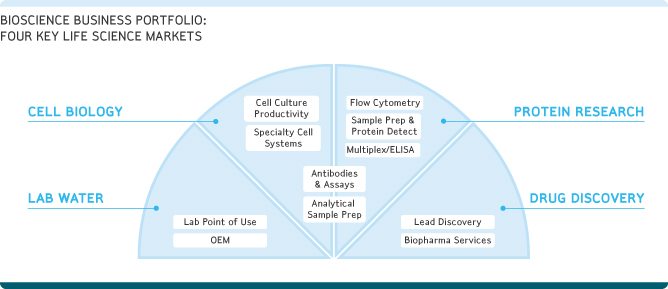

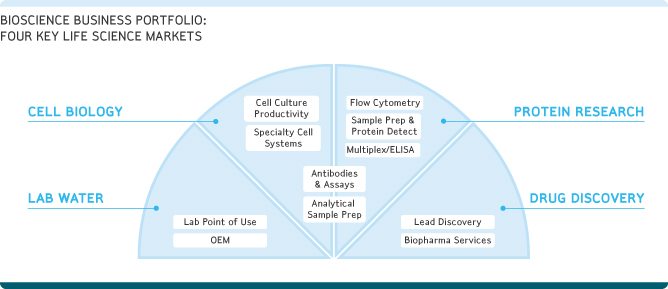

Our Bioscience Division focuses on four key life science markets: laboratory water, cell biology, protein research, and drug discovery. We target these markets because

we believe they are rapidly growing and we can provide competitively superior products, services, and work flow solutions.

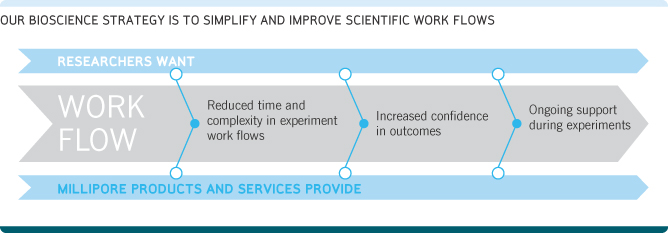

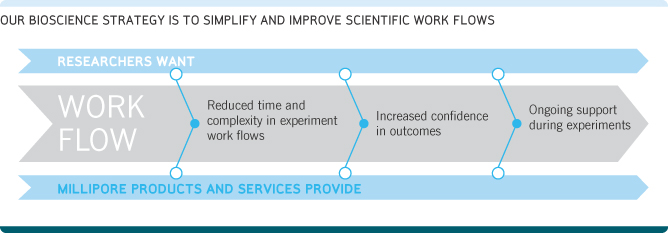

Researchers in these specific segments of the market want reduced complexity in their experimental work flows,

increased confidence in their scientific outcomes, and ongoing support during their experiments. Our Bioscience strategy is to create products and services that span the entire work flow by simplifying the work flow for researchers, offering

consolidated and validated solutions, and providing the necessary support along the way. Due to the complex nature of our four key markets and the diverse yet specialized needs of our customers, we offer products to advance life science research in

a wide variety of areas from neuroscience, infectious disease, oncology, and metabolic disorders to stem cells, cell signaling, nuclear function, and chromatin biology.

To address these markets, our Bioscience Division is organized as follows:

Life Science

26% of Company Revenues

We are focused on serving

the cell biology, protein research, and drug discovery markets with our life science product offerings. We sell thousands of products into these three markets, including instruments, consumable devices, reagents and services, to help customers

better understand diseases and biological functions.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

7 |

PART I

Their work typically involves conducting experiments on biological samples, such as cells, proteins, and nucleic

acids.

We also sell drug discovery products and services that help pharmaceutical and biotechnology companies discover, evaluate, and prioritize

potential drugs. Historically, we categorized drug discovery sales as a separate product application and reported that drug discovery revenues represented 5 percent of our total revenues in 2008. During 2009, we re-categorized our drug discovery

revenues into life science because of the synergy and customer overlap of our multiplex immunoassays with our existing life science product offerings in cell biology and protein research.

CELL BIOLOGY & PROTEIN RESEARCH

Most researchers follow a

work flow protocol that requires the use of a broad range of products, including consumable devices, reagents, kits, antibodies, and other molecular biology tools for purifying, preparing, or screening biological samples. We offer product and

service solutions designed around the entire protocol, so researchers can work faster, better, and easier than if they did not use our products and services. Many of our life science products span across both the protein research and cell biology

markets. These product categories are listed to the right.

|

Analytical Sample Preparation |

The

consistency and reproducibility of experimental results requires that samples used by researchers are pure and properly isolated. The varying physical and biochemical characteristics of biological samples make the processes of isolation extremely

complex. Research, clinical, and analytical laboratories use many sample preparation steps for a variety of laboratory procedures. Our filtration devices and specialty membranes are designed to accommodate the parameters of a wide variety of

experiments.

|

Antibodies & Reagents |

Our customized antibodies serve as biological markers that can be used to produce consistent and repeatable results, saving time, and reducing costs. Research scientists also outsource various services such as the development and production

of custom antibodies, which we provide. Life science researchers who study the structure and function of cells and proteins require innovative and high-quality biological reagents to conduct their experiments consistently. A reagent is a substance

used to detect, quantify, produce, modify or otherwise manipulate a biological target. Millipore offers a wide range of biological reagents. We also offer a wide variety of kits that improve research productivity and efficiency. Kits enhance

research productivity by combining in one box all the disposables, reagents, and protocols needed to reliably and reproducibly conduct a particular experiment.

|

|

|

| 8 |

|

MILLIPORE FORM 10-K 2009

|

PART I

Within the protein research market, we offer multiplex immunoassay and ELISA kits, protein detection products, and

flow cytometry instruments and kits. Researchers use our multiplex immunoassay kits to understand which proteins may be indicative of a disease state, measure how a drug affects protein biomarkers, and determine what side effects a drug creates. We

are a leader in developing multiplex kits, reagents, and assays for researchers studying immunology, inflammation, and metabolic diseases (diabetes, obesity, cardiovascular disorders).

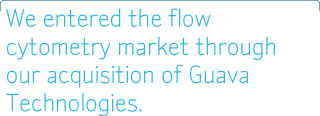

We entered the flow cytometry market through our partnership and subsequent acquisition of Guava Technologies. Flow cytometry is a powerful research technique used by scientists to measure changes in protein

expression in individual cells. Today, many of these experiments are conducted in centralized, or core, laboratories. Millipore is integrating instrumentation, reagent kits, validated protocols, and technical support to bring the advantages of flow

cytometry to the bench tops of cell biologists. As a result, researchers who are growing or monitoring cells can benefit from this analytical platform by conducting cell analysis at the bench rather than running routine assays at a core laboratory.

Within the cell biology market, we offer products for cell culture productivity and specialty cell systems. These products include specialty cell lines,

such as stem cell lines that are used to study their role in disease. We also sell a variety of products that are used to prepare, grow, and genetically modify cells.

DRUG DISCOVERY SERVICES

A major challenge for our customers is to find promising drug candidates faster and then

ensure that they will not generate unwanted or unexpected side effects in clinical trials or when they are commercially on the market. To improve the efficiency and economy of this research, these customers outsource research work to Millipore

rather than conduct the work in-house. We provide services to identify disease targets and better understand how to improve the efficacy of drugs on targeted patient groups and prevent side effects.

Our services offering consists of lead optimization services to help pharmaceutical customers screen small molecule compounds against

drug targets of interest, particularly kinases, ion channels and G-Protein Coupling Receptors (“GPCR”), and biopharmaceutical services to help customers better understand the safety and efficacy of biologic drugs and vaccines.

As an increasing number of biologics enter the pipeline, companies are leveraging our expertise to help them evaluate the efficacy of biologics. We help our

customers by providing a broad range of services to assist with evaluating and advancing these therapeutics from the drug development pipeline to the market. This offering includes biomarker analytical services, assay transfer/development,

validation and sample analysis, pharmacokinetics,

toxicokinetics, immunogenicity, biological potency, and vaccine services.

Laboratory Water

18% of Company

Revenues

Most research starts with the use of purified water, which is a universal reagent in scientific experiments. Water purification systems are

present in nearly every laboratory. Daily demand for purified water can range from a few liters to several thousand liters. We offer a wide selection of sophisticated benchtop laboratory water instruments that ensure water purity for critical

laboratory analysis and clinical testing. These benchtop instruments provide the flexibility to produce the water quality needed for a variety of laboratory needs and applications.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

9 |

PART I

Water quality is a critical variable for researchers to control since contaminated water can adversely affect the

scientific outcome of a research project. The level of water purity needed depends on the complexity of the scientific experiment the researcher is conducting. More complicated experiments require extremely high levels of water purity. Millipore

offers a range of lab water instruments to meet the diverse water purification needs of our customers. These products remove micro-organisms, dissolved gasses, particulates, and organic and inorganic compounds from water.

Approximately 60 percent of our laboratory water revenues are derived from consumables and service, while approximately 40 percent is derived from lab water

instruments.

BIOPHARMACEUTICAL MANUFACTURING MARKETS

Industry Background

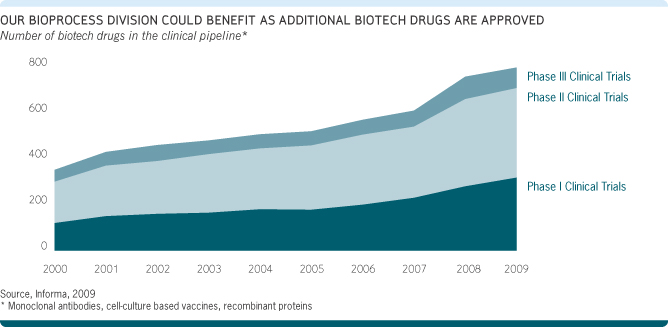

Our Bioprocess Division provides products, services, and integrated solutions to

help companies manufacture drugs efficiently and ensure drug purity and safety. Our products are primarily used in the production of biologic and synthetic drugs. Manufacturers of these products are under increasing competitive and economic pressure

to maintain safety and quality, shorten production times, and improve manufacturing productivity and yields.

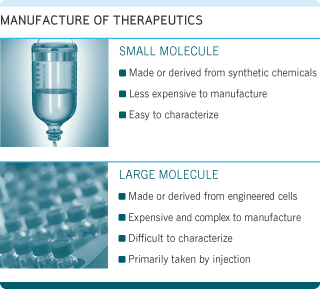

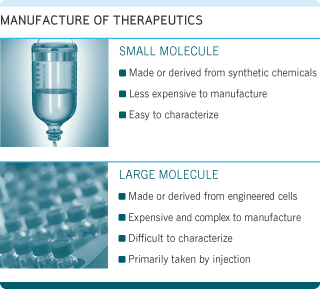

Manufacturing of therapeutics generally

encompasses small molecule drugs and large molecule drugs. Small molecule therapeutics are primarily chemical compounds that are made through an organic or inorganic chemistry process. These are sometimes referred to as synthetic pharmaceuticals,

which are generally manufactured in bulk.

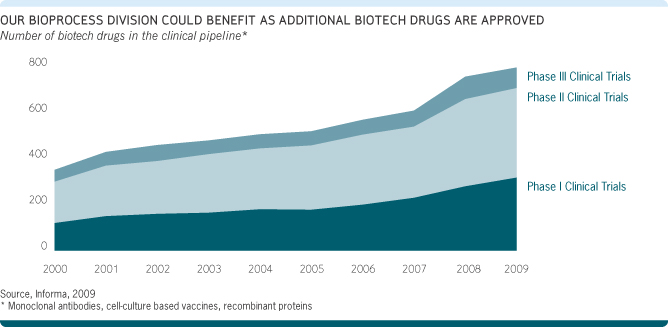

Large molecule therapeutics are primarily protein-based biologics, which are derived from living organisms, generated in a bioreactor

or fermentor. They include therapeutic products and vaccines based on recombinant proteins, such as monoclonal antibodies, and represent the fastest growing segment in the drug industry. About half of our Bioprocess business is related to the

production of biotechnology drugs.

In many instances, recombinant proteins replace or mimic naturally occurring human proteins and are produced by cells

containing modified DNA. One subset of recombinant protein-based drugs, monoclonal antibodies, has been shown to be extremely effective at treating otherwise intractable diseases such as cancer. This efficaciousness has led to a fast growing market

for monoclonal antibodies, which are difficult to produce and require a variety of complex technologies and processes to enable their development and production.

Industry sources predict that volumes of monoclonal antibodies and cell-based vaccines will continue to grow substantially over the next five years.

|

|

|

| 10 |

|

MILLIPORE FORM 10-K 2009

|

PART I

In addition, applications and approvals for biologic drug supplements, which address incremental indications for a

previously approved biologic, are also on the rise. In contrast, growth in sales of small molecule pharmaceuticals is expected to be lower because of intense generic competition as the patents expire on the chemical compounds comprising the drugs.

Synthetic pharmaceuticals, however, continue to constitute a significant percentage of all marketed therapeutic products and are manufactured in large volumes.

As the demand for marketed biologics and vaccines grows and new products and applications are approved, the market for products that facilitate and accelerate the identification, development, and production of biologics and cell-based

vaccines is expanding. Successfully bringing a biologic or a cell-based vaccine to the market is a complex and lengthy process. It begins with extensive laboratory research and discovery; continues with years of development, clinical trials and

scale-up of the manufacturing process; and culminates with satisfying regulatory requirements and commencement of commercial production.

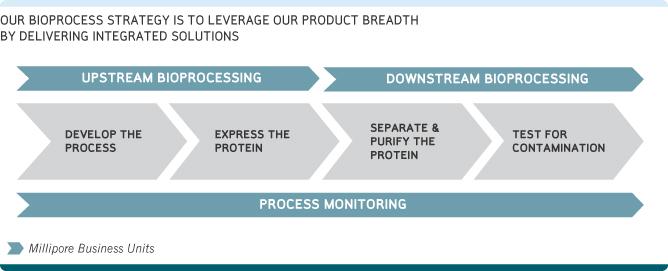

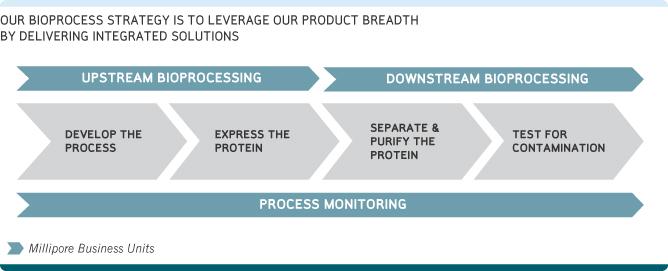

The value chain

of our Bioprocess customers includes:

|

Process development and scale up |

|

Upstream bioprocessing (the growth and expression of proteins in bioreactors) |

|

Downstream purification and filtration (the harvesting and refinement of therapeutic proteins) |

|

Monitoring and testing |

We believe we offer one of the

industry’s broadest product offerings for biopharmaceutical production. Additionally, we believe we are the only company to offer consumable products in both upstream and downstream bioprocessing. Our Bioprocess Division serves the breadth of

this development and production process by targeting the three principal applications described below. The development of a customer’s process involves aspects from each of these three product applications.

Upstream Bioprocessing

5% of Company

Revenues

Biologic products must be grown in living cells since they cannot be made chemically. We provide products and technologies that improve the

ability of cells to efficiently produce proteins that ultimately become therapeutic drugs and vaccines.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

11 |

PART I

The cells are grown in cell cultures held in large bioreactors or fermentation tanks of varying capacity. In order to

achieve high protein concentrations, cells in the bioreactor require nutrients and supplements. As the cells grow and metabolize, they secrete into the cell culture medium the therapeutic protein that is then harvested, purified, and further

processed.

To facilitate the manufacture of biologic drugs in mammalian cell cultures, we offer high-quality nutrients and supplements for these

cultures. Our products include the leading branded fatty acid supplements, recombinant insulin, bovine serum albumin, and other growth factors that improve the ability of cells to produce proteins efficiently. We also offer unique gene expression

technology which permits screening and isolation of highly productive cell lines much faster than conventional technologies. This technology enables our customers to more efficiently produce recombinant proteins in mammalian cells by generating

higher protein yields. Today, some of our upstream products are derived using materials from animals. Many customers are increasingly demanding products that do not use animal-derived products. We are actively expanding our portfolio of animal-free

cell culture supplements through our collaboration with Novozymes and have several animal free supplements currently on the market.

We also launched our first disposable bioreactor from our partnership with Applikon Biotechnology, the Mobius

CellReady™ 3L Bioreactor. Mobius CellReady™ can be used by customers during process development and eliminates the cleaning, sterilizing, and assembling required for traditional glass bioreactors. We believe that process development

represents an untapped market for the use of disposable technologies. In 2010, we expect to launch additional CellReady products, which will provide researchers with higher capacity bioreactors.

Downstream Bioprocessing

40% of

Company Revenues

FILTRATION & CHROMATOGRAPHY

The production of biologics requires the extraction of proteins from the fluids in which these proteins are grown. The process also requires the removal of impurities such as bacteria, viruses, cellular debris, and other contaminants.

Accordingly, manufacturing processes for biologics, particularly for monoclonal antibodies and vaccines, are separation-intensive, often requiring numerous filtration and chromatography steps for separation, clarification, concentration, and

sterilization.

|

|

|

| 12 |

|

MILLIPORE FORM 10-K 2009

|

PART I

A complex biologic, such as a monoclonal antibody, requires a significant number of steps to purify the drug, while a

typical synthetic drug requires far fewer purification steps.

We offer the broadest range of filtration, purification, and chromatography technologies

to clarify, concentrate and purify proteins, and remove viruses or other biological contaminants from biologics, vaccines, synthetic pharmaceuticals, and beverages. Approximately half of our business is related to biologic drug production, with the

remaining portion of our business primarily related to synthetic pharmaceutical manufacturing and beverage processing. Many of the same products used in the biotechnology industry are also used to remove contaminants in the production of

pharmaceuticals and beverages. We also sell membrane sheets and rolls and bulk chromatography media to original equipment manufacturers of medical devices, environmental testing equipment, or other products for use as a material or component in

these products.

DISPOSABLE MANUFACTURING

Until

recently, all biologic drugs were primarily produced with stainless steel equipment. This equipment includes large bioreactors, chromatography columns, and other systems used in the large-scale production of biologic drugs. The use of these

stainless steel systems requires a significant amount of cleaning and validation costs prior to running a manufacturing campaign.

Our strategic focus

has shifted away from selling and manufacturing stainless steel systems to selling and developing disposable manufacturing solutions. Although stainless steel systems are currently the prevalent processing tools, the industry has sought ways to

reduce the costs and delays associated with cleaning and sterilizing such equipment in between manufacturing runs. Contamination risks arise if the equipment is not thoroughly decontaminated of all residual materials from prior production runs.

Companies have begun to migrate to single use, disposable technologies that eliminate the need for cleaning and sterilization, thus shortening the time between processing runs.

Biopharmaceutical manufacturers are also seeking flexible manufacturing components and solutions that can be

configured and validated to meet customized biological manufacturing needs. Many of these companies have benefited from yield improvements in their processes and are seeking to manufacture drugs using smaller scale processes. This has been a

positive trend for our disposable manufacturing solutions as these products are better geared to smaller batch manufacturing than stainless steel equipment.

We are a leading innovator in the transition to disposable manufacturing, offering a broad range of integrated disposable manufacturing solutions. In the past few years, we have developed and/or acquired rights to products and technologies

that simplify and reduce the time and expense of steps in the downstream and final fill and finish processes of biotechnology and pharmaceutical drug production.

Process Monitoring

11% of Company Revenues

Regulatory agencies such as the U.S. Federal Drug Administration (FDA) require drug manufacturers to ensure the purity and sterility of products before they are

released to the public. This requires sampling and testing of therapeutics throughout the manufacturing process. During nearly all phases of drug development and production, companies take multiple steps to ensure their products are produced safely

and without contamination. Millipore provides a broad range of products and services that enable sampling and testing of drugs throughout the manufacturing process to ensure the safety and purity of drugs.

Companies that produce beverages (including wine, beer, and bottled juices and water) also benefit from using our process monitoring products to monitor for

microbiological contamination from bacteria and yeast.

Our process monitoring products are designed to test for microbiological, viral or other

contamination in biologics and synthetic pharmaceuticals as a quality control or assurance step in their manufacture or processing. We are also developing next-generation technologies that are faster and more sensitive so drug manufacturers can

identify

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

13 |

PART I

contamination earlier in their processes. We currently offer and continue to develop new process monitoring tools capable of significantly reducing the time-to-result from days or weeks to hours.

We also offer outsourced testing for biological and viral contamination of biologics.

Our Customers

The majority of our revenues are related to customers engaged in life science research or biopharmaceutical production.

BIOSCIENCE CUSTOMERS

Our Bioscience Division serves

hundreds of thousands of customers engaged in life science research. They conduct academic research, drug discovery and laboratory analysis at universities, biotechnology firms, pharmaceutical companies, and other life science research laboratories

worldwide. As a result, we have a significant amount of customer diversification within the bioscience research markets.

While the overall bioscience

market is very broad, we do not seek to serve all segments of the market. We focus our

offering on specific market segments such as cell biology, protein research, and drug discovery, which have unique needs. Our laboratory water and some sample preparation products are sold into

many different types of research, analytical, and clinical laboratories worldwide and serve a more general, diverse customer base.

BIOPROCESS CUSTOMERS

Our Bioprocess Division primarily serves biotechnology and pharmaceutical companies that develop, manufacture, and

sell products for the diagnosis, prevention, and treatment of diseases.

These Bioprocess customers are engaged in the development, scale-up,

manufacturing, and testing of therapeutic, vaccine, and diagnostic products, as well as a variety of healthcare and other products.

We also sell

products to beverage companies to be used in their production process.

Although no single customer accounts for 10 percent or more of our sales, our

Bioprocess Division has significantly higher customer concentration than our Bioscience Division, particularly in the biotechnology market.

|

|

|

| 14 |

|

MILLIPORE FORM 10-K 2009

|

PART I

Our Strategy

Our strategy is to drive long-term growth in our business by:

|

Capitalizing on opportunities in large, core markets |

|

Targeting fast growing market segments |

|

Delivering innovative products and services to meet customer needs |

|

Executing strategic acquisitions and partnerships |

|

Investing in sales channels and global infrastructure |

We are

focused on expanding our leadership in attractive, growing, and important core product categories such as laboratory water, sample preparation, antibodies, filtration, and chromatography. We seek to leverage our industry leadership, global

footprint, applications expertise, and brand in these markets to deliver deep, innovative solutions that create superior performance and value for our customers.

We are also selectively focusing on the most attractive segments of the life science tools market where we can establish market leadership, generate the highest levels of growth, and drive competitive differentiation. Some of these fast

growing markets include disposable manufacturing, virus filtration, benchtop flow cytometry, stem cell research, multiplex immunoassays, and biopharmaceutical services. From a

geographic perspective, we are focusing on expanding our presence in Brazil, Russia, China, India, and Singapore because of the substantial growth of life science research and biopharmaceutical

production in these countries. By selectively pursuing high growth markets, we expect that we will be able to grow our revenues and profitability.

Our

ability to anticipate customer needs and deliver high-value differentiated products is a critical part of our strategy. We believe our markets are driven by innovation. A central part of our strategy is to develop new products and services that

address unmet customer needs in large markets. Our depth of customer relationships and applications expertise allows us to identify, understand, and address these needs. We are also focused on increasing our growth opportunities by executing

strategic acquisitions and partnerships. We can enhance our product portfolio and enter new markets by acquiring key technologies and partnering with leading companies in targeted areas. Finally, we are investing in our sales channels and global

infrastructure to support future growth. For example, we have opened new, state-of-the-art customer training and scale-up facilities in Singapore and in Billerica, Massachusetts; we have invested in our e-business platform; and we have expanded our

sales and marketing capabilities to drive growth in the future.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

15 |

PART I

Selected 2009 Milestones

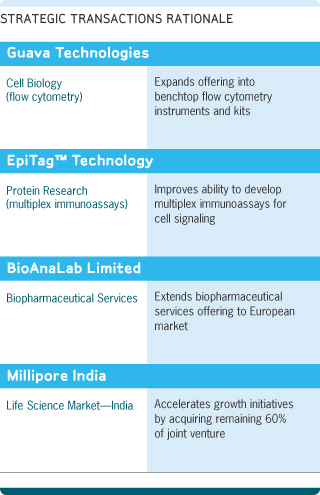

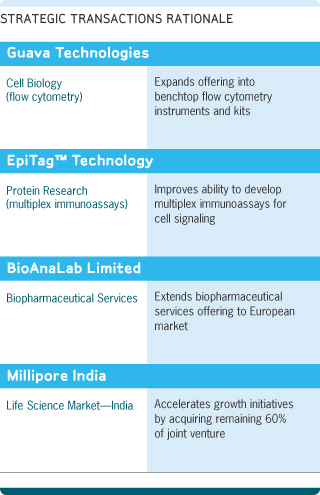

STRATEGIC TRANSACTIONS

In 2009, we completed four strategic transactions, which we show in the chart

on the right:

|

Acquired Guava Technologies – Q1 2009 |

|

Acquired EpiTag™ technology from Epitome Biosystems – Q1 2009 |

|

Acquired BioAnaLab Limited – Q3 2009 |

|

Purchased remaining 60% ownership of our joint venture in India – Q4 2009 |

SUSTAINABILITY

We are committed to sustainable growth. In our view, sustainability means being able

to operate efficiently and productively while minimizing the impact of our operations and products on the environment. Accordingly, we formally announced in 2008 an ambitious multi-year environmental effort to reduce the environmental impacts of our

processes, products and facilities. Central to this initiative is our goal to reduce our global carbon footprint by 20 percent from 2006 to 2011. Our initiative encompasses a wide range of programs focused on dramatically reducing our consumption of

non-renewable resources, eliminating waste, and adopting other changes that support long-term environmental sustainability.

A key part of our strategy

to meet our carbon reduction goal is the implementation of a comprehensive energy management program that includes a combination of energy efficiency and renewable energy projects. We are also active in numerous organizations with similar goals.

The following are some of the milestones we achieved in 2009 in pursuit of this goal.

|

Completed a 310 Kilowatt onsite solar system installation at two of our Massachusetts facilities |

|

Completed our first comprehensive annual sustainability report |

|

Named “Corporate Citizen of the Year” by the New England Clean Energy Council |

|

Reduced our carbon emissions 14 percent below our 2006 baseline, mostly since May 2008 |

|

Reduced our use of electricity by 4.3 million kilowatt- hours through efficiency programs |

|

Joined the U.S. Environmental Protection Agency’s Green Power Partnership as part of its commitment to use power generated from environmentally preferable renewable

resources. |

We intend to continue our leadership in corporate environmental responsibility which we believe will benefit both the

environment and our business.

|

|

|

| 16 |

|

MILLIPORE FORM 10-K 2009

|

PART I

NEW PRODUCTS

In 2009, we introduced many

new innovative products resulting from our own internal development as well as through collaborations with companies such as Novozymes and Applikon Biotechnology. We believe our business is

driven by innovation and our ability to successfully launch new products through internal development, acquisitions, and collaborations is critical to our future success. We list some of the

products that we launched or introduced in the table below:

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

17 |

PART I

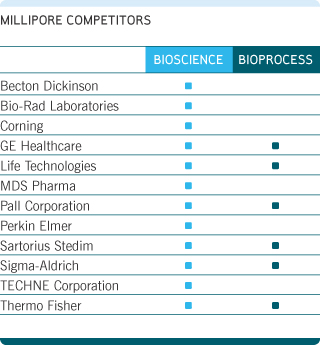

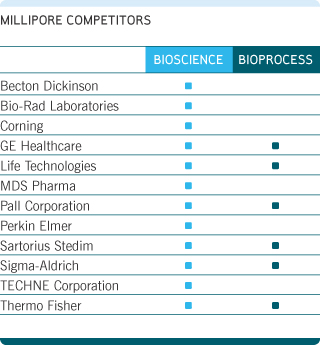

Competition

The markets for our products and services are intensely competitive and we compete with a variety of public and private companies. Given the breadth of our product and service offerings, our competition comes from a wide array of

competitors, ranging from specialized companies with strengths in niche segments of the life science markets to large manufacturers offering a broad portfolio of products, tools, and services. Many of these competitors have significant financial,

operational, sales, and marketing resources, and experience in research and development. In some cases, these and other competitors are also our customers, distributors, and suppliers, and in some circumstances we serve these roles for such

competitors as well.

We believe that a company’s competitive position in any of our markets is determined by a varying mix of product availability

and performance, quality, responsiveness, technical support, price, and breadth of product lines. Our customers are diverse and we believe they place varying degrees of importance on these competitive attributes.

We believe that we differentiate from our competitors by offering more innovative products, better technical support,

and higher levels of product quality. Our global presence, the strength of our brand, and our global sales and marketing capabilities also help us to win business over competitors.

Sales, Marketing, and Customer Support

Our direct sales organization is a critical competitive

differentiator for us. An important component of our strategy is to leverage our direct sales organization by expanding our product portfolio available for sale and increasing our penetration of our current customer base.

We sell our products to end users worldwide, primarily through our own direct global sales force. Augmenting our direct sales, we also sell our products through our

website and, in selected locations and markets, through independent distributors.

We market to our customers through advertising, trade shows,

conferences, and other techniques. Our marketing efforts focus on application development for existing products and on new and differentiated products for newly identified and proposed customer needs. We seek to educate customers about the variety

of problems that may be addressed by our products as well as to adapt our products and technologies to the problems identified by our customers. Our technical support services are important to our marketing efforts. These services include assisting

in defining a customer’s needs, evaluating alternative solutions, selecting or designing a specific system to perform the desired application, training users, and assisting the customer in compliance with relevant government regulations.

|

|

|

| 18 |

|

MILLIPORE FORM 10-K 2009

|

PART I

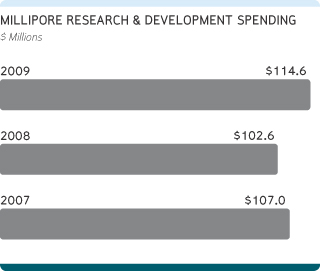

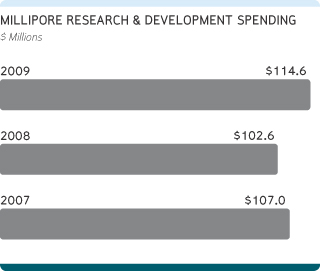

Research and Development

We believe that a strong research and product development effort is important to our future growth. We have added important scale and capabilities to our R&D organization over the past three years.

Our research and development activities are intended both to improve on our extensive core technologies and to create new applications and breakthroughs that

complement our business. Our core technologies include:

|

Assay development |

|

Separation and purification membranes |

|

Chromatography media |

|

Customized monoclonal antibodies |

|

Cell culture supplements |

|

Cell lines |

|

Immunodetection |

|

Disposable manufacturing |

|

Sterile sampling |

|

Sample preparation |

Some of these technologies are incorporated into

devices, cartridges, and modules of different configurations that span many of our markets while others are focused on a specific or customized application.

We conduct most of our own research and development. We have followed a practice of supplementing our internal research and

development efforts by acquiring or licensing new technologies from unaffiliated third parties, acquiring distribution rights for new technologies, and undertaking collaborative or sponsored research and development activities with unaffiliated

companies and academic or research institutions when we believe it is in our interests to do so. Additionally, we have greatly expanded our product development capabilities through acquisitions to include antibodies, enzymes, labeling and detection

reagents, molecular biology kits, multiplexed immunoassays, cell based assays, and drug profiling services.

For example, we purchased the EpiTag™

technology of Epitome Biosystems to expand our presence in the multiplex immunoassay market and to enable our future development of other novel profiling technologies. Our purchase of Guava Technologies provided a platform for benchtop flow

cytometry upon which we have developed an enhanced instrument and suite of customized reagents. We also completed 11 technology agreements in 2009. These agreements help us to bring new products to the market by enabling us to combine our device and

applications expertise with valuable technologies from third parties.

We continue to work closely with existing partners such as Novozymes, Applikon

Biotechnology, and Dow Chemical to bring new products to the markets.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

19 |

PART I

Global Operations

Supply

Chain—Manufacturing and Sourcing

We manufacture the majority of our products in our own manufacturing facilities, primarily at

those properties described and listed under Item 2 of this Form 10-K, although we have begun to outsource the manufacturing of select products to more cost competitive locations, primarily in China. Our global supply chain initiative, which

began in 2004, has resulted in a new manufacturing landscape through the consolidation of our sites, the implementation of new raw material procurement practices by consolidating our supplier base, and streamlining manufacturing processes through

improvements using Lean Six Sigma® methodologies. In September 2008, we announced the second phase of our global supply

chain program, which will result in the closure of five additional facilities and reduction of our customer service and distribution costs. We expect to complete this second phase by the end of 2010.

Environmental Health and Safety

We maintain an active

environmental, health and safety group charged with ensuring that our facilities and operations are safe and compliant with applicable laws. We promote a culture of safety and environmental responsibility throughout the company. This group also

administers our sustainability initiatives described under Selected 2009 Milestones.

Quality Assurance and Regulatory Compliance

To compete effectively in our markets, we maintain a global quality assurance system and program designed to assure compliance with the stringent

requirements of regulatory authorities, voluntary quality standards, industry trade associations, and our customers. Using our quality assurance compliance programs, we conduct periodic audits of each of our facilities. The audits, in combination

with performance metrics, are designed to ensure

adherence to regulations and our procedures and to assess the effectiveness of our quality system as a whole. The audits are one component of the key performance indicators that we collect,

review, and monitor to maintain our program of continuous improvement and compliance with our established systems and programs.

Most of our operating

facilities are registered to ISO 9001:2000 quality standards. The ISO 9001:2000 series of standards is a voluntary quality standard recognized throughout the world.

Our Employees

As of December 31, 2009, Millipore employed approximately 6,100 people worldwide,

of whom approximately 2,600 were employed in the United States.

Patents, Trademarks and Licenses

We obtain technology licenses to improve our ability to launch new products and to gain the right to re-sell certain products. We have been granted and have licensed

rights under a number of patents and have other patent applications pending both in the United States and abroad. While these patents and licenses in the aggregate are viewed as valuable assets, we believe that no individual patent is material to

our ongoing operations. We also own a number of trademarks, the most significant being “Millipore.”

Many of our research reagent products are

sold under licenses that have varying terms and conditions. We expect to continue to license new technologies from academic and government institutions, as well as biotechnology and pharmaceutical companies. We use licensed technologies to create

new products, including high-value kits and services, many of which address bottlenecks in research laboratories. No single license is material to our business.

|

|

|

| 20 |

|

MILLIPORE FORM 10-K 2009

|

PART I

Government and Industry Regulation

Many of our activities are subject to regulation by governmental authorities within the United States and similar bodies outside of the United States. The regulatory authorities may govern the collection, testing,

manufacturing, safety, efficacy, labeling, storage, record keeping, transportation, approval, advertising, and promotion of our products, as well as the training of our employees. Some of our products are subject to import and export regulations

specific to the country of import. Certain of our products are considered “medical devices” under the Food, Drug and Cosmetic Act. Accordingly, these products are subject to the law’s general control provisions that include

requirements for registration, listing of devices, quality regulations, labeling, and prohibitions against misbranding and adulteration. These products subject us to regulatory inspection and scrutiny. We believe that we are in substantial

compliance with all relevant laws and regulations.

Environmental Matters

We are subject to numerous federal, state, and foreign laws and regulations that impose strict requirements for the control and abatement of air, water, and soil pollutants and the manufacturing, storage, handling,

and disposal of hazardous substances and waste. We believe we are in substantial compliance with all applicable environmental requirements. We continue to invest in maintaining facilities that enable our compliance with these environmental laws.

These environmental related expenditures have not had a material effect on our financial results. Because regulatory standards under environmental laws and regulations have become increasingly stringent, there can be no assurance that future

developments will not cause us to incur material environmental liabilities or costs. See the applicable risk factor under Item 1A of this Form 10-K.

Raw Materials

Our products are made from a wide variety of raw materials that are generally available from alternate sources of supply. For certain critical raw materials, we have qualified only a single source. We periodically purchase quantities of

some of these critical raw materials in excess of current requirements in anticipation of future manufacturing needs. With sufficient lead time, we believe we would be able to validate alternate suppliers for each of these raw materials. As

described in the applicable risk factor under Item 1A of this Form 10-K, several of these critical raw materials are used in a significant portion of our products, and if we were unable to obtain supply of any one of them, our loss of revenues

would be material.

Seasonality

In

general, we do not believe our business is inherently seasonal.

Backlog

We do not have a material amount of firm commitments that serve as backlog orders.

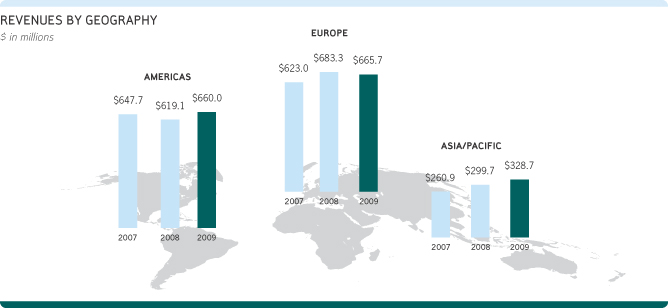

Geographic and

Segment Information

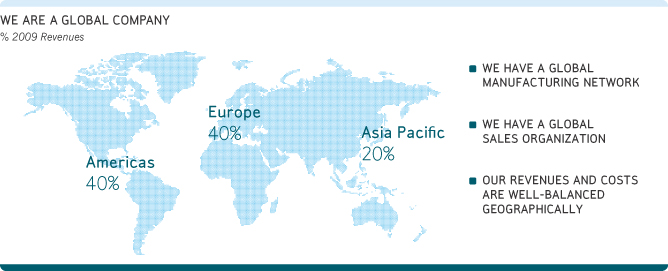

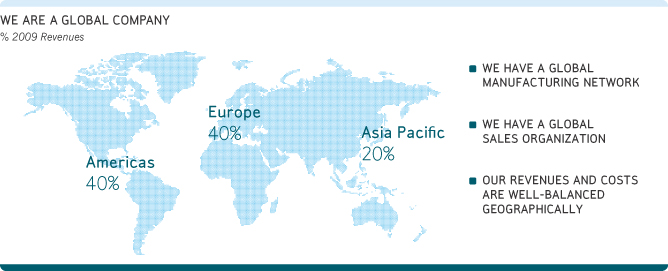

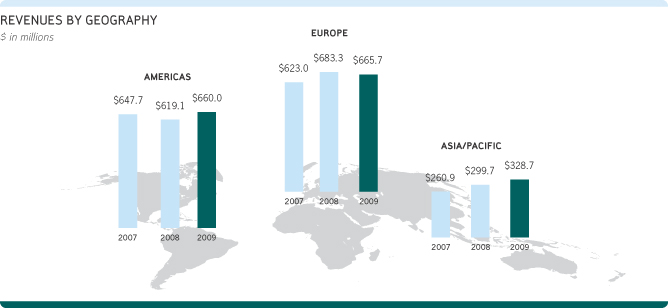

We are a multinational company with approximately 66 percent of our 2009 sales outside the United States and approximately 51

percent of our long-lived assets outside the United States at December 31, 2009. Geographic and segment information, including the identification of operating segments and their aggregation, is discussed in Note 18 to our consolidated financial

statements.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

21 |

PART I

Other Information

Millipore’s

corporate headquarters are at 290 Concord Road, Billerica, Massachusetts, and our telephone number at that location is 1-978-715-4321.

The U.S.

Securities and Exchange Commission (the “SEC”) maintains an internet website at http://www.sec.gov that contains our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and proxy statements, and all

amendments thereto. All reports that we file with the SEC may be read and copied at the SEC’s Public Reference Room at 100 F Street, N.E., Washington, DC 20549. Information about the operation of the Public Reference Room can be obtained by

calling the SEC at 1-800-SEC-0330.

Millipore’s internet website address is www.millipore.com. Our annual reports on Form 10-K, quarterly reports on

Form 10-Q, current reports on Form 8-K and proxy statements, and all amendments thereto, are available free of

charge on our website as soon as reasonably practicable after such reports are electronically filed with, or furnished to, the SEC. In addition, our corporate governance guidelines, the charters

of each of the committees of our Board of Directors, our code of ethics (consisting of our Corporate Compliance Policy, our Employee Code of Conduct and our Rules of Conduct) and our Director Code of Conduct are available on our website and are

available in print to any Millipore shareholder upon request in writing to “General Counsel, Millipore Corporation, 290 Concord Road, Billerica, MA 01821”.

The certifications of Millipore’s Chief Executive Officer and Chief Financial Officer, as required by the rules adopted pursuant to Section 302 of the Sarbanes-Oxley Act of 2002, are filed as exhibits to

this Form 10-K. Millipore’s Chief Executive Officer, Martin D. Madaus, provided an annual certification to the New York Stock Exchange dated June 8, 2009, that he was not aware of any violations by the Company of the New York Stock

Exchange corporate governance listing standards.

|

|

|

| 22 |

|

MILLIPORE FORM 10-K 2009

|

PART I

Lack of early success with our pharmaceutical and biotechnology customers can shut us out of future business with those customers.

Many of the products we sell to the pharmaceutical and biotechnology customers are incorporated into our customers’ drug manufacturing processes.

In some cases, once a customer chooses a particular product for use in a drug manufacturing process, it is unlikely that the customer will later switch to a competing alternative. In many cases, the regulatory license for the product will specify

the separation and cell culture supplement products qualified for use in the process. Obtaining the regulatory approvals needed for a change in the manufacturing process is time consuming, expensive, and uncertain. Accordingly, if we fail to

convince a pharmaceutical or biotechnology customer to choose our products early in its manufacturing design phase, we may lose permanently the opportunity to participate in the customer’s production of such product. Because we face vigorous

competition in this market from companies with substantial financial and technical resources, we run the risk that our competitors will win significant early business with a customer making it difficult for us to recover that opportunity.

The suspension or termination of production of a customer’s therapeutic product may result in the abrupt suspension or termination

of their purchases of our products, resulting in an unexpected reduction in our revenue.

Success in our Bioprocess Division substantially depends on the

incorporation of our products into a customer’s manufacturing process. If this “design in” is achieved, we will likely have the opportunity to sell consumable products to the customer during the life cycle of the customer’s

product, which could continue for many years. Our planning and growth projections are built in part on the volume assumptions deriving from these customer successes. If a customer stops production of its product, either temporarily or permanently,

our sales to the customer for the applicable product will drop or stop.

A customer may suspend or terminate production of a product, either voluntarily or involuntarily, and related sales and distribution for many reasons. These may include adverse regulatory,

competitive, legal or economic circumstances. We have had in the past, and expect to have in the future, situations in which a customer suspends its purchases of our products. A suspension or permanent cessation of a process in which we would

otherwise anticipate selling a significant volume of consumables will reduce our revenues and negatively impact our earnings.

Disruptions in the supply of raw materials and distributed products from our single source suppliers could result in a significant disruption in sales and profitability.

Our products are made from a wide variety of raw materials that are generally available from alternate sources of supply. However, certain critical raw materials and supplies required for the production of some of

our principal products are available only from a single supplier, as are some products that we distribute. Such raw materials and distributed products cannot be obtained from other sources without significant delay or at all. If such suppliers were

to limit or terminate production or otherwise fail to supply these materials for any reason, such failures could have a material adverse impact on our product sales and our business.

If our efforts to integrate acquired or licensed businesses or technologies into our business are not successful, our business could be harmed.

As part of our business strategy, we have grown our business through acquisitions of technologies or of companies that offer products, services and technologies that

we believe complement our products, technologies, and services. We expect to continue to grow our business through additional acquisitions if appropriate opportunities arise.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

23 |

PART I

Managing these recent acquisitions and any future acquisitions will entail numerous operational, legal, and financial risks, including:

| n

|

|

difficulties in assimilating new technologies, operations, sites, and personnel |

| n

|

|

inability to achieve anticipated revenue and cost synergies and other financial objectives |

| n

|

|

diversion of resources and management attention from our existing businesses and technologies |

| n

|

|

inability to maintain uniform quality standards, controls, and procedures |

| n

|

|

inability to retain key employees of any acquired businesses or hire enough qualified personnel to staff any new or expanded operations

|

| n

|

|

impairment or loss of relationships with key customers and suppliers of acquired businesses |

| n

|

|

issuance of dilutive equity securities |

| n

|

|

incurrence or assumption of debt |

| n

|

|

exposure to unknown or unanticipated liabilities |

| n

|

|

additional expenses associated with future amortization or impairment of acquired intangible assets |

| n

|

|

exposure to federal, state, local and foreign tax liabilities in connection with any acquisition or the integration of any acquired businesses

|

If our consolidated manufacturing operations were disrupted, we may be unable to supply products to our customers and

achieve expected revenues.

In an effort to better serve our customers and to attain efficiencies of scale and expertise, we have consolidated the

majority of our production facilities into fewer sites. Each of these remaining facilities serves as our primary production facility for specific product lines. This concentration of production, however, exposes us to a greater risk of disruption to

our ability to manufacture and supply our products. If operation at any of these facilities were disrupted, we may not be able to deliver products to our customers and achieve expected revenues or earnings. If we were unable to reestablish

production in a timely manner, we may lose customers and have difficulty regaining them.

It is uncertain whether the safety measures and contingency plans that we have implemented or may implement will successfully address the risks that may arise if production is disrupted. Also,

there can be no assurance that the insurance that we maintain to protect against business interruption loss will be adequate or that such insurance will continue to remain available on acceptable terms, if at all. The extent of the coverage of our

insurance could limit our ability to mitigate for lost sales and could result in such losses materially and adversely affecting our operating results.

If we fail to maintain adequate quality standards for our products and services, our business may be adversely affected and our reputation harmed.

Our customers are subject to rigorous quality standards in order to maintain their products and the manufacturing processes and testing methods that generate them. A failure to sustain the specified quality

requirements, including the processing and testing functions performed by our products, could result in the loss of the applicable regulatory license. Delays or quality lapses in our customer’s production line could result in substantial

economic losses to them and to us. For example, large production lots of biotherapeutics are very delicate and expensive and a failure of a separation membrane could result in the contamination of the entire lot, requiring its destruction. We also

perform services that may be considered an extension of our customers’ manufacturing and quality assurance processes, which also require the maintenance of prescribed levels of quality. Although we believe that our continued focus on quality

throughout the company adequately addresses these risks, there can be no assurance that we will not experience occasional or systemic quality lapses in our manufacturing and service operations. If we experience significant or prolonged quality

problems, our business and reputation may be harmed, which may result in the loss of customers, our inability to participate in future customer product opportunities, and reduced revenues and earnings.

|

|

|

| 24 |

|

MILLIPORE FORM 10-K 2009

|

PART I

Reduction in our customers’ research and development budgets and government funding may result

in reduced sales.

Our customers include researchers at pharmaceutical and biotechnology companies, academic institutions, and government and private

laboratories throughout the world. Their research and development budgets and activities have a large effect on the demand for our products and services. Fluctuations in our customers’ research and development budgets occur due to changes in

available resources, mergers of pharmaceutical and biotechnology companies, spending priorities and institutional budgetary policies. Our Bioscience business could be adversely impacted by any significant decrease in life science research and

development expenditures by pharmaceutical and biotechnology companies, academic institutions or government and private laboratories. In addition, short term changes in administrative, regulatory or purchasing-related procedures can create

uncertainties or other impediments which can contribute to lower sales.

A portion of our Bioscience sales have been to researchers, universities,

government laboratories, and private foundations whose funding may be dependent in part upon grants from government agencies such as the U.S. National Institute of Health (“NIH”) and similar domestic and international agencies. NIH funds

are subject to reallocation, reduction or discontinuation, which could impact research projects using our products. Government funding of research and development is subject to the political process, which is inherently fluid and unpredictable. Our

revenues may be adversely affected if our customers delay purchases as a result of uncertainties surrounding the approval of government or industrial budget proposals. If researchers were not able to obtain, for any extended period, government

funding necessary to purchase our products or if there is a decrease in overall research funding, it could reduce our Bioscience sales and damage our business.

We may be unable to establish and to maintain collaborative development and marketing relationships

with business partners, which could result in a decline in revenues or slower than anticipated growth rates.

As a part of our business strategy, we have

formed, and intend to continue to form, strategic alliances, license agreements and marketing and distribution arrangements with corporate partners relating to the development, commercialization, marketing and distribution of certain of our existing

and potential products to increase our revenues and to leverage our product and service offerings. Our success will depend, in part, on our ability to maintain these relationships and to cultivate additional corporate alliances with such companies.

We cannot ensure that our historical collaborative relationships will be commercially successful or yield the desired results, that we will be able to

negotiate additional collaborative relationships, that such additional collaborative relationships will be available to us on acceptable terms, or that any such relationships, if established, will be commercially successful. In addition, we cannot

ensure that parties with which we have established, or will establish, collaborative relationships will not, either directly or in collaboration with others, pursue alternative technologies or develop alternative products in addition to, or instead

of, our products. Such parties may also be acquired by our competitors to terminate our relationship. They may also experience financial or other difficulties that lessen their value to us and to our customers. Our results of operations and

opportunities for growth may be adversely affected by our failure to establish and maintain successful collaborative relationships.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

25 |

PART I

Demand for our Bioprocess products and services are subject to the commercial success of our customers’ products and our

customers’ purchasing patterns, which may vary for reasons outside our control.

Even if we are successful in securing participation for our

products in a customer’s manufacturing process, sales of many of our Bioprocess products and services remain dependent on the timing and volume of the customer’s production or purchasing patterns, over which we have no control. The

customer’s demand for our products will depend on the regulatory approval and commercial success of the supported product, as well as the customer’s manufacturing schedules and related purchasing power. The regulatory process is complex,

lengthy and expensive and can often take years to complete, if at all. Commercial success of a customer’s product, which would drive demand in production and commensurate demand for our products and services, is dependent on many factors, some

of which can change rapidly, despite early positive indications. Any delay or cancellation by a customer of volume manufacturing may harm our revenues and earnings.

If we experience a significant disruption in our information technology systems or if we fail to implement new systems and software successfully, our business could be adversely affected.

We rely on one centralized information system throughout our company to keep financial records, process orders, manage inventory, process shipments to

customers, and operate other critical functions. If we were to experience a prolonged system disruption in the information technology systems that involve our interactions with customers and suppliers, it could result in the loss of sales and

customers, which could adversely affect our business. In addition, in order to maximize our information technology efficiency, we have physically consolidated our primary corporate data and computer operations into two geographically proximate

facilities. This concentration, however, exposes us to a greater risk of disruption to our internal information

technology systems. If operations at either or both of these centers were disrupted, it would likely cause a material disruption in our business.

Technology innovations in the markets that we serve may create alternatives to our products and result in reduced sales.

Our customers constantly attempt to reduce their manufacturing costs and to improve product quality. Technology innovations to which our current and potential

customers would have access could reduce or eliminate their need for our membrane or chromatography products. For example, if a new membrane or chromatography technology of one of our competitors is accepted by the pharmaceutical or biotechnology

industry as a market standard, sales of our membrane or chromatography products would be negatively impacted. In addition, a disruptive technology that reduces or eliminates the use of our core technologies would negatively impact the sale of our

products. As an example, animal–free serum products are generally favored over bovine serum. We may be unable to respond on a timely basis to the changing needs of our customer base and the new technologies we design for our customers may prove

to be ineffective. Our failure to develop and to introduce or to enhance products able to compete with such new technologies in a timely manner could have a material adverse effect on our business, results of operations, and financial condition. We

may be unable to respond on a timely basis to the changing needs of our customer base and the new technologies we design for our customers may prove to be ineffective.

We may be unable to realize our growth strategy if we cannot identify suitable acquisition opportunities in the future.

As part of our business strategy, we expect to continue to grow our business through acquisitions of technologies or companies. We may not identify or complete complementary acquisitions in a timely manner, on a

cost-effective basis, or at all.

|

|

|

| 26 |

|

MILLIPORE FORM 10-K 2009

|

PART I

In addition, we compete with other companies, including large, well funded competitors, to acquire suitable targets, and may not be able to acquire certain targets that we seek. There can be no

assurance that we will be able to execute this component of our growth strategy, which may harm our business and hinder our future growth.

To achieve

desired growth rates as we become larger, we may seek larger or public companies as potential acquisition candidates. The acquisition of a public company may involve additional risks, including the potential for lack of recourse against public

shareholders for undisclosed material liabilities of the acquired business.

Our continued growth is dependent on our development and

successful commercialization of new products.

Our future success will depend in part on timely development and introduction of new products that address

changing market requirements. We believe that successful new product introductions provide a significant competitive advantage because customers make an investment of time in selecting and learning to use a new product. Customers are reluctant to

switch to a competing product after making their initial selection. To the extent that we fail to introduce new and innovative products, we may lose market share to our competitors, which will be difficult or impossible to regain. An inability, for

technological or other reasons, to successfully develop and introduce new products could reduce our growth rate or otherwise damage our business. In the past, we have experienced, and are likely to experience in the future, delays in the development

and introduction of products. We cannot assure that we will keep pace with the rapid rate of change in life science research, or that our new products will adequately meet the requirements of the marketplace or achieve market acceptance.

If we fail to attract, hire, develop and retain qualified personnel, we may not be able to design,

manufacture, market or sell our products or successfully grow our business.

As part of our global supply chain initiative to improve customer service

and to amplify our product expertise, we have concentrated our facilities in fewer geographical areas in which there is high demand for qualified staff. Competition for individuals with skills including sales, marketing, research, product

development, engineering and others is strong and we may not be able to secure the personnel we need. The loss of the services of any key personnel, or our inability to hire new personnel with the requisite skills, could restrict our ability to

develop new products and services or enhance existing products and services in a timely manner, sell products to our customers, or manage our business effectively.

Our level of indebtedness may harm our business and prevent our achievement of anticipated growth.

As

of December 31, 2009, our total long term debt was $890.2 million. Our level of indebtedness could have important consequences because:

| n

|

|

a substantial portion of our cash flows from operations will be dedicated to interest and principal payments and may not be available for operations, working

capital, capital expenditures, expansion, acquisitions or general corporate or other purposes; |

| n

|

|

it may impair our ability to obtain additional or replacement financing in the future; |

| n

|

|

it may limit our flexibility in planning for, or reacting to, changes in our business and industry; and |

| n

|

|

it may make us more vulnerable to downturns in our business, our industry or the economy in general. |

Our operations may not generate sufficient cash to enable us to service our debt. If we fail to make a payment on any of our debt obligations or comply with financial

covenants in our debt agreements, we could be in default on such debts, and this default could cause us to be in default on our other outstanding indebtedness.

|

|

|

| MILLIPORE FORM 10-K 2009 |

|

27 |

PART I

In each case of default, we may be required to repay all of our outstanding indebtedness or renegotiate the terms of our indebtedness on unfavorable terms.

Sales of several of our products are dependent on a small number of customers, the loss of which may harm our business and result in a reduction in

revenues and earnings.

No single customer represents more than 10 percent of our annual sales. However, sales of some of our products are dependent on a

limited number of customers, who account for a significant portion of such sales. Continuing consolidation in the biopharmaceutical industry will likely concentrate our customer base further. Some of these products are in areas in which we plan to

grow substantially. The loss of such key customers for such products, or a significant reduction in sales to those customers, could significantly reduce our revenues in these products and adversely affect our future growth in such markets.

We may become involved in disputes regarding our patents and other intellectual property rights, which could result in prohibition on

the use of certain technology in current or planned products, exposure of the business to significant liability and diversion of management’s focus.

We and our major competitors spend substantial time and resources developing and patenting new and improved products and technologies. Many of our products are based on complex, rapidly developing technologies. Although we try to identify

all relevant third party patents and intellectual property rights, these products could be developed by the business without knowledge of published or unpublished patent applications that cover or use some aspect of these technologies. We also

license products and technologies developed by other biotechnology companies or academic research laboratories for further resale. We have been and may in the future be sued by third parties alleging that we are infringing their intellectual

property rights. These lawsuits are expensive, take significant time, and divert management’s focus from other business concerns.

If we are found to be infringing the intellectual property of others, we could be required to stop the infringing activity, or we may be required to design around or license the intellectual

property in question. If we are unable to obtain a required license on acceptable terms, or are unable to design around any third party patent, we may be unable to sell some of our products and services, which could result in reduced revenue. In

addition, if we do not prevail, a court may find damages or award other remedies in favor of the opposing party in any of these suits, which may adversely affect our earnings.

Concerns about products that are derived from animal materials, such as bovine serum, will further reduce the demand for our animal-based cell culture products.

The demand for several of our cell culture products will continue to decline due to concerns about the use of animal-based materials in the process by which they are

manufactured. The concern arises from the risk that animal contaminants might be present in the raw materials used in the production process and that such contaminants might be introduced into a therapeutic substance manufactured by one of our

customers. For example, the regulatory authorities of certain countries, including Japan, have refused to approve pharmaceuticals that are manufactured using a product that was derived from bovine serum or that was manufactured by a process that

uses bovine material. The regulatory authorities of other countries could adopt similar restrictions.

Our operations must comply with

environmental statutes and regulations, and any failure to comply could result in extensive costs which would harm our business.

The manufacture of some