Attached files

| file | filename |

|---|---|

| 8-K - FORM 8-K - ADA-ES INC | d8k.htm |

NASDAQ:ADES A Leader in Clean Coal Technology Analyst and Investor Plant Tour October 13, 2009 © Copyright 2009 ADA-ES, Inc. All rights reserved. Exhibit 99.1 |

-2- Please note that this presentation contains forward-looking statements within the

meaning of U.S. securities laws, including statements relating to future

contracts, projects, technologies, employees, project funding, ownership, tax credits, revenues and expenses; the new activated carbon (“AC”) facility ADA-CS is building; ADA-CS’ ability to supply AC; future AC supply and demand, the likelihood, timing and impact of new laws, regulations and court

rulings on our target markets; and anticipated sizes of and growth in our

target markets. These forward-looking statements involve

significant risks and uncertainties that could cause the actual results to

differ materially from those anticipated, including changes in laws and regulations, government funding, prices, economic conditions and market demand; impact of competition and litigation; availability, cost of and demand for alternative energy sources and other technologies; operational difficulties; availability of skilled personnel; failure

to satisfy performance guaranties; risks related to ADA-CS such as

changes in the costs and timing of construction of the AC facility, failure

to raise additional financing or satisfy conditions in existing agreements

and inability to sign or close acceptable coal supply and off-take agreements in a timely manner; availability of raw materials and equipment for our businesses; and other factors discussed in greater detail in our filings with the SEC. You are cautioned not to place undue reliance on our forward-looking statements. These

statements are presented as of the date made, and we disclaim any duty to

update them unless required by law to do so. |

Agenda 7:00am – 8:30am Breakfast & management presentations, Hilton Shreveport meeting room 8:45am Transportation to Red River AC manufacturing facility site in Coushatta, LA 9:45am-10:45am Tour of Red River AC Plant 10:45am – 11:15am Transportation to Natchitoches AC processing and logistics facility in Natchitoches, LA 11:15am – 11:30am Tour of Natchitoches AC facility 11:30 – 11:45 Transportation to Lunch – Natchitoches, LA Noon to 1:15pm Louisiana-style Lunch and Q&A 1:15pm Leave for Airport 2:30pm Arrive Airport -3- |

-4- Presentation Outline • Introduction • Mercury – Update on mercury regulations (Mike Durham) – Equipment sales (Mike Durham) – AC market and ADA Carbon Solutions (Jean Bustard) – Financing (Mike Durham) • Carbon Capture Technology (Sharon Sjostrom) • CyClean Refined Coal (Nina French) • Update on Norit and Calgon Lawsuits (Mike Durham) • Tour background (Mike Durham) |

-5- GROWTH AREA #1: Mercury Control |

-6- Activated Carbon Injection (ACI) Equipment Sales Contracts for ACI systems for over 130 boilers (55 GW) have been awarded by power companies to date – ADA market share: approximately 30% – The rest are split between 7 or 8 other companies An additional 15-20 contracts are expected for new power plants and current state regulations Additional ~ 450 systems expected with federal regulation Working closely with largest utilities in the U.S. and Canada Key supplier of mercury control technology to major air pollution control companies |

-7- Update on Federal Laws U.S. EPA MACT for Coal-Fired Boilers – Covers all 189 Hazardous Air Pollutants (HAPs) – Should result in 90 to 95% limit for mercury U.S. EPA Industrial Boiler MACT – Covers larger number of boilers, smaller units – Will require distribution for AC and simpler ACI systems U.S. EPA MACT for Cement – AC needed for both mercury and volatiles U.S. Legislation – 3-P Bill could be added to Climate bill by Sen. Carper (D-DE) and Alexander (R-TN) which includes 90% Hg Canadian-wide mercury standard has been passed |

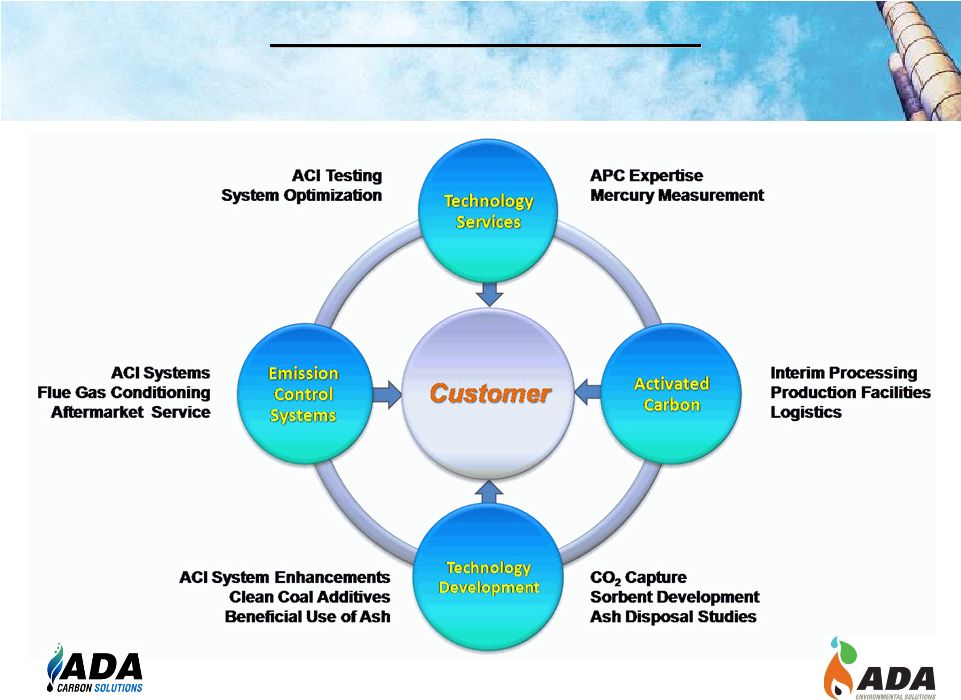

Total

Solutions Provider Total Solutions Provider The ADA Advantage The ADA Advantage -8- |

Sorbent Enhancement Option Sorbent Enhancement Option Sorbent Enhancement Module To Distribution Manifold ACI System Standard Sorbent (> 15 µm) Delivered to SEM Compressed Air Source > 100 psig Processed Sorbent (< 8 µm) + Air -9- |

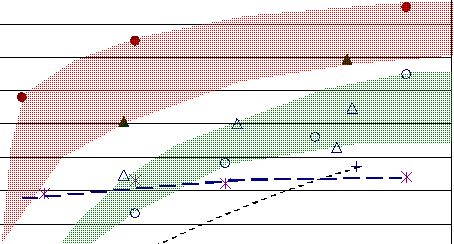

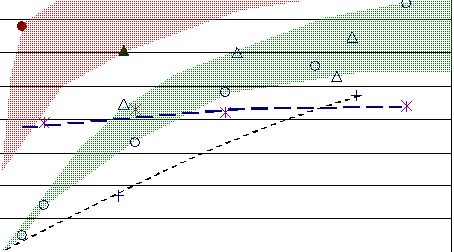

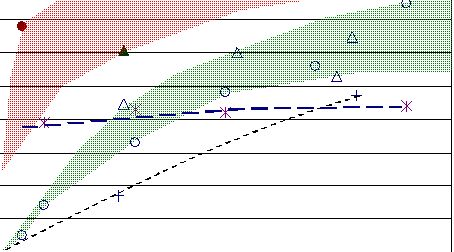

In-Line AC Milling In-Line AC Milling 60 65 70 75 80 85 90 95 100 3 5 7 9 11 Injection Conc [lb/Mmacf] U.S. Patent 7361209 Milled As-Received Labadie Data: DOE Cooperative Agreement DE-FC26-03NT41986 and EPRI -10- |

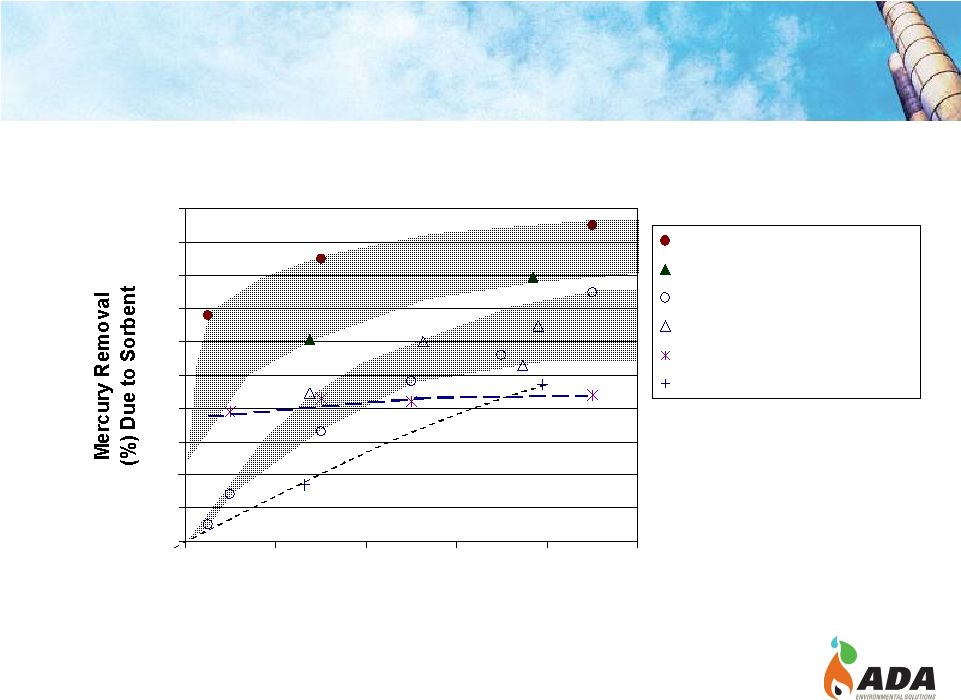

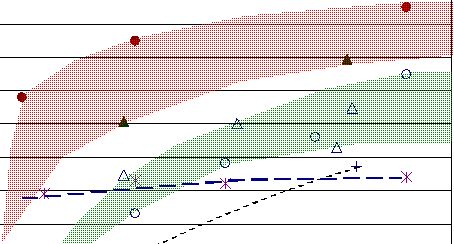

ACI ACI Upstream Upstream of of ESP—Impact ESP—Impact of of SO SO 3 3 0 10 20 30 40 50 60 70 80 90 100 0 2 4 6 8 10 Hg LH Injection (lb/MMacf) 0 ppm SO3 5.4 ppm SO3 10.7 ppm SO3 7.8 ppm SO3 Labadie Data: DOE Cooperative Agreement DE-FC26-03NT41986 -11- 2005, 2C ESP, 0 SO3 2006, Unit 2, 0 SO3 2005, 2 C ESP, 5.4 ppm SO3 2006, Unit 2, 5.4 ppm SO3 2005. 2B ESP, 7.8 ppm SO3 2006 Unit 2, 10.7 ppm SO3 |

AC

Production – Supply / Demand -12- |

ADA-CS New Activated Carbon Production ADA-CS New Activated Carbon Production Building largest AC plant(s) to date: 150 mm lbs/yr Capital cost: approx. $360 mm Plant designed to be low-cost producer 3-5 year development process: Under construction and on schedule Red River, LA plant startup target: mid-2010 Site permitted for 2 nd production line -13- |

-14- Low-Cost Producer Plant sited in the middle of lignite reserves – Provides access to a long term supply of low-cost feedstock material Minimal transportation costs for lignite Plant design with four furnaces in a single production line minimizes labor requirements Modern, state-of-the-art equipment, reduces maintenance costs Production designed for large volume customers, minimizes material handling and labor Energy efficient design with extensive energy recovery – Generates 19 MWs, 6 MW for internal use, 12 MWs to be sold on grid as revenue source |

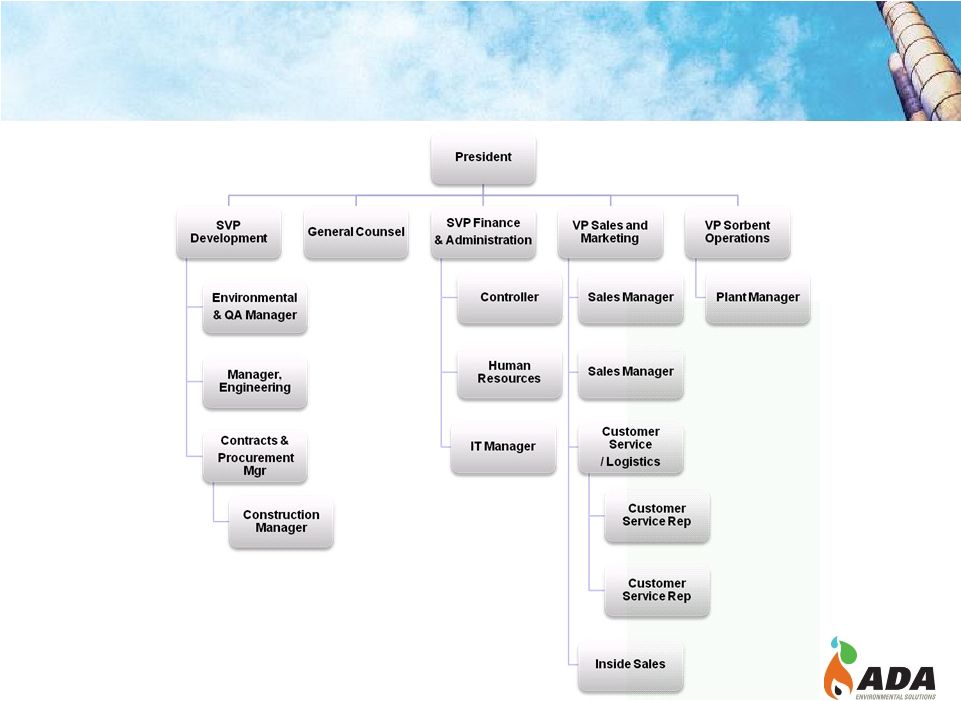

Ownership Structure after ECP Equity Investment Parent Companies Development Company Project Companies 35% Owner -15- *Based upon estimates of final capital and financing costs upon closing of debt financing. 25%* 75%* ADA - ES Energy Capital Partners (ECP) ADA Carbon Solutions, LLC * Red River Environmental Products, LLC Morton Environmental Products, LLC Crowfoot Supply Company, LLC Underwood Environmental Products, LLC |

ADA

Carbon Solutions October 2009 Expected Employees 2010 ~ 25 Hired to date = 17 -16- |

ADA

Carbon Solutions Key Management Sheila Glesmann, Senior Vice President, Development – More than 20 years experience in power plant operations, program management, emissions control and project development. Director of Environmental Technology for

an independent power producer, Principal Investigator for various

federally-sponsored research programs, Group Manager of an air quality

consulting group, Project Engineer for an air pollution equipment supplier,

business owner, and Engineer for the U.S. Environmental Protection Agency.

Jim Kelly, Senior Vice President, Finance and Administration – More than 30 years of strategic financial and operational management experience.

He has held multiple international and domestic financial positions and his

experience also includes strategic planning and analysis, worldwide general management, business development, mergers and acquisitions, and multinational sales force

management. John Rectenwald, Vice President, Sorbent Operations – More than 30 years’ experience in activated carbon manufacturing. He has managed both domestic and international activated carbon plants and has expertise in all types

of activated carbon manufacturing processes and equipment using bituminous

coal, lignite, wood, and a variety of other raw materials.

-17- |

ADA

Carbon Solutions Key Management Marilyn Treacy, – More than 25 years of Sales, Marketing and Operations experience in the chemical industry. She has extensive Sales and Marketing Executive experience and proven

abilities to develop innovative, successful business and marketing

strategies in highly competitive industries. She also brings

experience selling to the utility/power industry. Peter Hansen, – 13 years of experience in energy and natural resources transactions, financing and

commercial law and securities. He has represented both borrowers and

lenders in a wide variety of sophisticated secured and unsecured financing

transactions. He has also represented project developers, owners and

operators, tax credit investors and an electric utility site host in

numerous transactions for the facilities that produce fuel that

qualifies for tax credits. Prior to joining ADA Carbon Solutions, LLC, he was a partner in an international law firm headquartered in Denver. Byron Myers, – Over 20 years of operations experience in the chemical industry. He has held several high level plant management positions, including plant manager at three different lime

plants where he excelled in team building, leading safety and quality

assurance initiatives and improving reliability and P&L

performance. -18- Vice President Sales and Marketing General Counsel Red River Plant Manager |

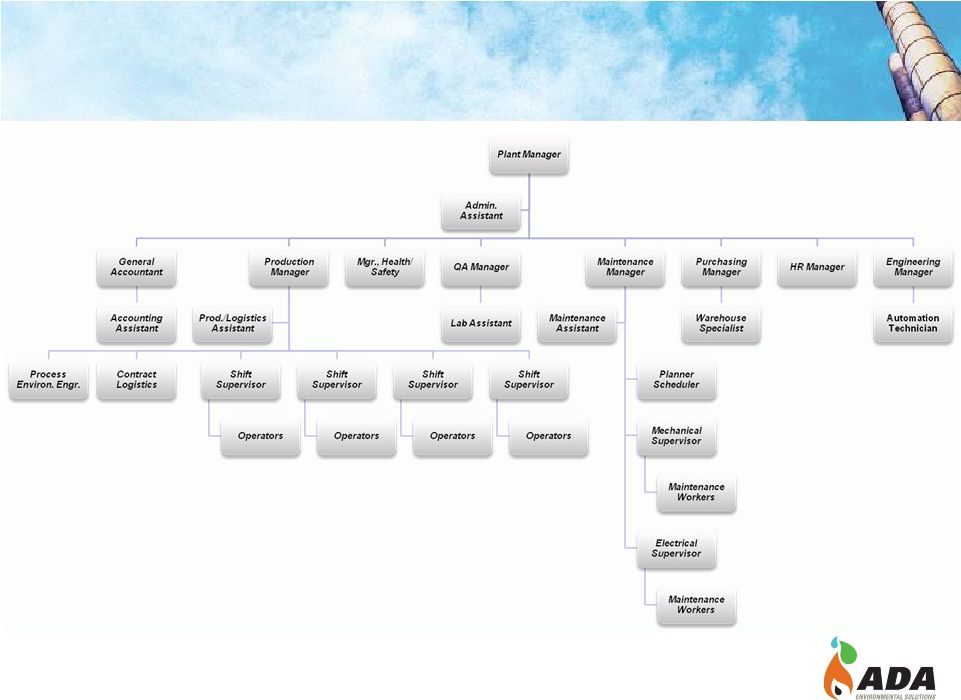

Red

River Environmental Products October 2009 Total Employees Full Production = 75 Hired to date = 18 -19- |

Natchitoches Processing & Logistics October 2009 Crowfoot Supply Company LLC -20- |

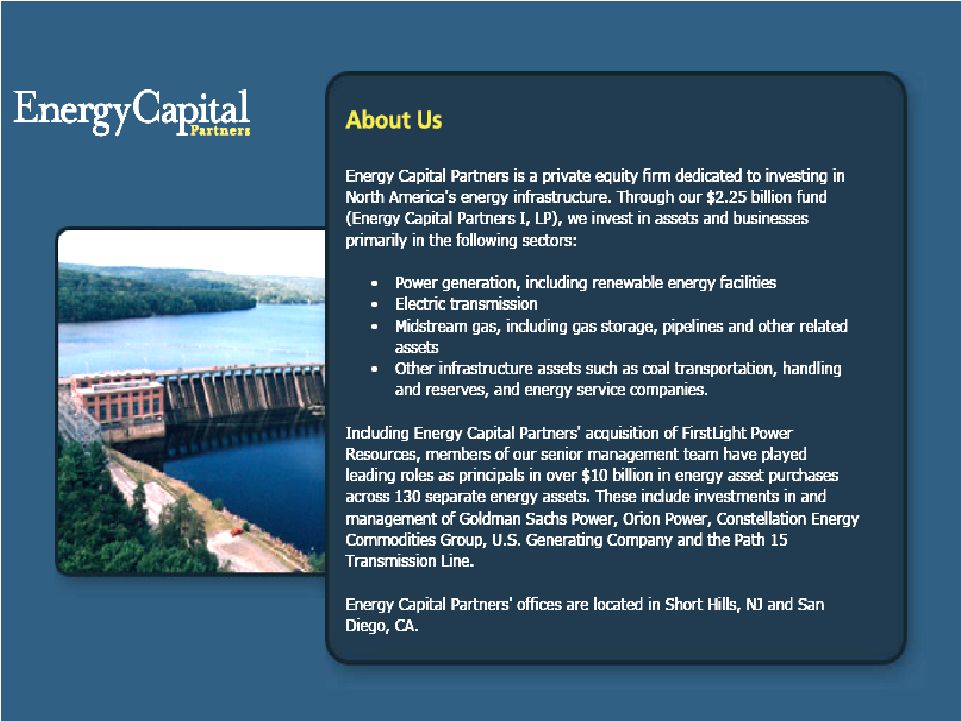

Provided by Energy Capital Partners -21- |

-22- Financing for AC Facilities Approximately $200 million spent on construction and related activities to date Plant remains on schedule with start expected April 2010 ECP has continued to fund construction beyond anticipated equity investment – Continued funding by ECP likely to result in 25% ownership by ADA* Permanent debt anticipated to replace interim financing * Based upon management estimates of debt sizing upon financial close and assuming closing of the Stock Purchase Agreement

|

GROWTH AREA #2: Control of Greenhouse Emissions: Carbon Dioxide -23- |

Carbon Capture and Storage (CCS) International, Federal, and State Regulations are being proposed requiring 50% to 80% reduction in CO 2 emissions Requires development of technology to capture carbon from existing plants -24- 0 100 200 300 400 1 50% CO2 Reduction New |

ADA-ES CO 2 Capture Technology Designed to capture CO 2 from flue gas in conventional coal- fired boilers Based on regenerable solid sorbents - advantages over competing technologies: – For the customer: lower cost and less parasitic energy – For ADA: continuous revenues from sale of proprietary chemical sorbents $3.2 million DOE R&D program with extensive industry support – Southern Company, Luminant, American Electric Power, Xcel Energy There has been a significant increase in funding opportunities for CCS technology through DOE. -25- |

Post-Combustion Capture Emission Control SO 2 , NO x , Hg, Particulate STEAM WATER Coal* 50% C 20% H2O 12% O2 5% Ash 3% H2 (S, Hg) CO 2 Capture Air 78% N2 21% O2 Purified CO 2 to Storage Regeneration Flue Gas 12% CO 2 74% N 2 12% H 2 O 4% O 2 -26- *Coal

composition varies greatly with grade and source. |

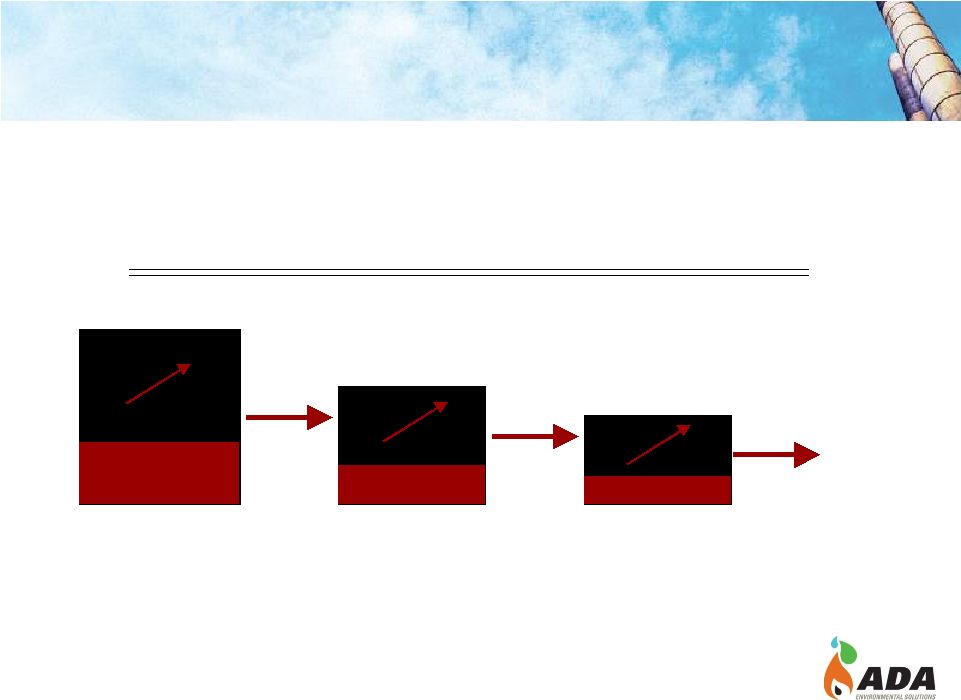

Why

Are Regenerable Sorbents Necessary? Coal In: CO 2 Out: Non-Reusable Sorbent Out: -27- |

Energy Costs for Carbon Capture 500 MW -175 MW CCS =325 MW with Carbon Capture 175 MW -60 MW CCS =115 MW with Carbon Capture 60 MW -20 MW CCS =40 MW with Carbon Capture … Aqueous MEA May Require Up to 35% of the Plant’s Power Reducing the Energy Penalty is Key -28- |

Solids Versus Liquids Solids Versus Liquids Solids Less Energy Required to Heat Material Higher Concentration of Active Chemical Interferences Liquids Depends SO 2 No Energy Loss Due to Evaporation -29- |

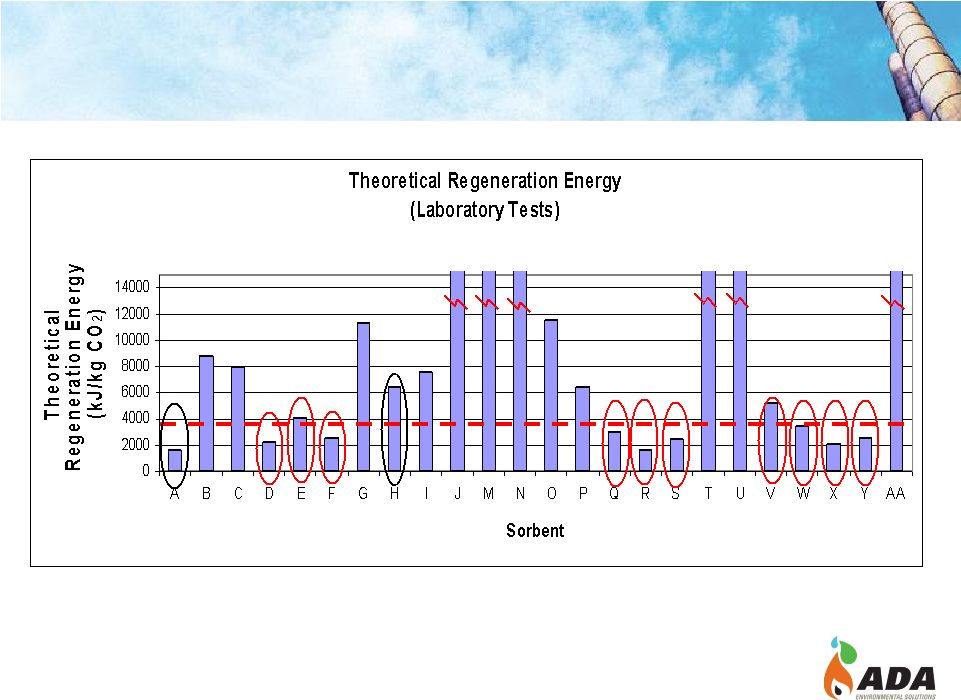

Laboratory Screening Results Laboratory Screening Results -30- Carbon-based Supported Amines |

Next

Steps for CCS Technology Next Steps for CCS Technology One more year on current DOE Program – Field tests using slipstream device • Bituminous Coal at Southern Company • PRB at Xcel • Lignite at Luminant – Design of conceptual 500 MW system DOE has announced that an RFP will be released this month for scaling up to 1-5 MW Opportunities for DOE and industry funding for full- scale demonstrations are expected in the future -31- |

GROWTH AREA #3: Refined Coal Product ADA-ES’ opportunity through joint venture with an affiliate of NexGen Resources Corporation -32- |

Clean Coal Solutions LLC ADA Joint Venture Clean Coal’s patented refined coal technology, CyClean, is designed to enhance combustion of PRB coals in cyclone boilers It produces significant benefits to the customer: – Reduces NOx and mercury emission – Greater PRB fuel flexibility – Enhanced operability – Decreased demand for activated carbon Customer can share up to half of the $6/ton tax credit for qualified product Equipment is simple to fabricate and install – Capital investment approximately $800k per site – Fabrication and installation 3-5 months -33- |

Section 45 Refined Coal Tax Credit Tax credit incentive – $6 ton/coal for ten years – Example for 500 MW plant: 2 mm tons/yr will create a tax credit of $12 million per year for 10 years Tax credit qualifications – Placed in service by January 1, 2010 – Owned and operated by third party – Reduces NOx by 20% – Reduces Hg by 40% IRS will provide guidance on certification and compliance – Final guidance has been delayed a number of times Window may be open for an extension -34- |

Opportunities and Challenges for CyClean Opportunity – Attempting to get two facilities installed before year-end – Produce >$3-6 million in earnings for ten years – $4 million due from NexGen to maintain 50% of JV Challenges – Equipment must be fabricated and installed by year-end – Approximately $1 million in JV capital expenditures – Waiting for explicit guidance from IRS – Permits required prior to installation – Complicated contracts with utility partners must be completed for each facility – Agreements with monetizers must be secured -35- |

Lawsuits Calgon – Suit based upon a contract Calgon signed with MidWest Generation for AC sales – Calgon and ADA had an MOU that provided a commission on sales of AC bid while the MOU was in place – ADA believes that it is owed >$8 million in commissions on this contract – Discovery near complete, trial expected in Q2-Q3 2010 Norit – In June, Norit tried to get an injunction to stop construction of the plant. This was summarily rejected by the Judge. – On October 6, the Judge ruled in favor of a motion ADA filed requiring that the suit be addressed by mandatory arbitration in Atlanta, GA. • We view this as a very positive development in the Case -36- |

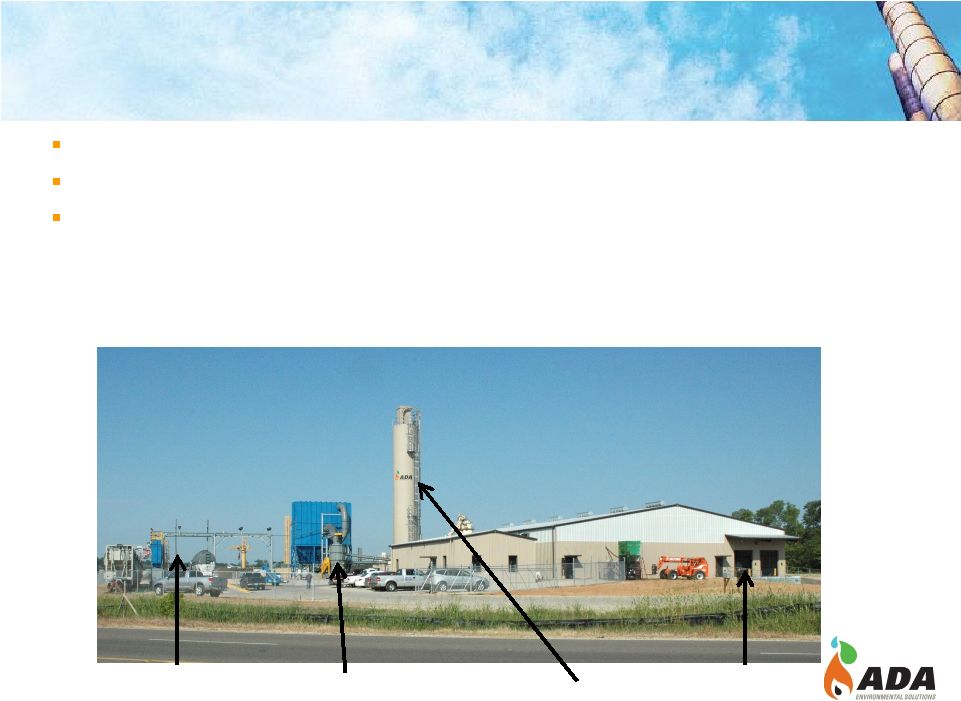

-37- Coal Silos Coal Day Silos and MHF’s After Burner Waste Heat Recovery Boiler Red River Construction Activity |

-38- ADA-CS Interim AC Supply Facility Currently supplying AC to utilities prior to new plant start-up Sourcing high-quality AC AC processing and logistics facility – Processing capacity of 8,000 lb/hr of Powdered AC – Equipment purchased to chemically treat, mill, package, and store AC – Easy access to rail and barge transportation Rail and truck loading Milling and Bromination Raw AC Silo Raw AC in bags stored and unloaded |

-39- Transportation and Logistics |

-40- Port of Natchitoches Rail spur for storing finished AC in rail cars Additional warehouse for storing raw AC Access to rail and barge |

Michael Durham, Ph.D., MBA President and CEO, ADA Environmental Solutions miked@adaes.com (303) 734-1727 Creating a Future with Creating a Future with Cleaner Coal Cleaner Coal |