Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K REG FD CITI PRESENTATION - Celanese Corp | form8kregfdciti.htm |

Celanese

Corporation

December

2009

2

Forward

Looking Statements, Reconciliation and Use of Non-

GAAP Measures to U.S. GAAP

GAAP Measures to U.S. GAAP

Forward-Looking

Statements

This

presentation may contain “forward-looking statements,” which include information

concerning the company’s plans, objectives, goals, strategies, future revenues

or performance, capital

expenditures, financing needs and other information that is not historical information. When used in this release, the words “outlook,” “forecast,” “estimates,” “expects,” “anticipates,” “projects,” “plans,” “intends,”

“believes,” and variations of such words or similar expressions are intended to identify forward-looking statements. All forward-looking statements are based upon current expectations and beliefs and various

assumptions. There can be no assurance that the company will realize these expectations or that these beliefs will prove correct. There are a number of risks and uncertainties that could cause actual results to differ

materially from the forward-looking statements contained in this release. Numerous factors, many of which are beyond the company’s control, could cause actual results to differ materially from those expressed as

forward-looking statements. Certain of these risk factors are discussed in the company’s filings with the Securities and Exchange Commission. Any forward-looking statement speaks only as of the date on which it is

made, and the company undertakes no obligation to update any forward-looking statements to reflect events or circumstances after the date on which it is made or to reflect the occurrence of anticipated or

unanticipated events or circumstances.

expenditures, financing needs and other information that is not historical information. When used in this release, the words “outlook,” “forecast,” “estimates,” “expects,” “anticipates,” “projects,” “plans,” “intends,”

“believes,” and variations of such words or similar expressions are intended to identify forward-looking statements. All forward-looking statements are based upon current expectations and beliefs and various

assumptions. There can be no assurance that the company will realize these expectations or that these beliefs will prove correct. There are a number of risks and uncertainties that could cause actual results to differ

materially from the forward-looking statements contained in this release. Numerous factors, many of which are beyond the company’s control, could cause actual results to differ materially from those expressed as

forward-looking statements. Certain of these risk factors are discussed in the company’s filings with the Securities and Exchange Commission. Any forward-looking statement speaks only as of the date on which it is

made, and the company undertakes no obligation to update any forward-looking statements to reflect events or circumstances after the date on which it is made or to reflect the occurrence of anticipated or

unanticipated events or circumstances.

Reconciliation

of Non-U.S. GAAP Measures to U.S. GAAP

This

presentation reflects five performance measures, operating EBITDA, affiliate

EBITDA, adjusted earnings per share, net debt and adjusted free cash flow, as

non-U.S. GAAP measures. The

most directly comparable financial measure presented in accordance with U.S. GAAP in our consolidated financial statements for operating EBITDA is operating profit; for affiliate EBITDA is equity in net earnings of

affiliates; for adjusted earnings per share is earnings per common share-diluted; for net debt is total debt; and for adjusted free cash flow is cash flow from operations.

most directly comparable financial measure presented in accordance with U.S. GAAP in our consolidated financial statements for operating EBITDA is operating profit; for affiliate EBITDA is equity in net earnings of

affiliates; for adjusted earnings per share is earnings per common share-diluted; for net debt is total debt; and for adjusted free cash flow is cash flow from operations.

Use

of Non-U.S. GAAP Financial Information

►Operating

EBITDA, a measure used by management to measure performance, is defined as

operating profit from continuing operations, plus equity in net earnings from

affiliates, other income and depreciation and

amortization, and further adjusted for other charges and adjustments. We may provide guidance on operating EBITDA and are unable to reconcile forecasted operating EBITDA to a U.S.GAAP financial measure

because a forecast of Other Charges and Adjustments is not practical. Our management believes operating EBITDA is useful to investors because it is one of the primary measures our management uses for its

planning and budgeting processes and to monitor and evaluate financial and operating results. Operating EBITDA is not a recognized term under U.S. GAAP and does not purport to be an alternative to operating

profit as a measure of operating performance or to cash flows from operating activities as a measure of liquidity. Because not all companies use identical calculations, this presentation of operating EBITDA may not

be comparable to other similarly titled measures of other companies. Additionally, operating EBITDA is not intended to be a measure of free cash flow for management’s discretionary use, as it does not consider

certain cash requirements such as interest payments, tax payments and debt service requirements nor does it represent the amount used in our debt covenants.

amortization, and further adjusted for other charges and adjustments. We may provide guidance on operating EBITDA and are unable to reconcile forecasted operating EBITDA to a U.S.GAAP financial measure

because a forecast of Other Charges and Adjustments is not practical. Our management believes operating EBITDA is useful to investors because it is one of the primary measures our management uses for its

planning and budgeting processes and to monitor and evaluate financial and operating results. Operating EBITDA is not a recognized term under U.S. GAAP and does not purport to be an alternative to operating

profit as a measure of operating performance or to cash flows from operating activities as a measure of liquidity. Because not all companies use identical calculations, this presentation of operating EBITDA may not

be comparable to other similarly titled measures of other companies. Additionally, operating EBITDA is not intended to be a measure of free cash flow for management’s discretionary use, as it does not consider

certain cash requirements such as interest payments, tax payments and debt service requirements nor does it represent the amount used in our debt covenants.

►Affiliate

EBITDA, a measure used by management to measure performance of its equity

investments, is defined as the proportional operating profit plus the

proportional depreciation and amortization of its equity

investments. Affiliate EBITDA, including Celanese Proportional Share of affiliate information on Table 8, is not a recognized term under U.S. GAAP and is not meant to be an alternative to operating cash flow of the

equity investments. The company has determined that it does not have sufficient ownership for operating control of these investments to consider their results on a consolidated basis. The company believes that

investors should consider affiliate EBITDA when determining the equity investments’ overall value in the company.

investments. Affiliate EBITDA, including Celanese Proportional Share of affiliate information on Table 8, is not a recognized term under U.S. GAAP and is not meant to be an alternative to operating cash flow of the

equity investments. The company has determined that it does not have sufficient ownership for operating control of these investments to consider their results on a consolidated basis. The company believes that

investors should consider affiliate EBITDA when determining the equity investments’ overall value in the company.

►Adjusted

earnings per share is a measure used by management to measure performance. It is

defined as net earnings (loss) available to common shareholders plus preferred

dividends, adjusted for other charges

and adjustments, and divided by the number of basic common shares, diluted preferred shares, and options valued using the treasury method. We may provide guidance on an adjusted earnings per share basis and

are unable to reconcile forecasted adjusted earnings per share to a GAAP financial measure without unreasonable effort because a forecast of Other Items is not practical. We believe that the presentation of this

non-U.S. GAAP measure provides useful information to management and investors regarding various financial and business trends relating to our financial condition and results of operations, and that when U.S.

GAAP information is viewed in conjunction with non-U.S. GAAP information, investors are provided with a more meaningful understanding of our ongoing operating performance. This non-U.S. GAAP information is

not intended to be considered in isolation or as a substitute for U.S. GAAP financial information.

and adjustments, and divided by the number of basic common shares, diluted preferred shares, and options valued using the treasury method. We may provide guidance on an adjusted earnings per share basis and

are unable to reconcile forecasted adjusted earnings per share to a GAAP financial measure without unreasonable effort because a forecast of Other Items is not practical. We believe that the presentation of this

non-U.S. GAAP measure provides useful information to management and investors regarding various financial and business trends relating to our financial condition and results of operations, and that when U.S.

GAAP information is viewed in conjunction with non-U.S. GAAP information, investors are provided with a more meaningful understanding of our ongoing operating performance. This non-U.S. GAAP information is

not intended to be considered in isolation or as a substitute for U.S. GAAP financial information.

►The

tax rate used for adjusted earnings per share approximates the midpoint in a

range of forecasted tax rates for the year, excluding changes in uncertain tax

positions, discrete items and changes in

management’s assessments regarding the ability to realize deferred tax assets. We analyze this rate quarterly and adjust if there is a material change in the range of forecasted tax rates; an updated forecast would

not necessarily result in a change to our tax rate used for adjusted earnings per share. The adjusted tax rate is an estimate and may differ significantly from the tax rate used for U.S. GAAP reporting in any given

reporting period. It is not practical to reconcile our prospective adjusted tax rate to the actual U.S. GAAP tax rate in any future period.

management’s assessments regarding the ability to realize deferred tax assets. We analyze this rate quarterly and adjust if there is a material change in the range of forecasted tax rates; an updated forecast would

not necessarily result in a change to our tax rate used for adjusted earnings per share. The adjusted tax rate is an estimate and may differ significantly from the tax rate used for U.S. GAAP reporting in any given

reporting period. It is not practical to reconcile our prospective adjusted tax rate to the actual U.S. GAAP tax rate in any future period.

►Net

debt is defined as total debt less cash and cash equivalents. We

believe that the presentation of this non-U.S. GAAP measure provides useful

information to management and investors regarding changes to

the company’s capital structure. Our management and credit analysts use net debt to evaluate the company's capital structure and assess credit quality. This non-U.S. GAAP information is not intended to be

considered in isolation or as a substitute for U.S. GAAP financial information.

the company’s capital structure. Our management and credit analysts use net debt to evaluate the company's capital structure and assess credit quality. This non-U.S. GAAP information is not intended to be

considered in isolation or as a substitute for U.S. GAAP financial information.

►Adjusted

free cash flow is defined as cash flow from operations less capital

expenditures, other productive asset purchases, operating cash from discontinued

operations and certain other charges and adjustments.

We believe that the presentation of this non-U.S. GAAP measure provides useful information to management and investors regarding changes to the company’s cash flow. Our management and credit analysts use

adjusted free cash flow to evaluate the company’s liquidity and assess credit quality. This non-U.S. GAAP information is not intended to be considered in isolation or as a substitute for U.S. GAAP financial

information.

We believe that the presentation of this non-U.S. GAAP measure provides useful information to management and investors regarding changes to the company’s cash flow. Our management and credit analysts use

adjusted free cash flow to evaluate the company’s liquidity and assess credit quality. This non-U.S. GAAP information is not intended to be considered in isolation or as a substitute for U.S. GAAP financial

information.

Results

Unaudited

The

results presented in this presentation, together with the adjustments made to

present the results on a comparable basis, have not been audited and are based

on internal financial data furnished to management.

Quarterly results should not be taken as an indication of the results of operations to be reported for any subsequent period or for the full fiscal year.

Quarterly results should not be taken as an indication of the results of operations to be reported for any subsequent period or for the full fiscal year.

3

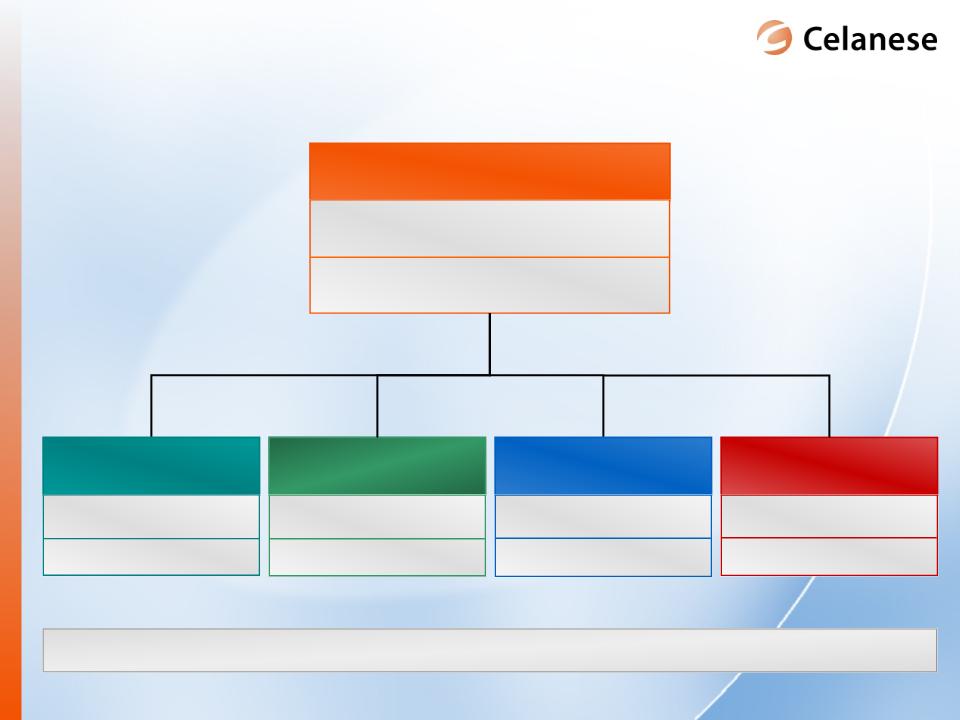

Celanese

($

million)

2008

Revenue: $6,823

2008

Operating EBITDA: $1,169

2009

3Q YTD Revenue: $3,694

2009

3Q YTD Op. EBITDA: $620

Consumer

Specialties

2008

Revenue: $1,155

2008

Operating EBITDA: $293

2009

3Q YTD Revenue: $817

2009

3Q YTD Op. EBITDA: $283

Advanced

Engineered

Materials

Materials

2008

Revenue: $1,061

2008

Operating EBITDA: $170

2009

3Q YTD Revenue: $569

2009

3Q YTD Op. EBITDA: $84

Industrial

Specialties

2008

Revenue: $1,406

2008

Operating EBITDA: $117

2009

3Q YTD Revenue: $745

2009

3Q YTD Op. EBITDA: $90

Acetyl

Intermediates

2008

Revenue: $3,201

2008

Operating EBITDA: $676

2009

3Q YTD Revenue: $1,860

2009

3Q YTD Op. EBITDA: $229

Strong

financial performance in a challenging year

Celanese

diversified portfolio delivers

shareholder value through leading franchises

shareholder value through leading franchises

4

|

|

Portfolio

Characteristics

|

Financial

Impact

|

|

Advanced

Engineered

Materials (Engineered

Thermoplastics and

Polymers) |

► Industry-leading

technology

► Strong product

pipeline

|

► Higher

growth

► Margin

expansion

|

|

Consumer

Specialties

(Acetate

Flake and Tow, High

Intensity Food Sweetener) |

► Stable cash

generation

► Industry-leading

partnerships in

Asia |

► Cash

flow

► Stable

|

|

Acetyl

Intermediates

(Acetic

Acid, Vinyl Acetate

Monomer, Acetyl Derivatives) |

► A global

leader

► Advantaged

technology

► Superior cost

position

|

► Capital

efficient

► More stable

EBITDA

|

|

Industrial

Specialties

(Vinyl

Emulsions and Polymers)

|

► Upstream

integration

► Emerging

economy opportunities

► Growth through

innovation

|

► Asia

growth

► Increased

demand for low VOC

|

Balanced

portfolio creates a unique hybrid business model

Portfolio

well-positioned to deliver and

execute

execute

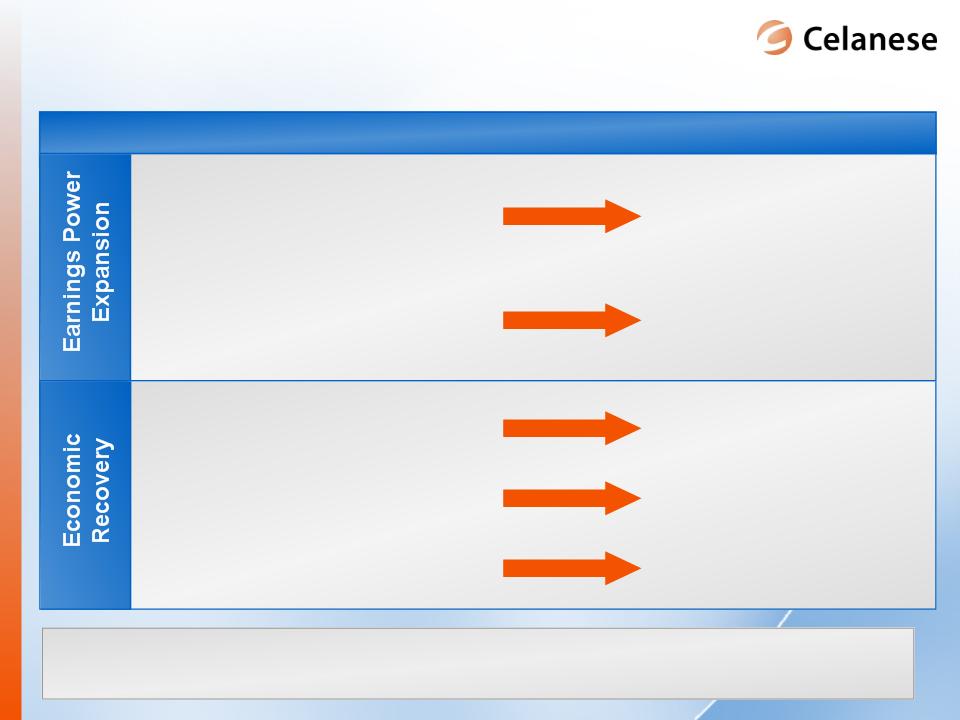

5

► Balanced footprint

in key

regions

regions

► Recovering

conditions in key

end-use industries

end-use industries

► Attractive balance

sheet with

strong cash generation

strong cash generation

Geographic

Demand

Capital

Structure

► Sustainable fixed

spending

reductions

reductions

► Efficient and

scalable capital

► Global macro trends

driving

customer growth

customer growth

Operating

Innovation

Celanese

Advantages Celanese

Levers of Value

Increasing

the earnings power of the business through multiple

levers

levers

Why

Celanese? Why

Celanese Now?

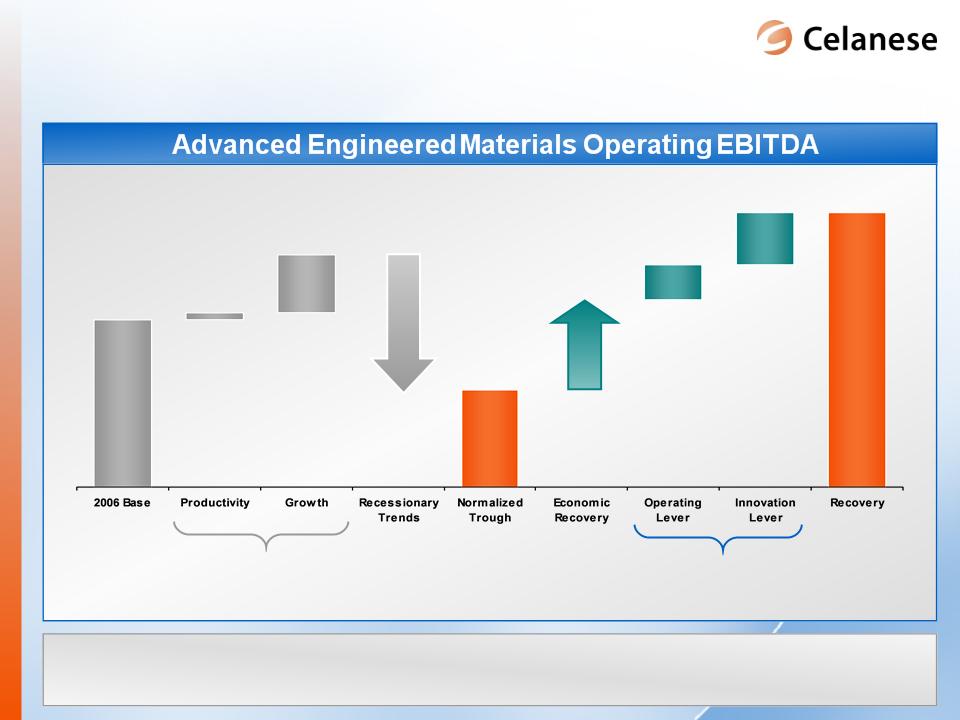

6

Operating

EBITDA

2006

- 2010 Strategic Objectives

$350-400

million

~$1,100

million

$1,600-1,800

million

2009

to “Recovery” Strategic Objectives

$250-350

million

$800-1,000

million

Increased

earnings power drives significant

shareholder value

shareholder value

7

2006

- 2010 Strategic Objectives

>$100

million

2009

to “Recovery” Strategic Objectives

$70-90

million

Earnings

power improvement substantial with initiatives - innovation

will play a key role

will play a key role

$400-450

million

$140-160

million

New

initiatives increase earnings

8

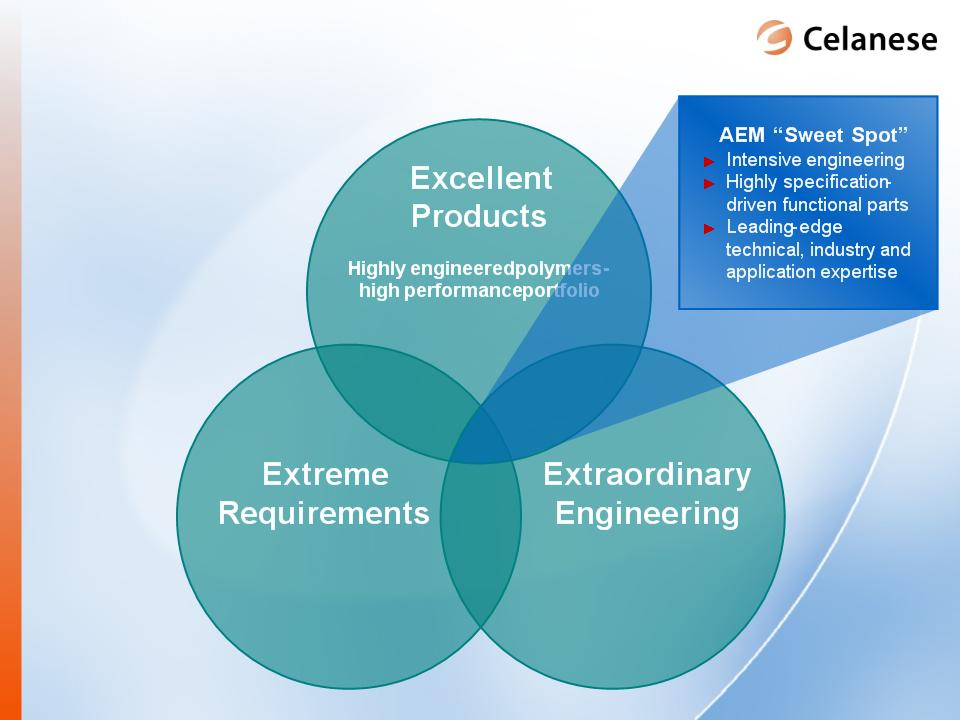

Precise

applications

in complex

environments

in complex

environments

Collaborative

engineering

right people - right place -

right time

right people - right place -

right time

Providing

valuable solutions to extreme

requirements

requirements

9

95%

5%

Standard

Polymers

High-Performance

Polymers (HPP)

Engineering

Thermoplastics (ETP)

ABS,

SAN, ASA = 3%

PE

= 28%

PP

= 19%

PET

= 7%

PU

= 6%

PVC

= 14%

PS,

EPS = 8%

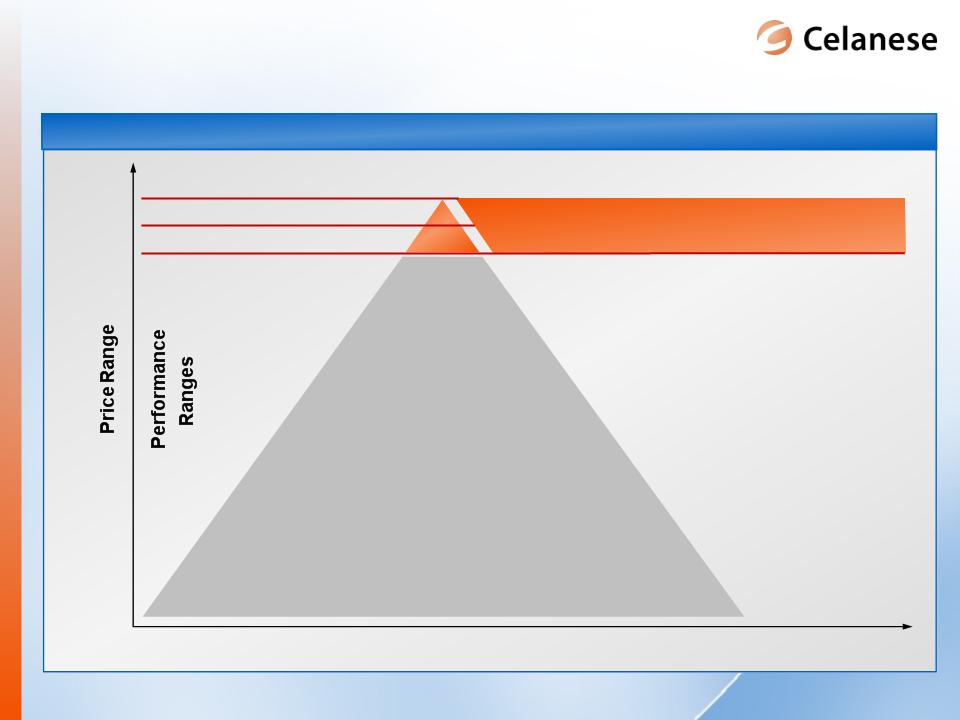

Range

of Products

$1/kg

$100/kg

$10/kg

$3/kg

Price

for Performance

PA

= 5%

PC

= 5%

Value

of technology and performance is

differentiated

differentiated

10

|

Key

Products

|

Ticona

|

DuPont

|

DSM

|

Sabic

|

Solvay

|

BASF

|

Major

End Uses

|

|

Hostaform®

Polyacetal

Copolymer (POM) |

+++

|

+++

|

--

|

--

|

--

|

++

|

|

|

Vectra®

Liquid

Crystal

Polymer (LCP) |

+++

|

++

|

--

|

--

|

++

|

--

|

|

|

GUR®

Ultra-high

molecular

weight polyethylene (UHMW-PE) |

++++

|

--

|

++

|

+

|

--

|

--

|

|

|

Fortron®

Polyphenylensulfide

(PPS)

|

++++

|

++

|

+++

|

++

|

++

|

+

|

Tech

Fibers

Connectors

Battery

Membranes

Filtration

Joint

Replacements

Auto

Appliances

Fuel

AEM

clear leader in key high performance polymers

Product

portfolio unmatched in the industry

11

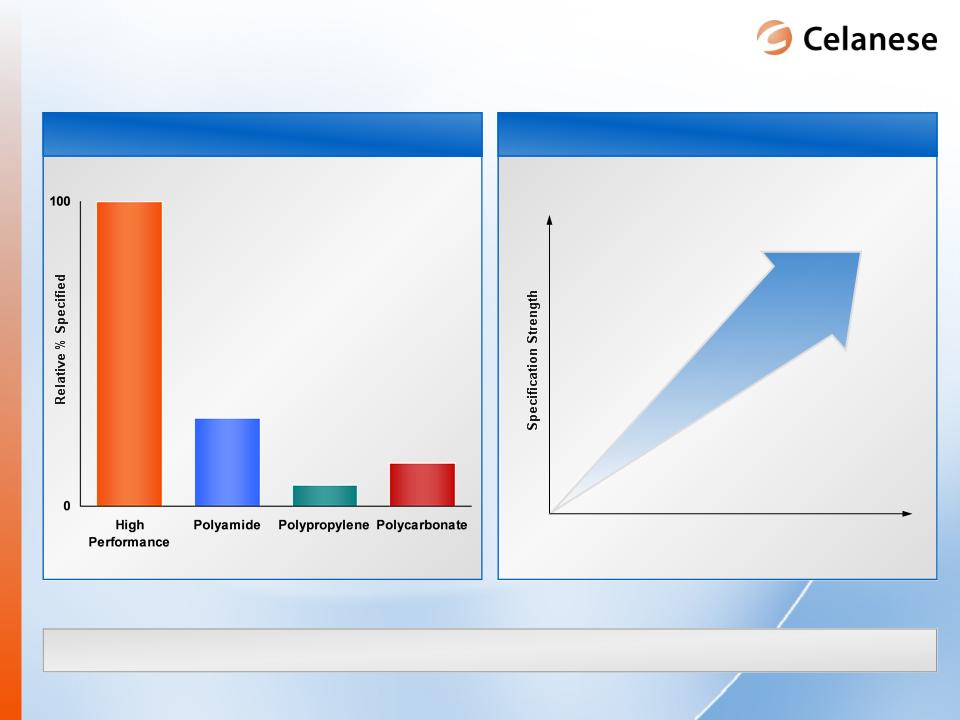

Value

of Specification

Value

Delivered

LANXESS

AEM

DuPont

SABIC/PC

BASF

DSM

Solvay

DOW

SABIC/Core

Specification

drives sustainable value for high performance polymers

Average

Specification by Material Type

Source:

Celanese internal estimates

Specification

position demonstrates strength

of the franchise

of the franchise

12

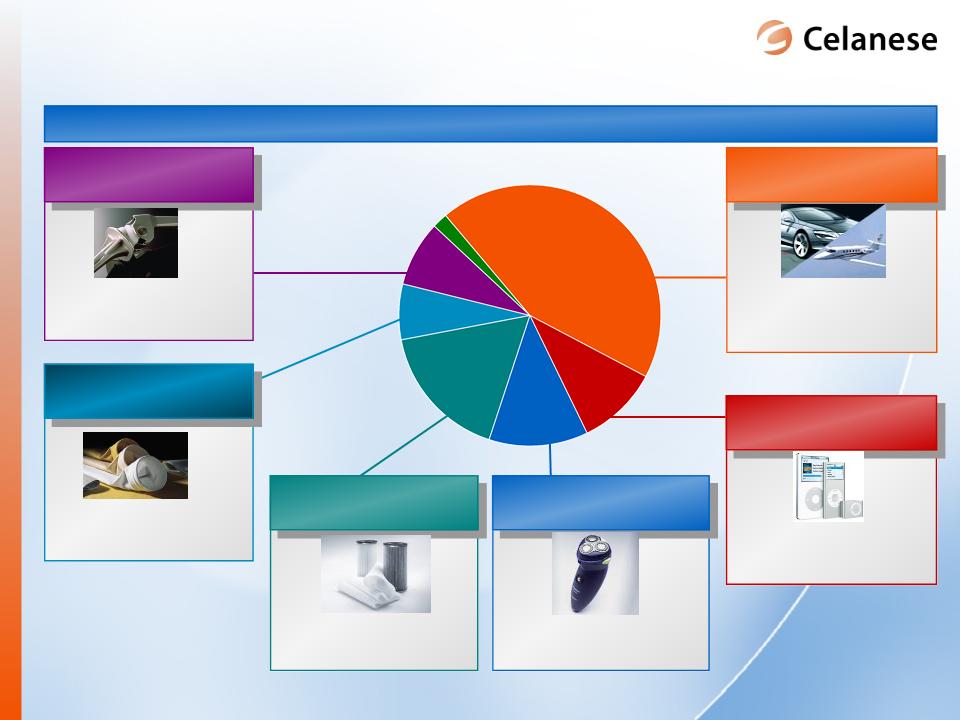

Other

2%

2008

Revenue ~ $1.1 billion

Alternate

Fabrication

7%

Transportation

44%

44%

► Fuel

systems

► Safety

systems

► Mechanical

components

Electrical

& Electronics

10%

10%

► Consumer

electronics

► LED

lighting

►

Connectors

Consumer

& Appliance

12%

12%

► Water

purification

► Durable household

goods

Industrial

17%

17%

► Fluid

handling

►

Gearing

► Drug delivery

systems

► Medical

implants

Medical

8%

8%

► Emissions

filtration

►

Textiles

Broad

range of end-use applications to

targeted value-added niches

targeted value-added niches

13

Project

Pipeline Development

► Continued

increases in new

project opportunities with

focus on:

project opportunities with

focus on:

• High-growth

end-segments

• Regional

penetration

► Pipeline

drivers continue to

be:

be:

• Regulatory

trends

• Consumer

preferences

• Geographic shift to

adopt

Western standards

Western standards

• Productivity

emphasis

Innovation

remains a key element to growth trajectory

Robust

and balanced pipeline continues to

grow with emphasis on automotive programs

grow with emphasis on automotive programs

14

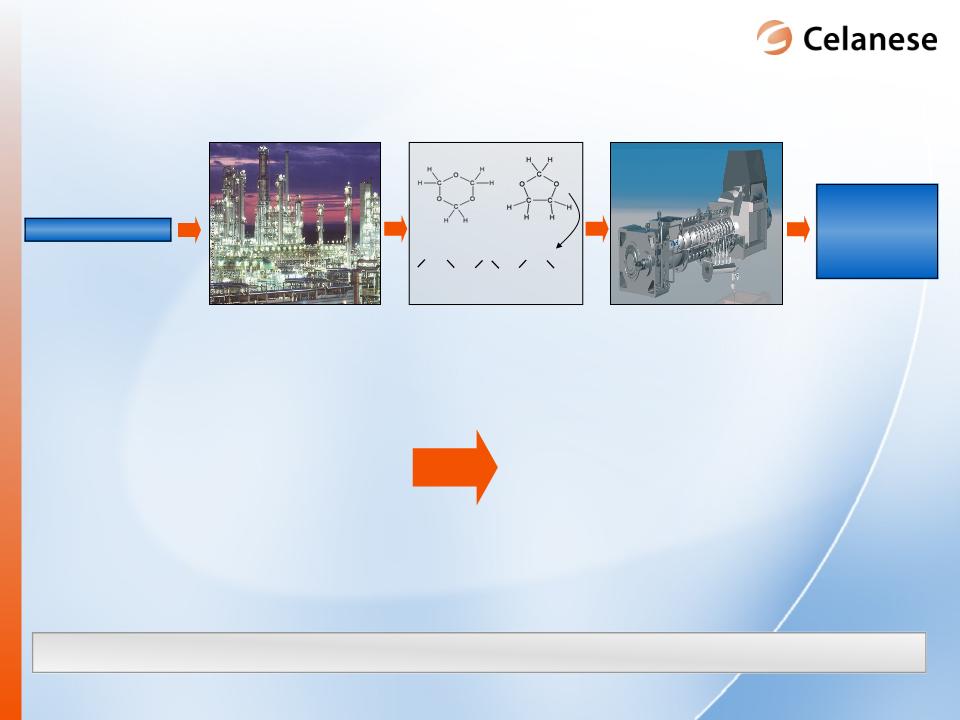

Unique

Properties:

• Inherent

lubricity

• Chemical

resistance

• Long-term fatigue

strength

Primary

Applications:

• Automotive fuel

systems

• Consumer

appliances

• Medical delivery

devices

• Fluid

handling

Estimated

global POM market size is ~$2 Billion*

* At 90%

industrial utilization rate

Methanol

POM

Monomer

Formation

Polymer

Production

Polymer

Reaction

+

R

CH2

CH2

O

CH2

CH2

O

CH3

Source:

Celanese internal estimates

Polyacetal

(POM) - key engineered polymer

provides technology platform for continued

growth

provides technology platform for continued

growth

15

48

years of innovative development

1961

1968

1976

1982

1993

1997

1999

2001

2005

Over

48 years of Hostaform® POM production

- innovation through product and application

development

- innovation through product and application

development

2005

Technology

breakthrough drives further innovation…

16

► Filed

more than 100 patents for intellectual property protection

Reactive

end

groups

groups

R

OCH3

CH2

O

CH2

Standard POM

Chain

Non-reactive

end group

end group

R

CH2

O

CH2

R

Significant

innovation in POM chemistry

Breakthrough

in reactive end group formation

IM POM

Chain

Methanol

Monomer

Formation

Polymer

Production

Polymer

Reaction

+

R

CH2

CH2

O

CH2

CH2

O

CH3

Impact

Modified

POM

Innovative

backbone modification results in

breakthrough new POM product

breakthrough new POM product

17

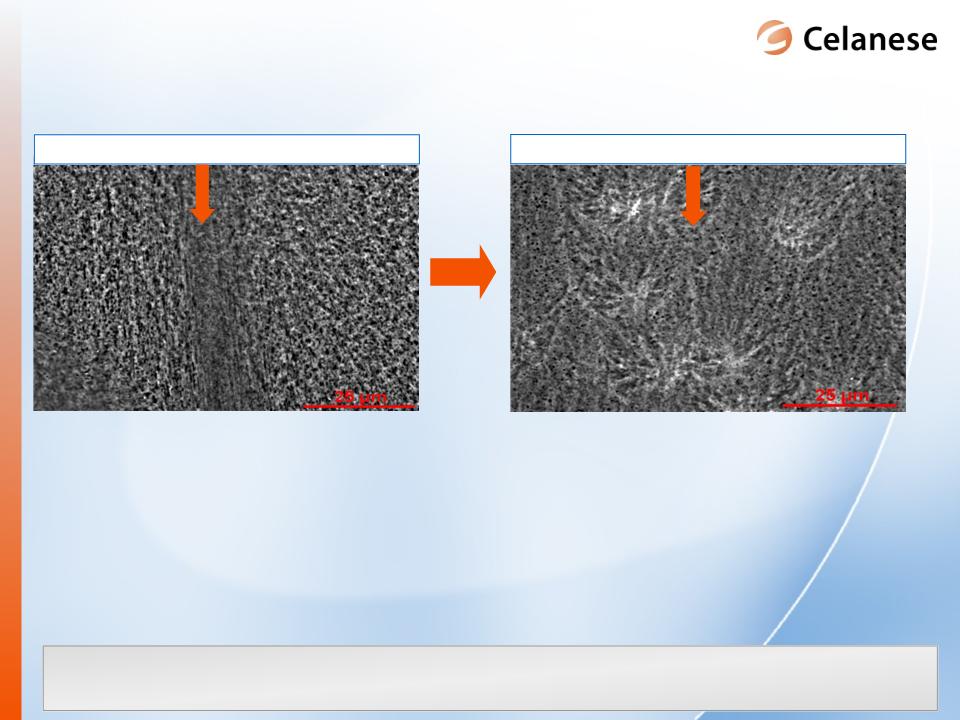

► Improved

impact strength by 75%

► Best

in class weldline performance by

300%

300%

► Higher

stiffness (modulus) - Up to 25%

► Reduce

cooling times for molded parts

by 30%

by 30%

► Elevated

heat deflection temperature

Conventional Impact

Modified POM

Visible

weld

line

line

NEW

Impact Modified POM

No

weld line

Significant

improvement in polymer performance in end applications

and part manufacturability

and part manufacturability

Innovative

technology drives improved impact

performance & weld line strength

performance & weld line strength

18

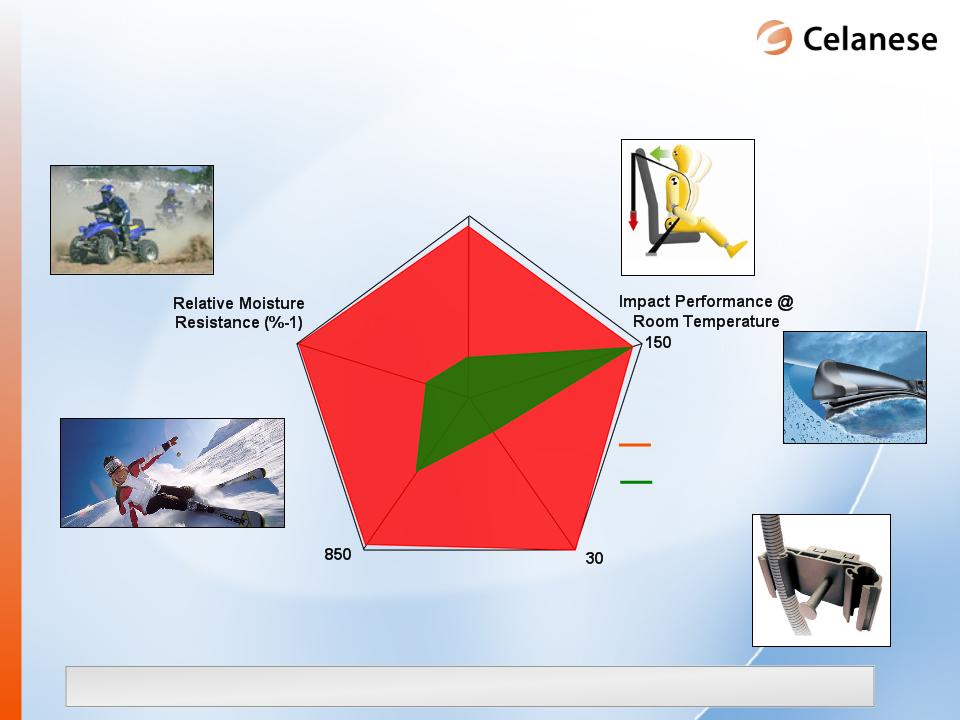

NEW

POM

IM

Nylon

Stiffness

(Mpa)

Elongation

@

Break (%)

Break (%)

330

Impact

Performance

@ Cold

Temperature

@ Cold

Temperature

4

Versatility

and reliability to meet all the requirements

New

POM product family offers design

freedoms and access to new growth

opportunities

freedoms and access to new growth

opportunities

19

Improvement

in POM Technical

Performance

Performance

New

Ticona

POM Space

POM Space

Existing

POM

Space

Increase

weldline strain @ break %

Technology

enables additional estimated

$500

million application

space opportunity

space opportunity

Automotive

Applications

► Chemical

resistance

► Superior impact

& weldline strength

► Elevated heat

deflection temperature

Industrial

Applications

► Higher stiffness

(Modulus)

► Improved slip &

wear performance

► Less mold

deposit

Consumer

Applications

► Design

freedom

► Superior impact and

weldline strength

Incremental

$500 Million

Application Opportunity

Application Opportunity

Ticona:

Growing application space through

innovation

innovation

20

|

|

Global

Automotive Trends

|

|||||

|

|

Regulatory

|

Consumer

|

Manufacturing

|

|||

|

|

Emissions

|

Fuel

Efficiency |

Adoption

of

Western Standards |

“Green”

Initiatives |

Global

Platforms |

Productivity

|

|

North

America |

ü

|

ü

|

|

ü

|

ü

|

ü

|

|

Europe

|

ü

|

ü

|

|

ü

|

ü

|

ü

|

|

Asia

|

ü

|

|

ü

|

ü

|

|

ü

|

Indifferent

to producer, model or manufacturing location…

AEM delivers solutions globally

AEM delivers solutions globally

Changing

automotive environment favors

high performance plastics

high performance plastics

21

Efficient

engines

engines

Hybrid-

engine

systems

engine

systems

Alternative

fuels

fuels

Metal

replacement

replacement

ü

Ticona

high

temperature polymers

for turbo-charged

engines

temperature polymers

for turbo-charged

engines

Ticona

polymers in

hybrid vehicle

systems

hybrid vehicle

systems

New

Hostaform®

POM

products meet more

aggressive conditions in

fuel delivery systems

products meet more

aggressive conditions in

fuel delivery systems

Ticona

portfolio for

components in door

module

components in door

module

ü

ü

ü

Ticona

is well-positioned to capitalize

on growth opportunities

on growth opportunities

22

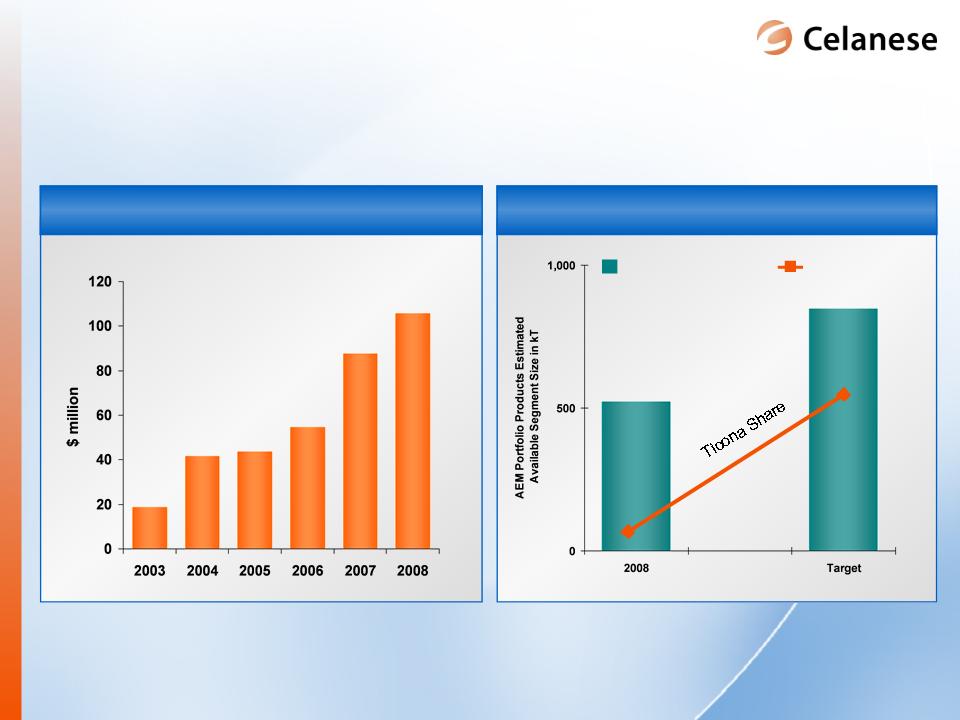

Asia

Sales for Ticona Global Portfolio

Ticona

Key Products - Asia Trajectory

Asia

segment size (est.)

CE

share (est.)

Source:

Form 10-K, Celanese internal estimates

We

are making progress in Asia… and the

platform is in place to capture growth

platform is in place to capture growth

23

Automotive

Opportunity

► Current

“best-in-class”

translation to all models

yields translation

opportunity

translation to all models

yields translation

opportunity

► Westernization

of current

China production drives

China opportunity

China production drives

China opportunity

► Successful

commercialization of

application R&D creates

pipeline opportunity

commercialization of

application R&D creates

pipeline opportunity

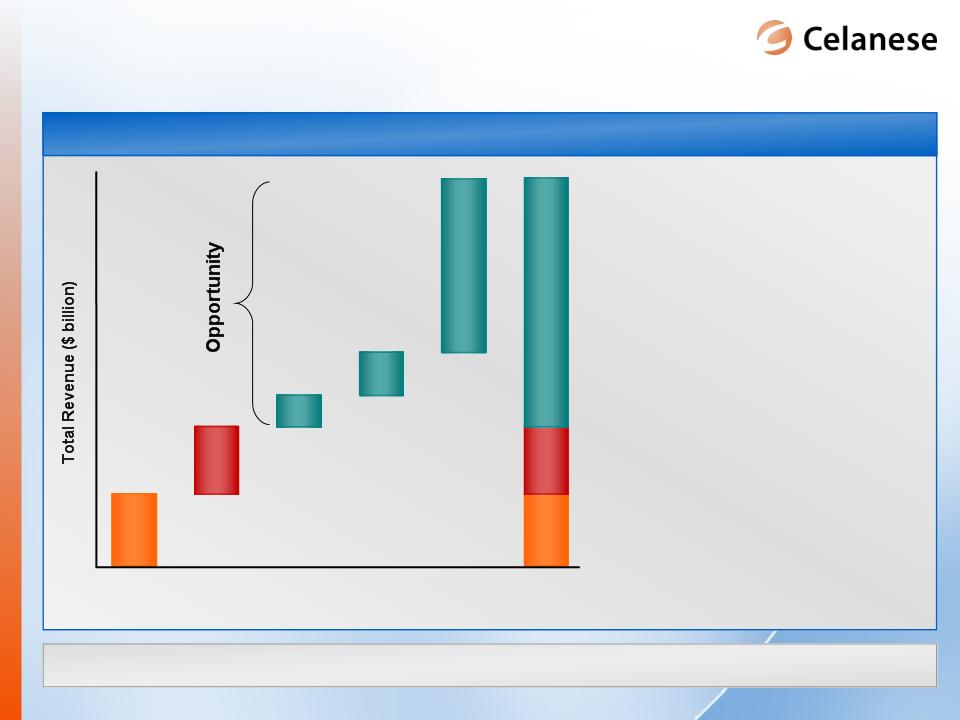

3.0

Total

AEM

Today

Total

Competitors

Today

Translation

China

Pipeline

Total

Opportunity

Opportunity

Significant

opportunities exist in ~$3 billion industry space

AEM: Application

development creates

current - and future - opportunities

current - and future - opportunities

24

kT

kT

Source:

Celanese internal estimates

Well-positioned

for growth in China with the right partner

China

ROW

Chinese

Imports

Chinese

Domestic

Production

Production

Worldwide

Tow Demand

Tow

Demand Growth

Acetate

Tow demand in China will drive

worldwide growth

worldwide growth

25

Productivity

Driven

Tax

Rate

Represents

approximately $1.00 per share in

2010

earnings improvement

2010

Earnings Improvement

► AEM: Destocking

complete

► CS: Sustain

performance

► AI: Technology,

2009 FIFO effect

► IS: Asia

growth focus

► Pardies &

Cangrejera closures

► Other manufacturing

realignment

► SG&A

realignment

► Sustain lower tax

rate

► Benefits of

manufacturing and

administrative

restructuring

► Cash taxes rate

expected

to be

similar

Volume

Driven

$80

- $100

At

least $100

Low

20% range

vs. 29%

vs. 29%

$

in millions

26

Why

Celanese? Why

Celanese Now?

Significant

value upside over current share price

Geographic

Demand

Capital

Structure

Operating

Innovation

Track

record

of execution

of execution

High

return

opportunities

opportunities

► $1.6-1.8 billion

recovery

earnings

earnings

► Rapid earnings

growth of

the current base -

$1.00/share growth in

2010

the current base -

$1.00/share growth in

2010

► Over $2 billion of

cash

generation through 2014

generation through 2014

► Returns continue

to

exceed weighted

average cost of capital

exceed weighted

average cost of capital

► More stable

earnings

profile

profile

Levers

of Value Shareholder

Value

Celanese

Corporation

December

2009

28

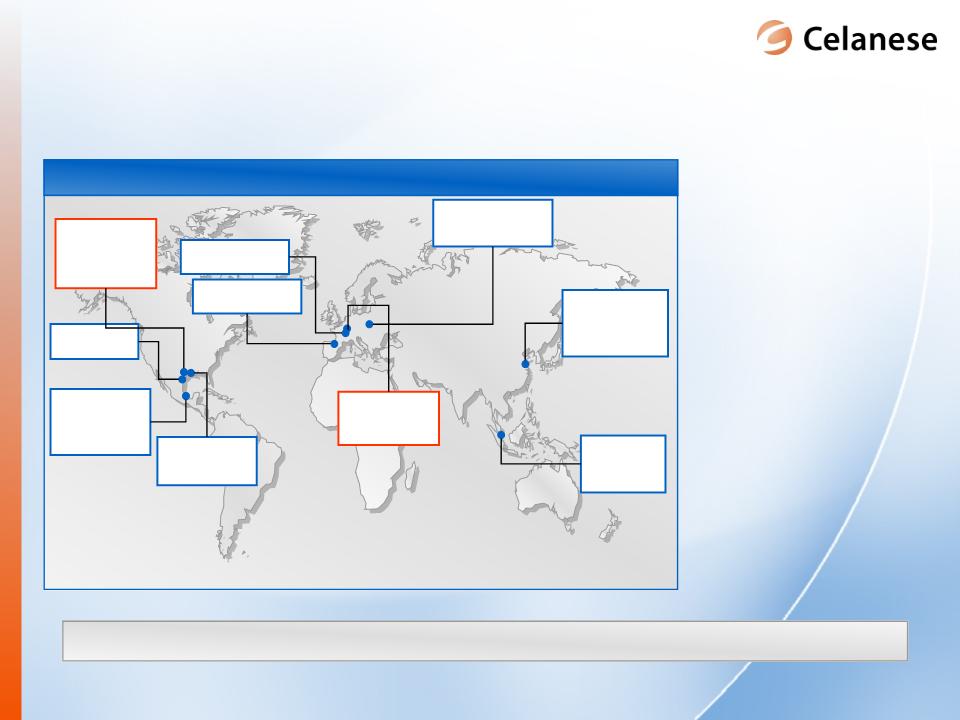

Celanese

Global Manufacturing Locations

All

values shown in kT per year

Singapore

Acid =

600

VAM =

210

Esters =

130

Frankfurt,

Germany

VAM =

285

Esters =

40

Tarragona,

Spain

VAM =

200

Bay

City, TX

VAM =

300

Clear

Lake, TX

Acid =

1,200

VAM = 310

Cangrejera,

Mexico

Mexico

Anhydride = 90

Esters =

105

VAM =

115

Pardies,

France

(announced

closure)

Acid =

440

VAM =

150

Nanjing,

China

Acid =

1,200

(expansion)

VAM = 300

(expansion)

VAM = 300

Anhydride =

100

► Utilization of

all

global Celanese

acetic acid and

downstream sites to

meet global customer

needs

global Celanese

acetic acid and

downstream sites to

meet global customer

needs

► Ensure all

Celanese

sites have a leading

cost structure

sites have a leading

cost structure

► Strategy to

remove

high cost facilities

high cost facilities

Roussillon,

France

Anhydride =

30

Celanese

well-positioned globally to meet changing

demand landscape

Pampa,

TX

(site

closed)

Acid =

290

Anhydride =

145

Esters =

60

Leading

global footprint positioned to meet

customer demand

customer demand

29

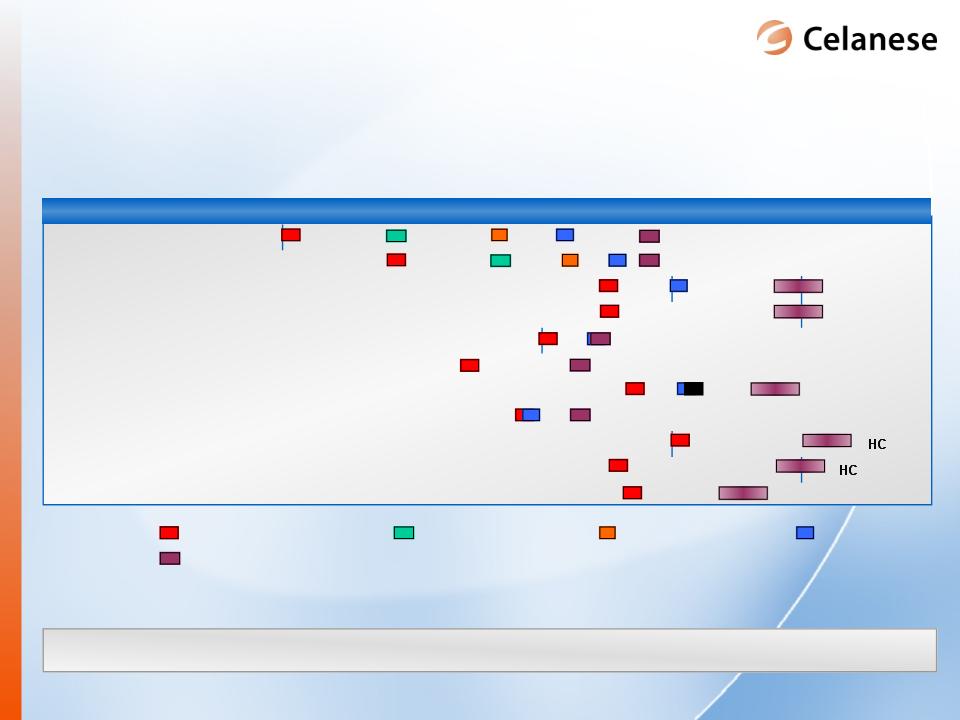

|

Company

|

Capacity

|

2007

|

2008

|

2009

|

2010

|

2011

|

|

BP

/ Sinopec

|

550

kt

|

|

|

|

|

|

|

Sipchem

|

430

kt

|

|

|

|

|

|

|

Sopo

(expansion)

|

600

kt

|

|

|

|

||

|

Wujing

(expansion)

|

500

kt

|

|

|

|

|

|

|

Yangkuang

Cathay

|

350

kt

|

|

|

|

|

|

|

Henan

Shunda

|

200

kt

|

|

|

|

|

HC

|

|

Tianjin

Bohei

|

200

kt

|

|

|

|

HC

|

|

|

Hualu

Hensheng

|

200

kt

|

|

|

|

|

HC

|

|

Henan

Yima

|

200

kt

|

|

|

|

||

|

Yunan

Yunwei

|

200

kt

|

|

|

|

|

|

|

Kingboard

|

400

kt

|

|

|

|

|

|

A

A

A

A

A

A

A

A

X

X

X

X

X

X

X

X

X

Company

Announced Startup

Current

Update

A

CE 2005

Update

SU

=

Actual plant startup

X

CE 2006

Update

HC

= Highest Cost

X

CE 2007

Update

X

X

X

X

X

X

X

SU

X

SU

Viability

of many higher cost projects is in question

1Celanese internal analysis

and opinion

?

A

SU

X

A

A

?

Timing

in question

Timing

in question

Forecast

Capacity Expansions1

Delays

in project startups likely to continue

30

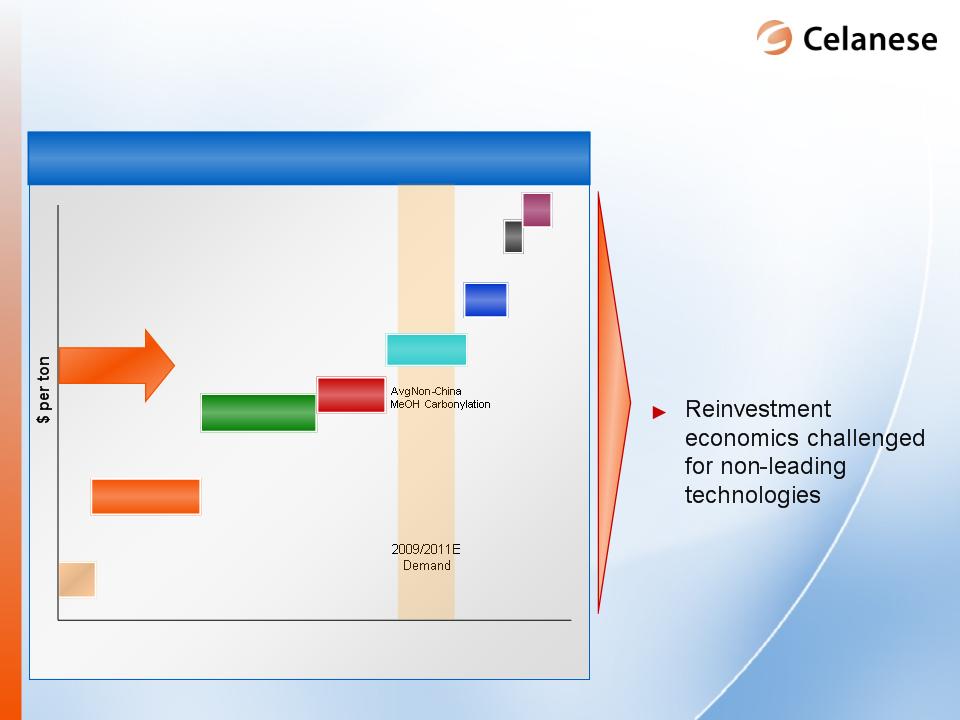

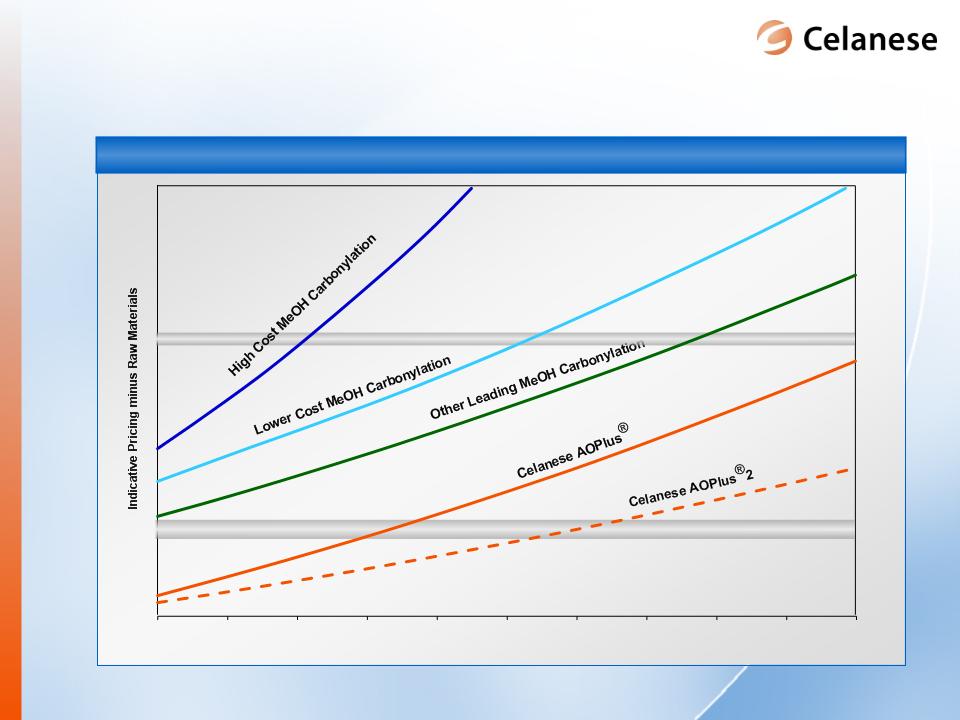

► Majority of

planned

capacity additions and

expansions may be

disadvantaged

capacity additions and

expansions may be

disadvantaged

2009/2011E

Acetic Acid Cost Curve (kT)

By

Prod

Avg

Other Leading

Technology

Effective

Industry Utilization Rates

Ethylene

Highest

Cost

China MeOH

China MeOH

Ethanol

Average

Celanese

Lower

Cost

China MeOH

China MeOH

Source:

Celanese internal estimates

Pricing

for CE to

earn

>15% EBITDA

AI: New

capacity not expected to impact

Celanese’s advantaged position

on the cost curve

Celanese’s advantaged position

on the cost curve

31

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

Return

on Invested Capital

Source:

Celanese internal estimates; available public data

AI: Celanese

is able to achieve >15% ROIC

when others are not able to profitably reinvest

when others are not able to profitably reinvest

Recent

Peak Pricing $600-700

Current

Pricing $350-400

Return

on Invested Capital vs. Acetic Acid Margin

32

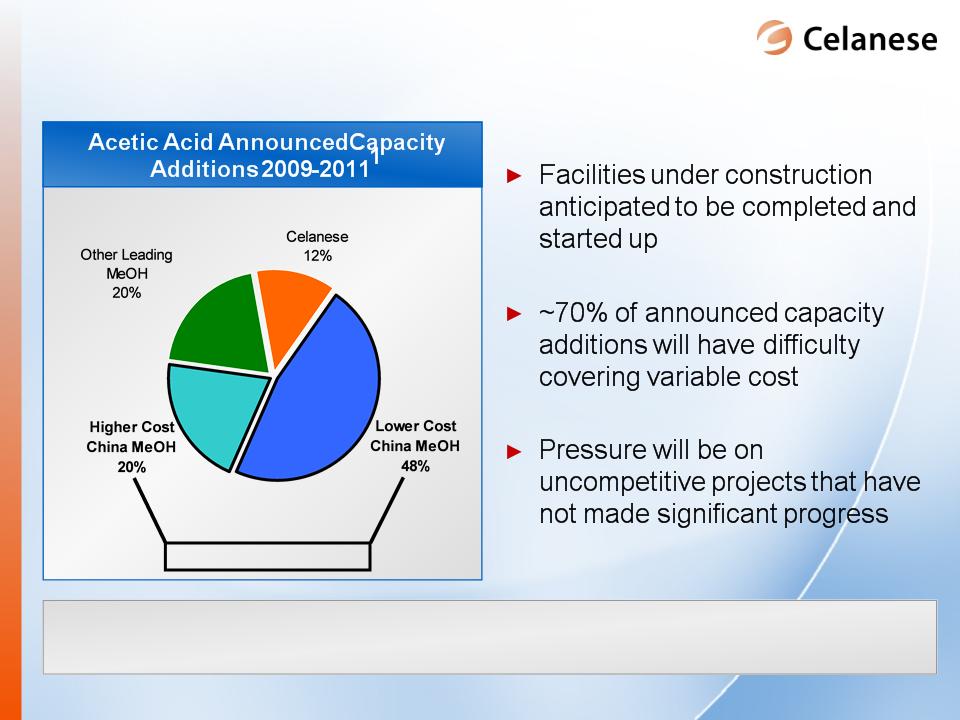

Majority

of announced capacity additions challenged in today’s

pricing environment

pricing environment

1Source: Celanese internal

estimates, Tecnon 2008. Based on

nameplate capacity

Disadvantaged

technology

Significant

differentiation in technology of

announced expansions

announced expansions

33

|

Available

Cash

|

|

|

Cash

(as

of 9/30/2009)

|

$1,293

|

|

Kelsterbach

Spending

|

~($300)

|

|

Operating

Cash

|

~($300)

|

|

Cash

Available for

Strategic Purposes |

~$700

|

► Ticona

Kelsterbach relocation

cash flow neutral through end of

2010

cash flow neutral through end of

2010

► Expect

to continue to generate

positive free cash flow

positive free cash flow

Significant

cash available after anticipated cash commitments

$

million

Positive

cash generation and portfolio

improvements enhance our cash position

improvements enhance our cash position

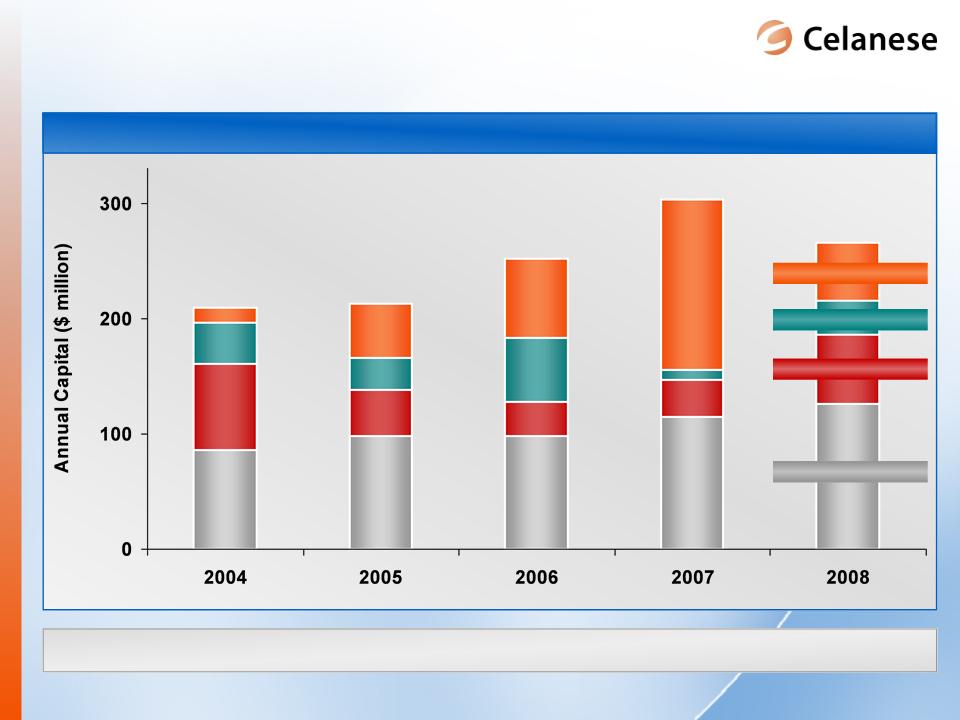

34

Balance

for “high return” productivity and capital efficient growth

Note:

Not including Kelsterbach plant relocation

Maintain

Plant

Other

Growth

Nanjing

Productivity

Capital

Spending by Category

Efficient

use of cash

35

*Starting from an Operating

EBITDA base

Positive

cash generation even in normalized trough

Normalized

Trough

18

- 20%

18

- 20%

8

- 10%

8

- 10%

22

- 25%

22

- 25%

18

- 20%

18

- 20%

21

- 23%

21

- 23%

10

- 12%

10

- 12%

13

- 15%

13

- 15%

20

- 22%

20

- 22%

Industrial

Specialties

Acetyl

Intermediates

Advanced

Engineered Materials

Consumer

Specialties

Other

Activities

$800-1,000

million

million

|

2009E

Cash Flow Guidance

|

|

|

$

in

millions

|

2009E2

|

|

Cash

Taxes

|

$40

- $50

|

|

Capital

Expenditures

|

$165

- $175

|

|

Reserve/Other

|

$80

- $90

|

|

Net

Interest

|

$200

- $210

|

|

Pension

|

$40

- $50

|

|

Adjusted

Free Cash Outflows

|

$525

- $575

|

|

Dividends /

Debt Service

|

$75

- $100

|

|

Total

Cash Outflows

|

$600

- $675

|

Hybrid

portfolio well positioned in peak or

trough conditions

trough conditions

36

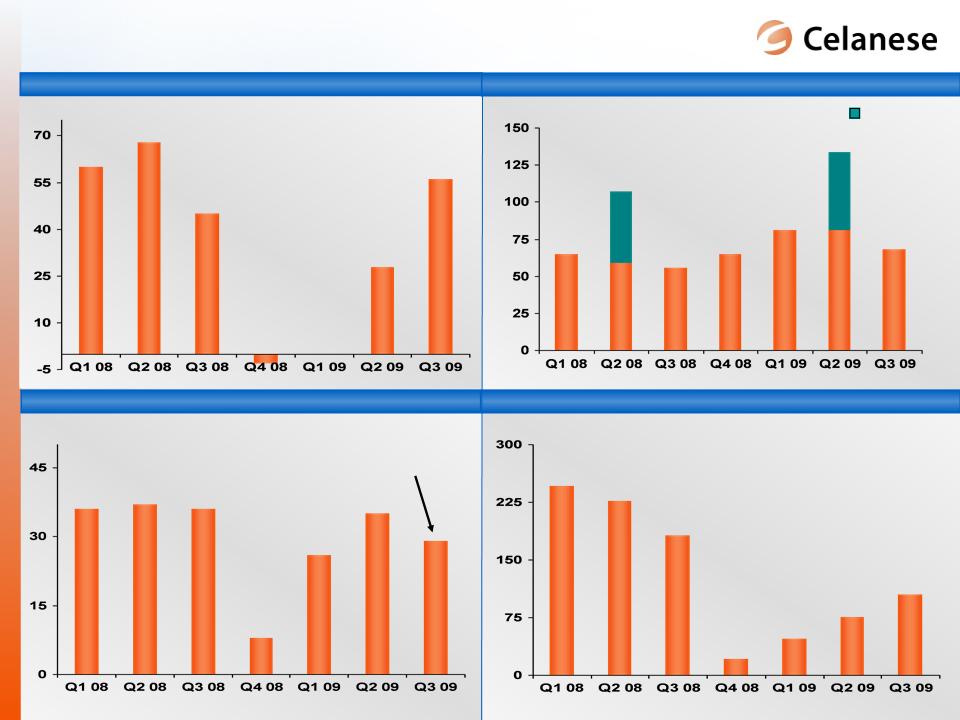

Acetyl

Intermediates

Industrial

Specialties

Advanced

Engineered Materials

Consumer

Specialties

JVs

Dividends

PVOH

Divesture

3Q

2009

Segment

Operating EBITDA Recovery

37

Term

Loan - $2.8 billion

Other

Debt Obligations - $775 million

Cash

- $1.3 billion

Net

Debt - $2.3 billion

Revolver

- $600 million

Cost

Stability

Flexibility

Structure

Characteristics

Primary

Components

Solid

liquidity position and covenant-lite term loan create

advantaged capital structure

advantaged capital structure

Credit

Linked Facility - $136 million

Celanese

capital structure

38

39

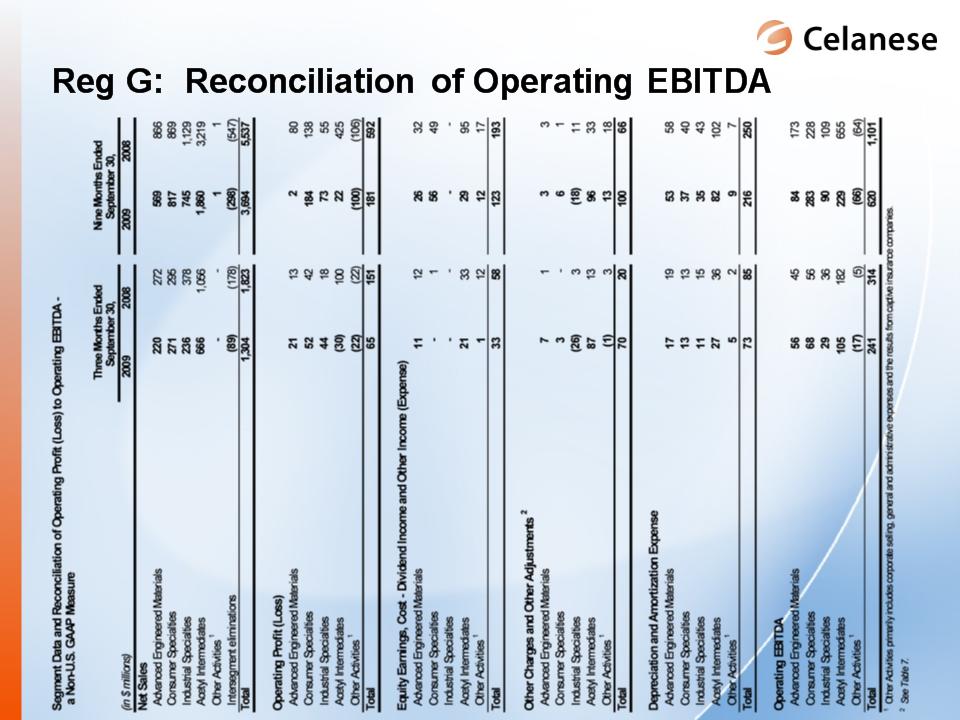

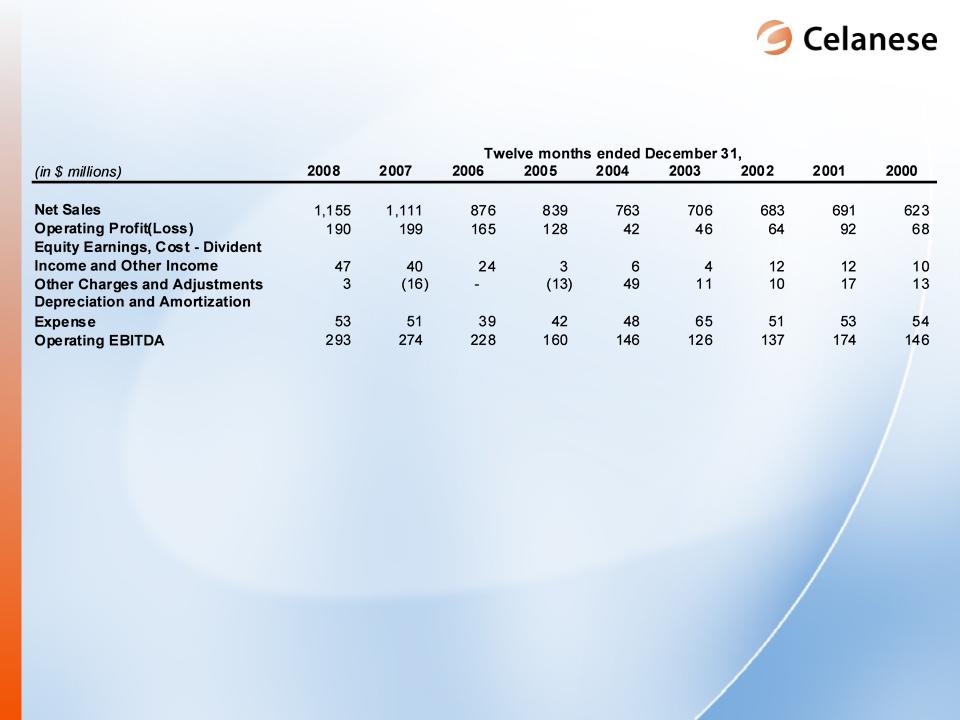

Reg

G: Reconciliation

of Consumer

Specialties Operating EBITDA: 2000-2008

Specialties Operating EBITDA: 2000-2008

40

Reg

G: Reconciliation

of Celanese Operating

EBITDA: 2001

EBITDA: 2001